AIRCONDITIONINGCOMPRESSOR1-7

PressureReliefValve

Whena faultypressurereliefvalve,locatedintherear

headcasting,isencountered,thevalveassemblyshould

beremovedafterpurgingthesystemanda newvalveand

gasketinstalled.Theentiresystemshouldthenbe

evacuatedandrecharged.

CompressorRearHeadandInternalMechanism

Serviceoperationstotherearheadorinternalmech-

anismofthecompressorshouldbeperformedwiththe

compressorremovedfromthevehicletoinsurethatthe

necessarydegreeofcleanlinessmaybemaintained.

Cleanhandsanda cleanbench,preferablycoveredwith

cleanpaper,areofextremeimportance.

RearHead,OilPumpandValveAssemblies

Removal

1.

Removethecompressorfromthevehicle,drain

compressoroilintoa cleancontainer,cleanthe

exteriorofthecompressorcaseandrearheadcast-

ingwitha suitablesolventandmountthecompres-

sor,rearheadup,inholdingFixtureJ-9396which

shouldthenbemountedsecurelyina vise.

2.

Removethefournutsfromtheshellstuds.

3.

Removetherearhead.Examinetheteflonsurface

onthecastingwebs.Ifthissurfaceisdamagedby

nicksorscratches,theheadshouldbereplaced.

4.

Examinethesuctionscreenintherearheadforany

damageorcontamination.Cleanorreplacethe

screenasnecessary.

5.

Removeandexaminetheoilpumpgears.Ifeitherof

thegearsshowsanywearordamage,replaceboth

gears.

NOTE:Keeptheendsofthetwooilpumpgears

matchedandreplacethesameendtowardthe

dischargeplateuponreassembly.

6.Removetherearhead-to-shell"O"ringanddis-

card.

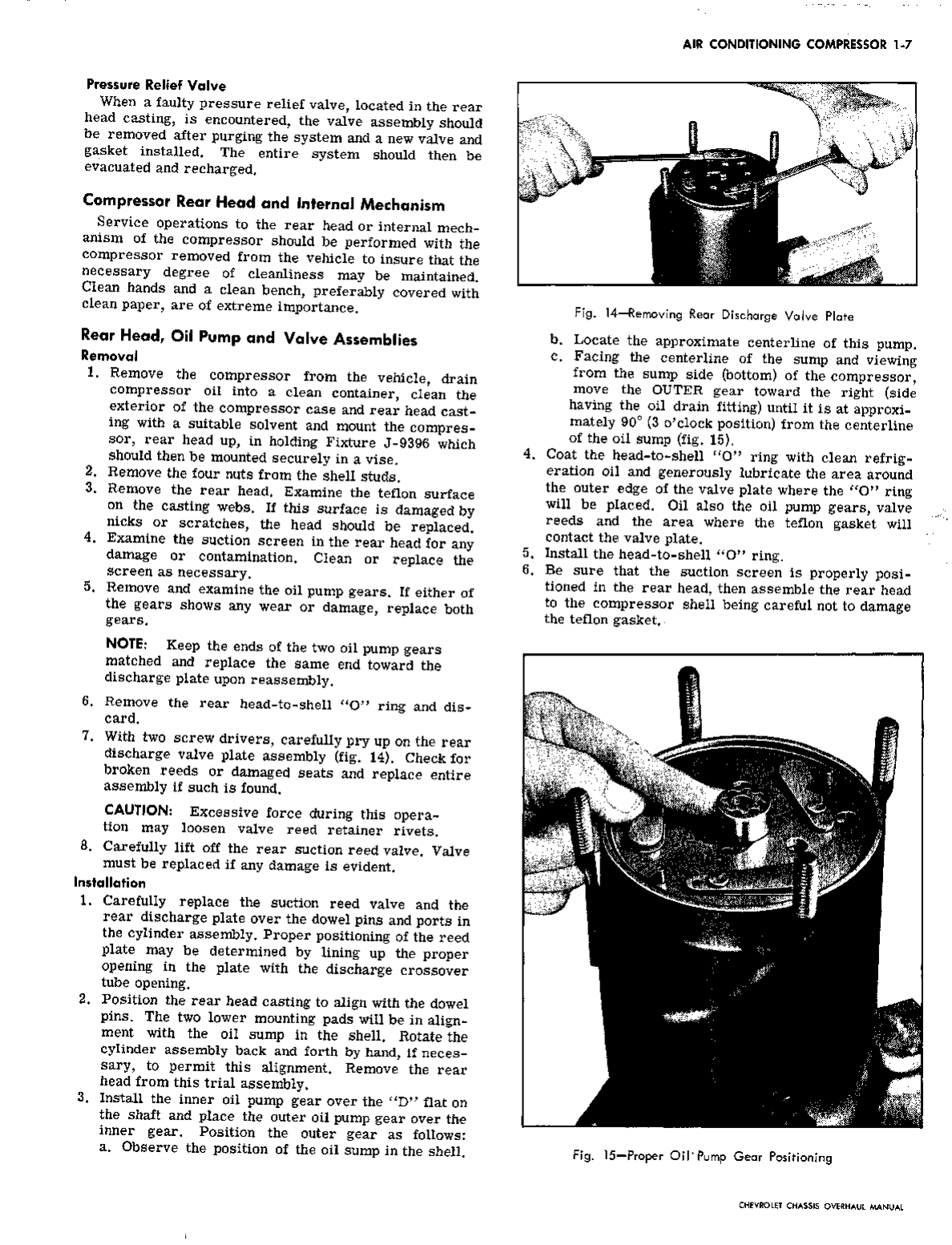

7.

Withtwoscrewdrivers,carefullypryupontherear

dischargevalveplateassembly(fig.14).Checkfor

brokenreedsordamagedseatsandreplaceentire

assemblyifsuchisfound.

CAUTION:Excessiveforceduringthisopera-

tionmayloosenvalvereedretainerrivets.

8.Carefullyliftofftherearsuctionreedvalve.Valve

mustbereplacedifanydamageisevident.

Installation

1.

Carefullyreplacethesuctionreedvalveandthe

reardischargeplateoverthedowelpinsandportsin

thecylinderassembly.Properpositioningofthereed

platemaybedeterminedbylininguptheproper

openingintheplatewiththedischargecrossover

tubeopening.

Positiontherearheadcastingtoalignwiththedowel

pins.

Thetwolowermountingpadswillbeinalign-

mentwiththeoilsumpintheshell.Rotatethe

cylinderassemblybackandforthbyhand,ifneces-

sary,topermitthisalignment.Removetherear

headfromthistrialassembly.

Installtheinneroilpumpgearoverthe"D"flaton

theshaftandplacetheouteroilpumpgearoverthe

innergear.Positiontheoutergearasfollows:

a.Observethepositionoftheoilsumpintheshell.

2.

3.

Fig.

14—RemovingRearDischargeValvePlate

5.

6.

b.

Locatetheapproximatecenterlineofthispump.

c.Facingthecenterlineofthesumpandviewing

fromthesumpside(bottom)ofthecompressor,

movetheOUTERgeartowardtheright(side

havingthe^oildrainfitting)untilitisatapproxi-

mately90°(3o'clockposition)fromthecenterline

oftheoilsump(fig.15).

Coatthehead-to-shell"O"ringwithcleanrefrig-

erationoilandgenerouslylubricatetheareaaround

theouteredgeofthevalveplatewherethe"O"ring

willbeplaced.Oilalsotheoilpumpgears,valve

reedsandtheareawheretheteflongasketwill

contactthevalveplate.

Installthehead-to-shell"O"ring.

Besurethatthesuctionscreenisproperlyposi-

tionedintherearhead,thenassembletherearhead

tothecompressorshellbeingcarefulnottodamage

theteflongasket.

Fig.

15—ProperOil"PumpGearPositioning

CHEVROLETCHASSISOVERHAULMANUAL