CHESTER U.K. Cobra User manual

Contents

1. Introduction 2

2. Health&Safety 35

3. MachineSpecification 6

4. Testing 7

5. Operation 816

6. Maintenance 17

7. OilingPoints 18

8. ChangeGearTable 19

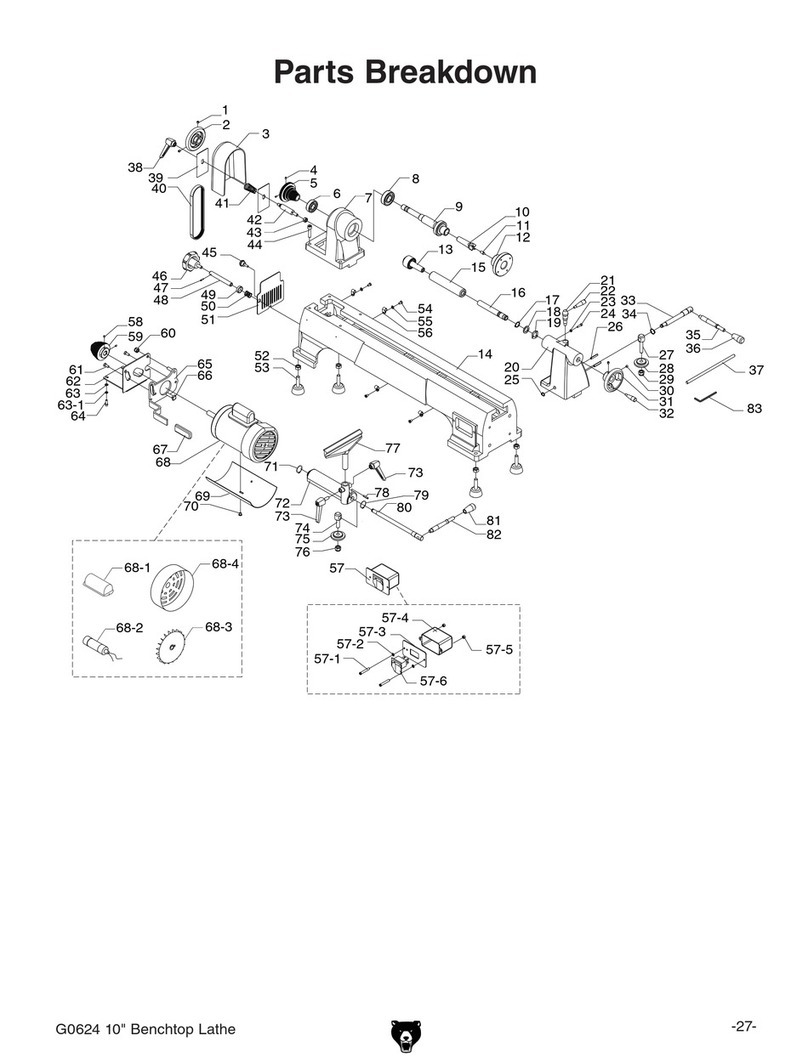

9. PartsList&Diagrams 2025

10.WiringDiagrams 2627

11.CEDocument 28

ChesterUKCobraLathe

1

Introduction

ChesterUKLimitedisaspecialistcompanythathasbeensupplyingthemachinetoolindustryfor

over15years.TheChesterUKHeadOfficecomprisesofa30,500sq.ftfactorycompletewithofficesand

a showroom. Specialising in conventional machine tools, Chester has built a reputation for quality and

reliability,whichishighlyregardedinthemachinetoolindustryandthemodelengineeringmarket.

Thereareseveraldivisionswithin thecompany;Export, Education,ModelEngineering&UKSales,all

withdedicatedsalespersonnelwhoaretrainedtoansweryourquestions.

When buying from Chester you can be assured of a complete backup service with mechanical and

electricalengineersthatareavailabletogiveadviceifrequired.

StockisalargepartofanybusinessandChesterhavealwaysinvestedsubstantiallyinbuildingalarge

quantity of machines and spares, ready to satisfy customer requirements. Chester UK has one of the

largest stocks ofconventional new machinesand accessories within Great Britain. Please taketime to

visitourwebsite: www.chesteruk.net

ChesterUKCobraLathe

2

Health&Safety

Aswithallmachinerytherearecertainhazardsinvolvedwiththeoperationanduseofthelathe.

Using the machine with respect and caution will considerably lessen the possibility of person injury.

However, if normal safety precautions are overlooked or ignored, personal injury to the operator may

result.

Thismachinewasdesignedforcertainapplicationsonly.Westronglyrecommendthatthemachineisnot

modified,and/orusedforanyapplicationotherthanwhichitwasdesigned.Ifyouhaveanyquestions

relativetoitsapplicationdonotusethemachine,untilyouhavefirstbeenincontactwithChester

UK.

The lathe may not arrive with a power socket or plug. In the event of this happening, please inform

ChesterUKonTel:(01244)531631.

Safetyrulesforalltools

User

1. Wearcorrectapparel

Nolooseclothing,gloves,rings,braceletsorotherjewellerytogetcaughtinmovingparts.Non

slipfootwearisrecommended.Wearprotectivehaircoveringtocontainlonghair.

2. Alwaysweareyeprotection

Refer to ANSLZ87.1 standard for appropriate recommendations. Also use face and / or a dust

maskifthecuttingoperationisdusty.

3. Don’toverreach

Keepaproperfootingandbalanceatalltimes.

4. Neverstandonatool

Seriousinjurycouldoccurifthetoolistippedorifthecuttingtoolisaccidentallycontacted.

5. Neverleavethetoolrunningunattended

Turnpoweroff.Leavetooluntilitcomestoacompletestop.

6. Drugs,alcoholandmedication

Donotoperatethetoolwhileundertheinfluenceofdrugs,alcoholoranymedication.

7. Makesurethetoolisdisconnectedfromthepowersupply

Whilemotorisbeingmounted,connectedorreconnected.

8. Always

Keephandsandfingersawayfromanymovingparts.

9. Stop

Themachinebeforemovingchips.

10.Shutoff

Powerandcleanthelatheandworkareabeforeleavingthemachine.

Useofthemachine

1. Removeadjustingkeysandwrenches

Form a habit of checking to see that keys and adjusting wrenches are removed from the tool

beforeturningit‘on’.

2. Don’tforcethetool

Itwilldothejobbetterandbesaferattherateforwhichitwasdesigned.

3. Usetherighttool

Don’tforcethetoolorattachmenttodoajobforwhichitwasnotdesigned.

4. Securework

Useclampsoravicetoholdworkwhenpractical.It’ssaferthanusingyourhands,andfreesboth

tooperatethemachine.

ChesterUKCobraLathe

3

5. Maintaintoolsintopcondition

Keeptoolssharpandcleanforthebestandsafestperformance.Followinstructionsforlubricating

andchangingaccessories.

6. Userecommendedaccessories

ConsultChesterUKforrecommendedaccessories.Theuseofimproperaccessoriesmaycause

hazards.

7. Avoidaccidentalstarting

Makesuretheswitchisinthe‘OFF’positionbeforeplugginginpowercord.

8. Stop

Themachinebeforeputtingmaterialinthevice.

9. Always

Havestockfirmlyclampedinthevicebeforestartingthecut.

10. Groundalltools

If the tool is equipped with a threeprong plug, it should be plugged into a threehole electrical

receptacle.Ifanadapterisusedtoaccommodateatwoprongreceptacle,theadapterplugmust

beattachedtoaknownground.Neverremovethethirdprong.

Adjustment

Make all adjustments with the power off. When assembling follow the manuals instructions, this

willensurecorrectinstructionandasafestructure.

Workingenvironment

1. Keeptheworkareaclean

Clutteredareasandbenchesinviteaccidents.

2. Don’tuseinadangerousenvironment

Don’tusepowertoolsindamporwetlocations,orexposetorain.Keeptheworkareawelllit.

3. Keepchildrenetcatasafedistance.

Allchildrenetcshouldbekeptatasafedistancefromtheworkarea.

4. Don’t

Install&usethismachineinanexplosivedangerousenvironment.

Maintenance

1. Disconnect

Machinefromthepowersourcewhenmakingrepairs.

2. Checkdamagedparts

Beforefurtheruseofthetool,aguardorotherpartthatisdamagedshouldbecarefullycheckedto

ensure that it would operate properly and perform its intended function check for alignment of

movingparts,bindingofmovingparts,breakageofparts,mountingandanyotherconditionsthat

may affect its operation. A guard or other part that is damaged should be properly repaired or

replaced.

3. Disconnecttools

Beforeservicingandwhenchangingaccessoriessuchasbladesbits,cutters,etc.

4. Toprevent

Thecorrosionofmachinedsurfaceswhenasolubleisusedascoolant,payparticularattentionto

wipingdrythesurfaceswherefluidaccumulatesanddoesnotevaporatequickly,suchasbetween

themachinebedandvice.

ChesterUKCobraLathe

4

SafetyDevice

1. Interlockswitchonpulleycover.Assoonasthepulleycoverisopen,themachinewillcometo

a stop with the function of this switch. Do not remove this switch from the machine for any

reason,andcheckit’sfunctionfrequently.

2. Interlockswitchoncuttingarea.Assoonasthepulleycoverisopen,themachinewillcometo

a stop with the function of this switch. Do not remove this switch from the machine for any

reason,andcheckit’sfunctionfrequently.

ChesterUKCobraLathe

5

MachineSpecification

DrillingCapacity 10mm

EndMillCapacity 10mm

FaceMillCapacity 20mm

SpindleStroke 30mm

Throat 140mm

TableWorkingSurface 50x145mm

LongitudinalTravel 180mm

CrossTravel 90mm

Max.DistanceSpindleToTable 220mm

No.OfSpindleSpeeds Variable

RangeOfSpeeds 1002000rpm

SpindleTaper MT2

Motor 150W

Supply 240V50Hz

Weight(nw/gw) 47/60Kg

Dimensions(LxWxH) 540x380x680mm

ChesterUKCobraLathe

6

Testing

Whenthelatheismountedtoyoursatisfaction,proceedasfollows:

a) Closethechuckjaws.

b) Checkthetailstockis‘nipped’andthebarrellockistightened.

c) Checkalllooseitemsareremovedfromthelathe.

d) Setthesaddleapproximatelymidwayalongthebed.

e) PresstheEmergencyStopButtonIN(EmergencyStopON).

f) ChecktheAutofeed/ManualLeverissettomanual(Handlogo).

g) Closethechuckguard.

h) CheckthespeedcontrolisswitchedOFF(fullyanticlockwise).

i) ChecktheForward/Off/ReverseSwitchisintheOFFposition.

j) ConnectthemachinetothemainssupplyandswitchpowerON.

k) TurnEmergencyStopswitchtotherightandallowittospringoutandreset.

l) ChecktheGreenPowerLEDisilluminated.

m) TurntheSpeedControlSwitchOn(ClicksOn).

n) ChecktheAmberLED(FaultLight)isilluminated.

o) SwitchtheSpeedControlSwitchOFF(ClicksOFF)andtheAmberLEDisnowoff.

p) SelectForwardontheForward/Off/Reverseswitch.

q) TurntheSpeedControlSwitchOnandadvanceuntiltheChuckstartstorotate.

r) LifttheChuckGuard;checkthespindlestopsandtheAmberfaultLEDilluminates.

s) ResettheChuckGuard,checkthespindledoesNOTrestartandtheAmberfaultLEDremains

On.

t) TurntheSpeedControlSwitchOFF,andthattheAmberLEDgoesoff.

u) TurntheSpeedControlSwitchON,advanceuntilthespindlestartstorotate.

v) Overaperiodofapproximately5minutesadvancethespeedinstagestomaximum,runat

maximumforatleast2minutes,checkthatthereisnothinguntoward(noexcessivevibration,

speedprogressionissmoothetc).

w) Ifalltheabovechecksarecorrect,stopthespindle;selecttheAutofeedfunction(ifnecessary

‘jog’theleadscrewhandletoenablethegearstomesh).Switchonandadvancetoa

reasonablespeed,checkthesaddledrivessmoothlytowardsthechuck.

x) Stopthespindle,selectreverse,switchONandadvancetoareasonablespeed,checkthe

chuckdrivessmoothlytowardsthetailstock.

y) Ifalltheabovechecksarecorrect,thefinalcheckistosetthespindlerunning,thenhitthe

EmergencyStopswitch.CheckthespindlestopsandallpowerindicationsgoOFF.

z) Yourlatheisnowreadyforuse.Enjoy.

ChesterUKCobraLathe

7

Operation

Definitions

MainAxis

Thisistheaxisestablishedthroughthespindleoftheheadstock.Itishorizontaltoandparallelwiththe

lathebedalongitslength,asdescribedbythesaddle

WorkAxis

This is the axis established by the work piece;it is horizontal to, but not necessarily parallel with, the

lathebed,alongitslength.

TraverseAxis

Thisistheaxisdescribedbythetraverseslidewhenitisbeingmovedindependentlyofthesaddle.Itis

perpendiculartothemainaxisinthehorizontalplane.

CompoundAxis

Thisistheaxisdescribedbythecompoundslide,iffitted,whenitisbeingoperatedindependentlyofthe

traverseslideandthesaddle.

Headstock

The‘engineblock’ofthelathe,supportsthemotor,thespindle,andthecoverforthechangegears,the

drive belt and the driven end of the leadscrew. It also mounts the control panel for the motor and the

selectorfortheleadscrew.

ChangeGearCover

Protectivecover,enclosingthemotorpulley,thedrivepulley&drivebeltandthechangegear.

Motor

220Vd.c.motor.

MountingFlange

The mountingflangeisintegralwith thespindle andmountsallthematerialcarriers(chucks,faceplate

etc), it is bored with a No.2 morse taper to accept the headstock centre. The boring is then carried

through the complete length of the spindle (10.5mm clear) to allow long lengths of round bar to be

machined. Your MicroLathe is supplied with a chuck adaptor plate and chuck already fitted to the

mountingflange.

ChuckSafetyCover

Aclearacetatecovermountedonapivotbaronthereartopfrontfaceoftheheadstock.Itcanbetipped

out of the way to access the chuck when it is stationary, and repositioned over the chuck during

operation.Itissafetyinterlocked,ifitisnotinpositionthemotorwillnotrun,orthemotorwillstopifitis

movedwhilstthespindleisturning.

MotorControlPanel

PowerOnLED

GreenLEDthatindicatesthatpowerisavailabletothemotor.i.e.mainsisapplied,fuseisintact

andtheEmergencyStopswitchisnotactivated.

ChesterUKCobraLathe

8

FaultLED(markedUNNORMAL)

Amber LED that indicates that there is a fault or an incorrect control sequence. e.g. the chuck

guard interlock has been activated or the speed control is activated without forward or reverse

directionbeingselected.TheMotorwillnotrunifthefaultLEDisilluminated.Ifthesafetyinterlock

is activated, if the safety interlock will remain in force until the interlock is reset and the start

sequenceisreinitiated.

FuseCap

Accesscapforthe20mmfusecartridge(1Amp250V).

SpeedControlKnob

Roundraisedridgeknobconnectedtothecircuitthatcontrolsthemotorspeed(1002000rpm).

Forward/Off/ReverseSwitch

Three position switch that controls the direction of the rotation of the spindle. Forward indicates

that the spindle is turning toward the operator; Reverse, the spindle is turning away from the

operator.ThecentreOffpositioninhibitsthespindlefromturningineitherdirection,undermotor

drive.

EmergencyStopSwitch

RedDomedMushroomswitch;ifpresseditremovesallpowertothemachine.Itisa ‘knockoff,

stayoff’switch.Toresettheswitchthedomedheadmustbeturnedclockwise,whichwillallowthe

switchtounlatchand‘springout’andresetitself.

ChesterUKCobraLathe

9

(Chuck&safetycoverremovedforclarity)

ChesterUKCobraLathe

10

LeadscrewSelector

Aroundcentreribswitch/lever,whichallowsselectionoftheleadscrewto‘Autofeed’,i.e.drivenbythe

changegeartrain(indicatedbyatriangularwaveformsign),ormanually,i.e.drivenbythehandleonthe

endoftheleadscrew(indicatedbya‘hand’logo).

LatheBed

Solid cast, machined bed. The face machining gives two flat bearing surfaces, whilst the ancillary

machininggivesadovetailformtothebed,andformsarigidstablelocatingandguidingsystemforall

themachinescomponents.

Saddle

Maincastingthatisprecisionmachinedtomarrywiththelathebed.Itmovesparalleltothemainaxis.It

mountsthetraverseslide.The‘gib’stripsetintherearofthesaddledovetailmaintainstheaccuracyof

thefitofthesaddletothebed.

TraverseSlide

Mountedona‘dovetail’landmachinedontothetopofthesaddle.The‘gib’stripsetintherighthandside

ofthetraversedovetailslidemaintainstheaccuracyofthefitoftheslide.Thebedofthetraversehastwo

‘T’slotsmachinedintoittoallowthemountingofthetoolpostorthecompoundslideaccessory.

TraverseSlideControl

Awheelandrodhandle,mountedonashaftthatisanchoredintoahousingmachinedinthefrontofthe

traverseslide,theshaftis threadedandis engagedina dogfixedtothesaddle,enablingthe traverse

slidetobedrivenbackandforthacrossthesaddleperpendiculartothemainaxis.Thereisagraduated

ring(thimble)ontheneckofthehandletoallowthemovementoftheslidetobemeasured.

ToolPost

A doublesided tool post. Each tool position has 2 securing bolts to clamp the tool in place. One tool

mountinghasafixed‘bed’theotherhasa‘rocking’bedinacurvedseatingtoallowthetooltobetilted

slightlyforwardorbacktoallowprecisetoolheightstobeachieved,withoutthenecessityforfineshims.

Thetoolpostissecuredintoeitheroneofthe‘T’slotkeeper.Thetoolpostisnotkeyedintothe‘T’slotso

itcanbeturnedtoanyanglebeforebeinglockedinposition.

ChesterUKCobraLathe

11

ChesterUKCobraLathe

12

GearChangeCoverKnob

Areededknobscrewedintothefrontoftheheadstock,itlocatesinaslotinthechangegearcover,and

isusedtosecurethecovertoallowittobesungopen.

Tailstock

Amachinedcastingthataccuratelyfitstothelathebed.Itcarriesthetailstockbarrel.Thetailstockbarrel

ismachinedwithaNo.1MT,whichallowstheaccessoriestobemounted(centres,drillchucks,reamers

etc).Thetailstockispositionedonthebedbyaclampmechanismatthefrontofthetailstockbody.The

twocapheadboltsinthefrontflangeofthecastingtightentheclamp.Thetailstockiscapableofbeing

offsettoallowfortaperturning.Theoffsetlockingscrewisontherightofthetailstock.

TailstockBarrelControl

Wheel androd handle that controls the backward and forward movement of the barrel in the tailstock.

Thebarrelhasatravelof22mm,toallowthetailstocktoolingtobebroughtintocontrolledcontactwith

theworkpiece;thisisindicatedona coarsescaleengravedonthebarrelitself.Thescaleindicates–0

andthen20plustwo(x1mm)divisions.Thesupplied tailstock centrewill self ejectat–0.Thetailstock

control has a graduated ring (thimble) mounted on the neck of the handle so that the amount of

movementcanbemeasured.

TailstockBarrelLock

Small‘petal’knobthatlocksthebarrelinplaceonceithasbeenmovedintotherequiredposition.

Leadscrew

Theleadscrewisathreadedshaftthatisanchoredintoahousingmachinedintotheendofthelathebed.

Theshaftrunsvirtuallythroughthecentreaxisoftheundersideofthebed,andisengagedinadogfixed

totheundersideofthesaddle,enablingthesaddletobedrivenbackandforthalongthemainaxisofthe

bed.Thefixeddogiswellsupportedfromthefrontapronofthesaddle,andcombinedwitheffectofthe

centralizedaxisoftheleadscrew,resultsinaverysmooth‘judder’freemovement.Theleadscrewcanbe

driven from either end, from the headstock end, via the change gear train, for auto feed and thread

cutting,ormanuallybytheleadscrewdrivehandle.

Note

The leadscrew is permanently engaged into the saddle dog. Any movement of the leadscrew is

transmittedtothesaddle.

LeadscrewDriveHandle

Wheel and rod handle locked onto the end of the leadscrew shaft. Turing the handle will turn the

leadscrewanddrivethesaddlebackandforthalongthemainaxisofthelathe.Thereisagraduatedring

(thimble)ontheneckofthehandletoallowthemovementofthesaddletobemeasured.

MotorSecuringBolts

Twocapheadboltsscrewthroughthechangegearcompartmentbulkheadandintothemotorflange.The

holesthroughthebulkheadareelongatedtoallowthemotortobemovedslightlytomaintainthedrive

belttension.

LeadscrewOilingPoint

Thisisasmallholesituatedbetweentwocapheadboltsonthelowerrightfaceofthesaddleapron.The

oil gallery gives direct access to the leadscrew dog, and enables oil to be spread onto the leadscrew

(whichismainlyobscuredbeneaththelathebed.)

MotorBrushCaps

Twobrushcapslocatedtopandbottomofthemotor;theyareaccessedbyremovingthesplashguard.

ChesterUKCobraLathe

13

ChesterUKCobraLathe

14

ChesterUKCobraLathe

15

YourCobraLathehasbeenfactorysetandadjusted,however,duringitslifetimeyoumay

find occasion whereby the lathe needs adjusting to maintain its accuracy and optimum

performance.Theseadjustmentscanbemadeasfollows:

Saddle&TraverseSlideAdjustment

Thesaddleandthetraverseslidearemountedoverdovetailsections.Inordertomaintainthe‘tightness’

of the fit; between the sloping surface of the component and its matting surface a gib strip has been

inserted(Attherearofthesaddle,andtotherighthandsideofthetraverseslide).

Toadjustthegibstrips,loosenthelocknutsandscrewtheadjustingscrewIN(No.4forthetraverseslide

andNo.3forthesaddle).‘Nipping’thecomponenttighttoitsbedway.Tightenallthescrewstothesame

torque.Check,usingthefeedhandles,thatthesaddle/slidearelockedinplace.

Unscreweachadjustingscrewbyquarterturn,holdthescrew(socketgrubscrew)inpositionandtighten

the locknut. Check the component now moves smoothly along its bed, using the feed handles. If not,

carry outthesameprocedure,unscrewby athirdturnthistime,etc,ifthemovementwastootight;by

lessthanaquarteretc.,ifthemovementbecametoloose.

Repeattheprocedureuntilthemovementsaresmoothandtight.N.B.Alwaystightenthelocknutsbefore

testing.

FeedScales

The two thimbles that are mounted on the feed shafts of the leadscrew and the traverse feed should

move freely with the motion of the handle and not slip. The thimbles can be turned, using more force,

independently of the handle in order to set a predetermined start or finish point. If the thimbles are

‘slipping’i.e.notmaintainingtheirplacerelativetothehandle,whilstthehandleisturning;thecauseis

almostinevitablydirt,swarfetal.,betweenthepressureplateandthethimble.Torectifythis,undothe

nut and washer securing the handle to the shaft, remove the hand wheel, and then remove the keyed

collarandthimbleassembly.Takecarethatthekeydoesnotdropoutoftheshaft.Graduallyseparate

the thimble from the keyed collar; by twisting and turning, until there is sufficient space to clean the

matingsurfaces.

BE WARNED The friction drive between the collar and the thimble is effected by a wire spring

(likepartofacirclip)thatishousedinagrooveinthecollarandrubsagainsttheinsideboreof

thethimble.Ifthecollarisseparatedtoofar,thegrooveandthespringareexposed.Thespring

canfalloutandifnotlost,itisawkwardtorecompressthespringsothatthethimblewillslide

completelybackontothecollar.

Oncethematingsurfacesareclean,matethekeyandthekeywayandfitthecollar/thimbleassemblyto

theshaft.Refitthewasher andthesecuringnut, andtighten.Tightenuntilthehandwheel,thimble and

collar assemble are too tight to move. Undo the securing nut a quarter turn and check that the drive

handlerotatesfreelyandthereisnotexcessivebackwardandforwardplayintheshaft(Thehandleetc,

formsonesideofthedrivescrewanchorintotheslide).

ChesterUKCobraLathe

16

Maintenance

TheLatheisaprecisiontool.Inordertomaintainthisprecisionand prolongitsusefullife,itis

advisedthatyoufollowtherecommendeddailyandperiodicmaintenancetablesprintedbelow.

Daily

Carry out a visual inspection. Repair any damage immediately. Minor damage to the beds should be

takenoutwithanoilstone.

Movethesaddleandthetraverseslidebackandforthbyhand;checkthatthemovementissmooth.

Spreadalightfilmofoiloverthebedandthetraverseslidebed.

Directlysprayoilontheleadscrewaftereveryuse.

Ifthelatheissubjecttoprolongeduse,oiltheleadscrewandbearingsevery34hours(Theleadscrew

islocatedunderneathandrunstheentirelengthofthelathebed).

DailyAfterUse

1. Cleanallswarfandchipsawayfromthemachinebed,slidesurfaces,andthetoolpost.

2. Exercisetheslidesandensurenoswarfetc.,islodgedinthedriveshafttunnels.Ifyouhave

beenusingacoolantmakesurethemachineisthoroughlydriedoff.

3. Checkthetool,ensureitisusableforthenexttime,ifnotresharpenorreplacethetooltip.

4. Lightlysprayoiloverallthemachinesbedsandsurfaces,andthetailstockbarrel.

5. Cleanandlightlyoilanytoolsyoumayhavebeenusing(centres,drillchucks,spanners,chuck

keysetc)andputthemaway.

6. SwitchOFFthepowersupply.Disconnecttheplug.

7. Coverthemachineoverwithadustcloth.

Weekly

1. Movethetraverseslidefullybacktogiveaccesstothetunnel,blowouttomakesureallswarf

is clearedawayandheavilysprayoil in thetunnel, exercisethe slideto workthe oilintothe

drivethreadandtolubricatethedog.

2. Sprayoiltheslideandthelathebed,exercisethesaddleandtheslidetospreadtheoiltoall

surfaces,bothhiddenandvisible.

3. Sprayoilunderthebedontotheleadscrew.

4. Check the movement of the saddle and the traverse slide, check it is smooth and ‘tight’, if

necessaryresetthegibstrips.

Monthly

Checkthebelttension.Ifnecessaryresetthebelttensionbylooseningthetwomotorsecuringcaphead

bolts,retensionthebeltandresecurethebolts.

Every6Months

Because the D.C. motor has a heavy permanent magnetic field, it is advisable to dismount the lathe

every6months,removethesplashguardandremovealltheswarfthatmayhavefounditswayintothe

motorhousing.

ChesterUKCobraLathe

17

OilingPoints

ChesterUKCobraLathe

18

ChangeGearTable

ChesterUKCobraLathe

19

Table of contents

Other CHESTER U.K. Lathe manuals