CHESTER Crusader VS User manual

2

Contents

1. Safety Rules for Lathes

2. Machine Specification

3. Constructional Indication

4. Unpacking and Installation

4.1. Unpacking

4.2. Cleaning

4.3. Installation

5. Lubrication

5.1. Headstock

5.2. Gearbox

5.3. Apron

5.4. Change Gears

5.5. Other Parts

6. Test Running

6.1. Spindle Speed Control

6.2. Operation Symbols

7. Thread and Feed Selection

7.1. Thread and Feed Selection

7.2. Feed and Thread Tables

7.3. Threading Dial Indicator

8. Chuck and Faceplate Removal/Installation

8.1. Chuck and Faceplate Removal

8.2. Chuck and Faceplate Installation

8.3. Camlock Stud Installation

9. Maintenance and Servicing

9.1 Lathe Alignment

9.2 Saddle Strip

9.3 Cross Slide

9.4 Compound Rest

9.5 Cross Slide Nut

9.6 Tailstock Bed Clamp

10. Parts List.

Bed Assembly

Headstock Assembly

Feed and Change Gearbox Control

Apron

Cross Slide and Compound

Tailstock Assembly

Steady Rest and Follow Rest

Coolant System and Compound

Electric Assembly

Optional Accessories

3

1. Safety Rules for Lathes

Safety is a combination of operator common sense and alertness at all times when

the lathe is being used. Study these safety rules and general safety rules before

operating and retain this manual for future use.

1. Wear eye protection.

2. Never attempt any operation or adjustment if the procedure is not understood.

3. Keep fingers away from rotating parts and cutting tools while in operation.

4. Never force the cutting action.

5. Never perform an abnormal or little used operation without referring to the manual

and without the use of adequate blocks, jig stops, fixtures etc.

6. Use of a shop manual such as “machinery’s handbook” or similar is recommended

for cutting speeds and operation detail.

7. Do not remove the drive cover while the machine is in operation. Make sure that

it is always closed.

8. Always remove the chuck key, even when the machine is not in operation.

9. Do not attempt to adjust or remove tools when in operation.

10. Always keep the cutters sharp.

11. Never use the machine in an explosive atmosphere or where a spark could ignite

a fire.

12. Always use identical replacement parts when servicing the machine.

Warning: Do allow familiarity (gained from frequent use of your lathe) to become

commonplace. A careless fraction of a second can lead to severe injury.

2. Machine Specification

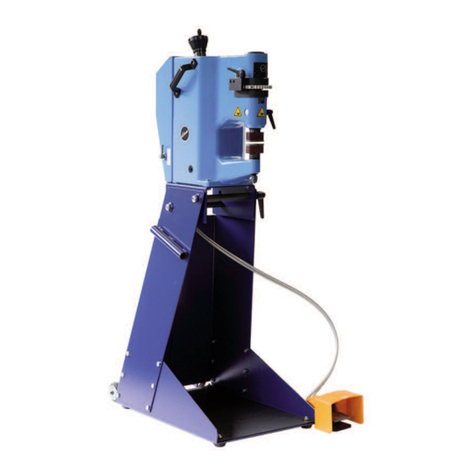

Bench lathes are especially suitable for machining, tool toms and repairing working

shops to machine shafts, sleeves and disc workpieces of medium and small sizes.

They can also be used to cut metric thread and imperial, with compact construction

and reasonable composition, they can cut very well. They are easy and reliable to

operate, convenient to repair, high in efficiency and have low noise levels.

Technical Specification

Type

VS3

VS4

Swing over bed

356mm

356mm

Swing over cross slide

230mm

230mm

Swing over gap

450mm

476mm

Carriage travel

710mm

960mm

Cross slide travel

178mm

Top slide travel

90mm

Tailstock quill travel

100mm

Tailstock taper

MT4

Bed width

186mm

Spindle bore

51mm

Cam lock system

D5

Spindle speed

70-2000rpm

Spindle taper

MT6

Cutting tool (max section)

20 x 20mm

4

3. Constructional Indication

No

Name

No

Name

1

Speed selector

22

Apron

2

Headstock

23

Threading cutting engagement lever

3

DRO for spindle speeds

24

Control lever

4

Feed direction selector

25

Cross travel control handwheel

5

Change gear box

26

Saddle

6

Feed box selectors

27

Cross slide

7

Feed gear box

28

Support casting

8

Demarcation frame work

29

Bed way

9

Leadscrew and safety guide

30

Tailstock set-over screw

10

Feed rod

31

Tailstock

11

Control bar

32

Quill travel handwheel

12

Oil Tray

33

Tailstock lock leer

13

Left stand

34

Quill lock lever

14

Indication light

35

Coolant system

15

Inching Button

36

Compound rest handwheel

16

Spindle speeds adjustable knob

37

Compound rest

17

Coolant knob

38

Tool post

18

Emergency stop button

39

Work light

19

Foot brake

40

Spindle and chuck

20

Right stand

41

Safety cover for chucks

21

Longitudinal traverse handwheel

42

Electric box

5

4. Unpacking and Installation

4.1 Unpacking

Unload the machine with a tackle, using clamping plates and eyebolts. Keep the

machine in balance by moving the tailstock and the bed slide to the right. Avoid using

sling chains as they could cause damage to the feed rod and the leadscrew. Lift the

lathe carefully and place it softly onto the floor or the workbench.

4.2 Cleaning

Before putting the machine into operation, use kerosene (paraffin) or white spirit to

remove the anti-corrosion coating or grease from all the slideways and the gear train.

Do not use lacquer thinner or other caustic solvents. Oil all bright machine surfaces

immediately after cleaning. Use heavy oil or grease on the change gears.

4.3 Installation

Place the machine on a solid

foundation. A concrete floor is the

best base for the machine (if

necessary, use an under frame

operational). Make sure that there is

sufficient space around the lathe for

easy work and maintenance. Use a

precision level on the bed way to make

further adjustment for level condition,

then tighten the foundation bolts

evenly and finally recheck the

machines level.

5. Lubrication

Before putting the lathe into operation, make the following lubrication check.

5.1 Headstock

The bearing of the headstock turns in an oil bath. Ensure that the oil level reaches

three quarters of the oil gauge glass.

When changing the oil, remove the end cover and the change gears with swing frame.

Drain off the oil by removing the drain plug on the bottom of the headstock. To fill,

take off the headstock cover. Check the oil level regularly. The first oil change should

be made after 3 months, then the oil should be changed annually.

5.2 Gearbox

Remove the end cover to expose the filling plug. Fill the tank with Shell Tellus 32 until

the oil level reaches the mark in the oil sight glass. The first oil change should be

made after three months then once every year.

5.3 Apron

The oil bath is filled with Shell Tellus 32 through the filling plug on the right side of the

apron. Check the oil level in the oil gauge glass on the front of the machine regularly.

The fist oil change should be made after three months then once a year. When

replacing the oil, drain the oil by removing the oil drain plug from the bottom of the

apron.

6

5.4 Change Gears

Lubricate the change gears with thick machine oil or grease once a month.

5.5 Other parts

There are other lubricating points on the input shaft bracket of the gearbox, the

handwheel on the apron, the longitudinal and cross slide, the thread dial indicator, the

tailstock and the bracket. Use a grease gun to put a few drops of oil onto the

lubricating positions from time to time. Lubricate the apron worm and worm gear, half

nut and leadscrew twice a month. Apply a light film of oil to the bed way and all the

other bright parts like the tailstock quill, feed rod etc. once a day.

6. Test Running

6.1 Spindle Speed Control

A. Identification before operation

Ensure that lubrication has been carried out as described before.

When the main spindle is rotating, the gearbox and the feed axis of the bed sides are

put into operation. The forward/reverse switch (4) should be in the neutral position.

The feed axis selector (6) and feed/thread selector handle (6) are in the disengaged

position. Under these circumstances, both the longitudinal travel handwheel (21) and

the cross travel handle (25) can be operated by hand.

B. Main spindle rotation

The main spindle rotation is selected by the forward/reverse switch.

C. Main spindle speed

The speed of the main spindle is selected by the high/low speed selector (1). For both

the high and low speeds, there are two different positions. For the correct speed, refer

to the speed chart. Never change the speed before the motor has stopped completely!

Adjustment of the speed can be assisted by turning the main spindle by hand.

D. Running In

Running in should be done at the lowest possible speed. Let the machine run at the

lowest speed for approximately 20 minutes, then check for any irregularities. If

everything seems in order, gradually increase the speed.

E. Operation

Only use high peripheral speed type chucks.

The maximum spindle speed for chuck plates with a 250mm should not be more than

1255rpm. When thread cutting or auto feeding are not in use, the feed/thread selector

should be in the neutral position so to ensure the disengagement of the leadscrew and

the feed rod. To avoid any unnecessary wear, the thread dial indicator should be out

of mesh with the leadscrew.

7

6.2 Operation Symbols

8

7. Thread and Feed Selection

7.1 Thread and Feed Selection

All threads and feeds are indicated on the tables fitted on the front of the change

gearbox. They are selected with the feed selector handles (6) on the feed gearbox.

A. Manual Operation

The carriage is moved by the handwheel (21), the cross slide handwheel (25) and the

compound rest handwheel (36). The slide can be anchored by turning the lock bolts

on the top and side of the slide.

B. Feed and Thread Tables

Longitudinal and cross feed table. Metric and imperial thread table.

C. Automatic Feed operation

Engage the 40T change gear at the transmission shaft and the 127T intermediate gear

with the feed direction selector (6) then set the feed/thread selector (6) to the left hand

position and position one lever at any of the 1-5 hole, the other at the A-E holes. The

feed rod will rotate. If the selector is pushed upwards, a longitudinal feed can be

obtained. If the selector is pushed down, across feed will be obtained.

D. Thread Cutting Operation

The direction of thread cutting is controlled by the feed director (6). By operating the

feed selector handle and the feed/thread selector handle according to the thread pitch,

the leadscrew will rotate. Operate the handle (23) down to engage with the leadscrew

to achieve the longitudinal travel of the thread cutting feed.

7.2 Feed and Thread Tables

A. Feed Table

Longitudinal and cross feed table for a metric

lathe.

Longitudinal and cross feed for an imperial

leadscrew.

9

B. Thread Tables

Thread table for a metric leadscrew

Thread table for an imperial leadscrew

7.3 Thread Cutting Operation

In order to obtain the desired thread, all the correct change gears must be installed in

strict accordance with the chart. Failure to do so will give incorrect threads.

Rotate the leadscrew by operating the feed/selector to any position and be sure the

feed selector handle is engaged. Operate the thread cutting engagement lever

downwards to engage with the leadscrew to obtain the longitudinal travel of the

carriage, i.e. the thread cutting feed. Make sure that the feed axis selector is

disengaged (at the neutral position) before operating the thread cutting engagement

lever as there is an interlock mechanism between the auto feeding and thread cutting

engagement. The direction of the thread can be chosen by turning the feed directing

10

selector at the headstock. There are 31 thread pitches in imperial and 26 metric

pitches which can be obtained by turning the feed selector handles.

A. Thread Dial Indicator

The thread dial indicator is installed on the right hand side of the apron. The indicator

is used for thread cutting to engage with the leadscrew.

To reduce the amount of wear on the thread dial indicator, the unit should be

disengaged by the swinging the pinion out of mesh with the lead screw when not in

use.

For these threads it is recommended that the thread dial indicator be used as this

allows the half nut of the leadscrew to be engaged at the end of the end of each thread

cutting pass, provided that they are re-engaged in accordance with the indicator table

mounted in front and down of the change gear box.

In column 1: millimeter pitches to be cut.

27T, 28T, 30T: The number of teeth in “pitch-off gear” arranged to mesh with the

leadscrew (this being selected from the stack, stored on the bottom of the dial spindle).

Dial graduation:

The dial numbers at which the half nut may be engaged under numbers of teeth of

pick-off gear.

Metric leadscrew machines (Metric thread only), the table shows:

Imperial leadscrew machines (imperial thread only), the table shows:

11

8. Chuck and Faceplate Removal/Installation

When fitting chucks or faceplates, ensure that the spindle and the chuck taper are

correct when mounting a new chuck to re-set the cam lock studs (A). Remove the cap

head locking screws (B) and set each stud so that the scribed ring (C) is flush with the

rear face of the chuck with the slot lining up with the locking screw hole.

Mount the chuck or the faceplate on the spindle nose and tighten the six cams in turn.

When fully tightened, the cam lock line on each cam should be between the two V

marks of the spindle nose.

If any of the cams do not fully tighten with in these limit marks, remove the chuck or

faceplate and re-adjust the stud as indicated in the illustration. Fit and tighten the

locking screw (B) at each stud before remounting the chuck for work. A reference

mark should be made on each correctly fitted chuck or faceplate to coincide with the

reference mark scribed into the spindle nose. This will assist subsequent remounting.

Do not interchange chucks or faceplates between lathes without checking for the

correct cam locking.

12

9. Maintenance and Servicing

9.1 Lathe Alignment

When the lathe is installed and ready for

use, it is recommended to check the

machines alignment before commencing

work. Alignment and levelling should be

checked regularly to insure continued

accuracy.

Adopt the following procedure:

Take a steel bar with a diameter of approx.

50mm and a length of approx. 200mm.

Spin it in the chuck without using the

centre and take a cut over a length of

150mm and measure the difference

between A and B. To correct any possible difference, loosen the screw (K) clamping

the headstock on the bed and adjust the headstock. Repeat this procedure until all

the measurements are the same.

9.2 Saddle Strip

Wear on the rear saddle gib strip may be

accommodated by the adjustment of the

socket head set screws.

First remove the rear splash guard and

release the hexagon nuts, turn the socket

head set screws slightly in clockwise and then

re-clamp the hexagon nuts. Care should be

taken not to over adjust the Gib strip. A 45°

turn at the socket head set screw approx.

0.125 (0.005”) take up in the gib.

9.3 Cross Slide

Wear the taper gib strip may be adjusted by a

clockwise rotation of the slotted head screw on

the front face of the cross slide. The procedure

is to slacken the similar screw at the rear then

retighten this after adjustment to clamp the gib

into its new position.

13

9.4 Compound Rest

It is the same procedure as the cross slide. To

take up for the wear on the compound rest

taper gib strip can adjust the slotted head

screw on the tool post side of the compound

rest by a clockwise direction. The procedure

is to slacken the similar screw at the rear then

retighten this after adjustment to clamp the gib

into its new position.

9.5 Cross Slide Nut

A provision is made for the elimination of

backlash in the cross slide nut, the procedure

for adjustment being as follows: take off the

dust plate which is mounted on the rear face of

the saddle groove, turn the cross feed nut until

it reaches the edge of the feed rod. Turn the

socket head cap screw in a clockwise direction

as required. Care should be taken to avoid

over adjustment, a 45° turn at the socket head

cap screw represents approximately 0.125

(0.005”) take up of backlash.

9.6 Tailstock Bed Clamp

The angular lock position of the bed clamp

lever is adjusted by means of the self-locking

hexagon bolt located on the underside of the

tailstock and between the bed ways.

14

10. Parts List and Diagrams

Bed Assembly (1/2)

15

No.

Part No.

Name

Specification

1

V-Belt

A838/A850/A864

2

D330A-11106

Pulley

3

GB1096

Key

8x35

4

GB5781

Hexagonal Head Tap Bolt

M8x25

5

GB97.1

Washer

8x55

6

Motor

415V 50Hz 1.5kW

7

GB78

Screw

M6x8

8

GB70

Socket Head Screw

M8x30

9

GB5781

Hexagonal Head Tap Bolt

M8x40

9a

GB6170

Nut

M8

10

GB70

Socket Head Screw

M12x35

11

GB97.1

Washer

12

12

GB5781

Hexagonal Head Tap Bolt

M12x40

13

D330B-11107G

Bracket

14

GB5781

Hexagonal Head Tap Bolt

M10x30

15

GB70

Socket Head Screw

M10x35

16

GB70

Socket Head Screw

M12x40

17

GB881

Assembling Pin

8x70

18

D330-11103G

Bridge

19

D330B-11101G

Bed

20

GB70

Socket Head Screw

M8x50

21

GB70

Socket Head Screw

M8x30

22

GB118

Taper Pin

6x30

23

GB879

Spring Pin

4x42

24

GB879

Spring Pin

4x32

25

D330B-11203G

Control Rod

26

D330B-11202G

Feed Rod

27

D330B-11201G

Leadscrew

Tr22x4-7h

D330B-11201G-1

Tr22x3.175-7h

28

GB879

Spring Pin

5x20

29

GB70

Socket Head Screw

M6x16

30

D330B-11205G

Short Rack

31

D330B-11204G

Long Rack

32

GB1096

Oriented Key

4x50

33

D330B-11217G

Collar

34

GB77

Screw

M8x8

35

Spring

6x1x15

36

D330B-11105G-1

Assembling Pin

37

Spring

32x3.6x50

38

D330B-11105G

Bracket

39

GB879

Spring Pin

5x20

40

Knob

BM10x32

41

D330B-11206G

Lever

42

GB879

Spring Pin

4x20

43

D330B-11104G

Bracket

16

44

GB78

Screw

M6x16

45

GB6170

Nut

M6

46

GB118

Taper Pin

6x45

47

GB7940.4

Oil Cup

6

48

GB70

Socket Head Screw

M8x60

49

GB78

Screw

M8x12

50

D330C-3012C

Plectrum

51

GB70

Socket Head Screw

M8x16

52

GB818

Screw

M4x42

53a

Switch

53

D330C-11301C

Box

54

D330C-11302C

Cover

55

GB818

Screw

M4x10

56

D330B-11210G-1

Cover

19

57

D330B-11210G-2

Cover

22

58

GB5781

Hexagonal Head Tap Bolt

M12x45

59

GB97.1

Washer

12

60

GB70

Socket Head Screw

M10x35

61

GB6170

Nut

M10

17

Bed Assembly (2/2)

18

No.

Part No.

Name

Specification

1

GB70

Socket Head Screw

M6x12

2

GB97.1

Tailor-Made Washer

6

3

D330B-14205

Splash Guard

4

GB818

Screw

M5x8

6

GB91

Pin

3x16

14

D330A-21105

Pulley

15

GB97.1

Washer

8

16

GB70

Socket Head Screw

M8x16

16a

GB1096

Key

8x20

19

D330B-14203

Oil Tray

20

D330B-14204

Oil Tray

23

D330B-14401

Water Tank

24

GB70

Socket Head Screw

M10x30

25

GB6170

Hexagon Nut

M10

27

D330B-14201

Left Stand

28

D330DV-14102

Cover

29

GB818

Screw

M5x12

30

D330B-14209

Cover

31

D330A-11237

Drawspring

32

D330A-11236

Pin

33

D330A-11242

Shaft

34

GB70

Socket Head Screw

M6x40

35

GB879

Spring Pin

5x40

36

D330A-11235

Rocker

37

D330A-11238

Long Shaft

38

D330B-14206

Angle Iron

39

GB6170

Hexagon Nut

M6

40

GB97.1

Tailor-Made Washer

6

41

GB70

Socket Head Screw

M6x12

42

GB879

Spring Pin

5x28

43

D330B-14207

Baffle Board

44

D330B-14212

Brake Pedal

45

D330A-11241

Short Shaft

46

D330B-14202

Right Stand

47

D330B-14208

Cover

48

D330B-14213

Funnel

50

D330DV-11211

Washer

51

D330DV-11210

Cam

52

GB78

Screw

M6x15

53

Switch

LXW5-11N1

54

GB818

Screw

M4x45

55

Cover

19

Headstock Assembly (1/3)

Table of contents

Other CHESTER Lathe manuals

CHESTER

CHESTER CONQUEST SUPER LATHE User manual

CHESTER

CHESTER CONQUEST SUPER User manual

CHESTER

CHESTER DB11VS User manual

CHESTER

CHESTER Cobra Mill User manual

CHESTER

CHESTER DB8VS User manual

CHESTER

CHESTER DB7VS User manual

CHESTER

CHESTER DB10VS User manual

CHESTER

CHESTER Coventry Pro User manual

CHESTER

CHESTER Centurion Series User manual

CHESTER

CHESTER Crusader Deluxe Lathe User manual