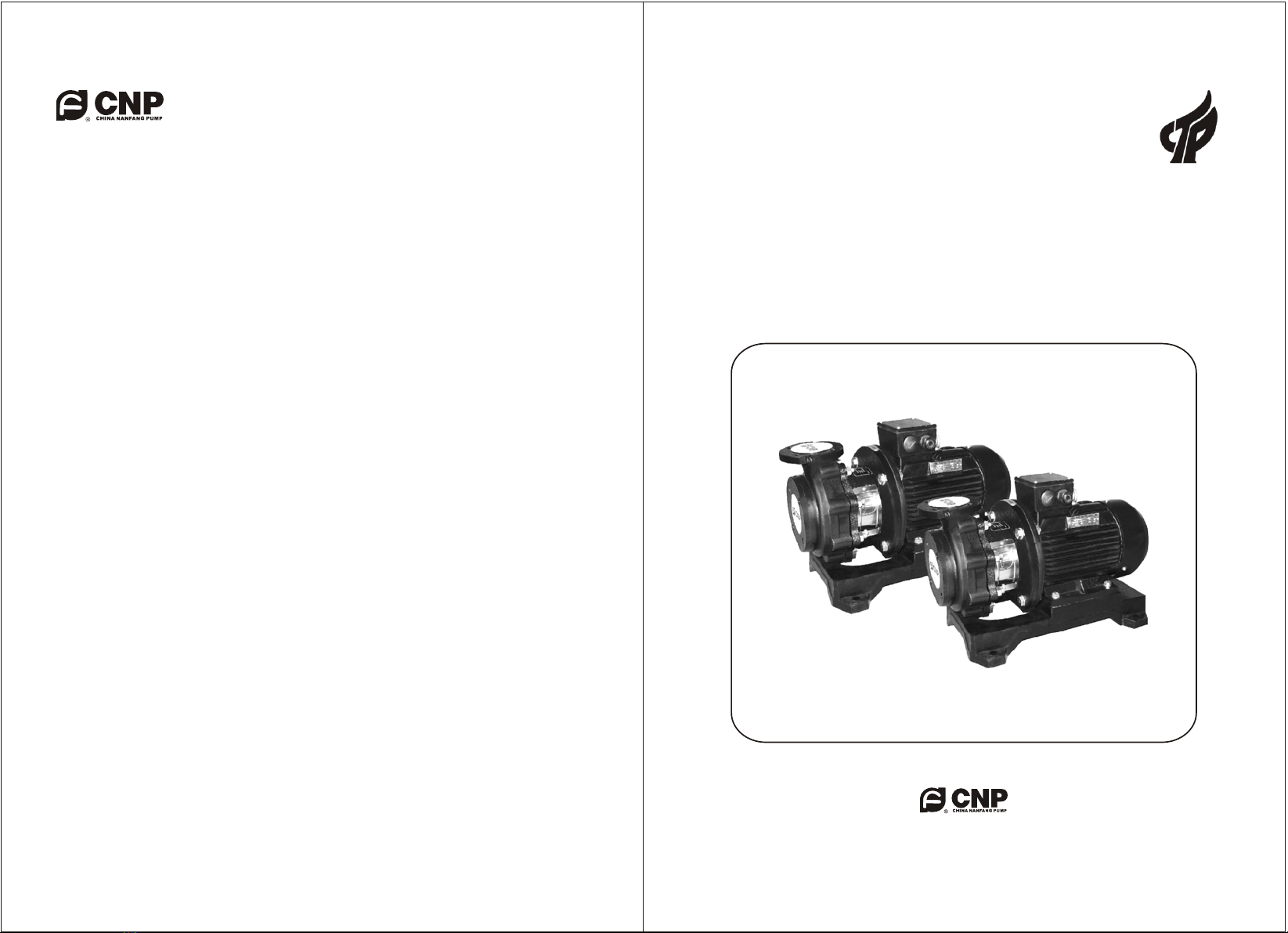

China Nanfang Pump SZ Series User manual

SZ Fluorin Plastic Centrifugal Pump

Operation Manual

Hangzhou Nanfang Special Pump Industry Co., Ltd.

State High-tech Enterprise

1

TABLE OF CONTENTS

1

1

1

2

2

3

4

5

6

6

8

9

I Introduction

II. Application

III. Operation Conditions

IV. Structure Feature

V. Model Definition

VI. Structure

VII. Installation

VIII. Start and Operation

IX. Pump Starting Times

X. Maintenance and Service

XI. Trouble and Trouble Shooting

XII. Important Notice

Read this manual carefully before install, start the pump.

Standard:JB/T8688 (Fluorin plastic centrifugal pump)

I Introduction

SZ Fluorin plastic centrifugalpump adoptsexcellent hydraulic

structure. It is made by matureprocessing technology. Thewet partis

made of Fluorin plastic(F46 or F26). It is made by adding metalcore and

pressed and burned to a whole in one time. Theproduct hasthe following

benefit, smallvolume, runningreliable, highefficiency,energy saving,

easy to install and operate. Wide range of duty points for choosing. It

can transfer strongly corrosiveliquid suchas sulfuricacid, royalwater,

high and low temperatureresistance, advancedmechanical seal,little

hole when pressing welding, high efficiency, longservice time,etc.

alkali of any concentration. It has the following advantages, anti-corrosive,

II. Application

Thin liquid without fibre and grain

Petrol, chemical industry.

Pharmacy, pesticide, acid cleaning, dying industry.

Painting

Smelting, paper making, galvanization;

Suitable for strongly corrosive liquid such as hydrochloric acid, nitric

acid, sulfuric acid, choric acid, phosphoric acid, royal water, alkali,brine,

strong oxidant, organic solution, etc of any concentration.

III. Operation Conditions

Liquid temperature: -20 +120 ,

3

Flow range: 2~60m /h

Max head: 54m

33

Max medium density: 1.35 10 kg/m

Ambient temperature: Max +40

Altitude:Max.1,000m;

Pressure: Max 10 bar

When the specific gravity and density of the pumped liquid is bigger,

the shaft power will be increased, must use the appropriate motor.

2

IV. Structure Feature

SZ pump is single impeller centrifugal pump, axial suction and radical

discharge.

Simple structure, shaft is directly connected with impeller.

Easy for pipe works, inlet and outlet are connected by standard flanges.

V. Model Definition

SZ 50 32 160 S F46

Pump material

S: Three phase( 3kW is

220/380V; >3kW is 380V

D: Single phase 220V

Nominal diameter (mm)

of impeller

Discharge diameter(mm)

Suction diameter(mm)

Fluorin plastic centrifugal

pump

3

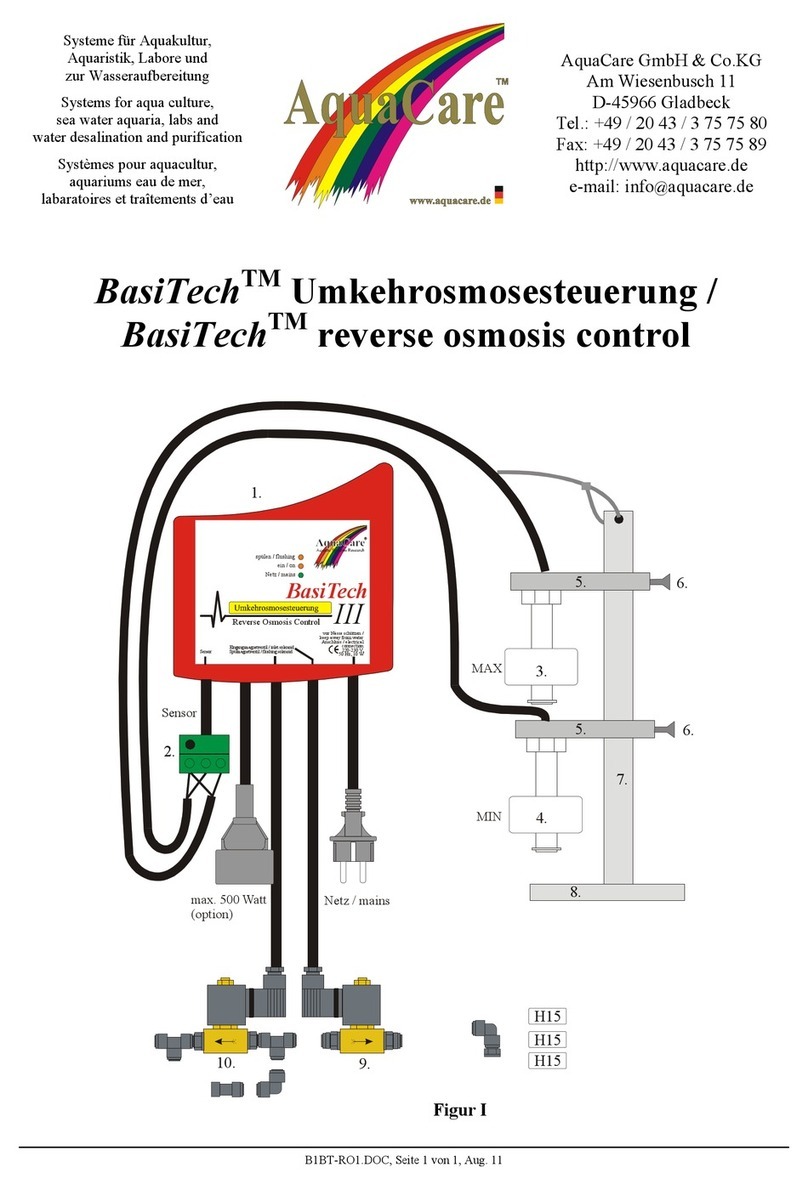

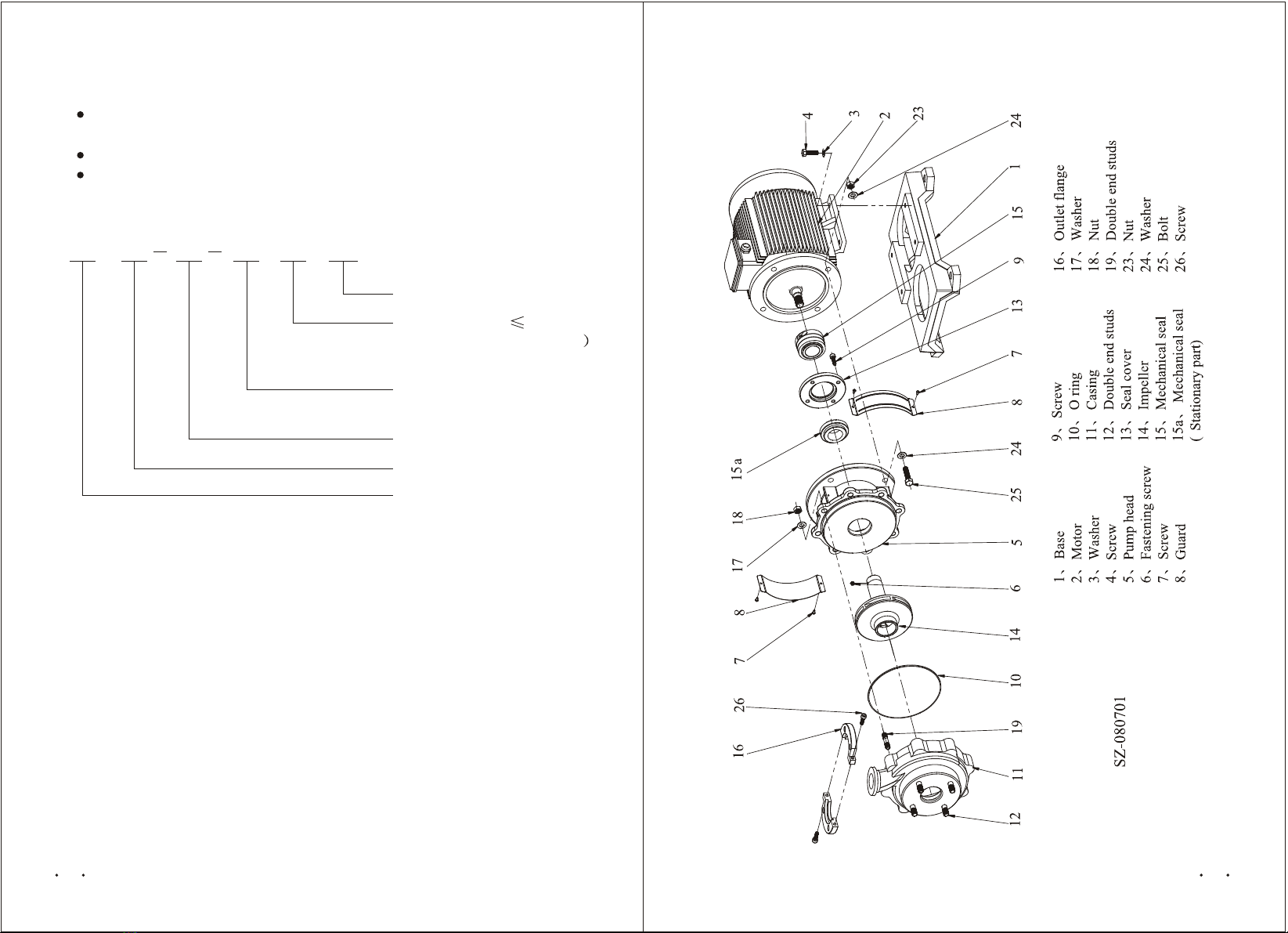

VI. Structure

SZ fluorin centrifugal pump is installed horizontally. Inlet and outlet

is connected by standard flanges inlet and outlet pipelines should be

supported separately. The weight of inlet and outlet must not be born by

pump itself.

When lifting or moving the pump, do not work it on the casing. You

can tight the motor rings or use steel string to tight the base to lift or move

the pump.

The installation height of the pump should be done according to the

requirement of NPSH, in order to prevent from cavitation corrosion

(Normally, the installation height should not be 3.5m higher than the liquid.)

If the position of the pump is higher than the liquid, a foot valve should

be installed in the suction, and fit screw hole and valve at the place of 0.3m

to 0.5m near the outlet for pouring liquid.

The pump installation should ensure that pump will not affected by

pipes force when operation.

Pump should be fixed stably on the base.

In order to ensure motor run well, pump should be installed at well-

ventilated and anti-frozen place.

2. Electrical connection

Before run pump, cables should be connected well, check voltage and

frequency.

Motor should be connected with a quick and efficient motor starter, to

ensure the motor will not be damaged by phase lack, unstable voltage and

overload.

VIII. Start and Operation

1.When the pump position is lower or same as the liquid level, before

start, open the valve at the suction pipeline to make the pump fully filled

with liquid, vent the air in the pump. If the position is higher than liquid

level, before start pull liquid to the pump from screw hole, to fill with the

pump fully and vent the air completely.

2.The outlet of the liquid should ensure the pump run continuously.

3.Check pump rotation direction.

Pump direction is indicated on the arrow on the pump, that is, viewing

from pump inlet, it is anti-clockwise.

Close outlet valve, start and stop the motor quickly, the direction can

be check from the rotating of the motor fan or coupling. After ensure the

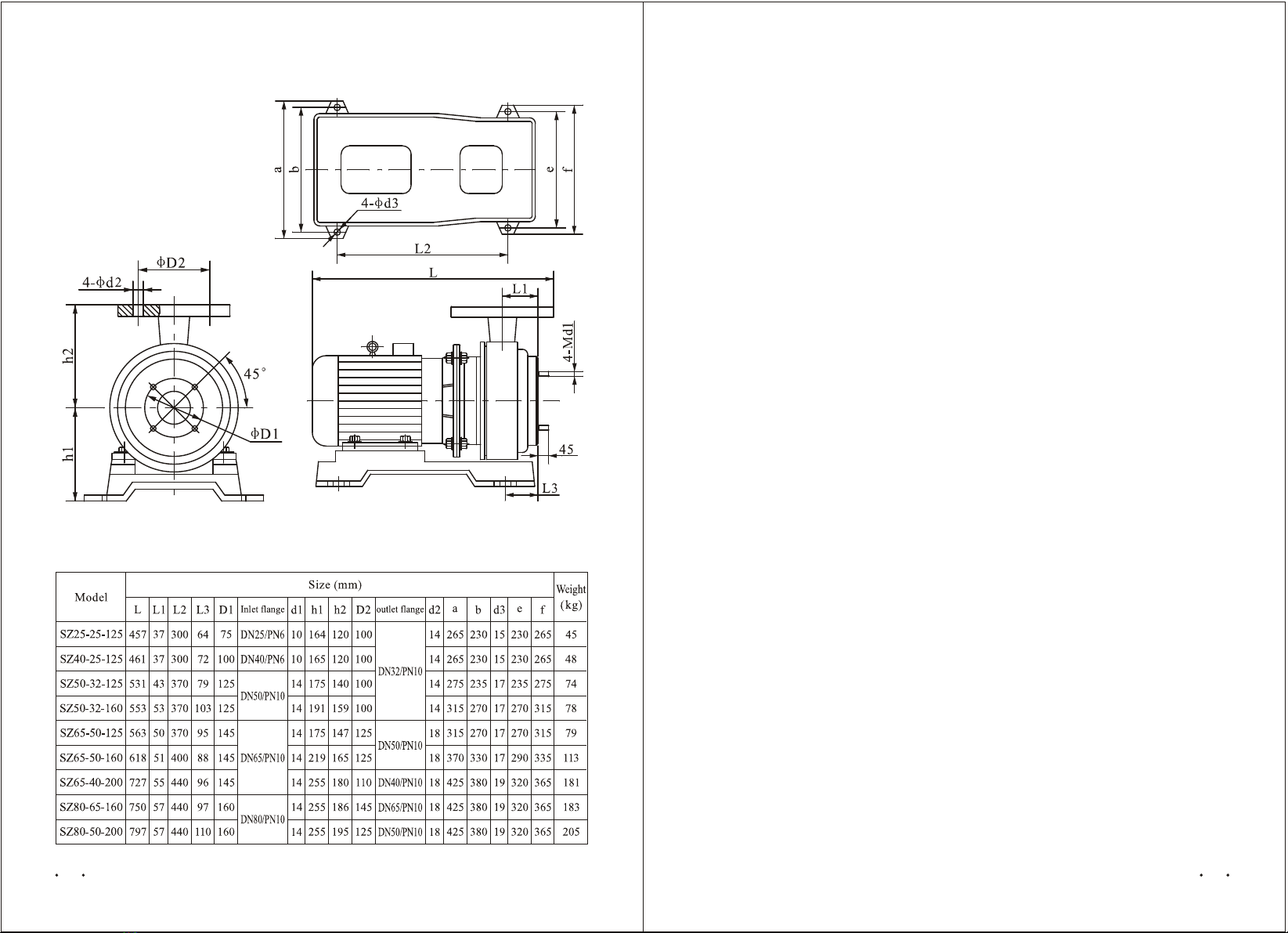

Figure 2 Pump installation and dimensions figure

Table 1 SZ pump dimensions

54

VII. Installation

turn 1 to 2 circles.

Unscrew the screws connecting motor and the base.

Unscrew the nut connecting casing and pump head, use a straight

screwdriver to open the casing slightly.

Unscrew the motor fan cover , take out the fans, use a key loc the shaft

at the motor side, and use a wrench unscrew the impeller, turn 2 circles.

Unscrew the screws connecting the motor and pump head.

Unscrew the impeller, takeout the pump head, take out the rotating part

of mechanical seal(do not unscrew the screws on the face of mechanical

seal), separate impeller and pump head, unscrew the seal cover of n the pump

head, take out the seal cover,take out the stationary part of mechanical seal.

3.When installation the pump, clean every parts, especially the touching

faces, reverse above steps to assemble a pump.

Clean the mechanical seal, put some PTFE washers, put it in the pump

head.

Note: The rubbing part is out, cover with seal cover, but do not screw it

very tighten to prevent from damaging the stationary part of mechanical seal.

Put on impeller, pumpon rotating part of mechanical seal(The faces of

mechanical seal should be cleaned and be lubricated with machine oil. Screw

the pump head and impeller on the motor,fasten them. When fastening the

nuts, pump head should be lifted a little to prevent from extended part of motor

shaft is not forced by pump head).

Fasten the screws connecting motor and pump head, fasten impeller loc

nuts, fit motor fan, cir-clip, fit motor fan cover.

Put on casing(put O ring in the casing in advance. If O ring is twisted,

broken, replace it with a new one and stick it with a silicon glue), put on

casing, tighten the nut, when tighten the nut, the casing should be laced evenly.

Screw the screws for motor and base, tighten it.

Use two small round rod at the left and right to press the rotating part

of mechanical seal, press appr. 1mm at the left and right, (make the spring

of mechanical seal compressed ), then loc the screws at the both sides of the

mechanical seal. After locked, check the clearance of both sides of mechanical

seal should be nearly same

Use hand to rotate motor shaft and impeller, ensure it is free, not blocked.

Fit the coupling guards.

rotation direction, start the pump. Then open the outlet valve slowly to the

required position. Attention: Pump can't work longer than two minutes

when the outlet valve is closed.

4.It is suggested that shut off the power when the outlet flow is 1/10

of the rated flow. Shut off the connected electrical meters and protective

devices. If the ambient temperature is lower than the frozen point of pumped

liquid, vent the liquid completely to prevent pump from frozen.

Pump is prohibited to run without liquid

IX. Pump Starting Times

In order to make the pump run well, it is suggested that, if the motor

power is equal or less than 4kW,the start times should less than 20 times in

an hour,if the motor power is bigger than 4kW, the start times should be

less than 10 times.

If the pump is not used for a long time, run pump at least twice in a year.

Before start, shut off power, use hand to rotate the coupling, ensure it runs

well. Then start the pump. The working time should not less than 0.2 hours.

X. Maintenance and Service

Mechanical seal is an important part of the pump, it is used in the liquid

that is clean and no floating grain. If it is new pipelines, clean the pipelines.

If the liquid maybe crystallize the mechanical seal, pump chamber should

be cleaned at least one time one day. If the pump is malfunction or need to

be check, please do as follows.

1.Normal check

Shut off power

Check inlet of the pump, to see if it is blocked by fibers. Check if inlet

is cracked or blocked.

Check pump outline to see if it is damaged, check if motor case is

corrosive, check if cable is disconnected.

Unscrew the screw of one coupling guard, take out the coupling guard,

use hand to rotate the pump shaft or pump coupling, to ensure it turns freely

without rubbing noise.

2.Pump dissemble and check :

Unscrew coupling guard, take out the coupling guard.

Unscrew the tighten screw near 10mm from the impeller, turn 3 to 4

circles, unscrew the 2 socket hex screws at the side of the mechanical seal,

76

XI. Trouble and TroubleShooting

Faults Possible reason Solutions Remark

Pump can't

be started

1.Power supply broken.

2.Fuse defected.

3.Motor switches off for

overload.

4.Controlling circuit is

broken or parts broken.

1.Check power supply.

2.Replace fuse, if fuse is down

again, open the pump to check.

3.Check power voltage, restart

it again.

4.Check controlling device.

1.Pump parts are rubbing.

2.The density of pumping

liquid is not suitable the

pump.

3.Too big flow

1.Too low sets for the

overload device.

2.Power supply failed

periodically.

3.Low voltage when

power supply is

consumed in the high

way.

1.Base is not strong.

2.Pump turns reversely.

3.Pump parts are rubbing.

4.The suction height is

too high or not enough

liquid filled.

5.Pump part is loose or

damaged.

1.There is not enough

liquid at suction.

2.Liquid level is too low.

3.Suction is blocked by

impurities.

1.Impeller is damaged.

2.Pump runs reversely.

3.Suction is blocked by

impurities.

4.Pipes are blocked or

there is leakage

5.Choose the wrong

model.

Cost too

much power

when

running

Overload

device trip

out

occasionally.

There is

noise in the

pump and

pump is

vibrated

abnormally.

The liquid

do not flow

evenly.

Insufficient

flow

1.Check parts.

2.Recalculate and replace with a

suitable motor.

3.Operate the pump in the flow

range.

1.Reset the overload device.

2.Check power supply.

3.Add a voltage stabilization

device.

1.Stable the base.

2.Check the rotation direction of

the pump.

3.Check pump.

4.Lower the location of the pump

or refill the pump to vent the

air in the pump.

5.Take out the loosing part,

replace damaged parts.

1.Improve system, add liquid.

2.Higher the liquid level.

3.Check and get rid of impurities.

1.Replace with a new impeller.

2.Check rotation direction.

3.Clean suction.

4.Check and repair pipes.

5.Re-choose the model

For first case,

user should not

service by

himself without

permission.

For case 3 and

case 5, user

should not

service by

himself without

permission.

XII. Important Notice

1.Customers will not be advised if this manual is updated.

2.Pump will be guaranteed for one year under normal operation with

the correct model. Wearing parts are not included.

3.Users shall be responsible for the damage if they dissemble the pumps

by themselves in guaranteed period.

Pump runs

with no

water.

Device trips

out or start

load is too

much.

Pumps no

water

There is

noise in the

pump and no

water out

1.Too big flow.

2. Too much resistance on

suction.

3. Suction height is too high.

4. The is air coming in the

suction.

1.Discharge valve is

closed.

2.No water sucked or

liquid level is too low.

3.Not fill liquid or not

filled enough liquid.

4.Suction blocked.

5.Pump damaged.

1.Fuse is down.

2.There is something

wrong with contact of

overload device.

3.Power supply cable is

loose or power supply

defected.

4.Motor windings are

defected.

5.Pump parts are blocked.

6.Haven't closed the

discharge valve when

start.

1.Suction is blocked by

impurities.

2.Discharge valve is

closed completely.

1.Check and clean.

2.Open valve.

1.Replace fuse.

2.Check starter.

3.Check cables and power supply.

4.Replace motor

5.Check pump.

6.Close valve and re-start.

1.Open discharge valve.

2.Adjust pump location.

3.Refill the liquid and vent the air

in the liquid.

4.Clean suction.

5.Repair of replace

1.Close the discharge valve a little.

2. Check suction pipes and suction

valve.

3. Lower the suction height.

4. Check suction pipes or suction

flange connections.

For case 5, user

should not

service by

himself without

permission.

For case 4 and

case 5, user

should not

service by

himself without

permission.

98

This manual suits for next models

9

Table of contents

Popular Water Pump manuals by other brands

BearCat Pumps

BearCat Pumps 110 Series manual

Giant

Giant P200A-5100 Series Repair and operating instructions

GORMAN-RUPP PUMPS

GORMAN-RUPP PUMPS 811/2B3-B Installation, operation, and maintenance manual with parts list

dosatron

dosatron D40MZ3000 manual

Steffens

Steffens Pomona Original user manual

Dover

Dover PSG Wilden PS800 Engineering, operation & maintenance