1979

CHASSIS

SERVICE

MANUAL

Covering

CHEVROLET.

MALIBU.

MONTE

CARLO,

NOVA,

ANDCAMARO

FOREWORD

This manual includes

procedures

for diasnosis,maintenance

and adjust

ments, minor sêruice

operations,removatand insta ation of cornponenrs.

exc€pt

the body, of 1979Chevrolet,

lvlalibu,

À4onte

Carto,Nova,

aDdCâmaro.

Procedures

involving dhassembty

ônd assembty

of mêjor componentsfor

these

vehicles

areconrai.ed

inthe 1979Passenger

Cêrand

LightDuty

Truck

Chassis

Overhaullvanual.Service

information for 1979 Chevrotet_

lMatibu.

Vonlê Car,o,Novc

andCdnâro

bodyitems

;( colra: eo .n Lhe19/9 Boov

ServicelVanuà1.

W;rinq

diâgrdmstor 1979

Ch"vrorer

pr""nq", "." ur" .ounà

in aseparateWirinsDiêsrêm

Bookler

(ST-359

7S).

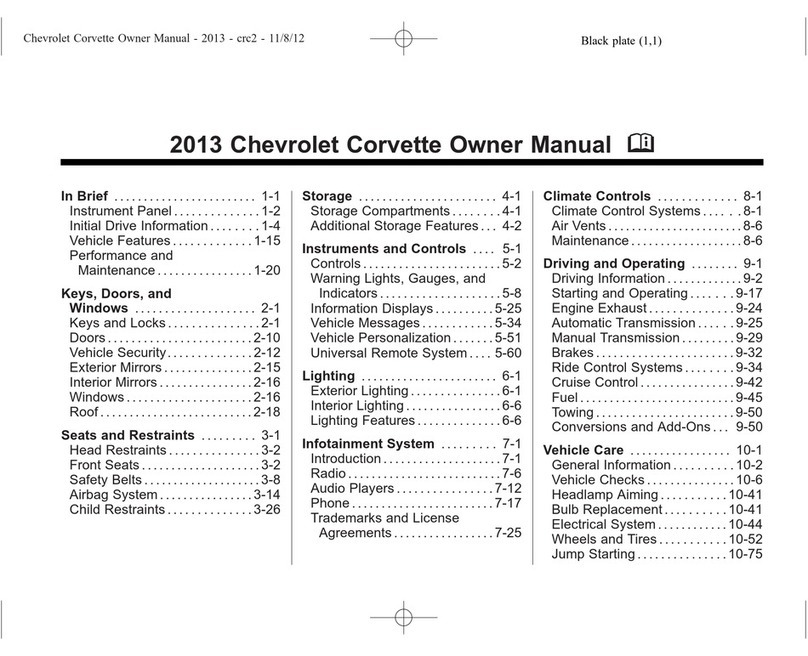

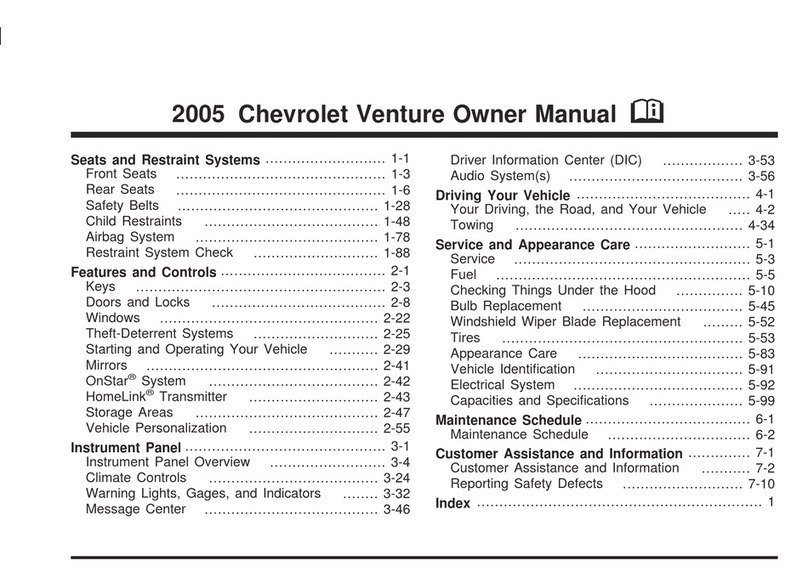

The Section lndex on this pageenabJes

rhe userto qlickty tocare

âny

desired

section.At the beginninsoi each

section

containins

morethên

one

majof

subject

isa Table

of Contents,

which

qives

the

pase

number

on which

eachmajor

subject

begins.An lndex isptaced

at the besinnins

of eachmajor

subjectwithin the section.

Summaries

of SpecialTook, whenrequked,arefound at the endof mêior

sections.

Specificêtionscoverinqvehictecomponentsare presented

at the

rear

of each

section.

Whenreference

is mâde

in thismanuat

to êbrand

name,.umber. or soecific

rool.

àr eqJivàlent

product

maybp ,sed

Inpt"ce

ot Lherecommended

irern.

Thismanual

shouldbe kept in a handy plêcê

for readyfêference.

tf prop-

erly used,

it will enable

the technician

to better serve

the owners

of Chev-

All information, illusrrations

andspeciTicationscontained

in this tirerature

ârebêsed

on the latest

productiôformationavaitabte

at the time of pubticâ

tron âpprovâ|.

The right h reserved

to make chansesêt anv time witholt

CAUTION

Thisvehiclecontainssome partsdimensionedin themetic svstem

aswell asin the customary system,

Some tasteners

arc metric and

ate very closein dimension to tamiliat customatv fastenersin the

inch system-ltis importantto note that duing any vehictemajnte.

nance proceclurct replacement lastenerc must have the same

measuremenEand strcngth as thoseremoved, whether meùic or

customary. (Numbercon the headsol met c botts andon suiaces

ol meùic nuts indicate theit strength. Customatvbotts use rcdiat

lines lor this purpose, while most customary nuts do not have

sttength matkings.)Mismatched ot inêoftect lastênerscanrcsutt in

uehicleclamage

or malfttnction, o. possibly petsonatiniu.y. Therc-

tote fasteners

removedl.om the vehicleshould besavedtot rc-use

in the samelocations whenêvêtpossibte. Whe.ethe tasteneÆ

arc

not satidactory tor re-use, carc should be taken to setect a .e-

placement that matches the o.iginal. For infonation and assis-

tance, seevour Chevroletdealer.

Ad'ditional

informârion

concerningrhis

subiect

wi befound

atthe

end

CHEVROI.ET

MOTORDIVISION

Generdl Moto.s Corporotion

DETROIT,

MICHIGAN

SECTION

CENEBAI.

INfORMATTON

MAINTENANCE

AND

TUBBICATION

MANUAI.

AIR

CONDITIONING

AUTOMATIC

AIRCONOITIONING

FRAME

ANDBODY

MOUI{TS

rRONT

ALIGNMENT

STEERING

tR0NT

SUSPÊt{St0N

REAR

SUSPENSION

WHEEI.S

ANOTIRES

PROPSHAFI

AND

UNIVERSAL

JOINTS

ENGINEMECHANICAI-

ENGINE

COOI.ING

ENGINE

EI-ECTRICAI

ENGINE

EMlSSr0r{

c0NTB0rs

ENGINEÊXHAUST

AUTOMATIC

TRANSMISSION

MANUAI.

TRANSMISSION

BODYAIIIO

CHASSIS

ETECTRICAT

ACCESS0nTES

O 1979

GênerâMorôrsCôrpoÉtion