CHESTER Champion 20VS User manual

1. Safety

1.1 Safety warnings

1.2 Proper use

1.3 Possible dangers caused by the milling machine

1.4 Qualification of personnel

1.5 Safety devices

1.6 Safety check

1.7 Individual protection gear

1.8 For your own safety during operation

1.9 Disconnecting the machine and making it safe

2. Technical Data

3. Assembly

3.1 Extent of supply

3.2 Transport

3.3 Storage

3.4 Installation and assembly

3.5 First use

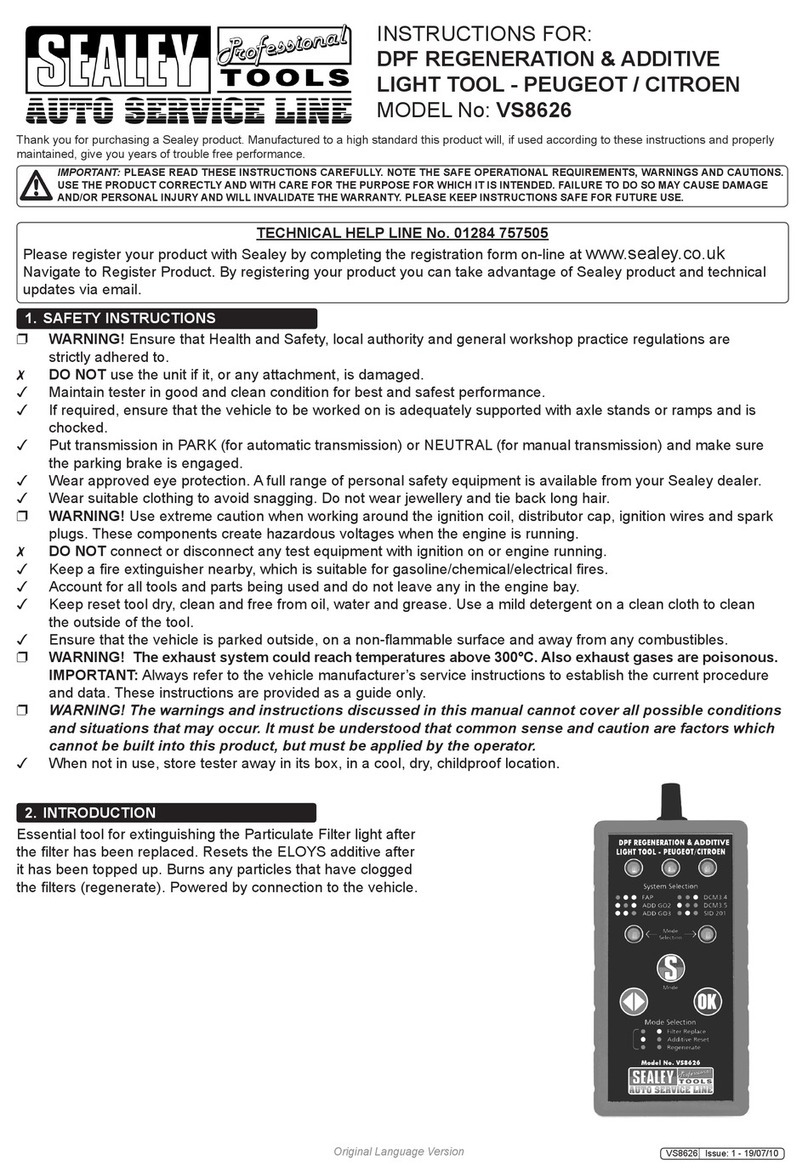

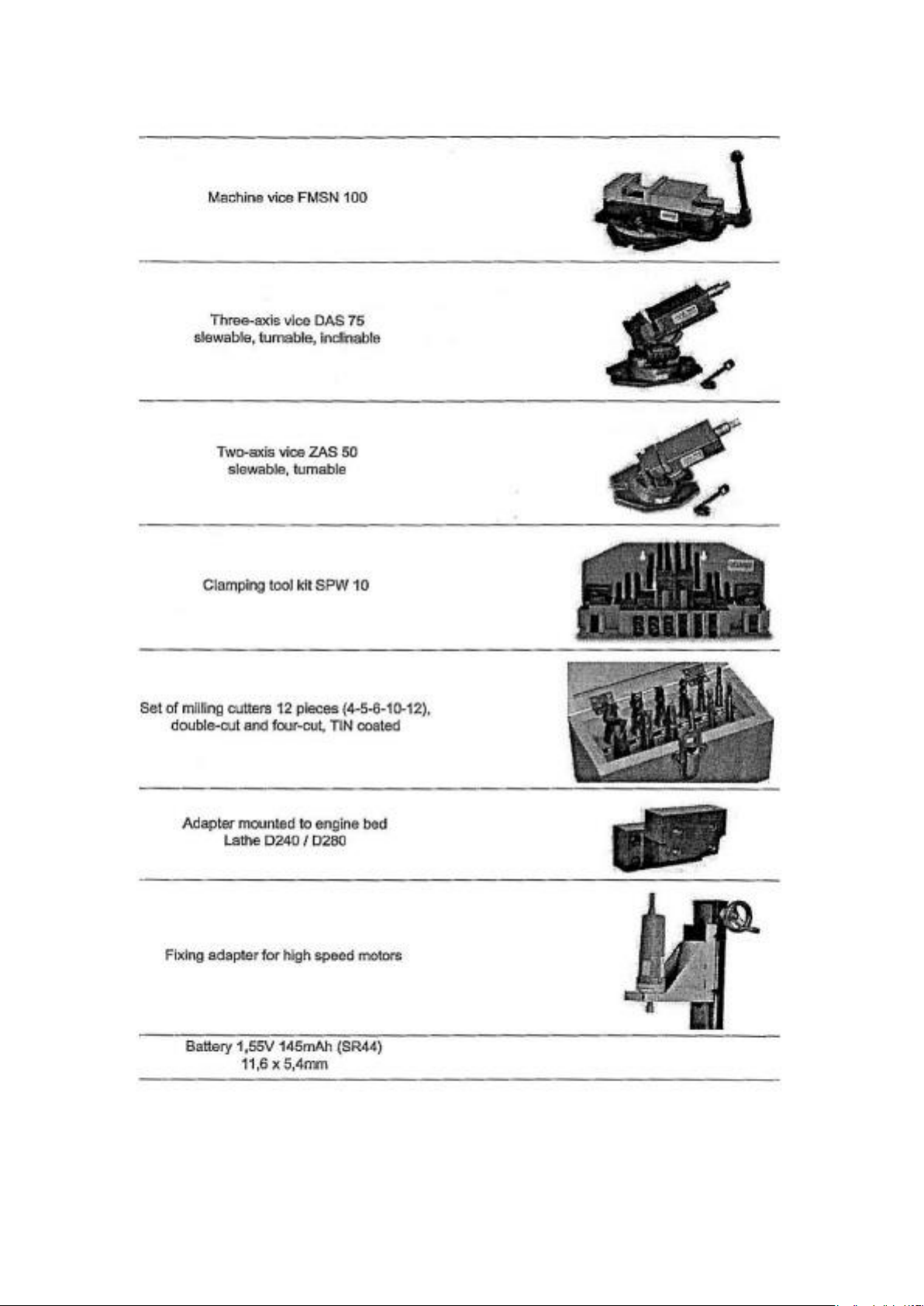

3.6 Operational accessories

4. Operation

4.1 Safety

4.2 Starting the milling machine

4.3 Inserting tools

4.4 Clamping workpieces

4.5 Changing the speed range

4.6 Selecting the speed

4.7 Manual spindle sleeve feed with the fine feed

4.8 Digital display

4.9 Swiveling the mill-drill head

4.10 Clamping Levers

4.11 End Stops

4.12 Installation on a lathe

5. Maintenance

5.1 Safety

5.2 Inspection and maintenance

5.3 Repair

5.4 Spare parts

5.5 Terminal connecting plan for control system

6. Anomalies

2

1. Safety

This part of the operating manual

•Explains the meaning of use of the warning references contained in the operating

manual

•Explains how to use the machine properly

•Highlights the dangers that might arise for you or others if these instructions are not

obeyed

•Tells you how to avoid dangers

In addition to this manual please observe

•Applicable laws and regulations

•Legal regulations for accident prevention

•The prohibition, warning and mandatory signs as well as the warning notes on the

machine

European standards must be observed during installation, operation, maintenance

and repair of the machine.

If European standards are not applied in the national legislation of the country of

destination, the specific applicable regulations of each country must be observed.

Where necessary, the required measures must be taken to comply with the specific

regulations of each country before the machine is first used.

Always keep this documentation close to the machine.

1.1 Safety warnings

Special Warnings for this Machine

Warning! There is a risk of the machine accidentally restarting after a power failure,

make sure that all of the operation switches are in the off or neutral positions if the

power is interrupted.

Warning! Always wear approved eye protection when operating this machine.

1.2 Proper use

In the event of improper use the machine will

•endanger personnel,

•endanger the machine and other material property of the operator,

•may affect proper operation of the machine

3

This milling machine is designed and manufactured to be used for milling and drilling

cold metals or other non-flammable materials that do not constitute a health hazard by

using commercial milling and drilling tools.

This machine must only be installed and operated in a dry and well-ventilated place.

If the milling machine is used in any way other than described above, modified without

authorization or operated with different process data, then it is being used improperly.

We do not take any liability for damages caused by improper use. Any such

modifications would also render the guarantee null and void.

It is also part of proper use that:

•the maximum values for the machine are complied with

•the operating manual is observed

•inspection and maintenance instructions are observed

1.3 Possible dangers caused by the milling machine

As the machine operates with

•high revolutions

•rotating parts and tools

•electrical voltage and currents

There is a residual risk with use. We have used construction resources and safety

techniques to minimize the risk to health to personnel resulting from these hazards.

We have used construction resources and safety techniques to minimize the risk to

health to personnel resulting from these hazards.

If the machine is used and maintained by personnel who are not duly qualified, there

may be a risk resulting from incorrect or unsuitable maintenance.

All personnel involved in assembly, commissioning, operation and maintenance must

•be duly qualified,

•follow this operating manual

Disconnect the machine whenever cleaning or maintenance work is being carried

out.

Warning!

This machine may only be used with the safety devices activated.

Disconnect the machine immediately whenever you detect a failure in the safety

devices or when they are not fitted. All additional installations carried out by the

operator must incorporate the prescribed safety devices.

4

1.4 Qualification of personnel

This manual is addressed to

•operators,

•users,

•maintenance staff

The warning notes therefore refer to both operation and maintenance of the milling

machine.

Always disconnect the machine plug from the electrical power supply. This will

prevent it from being used by unauthorized personnel.

All personnel involved in assembly, commissioning, operation and maintenance must

•be duly qualified,

•follow this operating manual

In the event of improper use

•there may be a risk to personnel,

•there may be a risk to the machine and other material property,

•the proper operation of the machine may be affected

1.5 Safety devices

Use the milling machine only with properly functioning safety devices.

Stop the machine if there is a failure in the safety device or if it is not functioning for

any reason.

If a device has not been activated or has failed, the milling machine must only be

used when

•the cause of failure has been removed

•it has been verified that there is no resulting danger for personnel or objects

Warning!

If you bypass, remove or override a safety device in any way, you are endangering

yourself any other personnel working with the milling machine. The possible

consequences are

•damage as a result of components or parts of components flying off at high speed.

•contact with rotating parts,

•fatal electrocution

The milling machine includes the following safety devices:

•a self-locking emergency stop button

•a protective cover at the drill-mill head

5

Emergency stop button

The emergency stop button switches the machine off.

Open the cover of the emergency stop button in order to

switch the machine on again.

Protective cover

The drill-mill head is fitted with a protective cover.

Warning!

Remove the protective cover after the mains plug of the machine has been pulled.

1.6 Safety check

Check the milling machine regularly

•at the beginning of each shift,

•once a week,

•after every maintenance and repair operation

General Check

Equipment

Check

OK

Protective covers

Mounted, firmly bolted and not damaged

Labels, markings

Installed and legible

Run Test

Equipment

Check

OK

Emergency Stop

When the Emergency Stop button is activated, the machine

should switch off automatically. A restart will not be possible

until the Emergency Stop button has been unlocked and the

On switch has been activated.

1.7 Individual protection gear

For certain work individual protection gear is required.

Protect your face and eyes. During all work and specifically work during which your

face and eyes are exposed to hazards, a safety helmet with facial protection should

be worn.

Use protective gloves when handling pieces with sharp edges.

Wear safety shoes when you position, dismantle or transport heavy components.

6

Use ear protection if the noise level (inmission) in the workplace exceeds 80 dB (A).

Before starting work, make sure that the prescribed individual protection gear is

available at the workplace.

Caution!

Dirty or contaminated individual protection gear can cause disease. Clean it after

each use and once a week.

1.8 For your own safety during operation

Warning!

Before activating the machine, double check that it will not endanger other people or

cause damage to equipment.

Avoid unsafe working practices:

•The instructions in this manual must be observed during assembly, handling,

maintenance and repair.

•Use protective goggles

•Turn off the machine before measuring the workpiece.

•Do not work on the machine if your concentration is reduced, for example, because

you are taking medication.

•Stay on the machine until all rotating parts have come to a halt.

•Use the prescribed protection gear. Make sure to wear a well-fitting work suit and a

hairnet, if necessary.

•Do not use protective gloves during drilling or milling work.

•Unplug the shockproof plug from the mains before changing the tool.

•Use suitable devices to remove drilling and milling chips.

•Make sure your work does not endanger anyone.

•Clamp the workpiece tightly before activating the machine.

In the description of work on the drilling-milling machine we highlight the dangers

specific to that work.

1.9 Disconnecting the machine and making it safe

Pull the main plug before beginning any maintenance or repair work.

Warning!

Use of unstable lifting equipment and load-suspension devices that break under load

can cause very serious injuries or even death.

Check that the lifting equipment and load-suspension devices are of sufficient load

capacity and in perfect condition.

7

Observe the rules for preventing accidents issued by your association for the

prevention of occupational accidents and safety in the workplace or other inspection

authorities.

Tighten loads properly.

Never walk under suspended loads!

8

2. Technical Data

The following information gives the dimensions and weight and is the manufacturer’s

authorized machine data.

Engine power consumption

750W/240V/50Hz

Drilling capacity

16mm

Face milling capacity

63mm

End milling capacity

20mm

Working radius

185mm

Spindle taper

MT2

Spindle stroke

42mm

T-slot size

12mm

Headstock tilt

±90º

Cross travel

160mm

Longitudinal travel

660mm

Vertical travel

290mm

Dimensions

960 x 570 x 970mm

Net weight

113kg

Emissions

The noise level (emission) of the drilling-milling machine ranges below 78 dB(A). If

the drilling-milling machine is installed in an area where various machines are in

operation, the acoustic influence (inmission) on the user of the drilling-milling

machine may exceed 85 dB(A) in the working area.

We recommend the use of soundproofing and ear protection. Remember that the

duration of the noise pollution, the type and characteristics of the work area and

operation of other machines influence the noise level in the working area.

9

3. Assembly and Connection

The drilling-milling machine comes pre-assembled.

3.1 Extent of supply

When the drilling-milling machine is delivered, check immediately that the machine

has not been damaged during transport and that all components are included. Also

check that no fastening screws have come loose.

Compare the parts supplied with the information on the packaging list.

3.2 Transport

Warning!

Machine parts falling off forklift trucks or other transport vehicles could cause very

serious or even fata injuries. Follow the instructions and information on the transport

case:

•Centers of gravity,

•Suspension points,

•Weights,

•Means of transport to be used,

•Prescribed shipping position.

Use of unstable lifting equipment and load-suspension devices that break under load

can cause very serious injury or even death.

Check that the lifting and load-suspension gear has sufficient load capacity and that

it is in perfect condition.

Observe the rules for preventing accidents.

Holds the load properly.

Never walk under suspended loads.

3.3 Storage

Improper storage may cause important parts to be damaged or destroyed.

Store packed or unpacked parts only under the intended environmental conditions.

Consult Chester UK if the machine or accessories have to be stored for a period of

over three months or under different environmental conditions than those given here.

3.4 Installation and assembly

The work area for operation, maintenance and repair work must not be hindered.

The mains plug of the drilling-milling machine must be freely accessible.

10

Proceed with extreme caution when lifting, installing and assembling the machine.

Danger of crushing and overturning.

•Secure the load-suspension device around the drill-mill head. Use a lifting sling for

this purpose.

•Clamp all the clamping levers at the machine before lifting it.

•Make sure that no add-on pieces or varnished parts are damaged due to the load-

suspension.

•Check the horizontal orientation of the base of the machine with a spirit level.

•Check that the foundation has sufficient floor-load capacity and rigidity.

Insufficient rigidity of the foundation leads to the superposition of vibrations between

the drilling-milling machine and the foundation (natural frequency of components).

Insufficient rigidity of the entire milling machine assembly also rapidly causes the

machine to reach critical speeds, with unpleasant vibrations, leading to bad milling

results.

•Position the drilling-milling machine on the intended foundation.

•Attach the drilling-milling machine using the provided recesses in the machine base.

11

3.5 First use

Cleaning and lubricating.

Remove the anticorrosive agent applied on the drilling-milling machine for transport

and storage purposes. We recommend the use of kerosene.

Do not use any solvents, thinners or other cleaning agents which could corrode the

varnish on the drilling-milling machine. Follow the specifications of the manufacturer

of the cleaning agent.

•Lubricate all bright machine parts with non-corrosive lubricating oil

•Grease the machine according to the lubrication chart

•Check smooth running of all spindles. The spindle nuts can be readjusted.

•Check the fuse protection of your power supply against the technical data for the total

connection value of the machine.

12

3.6 Optional accessories

13

14

4. Operation

4.1 Safety

Use the drilling-milling machine only under the following conditions.

• The machine is in proper working order

• The machine is used as prescribed

• The operating manual is followed

• All safety devices are installed and activated

All anomalies should be eliminated immediately. Stop the drilling-milling machine

immediately in the event of any anomaly in operation and make sure it cannot be

started up accidentally or without authorization.

4.2 Starting the milling machine

Wait until the machine has come to a complete halt before inverting the turning

direction using the change-over switch.

The speed of the spindle is a little smaller in left-

handed motion than in right-handed motion.

• The rotating direction of the milling machine is

selected using the change-over switch.

• Press the ON button. The milling machine will

be activated and turn in the pre-selected rotating

direction.

Turning on the machine

Turn the change-over switch into the ‘0’position.

4.3 Inserting tools

When milling operations are performed the cone seat must always be fixed to the

draw-in rod.

All cone connections with the taper bore of the work spindle without using the draw-

in rod is not allowed for milling operations. The cone connector should be released

by the lateral pressure. Injuries by parts flying off.

In the work spindle you may only use tool holding fixtures and clamping tools with

morse taper MK2 and internal screw thread M10 for an interlocking fixture. Reducing

bushes is not allowed.

The mill head is equipped with an MT2 seat and a M10 draw-in rod.

15

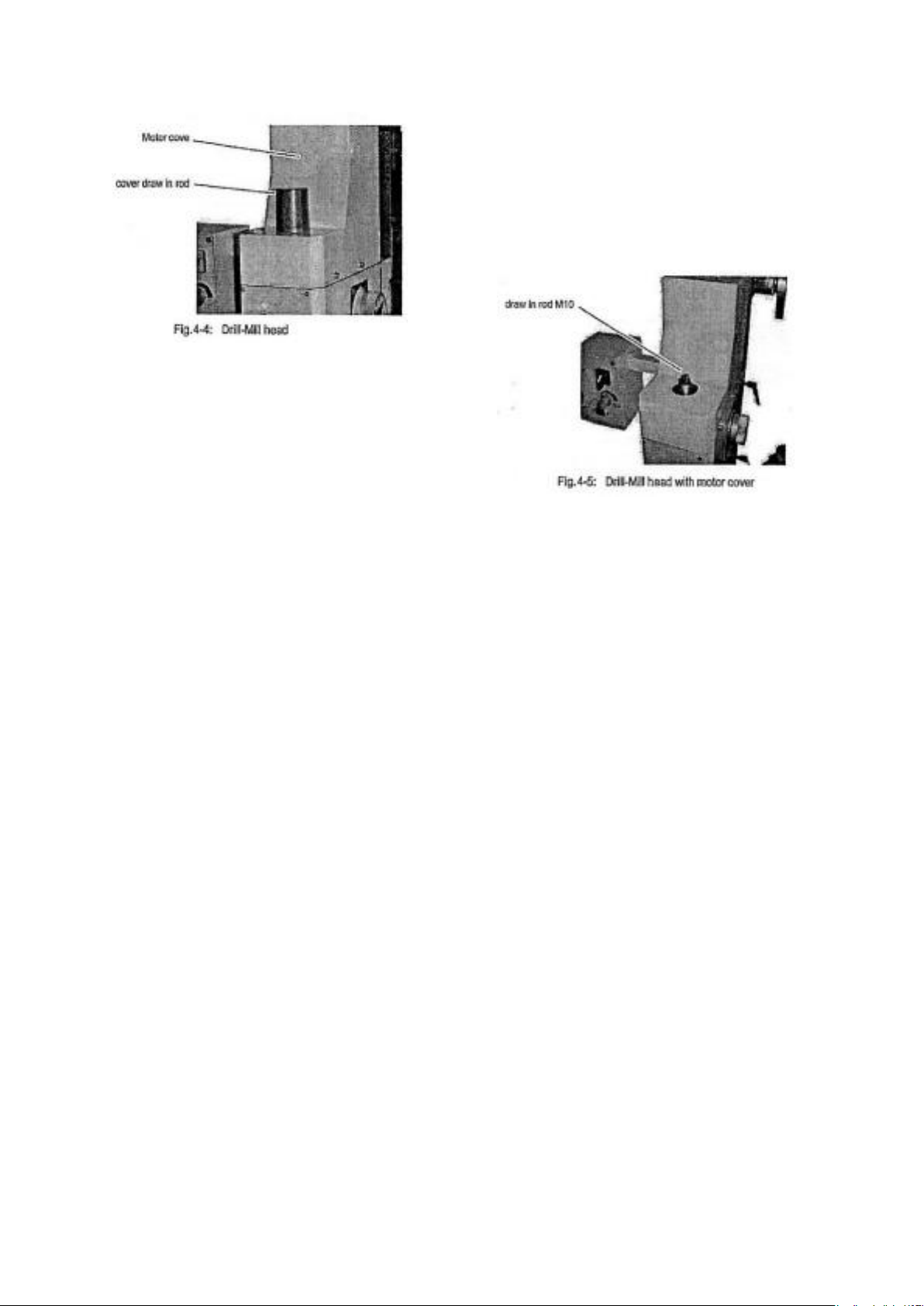

• Remove the cover. There is no need to

disassemble the motor cover completely

• Clean the conical holding fixture in the mill

head.

• Clean the taper of your tool

• Insert the tool into the tool holding fixture

• Screw the draw-in rod into the taper of

your tool.

• Tighten the draw-in nut and fix the spindle.

Use a wrench to hold the spindle

Removing a tool

• Hold the spindle with the wrench and loosen the draw-in rod. Turn the draw-in rod

further so that the tool from the cone admission is squeezed out.

Use of collet chucks

When using collet chucks for the reception of milling tools, a higher operation

tolerance is possible. The exchange of the collet chucks for a smaller or larger end

mill cutter is performed simply and rapidly and the disassembly of the complete tool

is not required.

The work spindle is equipped with a surface for the hold-up with a fork wrench to

unfasten the swivel nut of the collet chuck retainer. The collet chuck is pressed into

the ring of the swivel nut and must hold there by itself. By fastening the swivel nut on

the tool the milling cutter is clamped.

Make sure that the correct collet chuck is used for each milling cutter diameter, so

that the milling cutter may be fastened securely and firmly.

4.4 Clamping workpieces

Tools or collet chucks with a MT2 shank may be clamped directly into the work

spindle. For mounting these tools, proceed as described in ‘inserting tool’ above.

Make sure that the tool is clamped with the draw-in rod.

The workpiece is always to be fixed by a machine vice, jaw chuck or other

appropriate clamping tool.

16

4.6 Changing the speed range

Wait until the machine has come to a complete halt before changing the speed using

the gear switch.

• Turn the gear switch in the position ‘H’ for a speed range of 200 – 3000 min

• Turn the gear switch into the position ‘L’ for a speed range of 100 – 1500 min

• Adjust the speed with the potentiometer. The speed and the cutting speed depends

on the material of the workpiece, the milling cutter diameter and the cutting type.

The electronics controls the rotation speed slowly with a ramp to the set point.

Therefore, wait briefly before you continue with feed motion while milling or drilling.

4.6 Selecting the speed

For milling operations, the essential factor is the selection of the correct speed. The

speed determines the cutting speed of the cutting edges which cut the material. By

selecting the correct cutting speed, the service life of the tool is increased and the

working result is optimized.

The optimum cutting speed mainly depends on the material and on the material of

the tool. With tools (milling cutters) made of hard metal or ceramic insert it is possible

to work with higher speeds than with tools made of high-alloy high speed steel

(HSS). You will achieve the correct cutting speed by selecting the correct speed.

For the correct cutting speed for your tool and for the material to be cut you may

refer to the following standard values or a table reference book.

The required speed is calculated as follows:

17

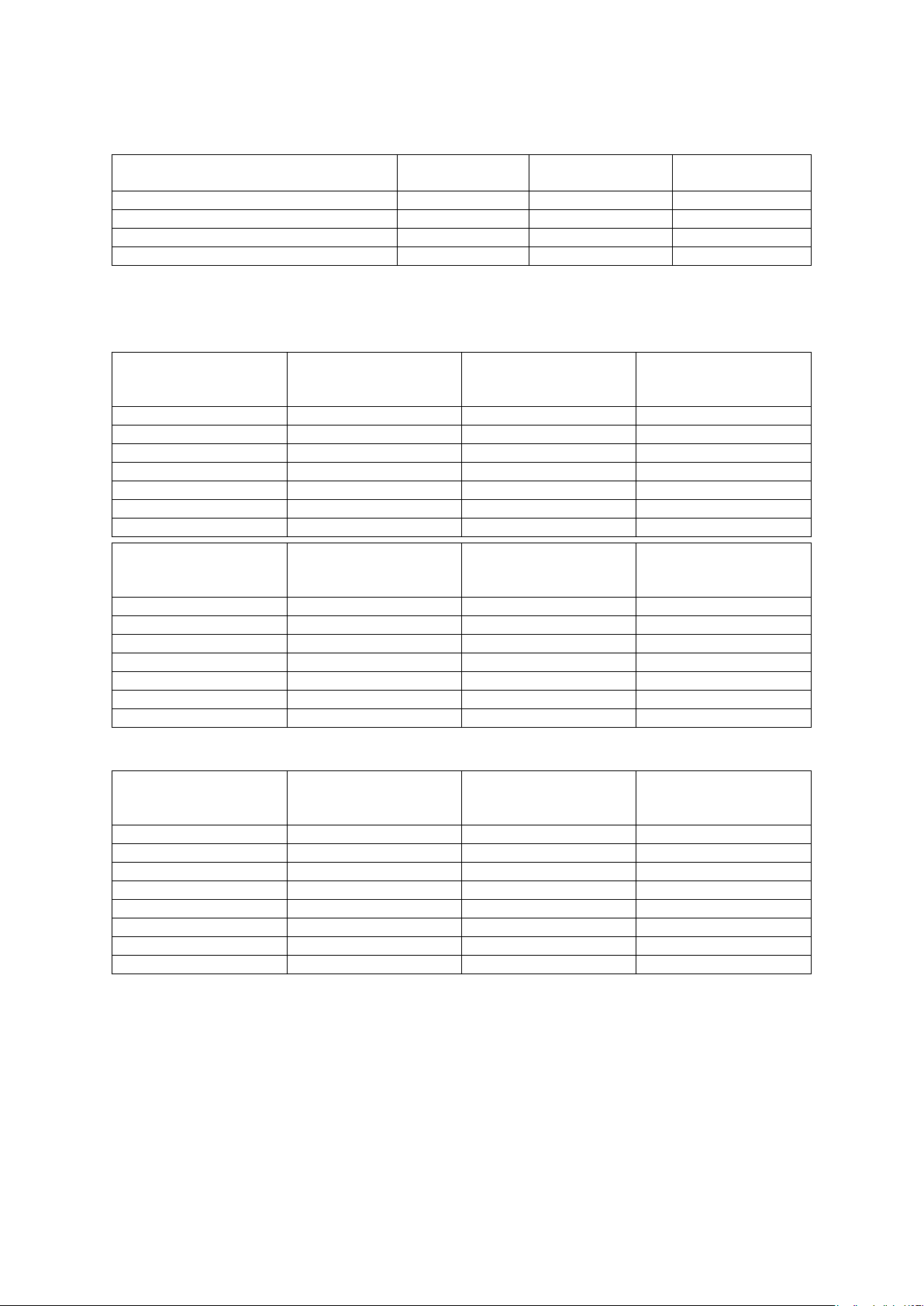

Standard values for cutting speeds

[m/min] with high speed steel and hard metal in conventional milling.

Tool

Steel

Gray cast iron

Age-hardened

Al Alloy

Peripheral and side milling cutters

10-25mm

10-22mm

150-350mm

Relived form cutters

15-24mm

10-20mm

150-250mm

Inserted tooth cutter with SS

15-30mm

12-25mm

200-300mm

Inserted tooth cutter with HM

100-200mm

30-100mm

300-400mm

The results are in the following standard values for speeds in dependence of the

milling cutter diameter, cutter type and material.

Tool diameter

Peripheral and side

milling cutters

Steel

10-25m/min

Grey cast iron

10-22m/min

Age hardened Al

Alloy 150-250 m/min

35mm

91-227

91-200

1365-3185

40mm

80-199

80-175

1195-2790

45mm

71-177

71-156

1062-2470

50mm

64-159

64-140

955-2230

55mm

58-145

58-127

870-2027

60mm

53-133

53-117

795-1860

65mm

49-122

49-108

735-1715

Tool diameter

Form cutters

Steel

15-24m/min

Grey cast iron

10-20m/min

Age-hardened

Al Alloy

150-250m/min

4mm

1194-1911

796-1592

11900-19000

5mm

955-1529

637-1274

9550-15900

6mm

796-1274

531-1062

7900-13200

8mm

597-955

398-796

5900-9900

10mm

478-764

318-637

4700-7900

12mm

398-637

265-531

3900-6600

14mm

341-546

227-455

3400-5600

16mm

299-478

199-398

2900-4900

Friction during the cutting process causes high temperatures at the cutting edge of

the tool. The tool should be cooled during the milling process. Cooling the tool with a

suitable cooling lubricant ensures better working results and a longer edge life of the

cutting tool.

Use a water soluble and non-pollutant emulsion as a cooling agent. This can be

acquired from authorized distributors.

18

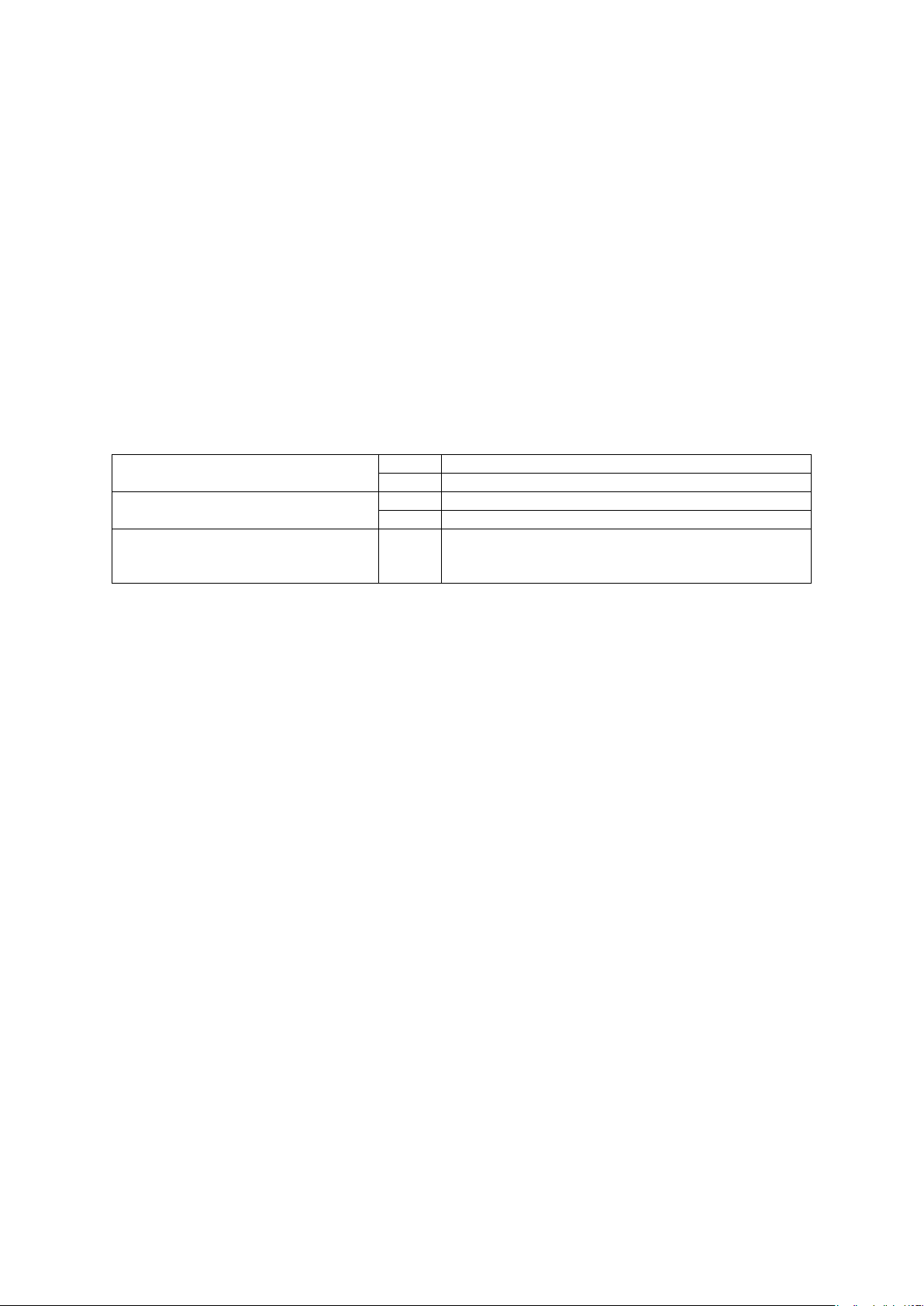

Tool diameter

peripheral and side

milling cutters

Steel

10-25m/min

Grey cast iron

10-22m/min

Age hardened

Al Alloy 150-

350m/min

35mm

91-227

91-200

1365-3185

40mm

80-199

80-175

1195-2790

45mm

71-177

71-156

1062-2470

50mm

64-159

64-140

955-2230

55mm

58-145

58-127

870-2027

60mm

53-133

53-117

795-1860

65mm

49-122

49-108

735-1715

Make sure that the cooling agent is properly retrieved. Respect the environment

when disposing of any lubricants and cooling agents. Follow the manufacturer’s

disposal instructions.

4.7 Manual spindle sleeve feed with the fine feed

Turn the handle screw. The spindle sleeve lever will move towards the drill-mill head

and will activate the clutch of the fine feed.

Turn the spindle sleeve fine feed in order to move the spindle sleeve.

4.8 Digital display

Display for spindle sleeve travel.

Measuring range

mm

0-999.99

inch

0-39.371”

Reading precision

mm

0.01

inch

0.0004”

Power supply (battery)

Round cell 1.55V

145mAh (SR44)

11.6 x 5.4mm

• ON / O switches the display on and resets the reading of the display to “0”

• mm / in converts the measuring unit from millimeters to inches and viceversa

• OFF switches the display off

• ↑ performs a value increase

• ↓performs a value decrease

4.9 Swiveling the mill-drill head

Manual spindle sleeve feed with the fine feed

The clutch of the fine feed has to be disengaged before the spindle sleeve lever can be

used. Activating the spindle sleeve lever when the fine feed is engaged may damage the

clutch.

Loosen the handle screw. The spindle lever moves away from the drill-mill head and

disengages the clutch of the fine feed.

The mill-drill head may be swiveled to the left.

Caution!

The drill head may tilt to the right or the left on it’s own after loosening a screw.

Proceed with extreme caution when loosening the clamping joints.

19

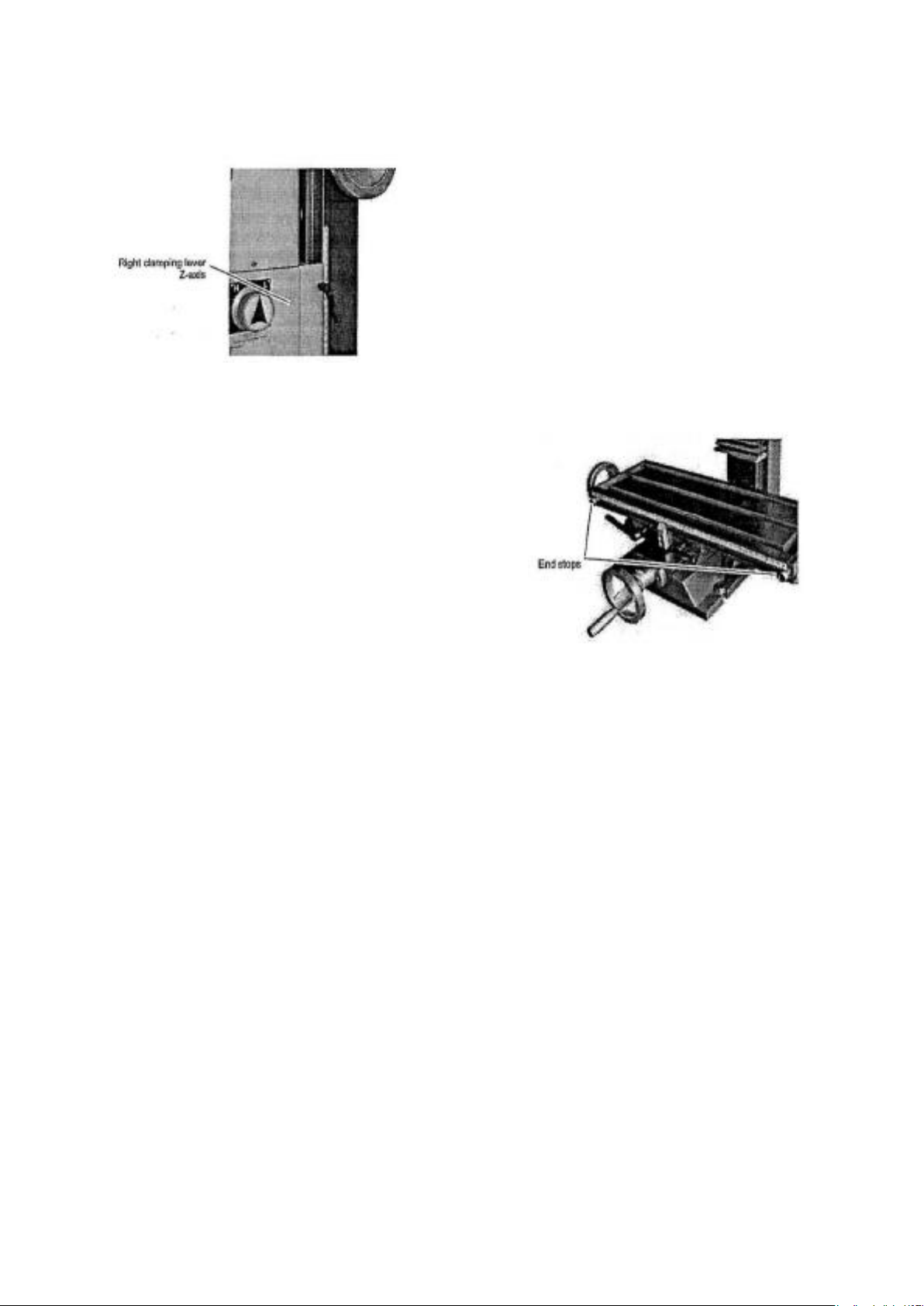

4.10 Clamping Levers

The machine is equipped with clamping levers

for the Z-Axis movement of the drill-mill head

and two clamping levers for the X and Y-Axis

movement of the cross table.

The spindle sleeve is fitted with a clamping

lever.

Use the clamping levers to lock the position of

the axes during milling or drilling operations.

4.11 End stops

The cross table is fitted with two adjustable end

stops on the X-Axis.

Use the end stops for limiting the travel

alongside the X-Axis in order to guarantee the

exact repeatability when manufacturing various

identical components.

4.12 Installation on a lathe

The mill head with column can be mounted on a lathe. For fastening an adapter is

required. The adapter needs to be fixed to the engine bed. It is not possible to fix it to

the lathe slide. The adapter is dimensioned in a way that the middle of the lathe

chuck should be reached with the center of the milling spindle (alignment headstock

– lathe chuck).

Due to the manufacturing tolerances of castings and the manufacturing tolerances of

two different machines it is however not possible to reach the exact center, the

adapter may be too long or short.

If required, the adapter is to be milled off or equipped with dummy sheets. When

using sheets the complete surface is to be filled.

In order to reduce the support expenditure of the column with milling head during the

orientation we recommend you disassemble the milling head off the column.

Unscrew the locking screw (safety screw) position 266. Disassemble the milling head

off the column by completely loosening the clamping screw and the lead screw and

stripping off the milling head.

Control the orientation (90° angle horizonal and vertical) of the column with the

reference planes on the engine bed of the lathe.

20

Table of contents