CHINT NVF2G-S Series User manual

Standard: EC 61800-3

NO:2023.07

NVF2G-S Series

Inverter

User's Guide

NVF2G-S series vector control inverter produced by Zhejiang Chint Electric Co., Ltd. !

NVF2G-S series inverters have V/F control and speed sensorless vector control technology, which

not only has high speed response and good low-frequency torque performance, but also has the

characteristics of convenient parameter debugging and simple and easy-to-use functions. At the same

time, the reliability and environmental adaptability have been strengthened, which can meet the

applications of fans, water pumps, mines, air compressors, HVAC and so on.

This manual introduces the functional characteristics and usage methods of NVF2G-S series inverters,

including product selection, installation and commissioning, parameter function description, etc. Please

read this manual carefully before using the inverter to ensure correct use of the inverter. After reading

and using this manual, please keep it properly for future use. If you encounter difficulties and problems

that cannot be solved during use, please contact the company's local distributors or directly contact the

company's professional and technical personnel for help. (400 customer service hotline: 400-817-7777)

The company reserves the right to continuously optimize and improve the NVF2G-S series inverters,

and the information is subject to change without prior notice.

Foreword

The product is strictly prohibited to be installed in an environment containing flammable and

explosive gas, moisture condensation, and it is strictly prohibited to operate the product with

wet hands.

When the product is working, it is strictly forbidden to touch the conductive part of the product.

When installing, maintaining and maintaining the product, it is necessary to ensure that the line

is powered off.

It is strictly forbidden for children to play with the unpacked product or packaging.

Sufficient space and safety distance should be reserved around the product installation.

Do not install it where the gas medium can corrode metal and damage insulation.

When the product is installed and used, standard wires must be used, and the power supply and

load that meet the requirements must be connected.

In order to avoid dangerous accidents, the installation and fixing of the product must be carried

out in strict accordance with the requirements of the manual.

After unpacking, inspect the product for damage and check the integrity of the item.

When installing live wires outside the product, in order to prevent electric shock, please insulate

the exposed wires.

If the inverter is damaged or its components are incomplete, please do not install and run it,

otherwise there is a risk of fire and injury.

Do not install in places where water droplets may splash, such as direct sunlight or water pipes,

otherwise there is a risk of damage to the equipment;

Do not short-circuit + and B. It is strictly forbidden to connect terminals other than RIA, RIB, R1C,

R2A, R2B, and R2C to AC 220V signals, otherwise there is a risk of damage to the equipment.

When transporting, do not let the operation panel and cover plate be stressed, otherwise there is

a risk of damage to the equipment and injury when falling.

Please install it in a place that can bear the weight of the inverter, otherwise there is a risk of

damage to the equipment and injury when it falls.

Before leaving the factory, all inverters have been tested for withstand voltage, and it is forbidden

to conduct withstand voltage tests for inverters, otherwise there is a risk of damage to the equipment.

When the length of the motor cable is greater than 100 meters, multi-twisted wires must be used

and an AC output reactor that can suppress high-frequency oscillation must be installed. Avoid

motor insulation damage, excessive leakage current and frequent inverter protection.

After replacing the control board, the parameters must be set correctly before running, otherwise

there is a risk of damage to the equipment.

Safety Alert

Safety Alert

It is forbidden for non-professional technicians to test the signal during operation , otherwise there

is a risk of injury or equipment damage.

It is not allowed to control the start and stop of the inverter by frequently turning on and off the

power, otherwise there is a risk of damage to the equipment.

In a domestic environment this product may cause radio interference, in which case additional

suppression measures (chokes, filters, etc.) may be required.

The electrolytic capacitor of the main circuit and the electrolytic capacitor on the printed circuit

board may explode when incinerated, and the panel and other plastic parts will produce toxic gas

when incinerated. Please dispose of it as industrial waste.

logo illustrate

Danger! Please be sure to read the user manual before installation and operation.

Danger! Do not remove the upper cover when the power is on or within 10 minutes

after the power is cut off.

001

001

001

001

001

002

003

003

003

006

006

007

007

009

012

015

018

018

020

Main purpose and scope of application 1

1.1 Unpacking inspection

1.2 Main purpose

1.3 Scope of application

1.4 Series model specifications and their meanings

1.5 Product specifications and models

Normal use, installation, transportation and storage conditions 2

2.1 Use, transportation and storage conditions

2.2 Installation conditions

Main technical parameters and performance 3

3.1 Technical parameters and performance

4 Structural features and working principle

4.1 Product Structure Features Figure

4.2 Main circuit terminal description

4.3 Description of Control Circuit Terminals

4.4 Instructions for use of control terminals

Product appearance and installation dimensions 5

5.1 Product appearance and weight

5.2 Dimensions of display box and pallet

SECURITY ALERT 000

PREFACE 000

Table of contents

021

021

Installation and Wiring 6

6.1 Installation Notes

022

023

024

025

025

027

032

035

035

037

046

049

050

052

052

053

053

056

057

6.2 Precautions for use

6.3 EMC Precautions

6.4 Power on for the first time

Operation and debugging 7

7.1 Operation panel introduction

7.2 Example of panel operation

7.3 Common parameters

Detailed Explanation of Basic Function Parameters 8

8.1 Running command setting

8.2 Frequency command setting

8.3 Start and stop method setting

8.4 Motor parameter self-learning

8.5 V/F Control Parameters

8.6 Vector control

8.7 Overflow stall protection

8.8 Overvoltage stall suppression

8.9 Protective functions

8.10 Monitoring functions

8.11 Terminal function setting

Table of contents

061

062

062

063

063

063

064

064

064

065

065

065

065

065

066

068

071

072

072

8.13 Jogging operation

8.14 Skip frequency

8.15 Forward and reverse switching

8.16 Dynamic braking

8.17 Frequency Detect Output ( FDT )

8.18 Zero Current Detection

8.19 Timing operation

8.20 Restart after power failure

8.21 Sleep function

RS485-MODBUS Communication Instructions 9

9.1 Networking mode

9.2 Interface mode

9.3 Communication methods

9.4 Protocol format

9.5 Protocol Applications

9.6 Control commands, status information, fault information

9.7 Parameter Management

9.8 Wiring Instructions

9.9 Communication exception code definition

060

8.12 Instantaneous power failure continuous operation function

(instantaneous power failure non-stop function)

Table of contents

10.1 Contents of this chapter

10.2 Inspection items

10.3 Routine care and maintenance

10.4 Regular maintenance

10.5 Replacement of Vulnerable Parts of Frequency Converter

10.6 Troubleshooting

10.7 Operation exception handling

10.8 Fault diagnosis process

Warranty period and environmental protection and other

laws and regulations

11.1 Warranty period

11.2 Environmental Protection

Appendix A Product Peripheral Devices

A.1 Connection between product and peripheral devices

A.2 Reactor selection

A.3 Classification table of braking unit and DC reactor

A.4 Braking resistor table

A.5 leakage protector

Appendix B General Table of Parameters

B.1 General table of parameters

11

075

075

075

076

076

077

080

081

083

083

083

084

084

085

086

086

087

088

088

073

075

9.10 Example of Modbus communication

10 Maintenance and troubleshooting

Table of contents

1Main purpose and scope of application

1.1 Unpacking inspection

After receiving the product, the following checks are required. If there is any discrepancy, please contact

the local dealer:

1. Whether the packing box is complete, whether it is damaged or damp, etc.;

2. Whether the model logo on the outside of the packing box is consistent with the model ordered;

3. After unpacking, please check whether there is water stain inside the packing box, and whether the

outer shell of the machine is damaged or broken;

4. Check whether the nameplate of the machine is consistent with the model logo on the outside of the

packing box;

5. Check whether the product accessories are complete (DC reactor (built-in for products above NVF2G-S-

110/TS4), instruction manual).

1.2 Main purpose

The frequency converter is mainly used for frequency conversion speed regulation, soft start, improvement

of operation accuracy, improvement of power factor, overcurrent, overvoltage, overload protection and other

functions for AC asynchronous motors. At the same time, it also has the effect of saving energy and reducing

equipment noise.

1.3 Scope of application

There are two main types of applicable loads: 1. Constant torque type, and general-purpose models.

2. Variable torque type.

1.4 Series Model Specifications and Their Meanings

The model on the product nameplate indicates the series it belongs to by combining numbers and letters,

as shown in Figure 1.1.

Figure 1.1 Description of nameplate

001

NVF2G-S Series Inverter User's Guide

MODEL

INVERTER TYPE

MATCHED MOTOR POWER

RATED INPUT

RATED OUTPUT

IP20

NVF2G-S-3.7/TS4

FACTORY NO.:

Company Code VOLTAGE LEVEL

INVERTER

INPUT VOLTAGE

DESIGN CODE SINGLE PHASE

THREE PHASE

IMPROVED TYPE

MATCHED MOTOR POWER

CONSTANT

FAN PUMP

TORQUE

/

Figure 1.1 Nameplate description and model naming rules

1.5 Product specifications and models

Table 1.1 Inverter specifications and models

voltage Specifications

battery

capacity

kVA

input

Output

Cable

Output

current

A

Adapted

motor

kW

Incoming line

switch circuit

breaker QF(A)

Three-

phase

AC

380V

NVF2G-S-1.5/T(P)S4 31.53.71.56

NVF2G-S-2.2/T(P)S4 4.2 2.55.0 2.210

NVF2G-S-3.7 /T(P)S4 7.648.53.716

NVF2G-S-5.5/T(P)S4 9.9412.25.520

NVF2G-S-7.5/T(P)S4 13 616.27.525

NVF2G-S-11/T(P)S4 18 10 24.611 40

NVF2G-S-15/T(P)S4 25 10 31.415 50

NVF2G-S-18 . 5/T(P)S4 29 16 37 18.563

NVF2G-S-22/T(P)S4 34 16 45 22 63

NVF2G-S-30PS4 34 25 60 22 100

NVF2G-S-30TS4 46 25 60 30 100

NVF2G-S-37/T(P)S4 57 25 75 37 125

NVF2G-S-45/T(P)54 69 3 590 45 160

NVF2G-S-55/T(P)54 85 35 110 55 160

NVF2G-S-75/T(P)54 114 50 150 75 250

NVF2G-S-90/T(P)S4 133 70 176 90 250

NVF2G-S-110/T(P)S4 160 120 210 110 315

NVF2G-S-132/T(P)S4 195 120 253 132 400

NVF2G-S-160/T(P)S4 236 120 300 160 630

NVF2G-S-185/T(P)S4 267 240 340 1 85 630

NVF2G-S-200/T(P)S4 289 240 380 200 630

NVF2G-S-220/T(P)S4 305 150*2420 220 630

NVF2G-S-245/T(P)S4 350 150*2470 245 800

NVF2G-S-280/T(P)S4 403 185*2520 280 800

NVF2G-S-315/T(P)S4 420 240*2 6 00 315 1000

NVF2G-S-355/T(P)S4 420 240*2640 35 51000

NVF2G-S-400/T(P)S4 460 300*2 690 400 1000

TYPE

002

NVF2G-S Series Inverter User's Guide

Code

name

Code

name

Code

name

2Normal use, installation and transportation, storage conditions

2.1 Conditions of use, transportation and storage

1. Use the ambient temperature (-10~+45)°C, derate use between 45°C~55°C, derate use by 1% for every

1°C increase in temperature;

2. Relative humidity (5~95)% RH;

3. Storage temperature -25°C~ + 55°C ,

4. If the altitude is above 1000 meters, please derate at the rate of 1 % for every 100m increase , but not

more than 3000m;

5. Indoors , without direct sunlight, without dust, corrosive gas, flammable gas, oil mist, water vapor,

dripping water or salt,

2

6. (2~9)Hz amplitude ≤ 0.3mm, (9- 200)Hz vibration acceleration ≤5.8m/ s ;

note: Inverters stored for a long time must undergo a power-on test within 2 years. When powering on, use a voltage

regulator to slowly increase to the rated value, and power on for 1 hour without load, otherwise there is a risk

of electric shock and explosion.

2.2 Installation conditions

When using the inverter, please pay attention to the installation spacing and distance requirements, as

shown in Figure 2.1 :

Figure 2.1 Schematic diagram of inverter installation

003

NVF2G-S Series Inverter User's Guide

For multiple installations, vertical installation and inclined installation can be used.

When multiple inverters are installed vertically, windshields must be added, otherwise multiple inverters

will affect each other and cause poor heat dissipation.

in Figure 2.2 :

Wind screen

Hot Wind

Cold Wind Hot Wind

Cold Wind

Figure 2.2 Vertical installation of multiple inverters

004

NVF2G-S Series Inverter User's Guide

When multiple frequency converters are installed obliquely, it must be ensured that the air duct on the air

inlet side of the inverter is separated from the air duct on the air outlet side to avoid mutual influence , as shown

in Figure 2.3:

Figure 2.3 Inclined installation of multiple frequency converters

note: Since the inverter itself generates a lot of heat, when it is installed in a cabinet, the cabinet should have good

heat dissipation conditions.

Hot Wind

Cold Wind

Hot Wind

Cold Wind

Hot Wind

Cold Wind

005

NVF2G-S Series Inverter User's Guide

3Main technical parameters and performance

3.1 Technical parameters and performance

Table 3.1 General technical specification parameters and performance

project project description

Input

Rated voltage Three-phase: 380~440 V: 380V(-15 %) ~ 440V(+15%)

Frequency 50Hz / 60Hz

Voltage range Three-phase: 380V(-15%)~440V( + 15%)

Frequency Range (47~ 63)Hz

Output

Voltage 0~ rated input voltage

Frequency (0- 600 ) Hz

Overload capacity T : 150% rated current for 1 minute, 180% rated current for 2 seconds

P type: 120% rated current for 1 minute, 150% rated current for 1 second

Main control

Performance

Control method Sensorless Vector Control(SVC)

V/F control

Modulation Space Vector PWM Modulation

Starting torque 150% rated torque at 0.5Hz(SVC)

Frequency resolution Digital setting: 0.01Hz; Analog setting: maximum frequency × 0.5%

Torque boost Automatic torque boost, manual torque boost

V/F curve Straight line V/F curve, 3 kinds of torque reduction characteristic curve

methods (2.0 power ,1.7 power ,1.2 power), multi -point V/F curve method

Acceleration and

deceleration curve Linear acceleration and deceleration ( 4 types )

Automatic current

limiting

Automatically limit the current during operation to prevent frequent over-

current fault tripping

Customization

function

Jogging Jogging frequency range: ( 0.10 ~ 600.00 ) Hz

Jogging acceleration and deceleration time (0.1 ~ 6500.0) s can be set,

interval time can be setjogging

Multi-speed operation Realize multi-stage speed operation through control terminals

Peripheral

Interface

Features

Run command channel Operation panel setting and control terminal setting communication control,

which can be switched in various ways

Digital input 6 multifunctional digital programmable inputs

Digital output 1 channel multi-function digital programmable output

Analog input 2 -way analog signal input , optional ( 0~20 ) mA , (4~20) mA current signal

input or (0 ~10 ) V voltage output

Analog output

2 channels of analog signal output , respectively optional (0~20) mA , (4~20)

mA current output or (0~10) V voltage output, which can realize the output

of physical quantities such as set frequency and output frequency

Relay output 2 relay outputs , 2 normally open and normally closed.

Contact capacity: NO 5A/NC 3A250V ( AC )

RS485 communication

interface 1 channel, support Modbus protocol

Operation

Panel

LED display Can display more than 20 parameters such as set frequency, output

frequency, output voltage, output current, etc.

Key lock Realize the locking of all or part of the keys

Feature selection Define the scope of action of some keys to prevent misuse

Protective

function

With overcurrent protection, overvoltage protection, undervoltage protection, overheat protection,

overload protection, phase loss protection and other protection functions

Structure Degree of protection IP20

Cooling method Axial DC fan cooling

Installation method Wall-mounted

Efficiency 37kW and below ≥ 93%; 45 kW and above ≥ 9 5%

006

NVF2G-S Series Inverter User's Guide

4Structural features and working principle

4.1 Product structure feature map

Figure 4.1 NVF2G-S-1.5/PS~NVF2G-S - 11/PS4 Outline Components

Figure 4.2 NVF2G-S- 11/TS4 ~ NVF2G-S - 30/PS4 Outline Components

FAN

Panel (Top)

Keyboard

Panel(Bottom)

INSTALL HOLE

SHELL

NAMEPLATE

BASEPLATE

FAN

Panel

Panel base

Keyboard

INSTALL HOLE

SHELL

NAMEPLATE

007

NVF2G-S Series Inverter User's Guide

FAN

Panel

Panel base

Keyboard

INSTALL HOLE

SHELL

NAMEPLATE

Figure 4.3 NVF2G-S-30/TS4 ~ NVF2G-S-75/TS4 external parts diagram

Figure 4.4 NVF2G-S -75/TS4 ~ NVF2G-S-315/PS4 Outline Components

008

NVF2G-S Series Inverter User's Guide

RINGS

FAN

Panel

Panel base

Keyboard

INSTALL HOLE

SHELL

NAMEPLATE

Panel (Top)

Panel base

Keyboard

Panel(Bottom)

INSTALL HOLE

RINGS

SHELL

NAMEPLATE

Figure 4.5 NVF2G-S-315/TS4 ~NVF2G-S400/TS4 external parts diagram

4.2 Main circuit terminal description

(1) Three-phase (380 ~ 440 ) V series (NVF2G-S -1.5/PS4 ~ 30/PS4 )

Figure 4.6 Main circuit terminal NVF2G-S-1.5/PS4 ~ 30/PS4

(2) Three-phase (380 ~ 440 ) V series (NVF2G-S -30/TS4 ~ 45/PS4 )

DC BUS 3PHASE INPUT 3PHASE OUTPUT

GROUND

Figure 4.7 Main circuit terminals NVF2G-S-30/TS4 ~ 45/PS4

009

NVF2G-S Series Inverter User's Guide

( 3) Three-phase (380 ~ 440 ) V series (NVF2G-S-45/PS4 ~ 110/PS4 )

DC CHOKE 3PHASE INPUT 3PHASE OUTPUT

DC BUS/BREAKER UNIT

GROUND

3PHASE INPUT 3PHASE OUTPUT

GROUND

EXTERNAL DC REACTOR/DC BUS

DC BUS/BREAKER UNIT

DC CHOKE 3PHASE INPUT

GROUND

3PHASE OUTPUT

Figure 4.8 Main circuit terminal NVF2G-S-45/TS4 -110/PS4

(4) Three-phase (380 ~ 440 ) V series NVF2G-S-110/PS4 ~ 160/PS4

Figure 4.9 Main circuit terminal NVF2G-S-110/TS4~160/PS4

Note: A DC reactor can be connected between , , DC bus positive and negative terminals; NVF2G-S-110/TS4

~ 160/PS4 models, if braking is required, an external brake component is connected between .

(5) Three-phase (3 80 ~ 440 ) V series NVF2G-S-160/TS4 ~ 315/PS4

+1 +2 +1

+1

Figure 4.10 Main circuit terminal NVF2G-S-160/TS4~ 315/PS4

Note: , can be connected with a DC reactor; , DC bus positive and negative terminals; if braking is required ,

an external braking component can be connected between , and .

(6) Three-phase (380 ~ 440 ) V series NVF2G-S-315/TS4 ~ 400/TS4

+1 +2

010

NVF2G-S Series Inverter User's Guide

Figure 4.11 Main circuit terminal NVF2G-S-315/TS4~400/TS4

Note : , DC bus positive and negative terminals ; if braking is required, external braking resistors are connected

between .

Table 4.1 Main circuit terminal description table

Terminal s

ymbol Terminal name Functional description

R , S , TMain circuit power input Three-phase AC input terminal, connected to the power grid

U , V , WInverter output Three- phase AC output , generally connected to the motor

Ground terminal The safety protection ground terminal P E must be reliably grounded

Connection terminals for DC bus

or external brake components

As a DC bus connection or an external brake component connection

terminal, it needs to be connected according to actual needs

DC reactor connection terminal For external DC reactor, please remove the short circuit when

connecting DC reactor

External braking resistor

connection terminal

When it is applied to the connection terminal of an external braking

resistor, connect it according to actual needs

+1

B

+1 +2

011

NVF2G-S Series Inverter User's Guide

Table 4.2 Main circuit terminal wiring and installation torque

Inverter model terminal screw Tightening torque (N·m)2

Wire specification (mm )

NVF2G-S-1.5/P(T)S4 M4 1.2~1.52.5

NVF2G-S-2.2/P(T)S4 M4 1.2~1.52.5

NVF2G-S-3.7/P(T)S4 M4 1.2~1.54

NVF2G-S-5.5/P(T)S4 M4 1.2~1.56

NVF2G-S-7.5/P(T)S4 M4 1.2~1.56

NVF2G-S-11/PS4 M4 1.2~1.56

NVF2G-S-11/TS4 M5 2.5~3.06

NVF2G-S-15/P(T)S4 M5 2.5~3.06

NVF2G-S-18.5/P(T)S4 M5 2.5~3.010

NVF2G-S-22/PS4 M5 2.5~3.016

NVF2G-S-22/TS4 M8 9.0~10.016

NVF2G-S-30/P(T)S4 M8 9.0~10.025

NVF2G-S-37/(T)PS4 M8 9.0~10.025

NVF2G-S-45/P(T)S4 M8 9.0~10.035

NVF2G-S-55/P(T)S4 M8 9.0~10.050

NVF2G-S-75/P(T)S4 M8 9.0~10.060

NVF2G-S-90/P(T)S4 M8 9.0~10.070

NVF2G-S-110/PS4 M8 9.0~10.0100

NVF2G-S-110/TS4 M10 17.6~22.5100

NVF2G-S-132/P(T)S4 M10 17.6~22.5150

NVF2G-S-160/PS4 M10 17.6~22.5185

NVF2G-S-160/TS4 M12 31.4~39.5185

NVF2G-S-185/P(T)S4 M12 31.4~39.5185

NVF2G-S-200/P(T)S4 M12 31.4~39.5240

NVF2G-S-220/PS4 M12 31.4~39.5150×2

NVF2G-S-220/TS4 M16 85.2~90.4150×2

NVF2G-S-245/P(T)S4 M16 85.2~90.4150×2

NVF2G-S-280/P(T)S4 M16 85.2~90.4185×2

NVF2G-S-315/P(T)S4 M16 85.2~90.4250×2

NVF2G-S-355/P(T)S4 M16 85.2~90.4325×2

NVF2G-S-400/P(T)S4 M16 85.2~90.4325×2

R, S , T , , , , , U, V, W

+1 +2

Table 4.3 Grounding Wire Standards

Cross-sectional area of power cord Cross-sectional area of grounding

S ≤ 16 S

16<S ≤ 35 16

35<SS/2

4.3 Description of control circuit terminals

4.3.1 Control terminal and wiring diagram

012

NVF2G-S Series Inverter User's Guide

This manual suits for next models

44

Table of contents

Other CHINT Inverter manuals

Popular Inverter manuals by other brands

Telefunken

Telefunken TF-PI03 instruction manual

Rayleigh Instruments

Rayleigh Instruments RI-ENERGYFLOW-MODULAR Series Quick start installation guide

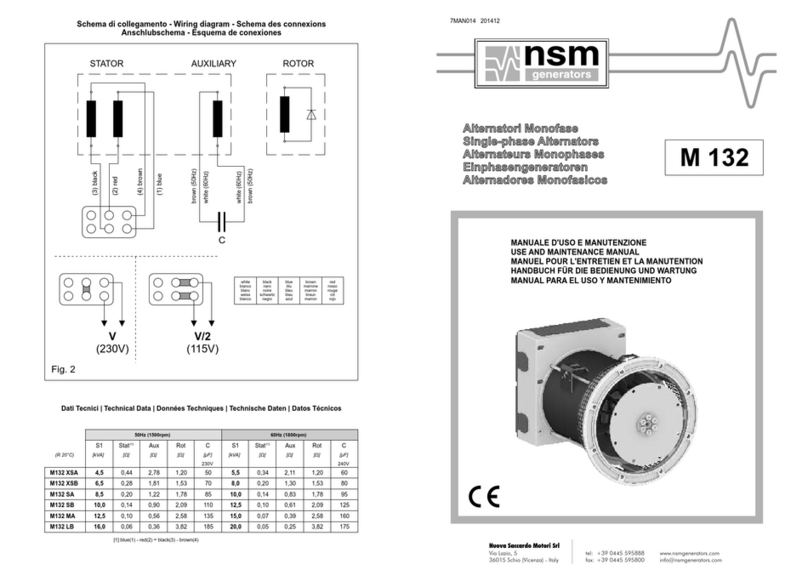

NSM

NSM M 132 Use and maintenance manual

Wagan

Wagan Elite 700W PRO user manual

Haier

Haier SUPER MATCH AS35S2SF1FA-BC Service manual

YASKAWA

YASKAWA VS MINI J7 series instruction manual