5

Revised 04/15

CHIEF®

Fume Extractor

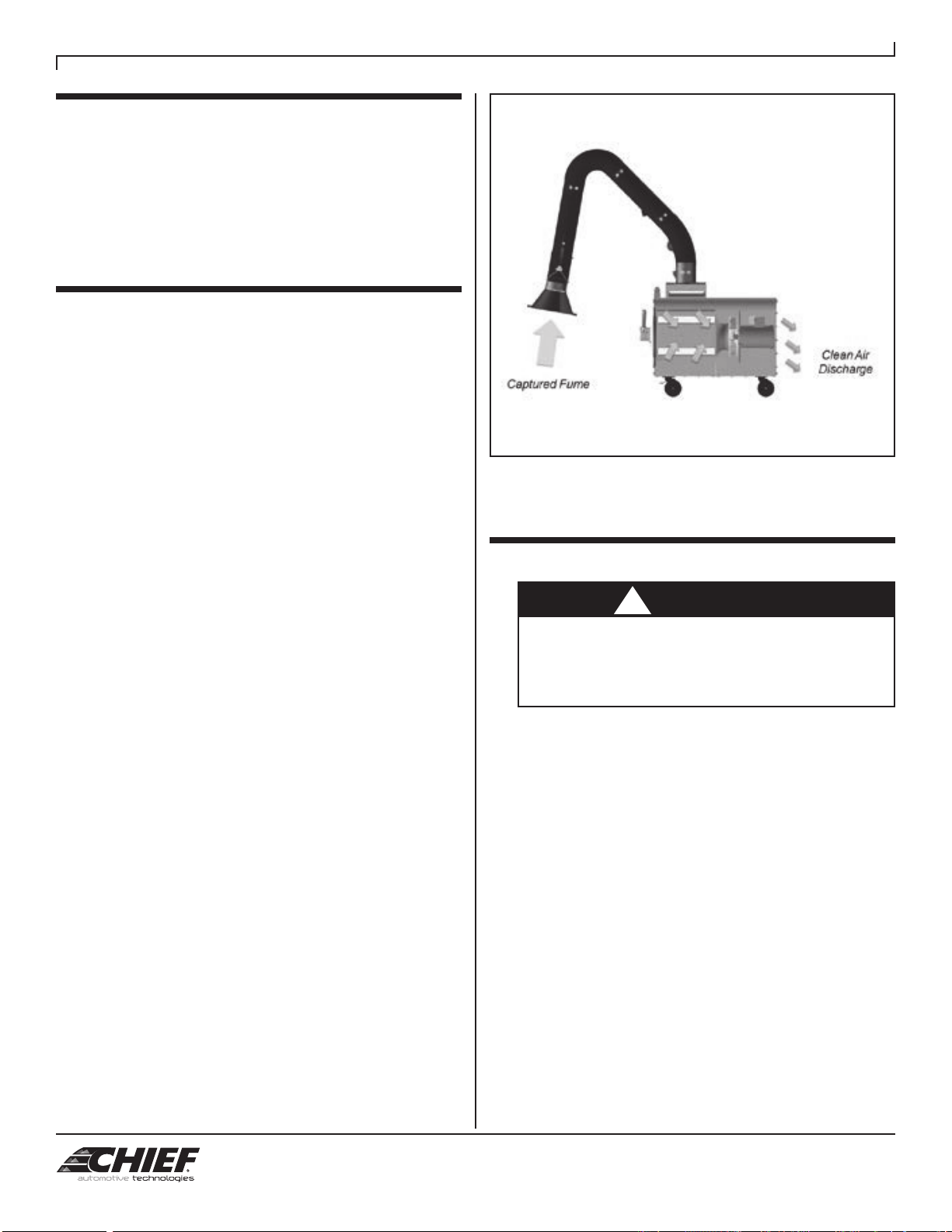

The position of the extraction hood is critical to the

overall performance of the fume extraction system.

The extraction arm and hood are designed to provide

maximum flexibility and convenience in operation. The

360° handle on the circumference of the hood should

be used to move the arm. Do not use the arm to move

or locate the fume extractor. Position the hood on the

opposite side of the weld target, approximately 10 –

14˝ from the fume source and at a 45° angle relative

to the welding surface, to draw the generated fume

away from the worker and avoid any airflow impedance.

Minimizing the bends present in the extraction arm will

reduce losses and improve extraction performance. Be

aware and minimize cross drafts or air movement that

may impact fume extraction such as cooling fans, HVAC

systems or open doors / windows.

6.4 EXTRACTION ARM DAMPER

Each extraction arm is equipped with an airflow damper

that can be used to control the airflow. Controlling

the airflow may be required to avoid disruption of the

arc gas during the welding process. The damper is

controlled by turning the handle of the right side of the

upper tube assembly. When the handle is perpendicular

to the duct, the damper is closed and open when in

parallel.

6.5 START-UP OPERATION

Roll the unit to the approximate location so that the

extraction arm can be proximate to the welding fume

source as described in Section 6.3. When in position,

engage the locking brakes located each front caster

(wheel) to secure the unit. Unwrap the power cord and

connect to a suitable electrical receptacle per Section

5.5. Adjust the fume extraction arm and hood in the

proper position and move the main power switch to the

On position to begin unit operation. Adjust the hood

location and damper position as necessary to achieve

proper fume extraction performance.

6.5.1 HOOD ACCESSORY KITS

If the hood switch and light kit option has been

installed, both the main power switch and the hood

switch will need to be on for the unit to operate. For

an arc sensor kit options that was installed for more

automated operation, place both the hood switch and

main power switch in the On position and the unit will

turn on once a welding arc is sensed and will remain

on for approximately 1 minute before shutting down if

additional arcs are not sensed

6.6 SHUT-DOWN AND STORAGE

To shut the fume extractor off, place the main power

switch into the off position. Unplug the power cord and

wrap the cord to the brackets located on the discharge

side of the unit. Compress the extraction arm into a

compact position and pivot above the fume extractor

unit. Release the front caster locking brakes and move

the unit to the storage location.

7.0 USER SERVICING INSTRUCTIONS

• Disconnect electrical power prior to servicing

equipment.

• Wear appropriate protective clothing.

• Collected particulate may be hazardous. Consult

proper authorities for handling and disposal.

• Disposal of collected particulate must be according

to federal, state and local regulations and all

appropriate authorities.

7.1 FILTER REPLACEMENT

• Removing the filters may expose you to hazardous

contaminants. Take all necessary precautions

including protective clothing such as eye protection

and gloves.

• Follow all local safety and environmental codes in

disposal of the accumulated particulate.

ProTura Nanofiber filters are the only replacement filters

which will provide the highest level of performance

expected from the fume extractor. Replacement

cartridge filters should be ordered when the differential

pressure is consistently above 4” w.g or system airflow

is inadequate to suitably capture and control the

welding fume.

1. Read and follow caution instructions in box above

before servicing your unit and refer to Figure 4 for

additional instruction.

2. Tap the metal surface of each filter access door to

dislodge collected particulate from the inner door

gasket. Pull the filter access door handle away from

the Fume extractor until the handle makes a 90°

angle with the door cover. The filter access door is

now in an unlatched position. Lift the filter access

door upward until the door rods clear the side

support brackets and pull the door away from the

Fume extractor. Tilt the door cover away from the

Fume extractor once free from the support brackets

to trap any dust on the inside of the filter access

door. Dispose of dust into a suitable container. Place

filter access door in a safe place.

3. Move filter from side to side to break the gasket seal

between filter and tubesheet (interior filter sealing

surface). Rotate the filter 180° to allow the dust on

top of the cartridge filter to fall into the bottom of the

fume extractor cabinet.

!DANGER

!CAUTION