Chiltrix CXRC1 User manual

Table of Contents

Operation Overview ……………………………………………………………..3

Theory of Operation & Application Notes ………………………..…..4

Installation Overview …………………………..……………………………....5

Fittings & Components Installation ……………………………………….6

Piping & Wiring Diagrams ………………………………………………….....9

Sensors Installation……………………………………………………………….10

Sensor Location …………………………………………....……………………..12

Controller Operation …………………………………………………………....13

Condensation Safety & Alarm Output ……………………………...…15

Testing & Troubleshooting …………………………………………………..16

Determining Set Points / Calculators …………………………………. 17

Augmentation ……………………………………………………………………..22

2

CXRC1 Operation Overview

Radiant cooling is the most efficient and comfortable method of

cooling available for users is a dry or moderate climate and be highly

beneficial even in humid climates.

However, if a radiant surface is operated below the dew point,

unwanted condensation will be produced. A fast acting radiant

cooling controller designed to prevent this, such as CXRC1, is

required.

The CXRC1 is designed to be added to any existing radiant heating

controller to enable the additional function of radiant cooling. The

existing radiant controller will need to have thermostat(s) that are

capable of calling for cooling. These can be added to nearly any

controller.

Below is a logical topology of the CXRC1 radiant cooling controller:

3

Theory of Operation

The CXRC1 monitors the indoor dew point and compares it to the water temperature

entering the supply manifold.

There is a cross-connect between the supply and return lines, and a motorized 3-way

mixing valve that can mix water returning from the radiant system back into the supply,

before entering the supply manifold, to quickly raise the temperature as needed to

adjust the water temperature so that it will be above the dew point or above a pre-set

delta to the dew point. This helps ensure that water entering the radiant system is at a

temperature that will not produce condensation.

Application Notes:

The CXRC1 is not a radiant controller, it is an add-on to most any Brand or model

standard radiant controller, to allow you to operate a radiant heating system In a cooling

mode without condensation issues.

BEFORE ORDERING OR INSTALLING THE CXRC1, PLEASE CONSULT WITH CHILTRIX

TECHNICAL SUPPORT DEPT. TO VERIFY THAT YOUR RADIANT CONTROLLER IS

COMPATIBLE. YOU WILL NEED TO PROVIDE THE MAKE AND MODEL, AND A PDF

MANUAL OR A LINK TO THE MANUAL ONLINE FOR YOUR RADIANT CONTROLLER.

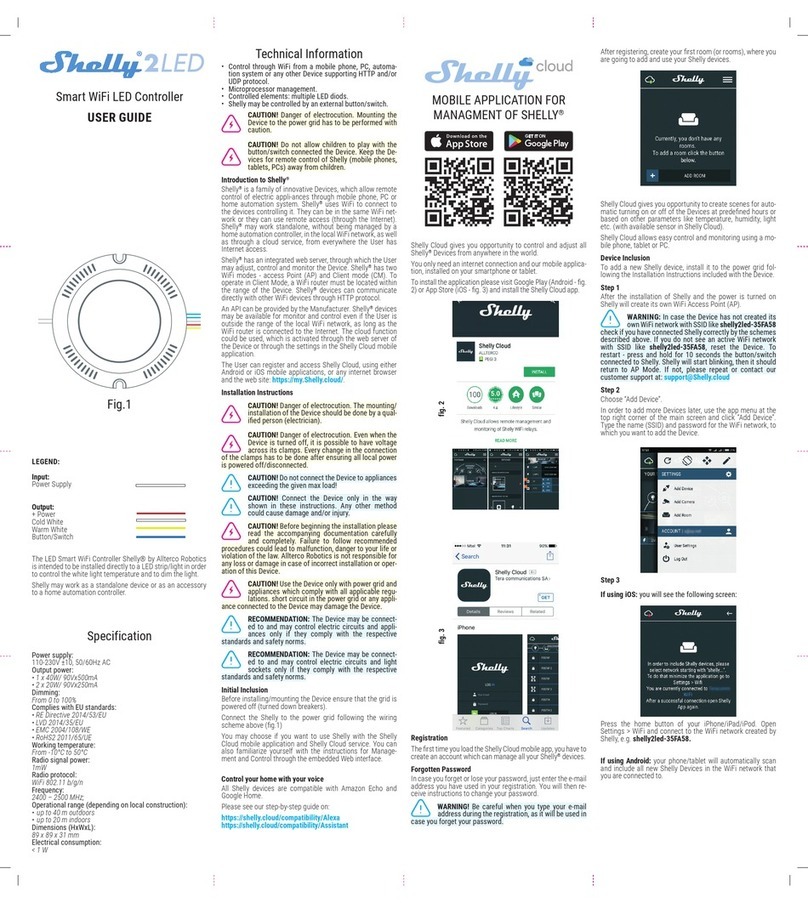

The radiant controller will need to have one or more thermostats that have the

capability of cooling function. You may need to replace or add to your current

thermostats.

2. This radiant cooling controller is designed to monitor indoor dew points and adjust the

temperature of the water (or water/glycol) entering the radiant system such that the

radiant surfaces do not drop below the dew point. This can prevent condensation

(accidental dehumidification) which could cause water damage or inconvenience.

3. The system is ordered as follows: CXRC1-4 has 4x RJ45 Ethernet ports, can connect to

one to four dew point sensors. CXRC1-8 has 8x RJ45 Ethernet ports, can connect to one

to eight dew point sensors. DPX1 Dew Point Sensors are ordered separately.

4. All dew point sensors connect to the CXRC1 via CAT6 cable (supplied by installer). Up

to 150 ft. cabling distance is allowed per sensor.

5. ASHRAE requires an indoor humidity </= 60% RH to prevent EMC, corrosion, or mold.

In some climates, you will need a dehumidifier to ensure this. A radiant cooling system

cannot and will not dehumidify.

4

Installation Overview

1. READ THIS MANUAL IN IT’S ENTIRETY BEFORE PROCEDING.

2. Verify the thermostats used with the existing radiant heating

controller are capable of a cooling setting. If not, augment or

replace the thermostats. Consult with the radiant cooling controller

manual to see how to connect any new or additional thermostat or

call Chiltrix technical support for assistance. Radiant cooling control

can be configured to work with nearly all radiant controllers.

3. Install sensor well and PT100 sensor fitting.

4. Install the controller CXRC1.

5. Install supply-return cross connect and proportional mixing valve.

6. Install dew point sensors, run cabling, connect CAT6 cables to all

dew point sensors to the controller according to this manual.

7. Connect all wiring according to this manual.

8. Determine and install optional customer-provided alarm output

device.

9. Configure controller according to the Chiltrix radiant calculators

particularly using the “Surface temperature” tab.

10. Test system operation.

5

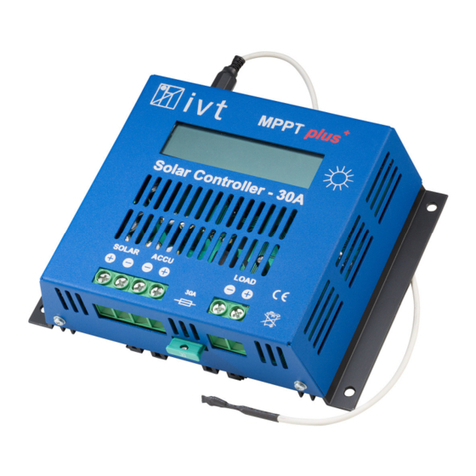

Installation of fittings

.

When installing any fittings, make sure that you use some type of

sealant on all threads. Regular Teflon tape will work fine for sealant.

The included sensor fitting is 1 ¼ “ FNPT, you can adapt to this as

needed for your PEX or copper fittings. The fittings on the included

3 way valve are 1”FNPT.

Above is an image of the sensor fitting, a Tee-adapter from 1 ¼” to

the ½”. This size fitting is used to create a near-0 pressure drop

sensor fitting for the PT100 sensor.

6

A properly installed PT100 sensor assembly

Three-way mixing valve

7

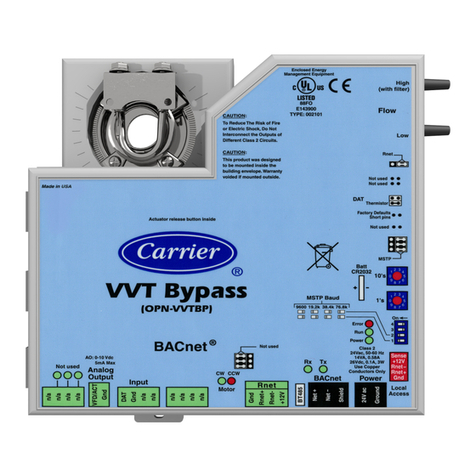

Installation of Mixing Valve

When installing the 3 way valve please use Teflon tape on the

fitting ports to prevent any water leakage. The 3 way valve must be

installed with the white actuator on top as shown below. Secure the

valve to a mounting board if it is directly connected to PEX tubing on

all ends. The orientation of the position of the valve (0 to 1) at time of

install does not matter, it will be addressed later in the manual.

IMPORTANT NOTE

The mixing valve, cross connect piping, and PT100, MUST all be on

the manifold supply line and MUST be “upstream” of the pump(s)

as shown in the various diagrams of this manual.

Above, valve supported by copper pipe on 2 sides

8

Example Piping Diagram

Wiring Diagram

9

Mounting of the Controller and Dew Point Sensors

Mount the controller in a interior location near the mixing valve and PT100 temperature

sensor fitting, and away from any exposure to water or dirt. Mounting tabs are located on

the control box on each side. This location may be near the buffer tank, or near the

manifolds.

NOTE: neither the controller or dew point sensors are water proof. It’s also recommended

to consider access to a wall outlet (110-120vac). The controller is powered by a 110-120

wall outlet plug.

Sensors

Mount each sensor in each area where you wish to monitor the dew point. The sensors

have mounting tabs on each side just like the control box. The wire connector can go in two

different ways. First method is to drill a hole in the wall and slide the connector through the

back of the sensor box, it is an oval shaped hole. The short end of the housing “vents” can

also be pushed out with your fingers to run the sensor wire through if you wanted to mount

the sensor on the celling or along side a wall. Note these vents are designed to

“breakaway” so they are relatively fragile. Be careful and don’t break them by accident.

10

Sensor cabling is an installer-provided item. After determining the sensor

locations you will need to measure the length you need and then order or

make cable of the correct length with RJ45 connectors in order to connect

the sensors to the controller. You can have up to 4/8 sensors connected to

the controller according to which model was ordered, you can use as few as

one sensor according to your needs.

USE CAT6 CABLE

Dew Point Sensors

CAT6 Sensor Cabling

11

Location, Location, location –where to put the dew point sensors? So here

we may hear a lot about classical physics and the ideal gas laws, in

particular, Avogadro's Law and Fick’s Laws of Diffusion. Without going

deeper into this, these laws tell us that 1) humidity seeks equilibrium and

does not need the actual movement of in order to equalized across an area,

and 2) that, as counterintuitive as it may seem, a volume of air is lighter

when it has a higher humidity, and therefore rises. Don’t worry about which

law wins. In a cooler part of an enclosed space, RH will be higher because

the air can hold less moisture, in a warmer area the air can hold more water,

so the RH is lower. Neither have anything to do with the dew point unless

the actual (absolute) humidity changes.

Don’t worry about it or let the experts confuse you. Just locate the dew

point sensors in the area served by the radiant cooling surface, and

generally as near as practical to the surface that you are protecting from a

dew point issue. We are only concerned about the dew point and not RH in

this regard.

For most users, one or two dew point sensors, more or less central to the

area, based on common sense, per floor, is all that’s needed. If you use

radiant from the ceiling you can put the sensors higher on the wall, for floor

radiant it really does not matter.

One note –if you have a persistent source of new absolute humidity, like a

leaky pipe, fix it.

Another note –if you have a high cathedral type ceiling, this is a good

location to pull in air for your dehumidifier,

Dew Point Sensors

Proper Location

12

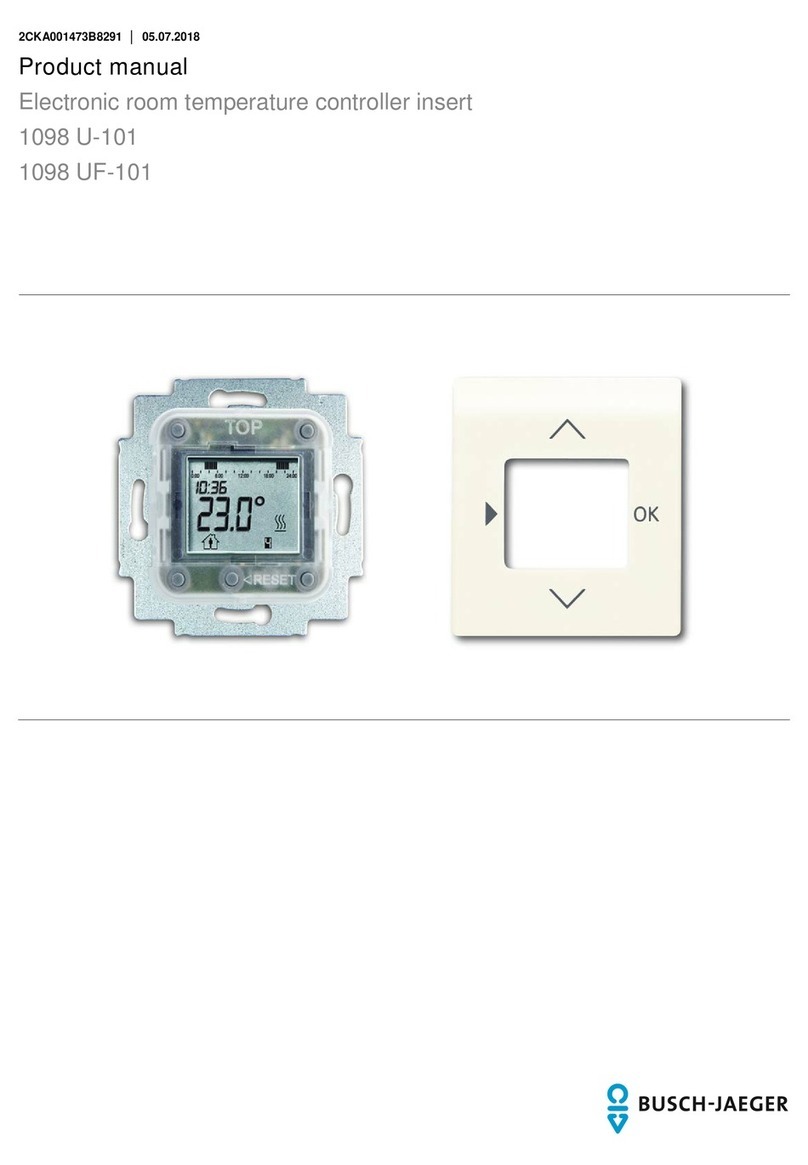

CXRC1 Controller Operation

The controller has firmware to read the sensors and control the valve

position, the end user will need to set a temperature dew point offset.

This temperature may the set by the user to automatically track the dew

point, or may be set to operate at some delta above or below the dew

point.

Note: In many cases the water temperature can be safely set below the

dew point. See the section on temperature selection.

Ex: If you set the controller at “+2F” the controller will operate with a

target temperature to the supply manifold as “dew point plus 2 degrees

Fahrenheit”.

The controller will cycle between two different menus as shown below.

13

CXRC1 Controller Operation Cont’d

In order to change any settings on the controller you will need to hold

down the menu button for about 5-10 seconds in order to enter into the

main menu.

Once in the main menu, you can select “Dew Pt Offset”, this setting is

the offset to which the controller will target the output water temp

based on the highest dew point read (the highest reading of any

individual sensor).

The dew point offset is a target in relationship to the dew point.

Example: if the offset is +4F and the highest dew point read from the

sensors is 54F then the controller will target an output temp of 58F. If

the setting is -4F and the sensors are reporting a dew point of 54F then

the target would be 50F.

The Dew Pt Offset is configurable to target an output water temp below

the dew point in cases where you have a sealed system and a known R

value between the surface of the water and the surface that is in contact

with the rooms air temperature. See temperature selection section.

14

Condensation Safety Precautions:

It is recommended that the CXRC1 be powered from the same circuit

as the pump(s) such that any power or circuit breaker problem that

stops power to the CXRC also disables the circulator pump(s).

Alarm Output

The CXRC1 has a low-amp (.2a) 5v alarm output that can be used

signal an error or loss of communication with dew point sensors. It is

recommended that this be connected to a small solid state relay that

can be set up to trigger a warning signal such as a bell or other alarm

to let you know of any failed sensor.

If the mixing valve fails to receive communications from the controller

but still has power, the mixing valve will move to full-recirculation as a

safety precaution.

15

Testing:

Run the system and pay close attention to the radiant surface temperatures and dew

point (see next page diagram) where unwanted condensation may occur and look for

any condensation. There should be no wetness at all. Temperatures should agree with

your projections within 1-2 degrees F, adjust as needed. Monitor this closely at various

temperatures and conditions after initial startup, until you are sure your settings are

sufficient.

Problem: Valve does not operate upon start up

Solution: Make sure your power wires are plugged in, if the controller LCD is not lit up

then the valve does not have power. Upon start up the valve will start at full

recirculation and then it will begin to modulate.

Problem: Valve is moving too much, too fast, too far, etc.

Solution: This is not exactly as it appears. This valve uses a gear reduction motor so the

valve manual positioner that you can see may appear to move a very large amount,

note that even an apparent full turn of the valve is only a small change to the actual

amount of in mixing/non-mixing adjustment applied.

Problem: I am getting unexpected condensation

Solution: Check your calculations for error, or there may be an error in your R-value

assumptions. If this cannot be corrected with adjustments on your own, please contact

Chiltrix technical support (advanced support dept.).

Testing & Troubleshooting

16

How To Select The

Proper Temperature Setting

For Maximum Capacity

In any case where there is uninsulated or exposed piping at any point

where condensation would be a problem, we suggest a setting of

dew point +2F. Likewise, if the thermal sandwich is not vapor tight and properly insulated,

use dew point +2. We suggest to properly insulate and use vapor tight taping or barrier to

allow a lower offset to dew point and therefore higher capacity.

If all piping is insulated, and the back side of the “thermal sandwich” is also insulated

well and vapor tight, a target below the dew point can be used to gain more cooling

capacity. The “thermal sandwich” refers to the radiant surface, and to what is behind it.

An example below shows a typical thermal sandwich on a ceiling. The same logic is to be

applied for floor or wall use.

PEX Tubing

Aluminum Transfer Plate

Drywall, Wood, etc.

Vapor-tight Insulation

Room, Air

Above, “thermal sandwich” shown as ceiling radiant.

For floor radiant, just turn it upside down.

In the above example, assuming the piping and all insulation is vapor tight and has an R-

value of at least as high as the sandwich section marked “drywall or wood”, the only

surface where condensation risk is presented is the drywall or wood surface (the

“radiant surface”.

The temperature target offset of the CXRC1 will be based on this surface and therefore

the water temperature target can be lower than the dew point. You can use our surface

temperature calculator to estimate a safe offset. See the calculators page. Any

questions or uncertainty can be resolved by contacting Chiltrix Advanced Support

(Engineering Department).

This is the “radiant surface” and

is the area where condensation

can form if not controlled

correctly.

Thermal Sandwich

17

Radiant Cooling (and Heating) Calculators

Find The Best Temperature Offset For Maximum Capacity

Please refer to the calculators here:

https://www.chiltrix.com/radiant-cooling/radiant-calculators/

Please continue reading for an explanation of how to use the calculators.

About these calculators -in spite of the fact that most radiant systems are

designed and configured based on rule-of-thumb or experience, there are

laws of physics that can and should be used for proper design and

configuration of any radiant system, for heating or cooling. Beyond just

physics in fact, in is mostly related to quantum mechanics. To spare our

partners and customers the burden of learning how to use Plancks constant,

Kirchhoff’s laws, Wien’s law, the Stefan-Boltzmann Law, Newtons Law of

Cooling, Fourier’s law, and others, we have created some basic calculators.

On the calculator page you will see there are four tabs across the top as

follows: Radiant, Surface Temp, Convert K to R, and Dew Point.

The Radiant Tab:

This calculator allows you to see the net radiant heating or cooling that can

be obtained from a square meter or square foot of a radiant surface based

on its temperature and the temperature of its local environment (i.e. the

temperature of the “things” in the room to be conditioned –walls,

furniture, floor, ceiling, people, etc. You will note there are two sections, in

the top section you will input the following:

1. The emissivity of the radiant surface. This can be measured with an

accurate laser thermometer with adjustable emissivity, used in

combination of an accurate surface temperature sensor. Or more easily,

you can look up the emissivity of most materials or coatings online, for

example, here https://www.engineeringtoolbox.com/emissivity-

coefficients-d_447.html

or here

https://www.transmetra.ch/images/transmetra_pdf/publikationen_liter

atur/pyrometrie-thermografie/emissivity_table.pdf

2. And there are many other resources online. 18

Radiant Cooling (and Heating) Calculators (cont’d)

Find The Best Temperature Offset For Maximum Capacity

2.

The next input of the Radiant calculator is the temperature. Note

this is not the water temperature, rather it refers to the

temperature of the radiant surface which we will get to in a

moment.

3.

The next input is the area, please leave this as-is at 1 M^2 (the

output will be converted for BTU per Ft.^2 automatically later on)

4.

In the next section, you can also input the average emissivity for a

collection of normal things found in a room –wood, stone, plastic,

fabrics, painted surfaces, etc. This can be left at the default value of

.91 unless you have reason to change it.

5.

And in this section, you can input the average temperate of these

“things” in the conditioned space. Generally for a radiant heating

calculation you would use 65-68F. For cooling, we suggest 76-78F.

Note that when using radiant, many users find that an indoor

winter air temperature of around 64-65F is quite comfortable, due

to the nature of radiant heating. Likewise with radiant cooling, user

are often comfortable at 80F and report that it feels more like 75F.

6.

At the bottom, you will find the net output.

So how to define the radiant panel temperature? It will not be the

same as the operating water temperature. Go to the Surface Temp

tab. 19

Radiant Cooling (and Heating) Calculators (cont’d)

Find The Best Temperature Offset For Maximum Capacity

The Surface Temp Tab:

This is a handy way to estimate the surface temperature when you

know the water temperature, and the R-value of what is between

the water (PEX tube) and the radiant surface, and the air

temperature of the room.

For “radiant temp” input a water temperature. You can play with

some worst case scenarios, maybe from 45-65F. For air temp, you

can also play with some worst case scenarios, maybe 70-90F.

For entering an R-value, this is where things get tricky. So in the

thermal sandwich there may be multiple different types of

materials. And many materials do not have a published R-value. But

don’t worry, there is a solution on the next page.

Once you have the R values (see next page for info on K to R

conversion) along with the water temp and the air temp, you will be

able to calculate the estimated surface temperature.

20

This manual suits for next models

2

Table of contents