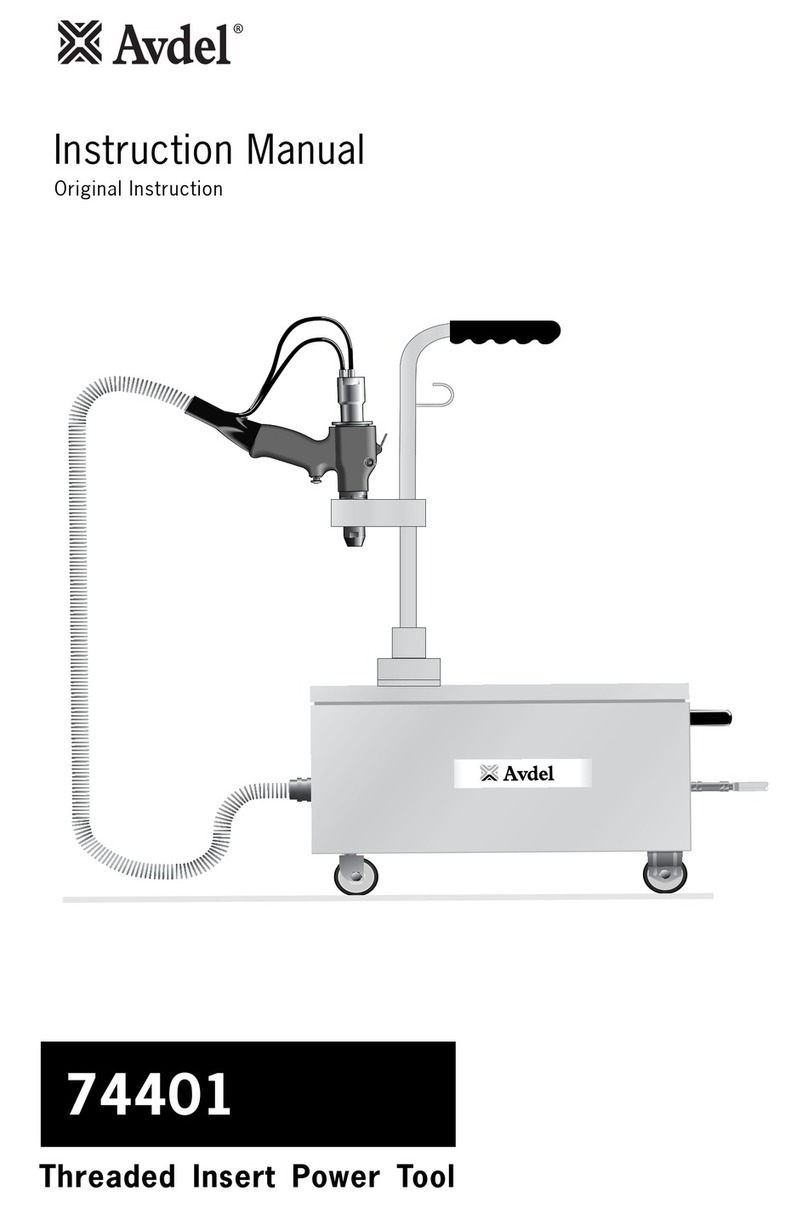

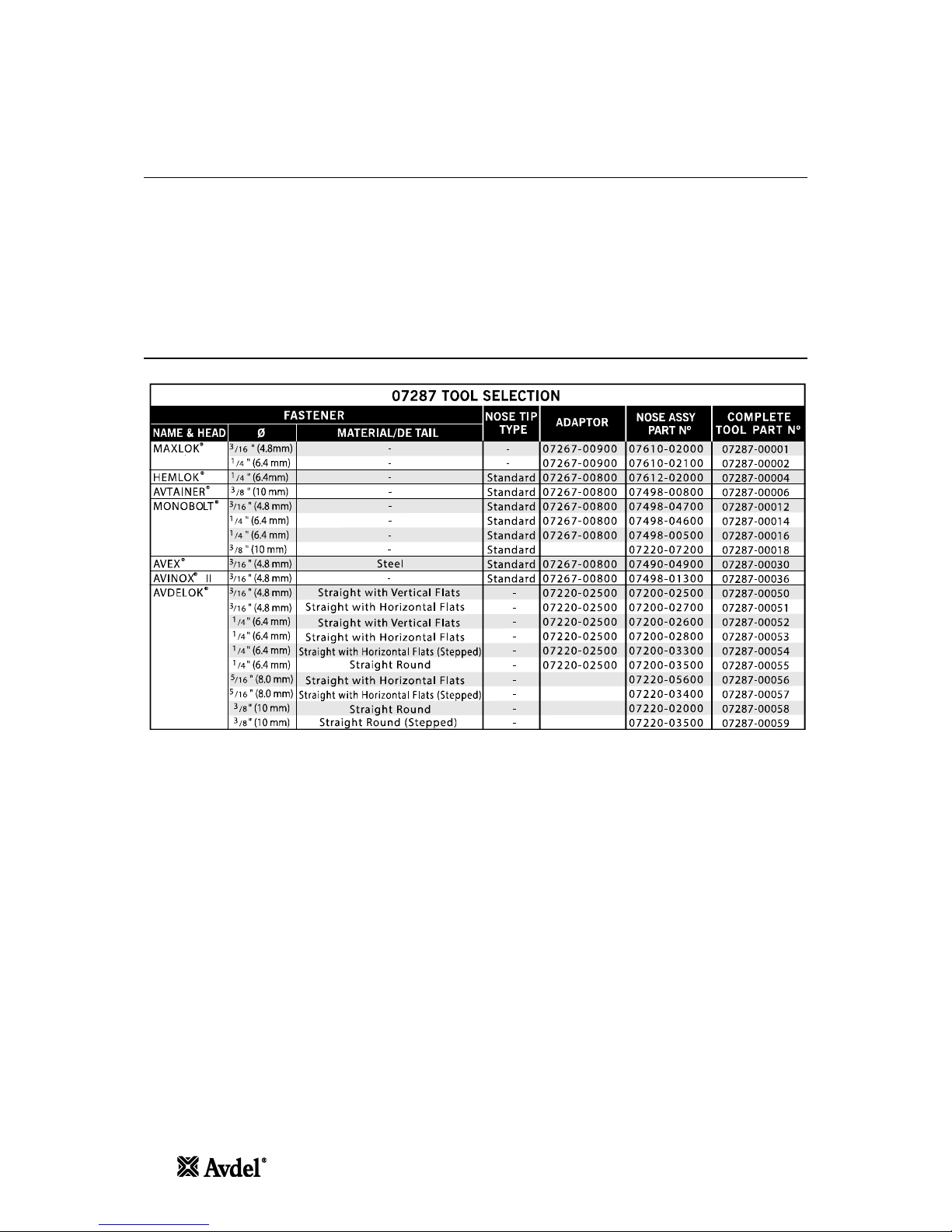

Avdel 7287 User manual

Other manuals for 7287

1

Table of contents

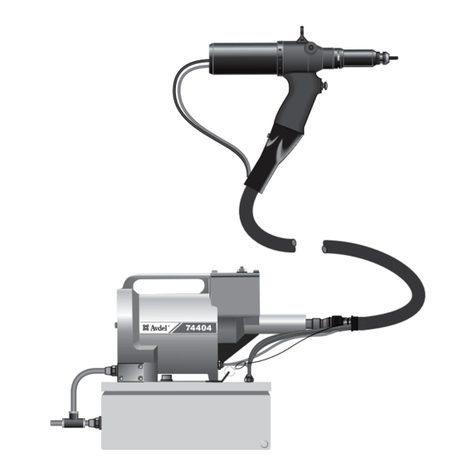

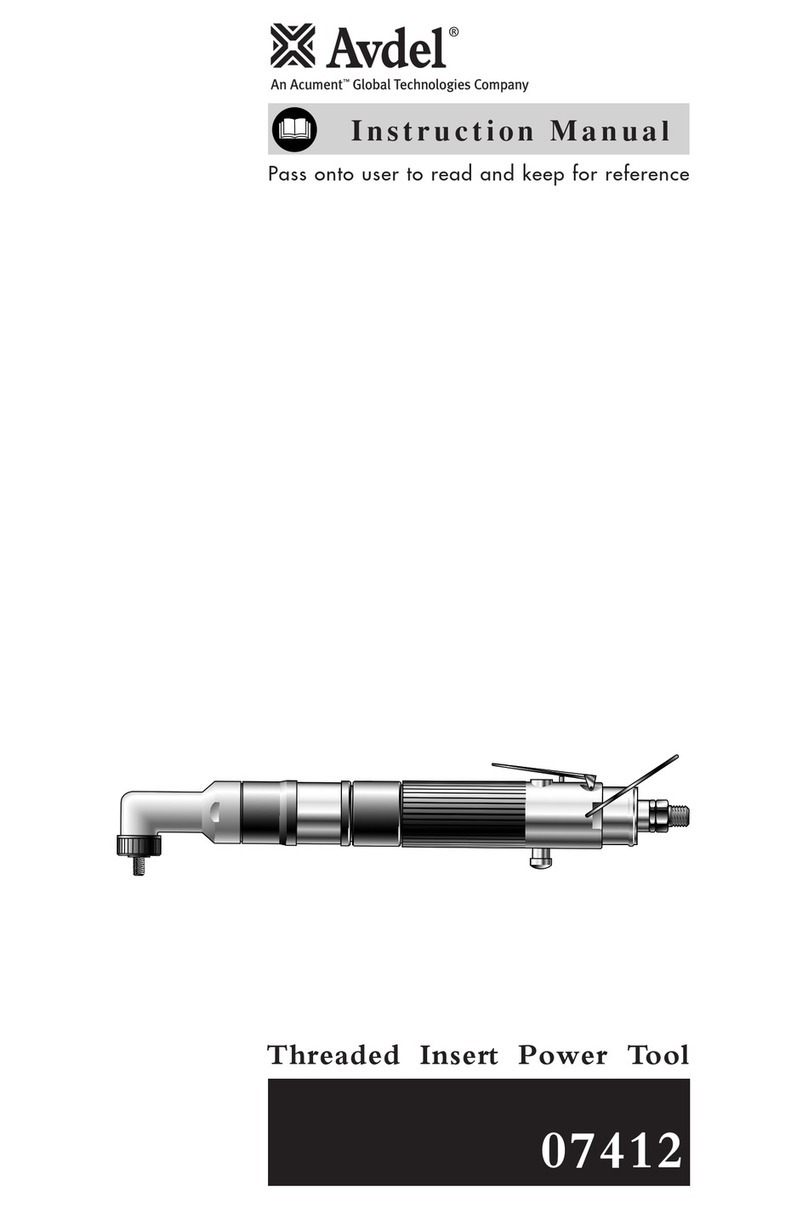

Other Avdel Power Tools manuals

Avdel

Avdel 7539-300X Series User manual

Avdel

Avdel 7271 User manual

Avdel

Avdel 73432-02000 User manual

Avdel

Avdel Genesis G4 HD Heavy Duty User manual

Avdel

Avdel TX2000 User manual

Avdel

Avdel 7611 User manual

Avdel

Avdel Genesis G2LB User manual

Avdel

Avdel 73414-02000 User manual

Avdel

Avdel TX2000 User manual

Avdel

Avdel 0753 MkII User manual

Popular Power Tools manuals by other brands

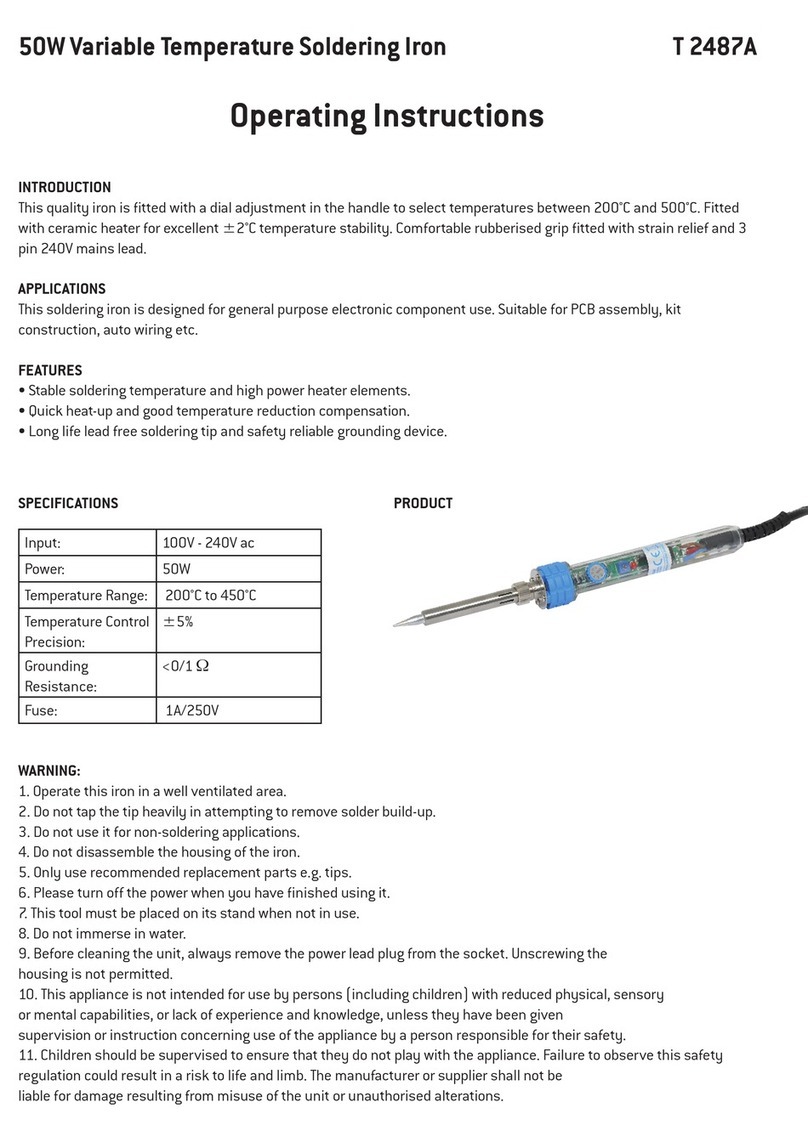

Altronics

Altronics T 2487A operating instructions

Black & Decker

Black & Decker CS3651LC Original instructions

Central Pneumatic Professional

Central Pneumatic Professional 42248 Set up and operating instructions

Kamikaze

Kamikaze KV 362 user manual

Retsch

Retsch BB 600 manual

Hilti

Hilti TE 800-AVR user guide

Matrix

Matrix EJS 800-1 Translation of the original instructions

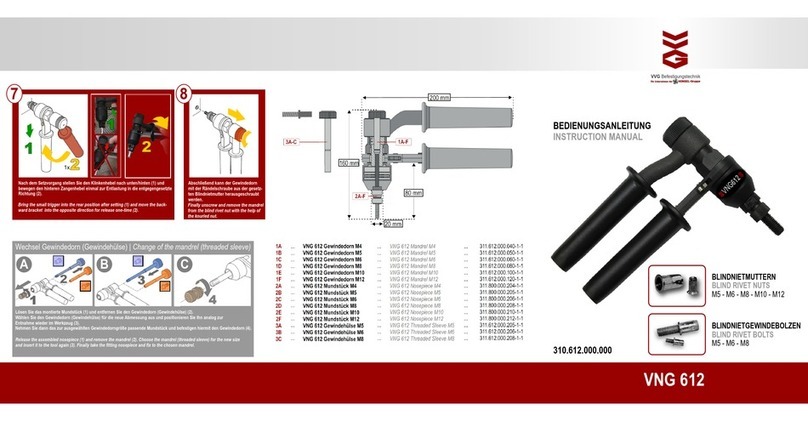

VVG

VVG VNG 612 instruction manual

Hilti

Hilti BX 3-BT Original operating instructions

Omer

Omer 90.38 CLD2-3 Use, maintenance and spare parts manual

AmazonBasics

AmazonBasics B074DF8129 quick start guide

Black & Decker

Black & Decker GK1000 Original instructions