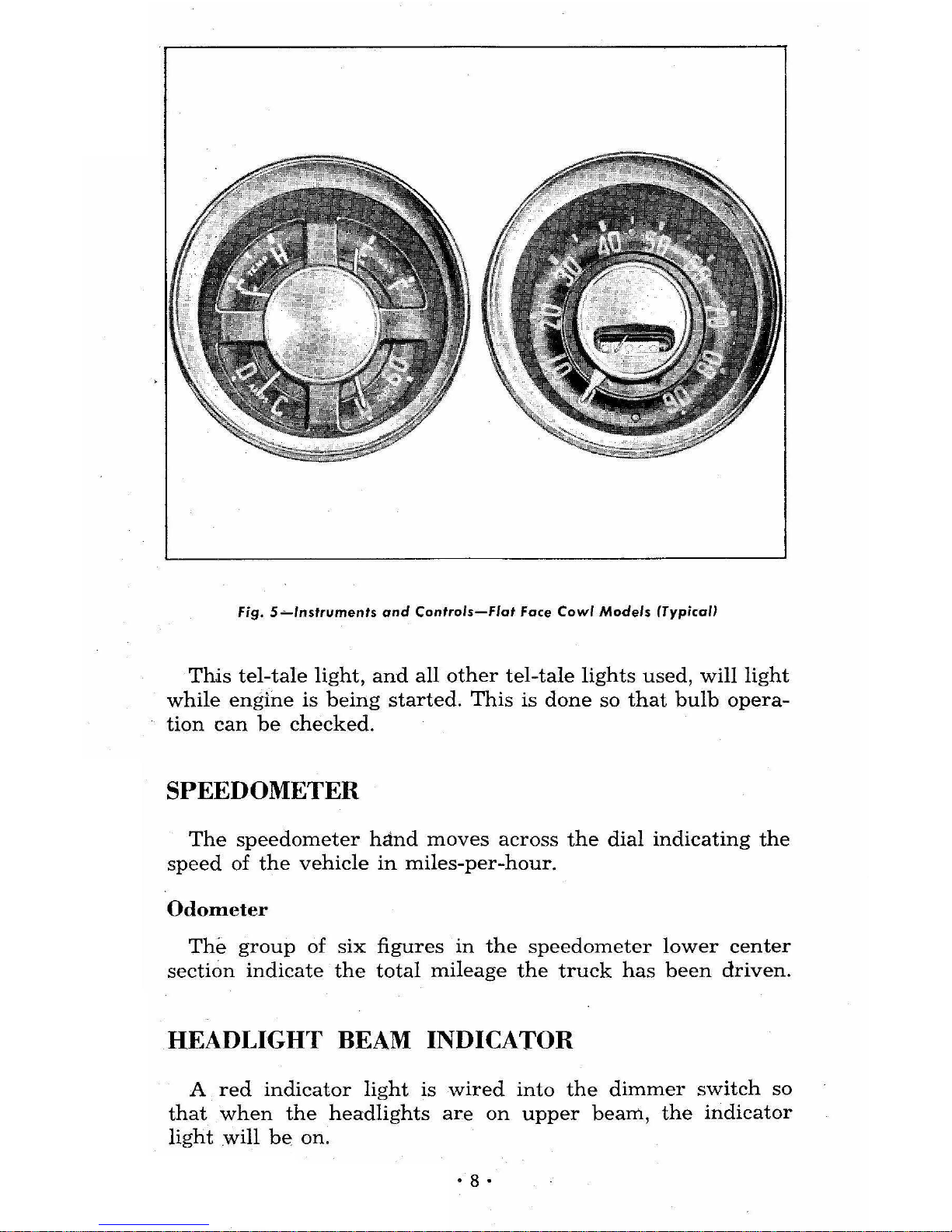

Chevrolet truck 1960 User manual

Other Chevrolet Automobile manuals

Chevrolet

Chevrolet S-10 User manual

Chevrolet

Chevrolet 1998 Corvette User manual

Chevrolet

Chevrolet 1994 S-10 Pickup User manual

Chevrolet

Chevrolet Silverado EV 2024 User manual

Chevrolet

Chevrolet Sail 2010 User manual

Chevrolet

Chevrolet 2007 Colorado User manual

Chevrolet

Chevrolet CORVETTE User manual

Chevrolet

Chevrolet 2011 HHR User manual

Chevrolet

Chevrolet 2009 Aveo User manual

Chevrolet

Chevrolet Traverse 2015 Assembly instructions

Chevrolet

Chevrolet 1986 Corvair User manual

Chevrolet

Chevrolet Traverse 2012 User manual

Chevrolet

Chevrolet 2001 Tahoe User manual

Chevrolet

Chevrolet 1993 Astro Passenger User manual

Chevrolet

Chevrolet Silverado 2005 Operating and installation instructions

Chevrolet

Chevrolet 2002 S10 Pickup User manual

Chevrolet

Chevrolet MALIBU 1998 User manual

Chevrolet

Chevrolet 2015 VOLT User manual

Chevrolet

Chevrolet 1957 User manual

Chevrolet

Chevrolet 2010 Corvette User manual