1.Technical Data

Model

Drive

Torque

Free speed Dimension

Lxh

Air Consumption

Average :HLJKW Inner Hose Dia. Air Inlet 6RXQGSUHVVXUH

/S$

6RXQGSRZHU

/Z$

9LEUDWLRQV

Working Max DKG K

L

W

H

12 34 5 6 7 8 9 10

[min-1] [inch]

>1P@ >530@ [inch]

>PP@

>1OV@

>6&)0@

>NJ@

>OE@

[inch]

>PP@ [inch] >G%$@ >G%$@ >PVt@ >PVt@

max. pressure 6.3bar(90psi)

ah9LEUDWLRQOHYHOk8QFHUWDLQW\LpA6RXQGSUHVVXUHG%$KpA KWA G%8QFHUWDLQW\

Declaration of noise and vibration statement,62DQG,62

All values are current as of the date of this publication.

These declared values were obtained by laboratory type testing in accordance with the stated standards and are suitable for comparison with the declared values of other tools

tested in accordance with the same standards. These declared values are not adequate for use in risk assessments and values measured in individual work places may be

higher. The actual exposure values and risk of harm experienced by an individual user are unique and depend upon the way the user works, the workpiece and the workstation

design, as well upon the exposure time and the physical condition of the user. We, CHICAGO PNEUMATIC TOOLS, cannot be held liable for the consequences of using the

GHFODUHGYDOXHVLQVWHDGRIYDOXHVUHÀHFWLQJWKHDFWXDOH[SRVXUHLQDQLQGLYLGXDOULVNDVVHVVPHQWLQDZRUNSODFHVLWXDWLRQRYHUZKLFKZHKDYHQRFRQWURO7KLVWRROPD\FDXVH

hand-arm vibration syndrome if its use is not adequately managed. We recommend a programme of health surveillance to detect early symptoms which may relate to noise

or vibration exposure, VRWKDWPDQDJHPHQWSURFHGXUHVFDQEHPRGL¿HGWRKHOSSUHYHQWIXWXUHLPSDLUPHQW

Additional Vibration Information

This tool may cause hand-arm vibration syndrome if its use is not adequately managed.

This additional vibration information may be of assistance to employers in meeting their obligations (for example under EU Directive 2002/44/EC) to assess the risks to their

workers arising from hand arm vibration associated with the use of this tool.

5DWFKHWZUHQFKHVDUHVXLWDEOHIRUDVVHPEO\DQGGLVDVVHPEO\RSHUDWLRQVLQFRQ¿QHGVSDFHV

• The declared vibration value can be used to estimate vibration during rundown. Continuous ratcheting against a run-down bolt may produce a vibration emission in the range

8 m/s2 to 15.5 m/s2(vibration total values)

• Only use this tool for work which other types of wrenches, which present lower vibration risks, are unable to perform satisfactorily.

• The vibration emission varies greatly with task and operator technique. Emissions outside the quoted range may occur for some applications.

• Operators should optimize their technique and select a suitable wrench in order to minimize the ratcheting time at the end of each run-down or when backing-off assembled

fasteners.

• For the intended application of this tool, we estimate that normal operation should involve a ratcheting time against a run-down fastener of less than 0,5s per fastener on a

hard joint and up to 3s on a soft joint.

:HSRLQWRXWWKDWDSSOLFDWLRQRI WKH WRRO WRDVROHVSHFLDOLVWWDVNPD\ SURGXFH D GLIIHUHQWDYHUDJHHPLVVLRQDQGLQVXFKFDVHVZH VWURQJO\ UHFRPPHQGDVSHFL¿FHYDOXDWLRQRIWKH

vibration emission.

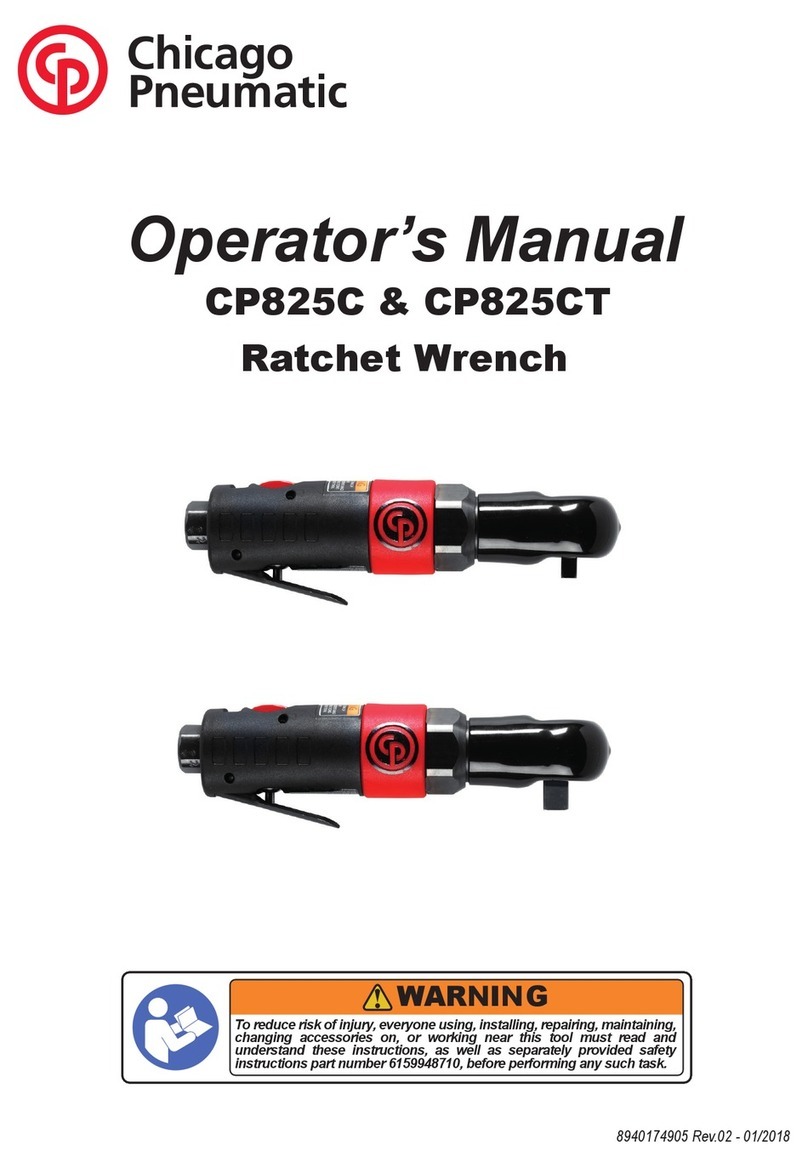

2. Machine type(s)

ವ 7KLVSURGXFWLVGHVLJQHGIRULQVWDOOLQJDQGUHPRYLQJWKUHDGHGIDVWHQHUVLQZRRGPHWDODQGSODVWLF1RRWKHUXVHSHUPLWWHG)RUSURIHVVLRQDOXVHRQO\

ವ 3OHDVHUHDGWKHLQVWUXFWLRQVFDUHIXOO\EHIRUHVWDUWLQJWKHPDFKLQH

3. Operation

• Fix the accessories properly to the tool.

• Connect device as shown in Fig. 01 to a clean and dry air supply.

• To start the machine, pull the trigger (A). Machine speed is increase by increasing pressure on the trigger. Release the trigger to stop.

• To switch rotation, turn the switch (B) as shown in Fig. 02.

4. Lubrication

• Use an air line lubricator with SAE #10 oil, adjusted to two drops per minute. If an air line lubricator cannot be used, add air motor oil to the inlet once a day.

5. Maintenance instruction

• Follow local country environmental regulations for safe handling and disposal of all components.

ವ 0DLQWHQDQFHDQGUHSDLUZRUNPXVWEHFDUULHGRXWE\TXDOLILHGSHUVRQQHOXVLQJRQO\RULJLQDOVSDUHSDUWV&RQWDFWWKHPDQXIDFWXUHURU\RXUQHDUHVWDXWKRULVHGGHDOHUIRUDGYLFH

RQWHFKQLFDOVHUYLFHRULI\RXUHTXLUHVSDUHSDUWV

ವ $OZD\VHQVXUHWKDWWKHPDFKLQHLVGLVFRQQHFWHGIURPHQHUJ\VRXUFHWRDYRLGDFFLGHQWDORSHUDWLRQ

ವ 'LVDVVHPEOHDQGLQVSHFWWKHWRROHYHU\WKUHHPRQWKVLIWKHWRROLVXVHGHYHU\GD\5HSODFHGDPDJHGRUZRUQSDUWV

ವ +LJKZHDUSDUWVDUHXQGHUOLQHGLQWKHSDUWVOLVW

6. Disposal

ವ 7KHGLVSRVDORIWKLVHTXLSPHQWPXVWIROORZWKHOHJLVODWLRQRIWKHUHVSHFWLYHFRXQWU\

ವ $OOGDPDJHGEDGO\ZRUQRULPSURSHUO\IXQFWLRQLQJGHYLFHV0867%(7$.(12872)23(5$7,21

• Repair only by technical maintenance staff.

7. EC Declaration of conformity

We : CHICAGO PNEUMATIC Tool Co.

Machine type(s): Ratchet Wrench

Declare that the product(s): CP7829 / CP7829H Serial Number: 0000 - 9999

Origin of the product : JAPAN

is in conformity with the requirements of the council Directives on the approximation of the laws of the Member States relating : to “Machinery“ 2006/42/EC (17/05/2006)

applicable harmonised standard(s) : EN ISO 11148-6:2012

Name and position of issuer : Pascal Roussy (R&D Manager)

Place & Date : Saint-Herblain, 04/09/2015

Copyright 2015, Chicago Pneumatic Tool Co. LLC

$OOULJKWVUHVHUYHG$Q\XQDXWKRUL]HGXVHRUFRS\LQJRIWKHFRQWHQWVRUSDUWWKHUHRILVSURKLELWHG7KLVDSSOLHVLQSDUWLFXODUWRWUDGHPDUNVPRGHOGHQRPLQDWLRQVSDUWQXPEHUVDQGGUDZLQJV

8VHRQO\DXWKRUL]HGSDUWV$Q\GDPDJHRUPDOIXQFWLRQFDXVHGE\WKHXVHRIXQDXWKRUL]HGSDUWVLVQRWFRYHUHGE\:DUUDQW\RU3URGXFW/LDELOLW\

Original Instructions

&3&3+

5DWFKHW:UHQFK

Learn more about air tools and compressors we have.