CHOFU AEYC-1639U-CH Quick guide

MADE IN JAPAN

AIR TO WATER HEAT PUMP

HEATING AND COOLING

MONOBLOC TYPE

DC INVERTER

INSTALLATION AND INSTRUCTION MANUAL

KEEP THIS MANUAL FOR FUTURE REFERENCE

GB

AEYC-0639U-CH

AEYC-1039U-CH

AEYC-1639U-CH

2

1. Responsibility and recommendations ......... 3

2. Specications........................................... 8

3. Installation ............................................... 9

3.1 Notice for safety installation

3.2 Positioning and securing

3.3 Main components

3.4 Pressures and quantity available at heat pump outlet

3.5 Water circuit connection

3.6 Electrical connections

3.7 Remote controller

4. Remote controller..................................... 26

4.1 Buttons

4.2 Display panel

5. Operation and functions

of the Remote controller............................ 28

5.1 System ON/OFF

5.2 Setting the day and time

5.3 Selecting the operating mode

5.4 Domestic Hot Water production

5.5 Setting the time bands for Heating/Cooling

5.6 Setting the time bands for DHW, Low tariff and Night mode

5.7 Procedure for accessing the Parameter setting menu

6. Electrical connections ............................... 49

6.1 PCB(Terminal)

6.2 PCB(Terminal) Input/Output

6.3 Parameters Input/Output

7. Unit Management..................................... 53

7.1 Operating modes

7.1.1 Select mode from user interface

7.1.2 Select mode by remote contact

7.2 Water temperature set point

7.2.1 Fixed set point

7.2.2 Climatic curve

7.2.2.1 Heating Climatic curves

7.2.2.2 Cooling Climatic curves

7.2.3

Additional Outdoor air temperature probe for Climatic

curves

7.2.4 Buffer tank temperature probe

7.2.5 HP unit control

7.2.5.1

HP unit controlled based on Outgoing water temperature

7.2.5.2

HP unit controlled based on Outgoing water temperature

and Room air temperature

7.2.5.3 HP unit controlled based on Buffer tank temperature

7.2.5.4 HP unit controlled based on Buffer tank temperature

and Room air temperature

7.2.5.5 HP unit controlled based on DHW tank temperature

7.3 Water pump management

7.3.1 Main water pump

7.3.1.1 Continuous operation “Always ON”

7.3.1.2 Snifng operation “Snifng cycle”

7.3.1.3 Unlock pump function

7.3.1.4 Pump output adjustment function

7.4 Frost protection

7.4.1 Frost protection based on Room air temperature

7.4.2 Frost protection based on Outdoor air temperature

7.4.3 Frost protection based on Outgoing water temperature

7.4.4 DHW tank frost protection

7.4.5 Secondary system circuit frost protection

7.5 Input/Output contact

7.5.1 Heating/Cooling mode remote contact

7.5.2 ON/OFF DHW production remote contact

7.5.3 ON/OFF remote contact

7.5.4 EHS Alarm

7.5.5 Flow switch

7.5.6 Dual set point control

7.5.7 Additional water pump

7.5.7.1 Additional water pump1

7.5.7.2 Additional water pump2

7.5.8 Heating/Cooling mode output

7.5.9 Congurable contact (Alarm)

7.5.9.1 Alarm

7.5.9.2 Ambient temperature reached

7.5.10 Night mode

7.5.11 Low tariff

7.5.12 Dehumidier management

7.5.13 Space Heating management

8. Domestic Hot Water Production................. 98

8.1 DHW 3way valve management

8.1.1 Max time for DHW request

8.1.2 DHW 3way valve change over time

8.2 DHW production mode

8.2.1 Heat pump only

8.2.2 DHW Electric heater only

8.2.3 Heat pump + DHW heater

8.2.4 Legionella prevention function

8.3 Backup heater

8.3.1 Backup heater in Replacement mode

8.3.2 Backup heater in Supplementary mode

8.3.3 Freeze protection function

8.4 EHS (External heat source)

8.4.1 EHS in Replacement mode

8.4.2 EHS in Supplementary mode

9. Parameter List .........................................

124

9.1 Access limitation

9.2 Parameter table

10. Installation check and Test operation........

138

10.1 Installation check

10.2 Test operation

11. Service and Maintenance ........................

140

11.1 Error code display

11.2 Error history display

11.3 Method of reset error code display

11.4 List of Error codes

11.5 Check and troubleshooting

11.6 Monitor display function

11.7 Maintenance

Index

3

1. Responsibility and recommendations

General Information

• Carefully read this manual and keep it for future reference.

• Carefully evaluate the potential risks before carrying out any repair or

maintenance, and take the necessary precautions to guarantee personal safety.

• Do not attempt to repair, move or re-install the unit without the help of a qualied

technician.

Responsibility

The manufacturer declines every responsibility and declares the warranty on the

unit void in the event of damages caused by:

• Incorrect installation, including noncompliance with the instructions contained in

the relative manuals.

• Modications or errors in the electric or cooling or hydraulic connections.

• Unauthorised coupling of other units, including units from other manufacturers.

• Use of the unit in conditions different to those indicated.

All materials used for manufacturing and packaging of the new equipment

are ecological and or recyclable.

Directive 2002/96/EC (WEEE): Information for the users

This product is in compliance with the EU 2002/96/EC Directive.

The symbol of the crossed bin on the appliance indicates that the product, at the

end of its life span, must be treated separately from household waste. It must be

taken to a differentiated collection centre for electric and electronic appliances or

taken back to the supplier on the purchase of a new equivalent appliance.

The user is responsible for taking the appliance to an appropriate collection centre

at the end of its life span. Disposing of a household appliance separately avoids

possible negative consequences for the environment and health deriving from

inappropriate disposal and enables the constituent materials to be recovered to

obtain signicant savings in energy and resources.

For more detailed information regarding the collection systems available, contact

the local waste disposal service or the supplier where the purchase was made.

4

1. Responsibility and recommendations

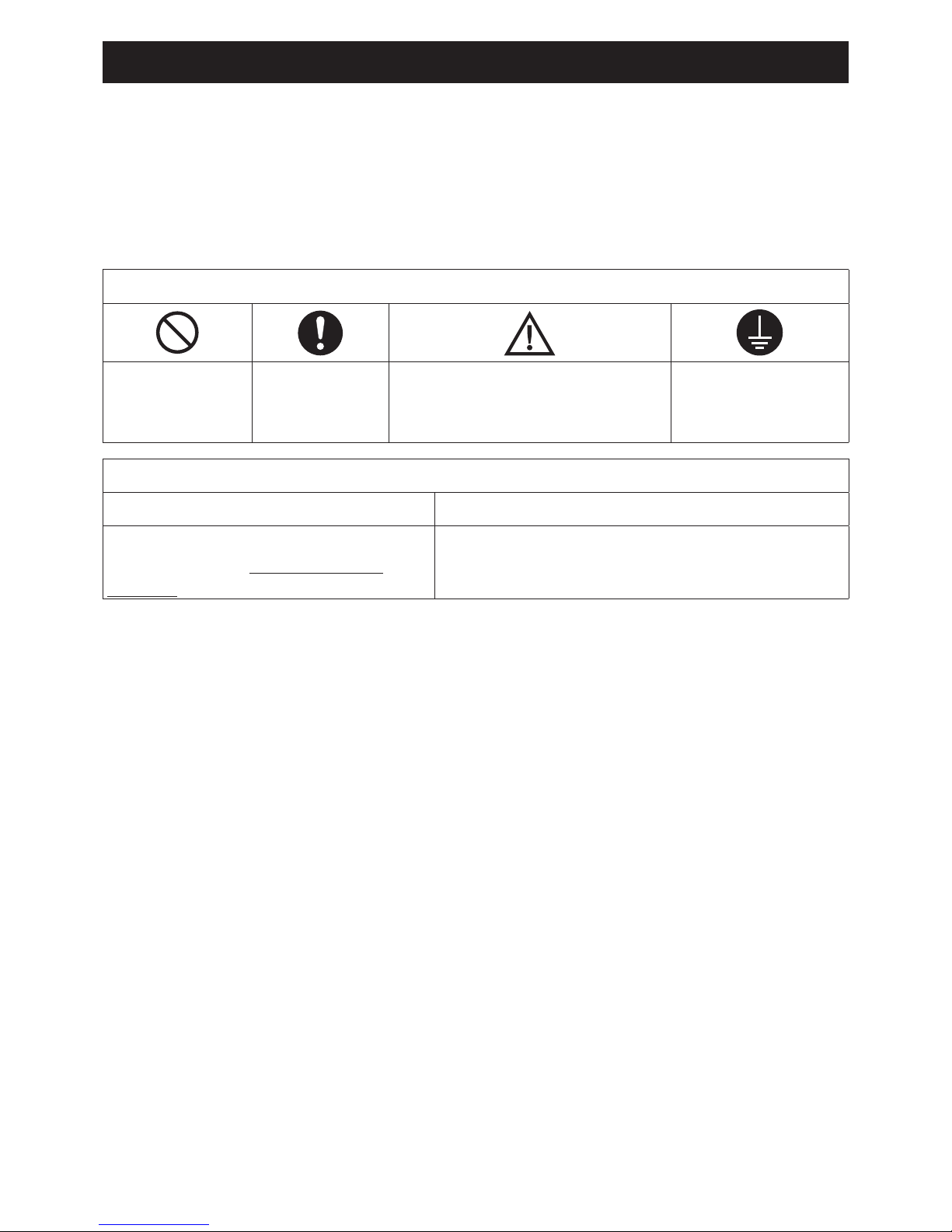

MEANING OF THE SYMBOLS

Indicates

PROHIBITION

Indicates

OBLIGATION

Indicates

PRECAUTION

(also dangerous/warnings)

CONNECT THE

GROUND CABLE

MEANING OF THE INDICATION

DANGER ATTENTION

Indicates the risk of death or

serious injuries in the event of

misuse.

Indicates the risk of personal injury or

damage to property, furniture or animals in

the event of failure to follow the instructions.

Important information on safety is reported on the product and contained in this

Manual. Carefully read this installation manual before installing the unit. Important

information for correct installation is contained in the Manual.

Safety procedures

5

1. Responsibility and recommendations

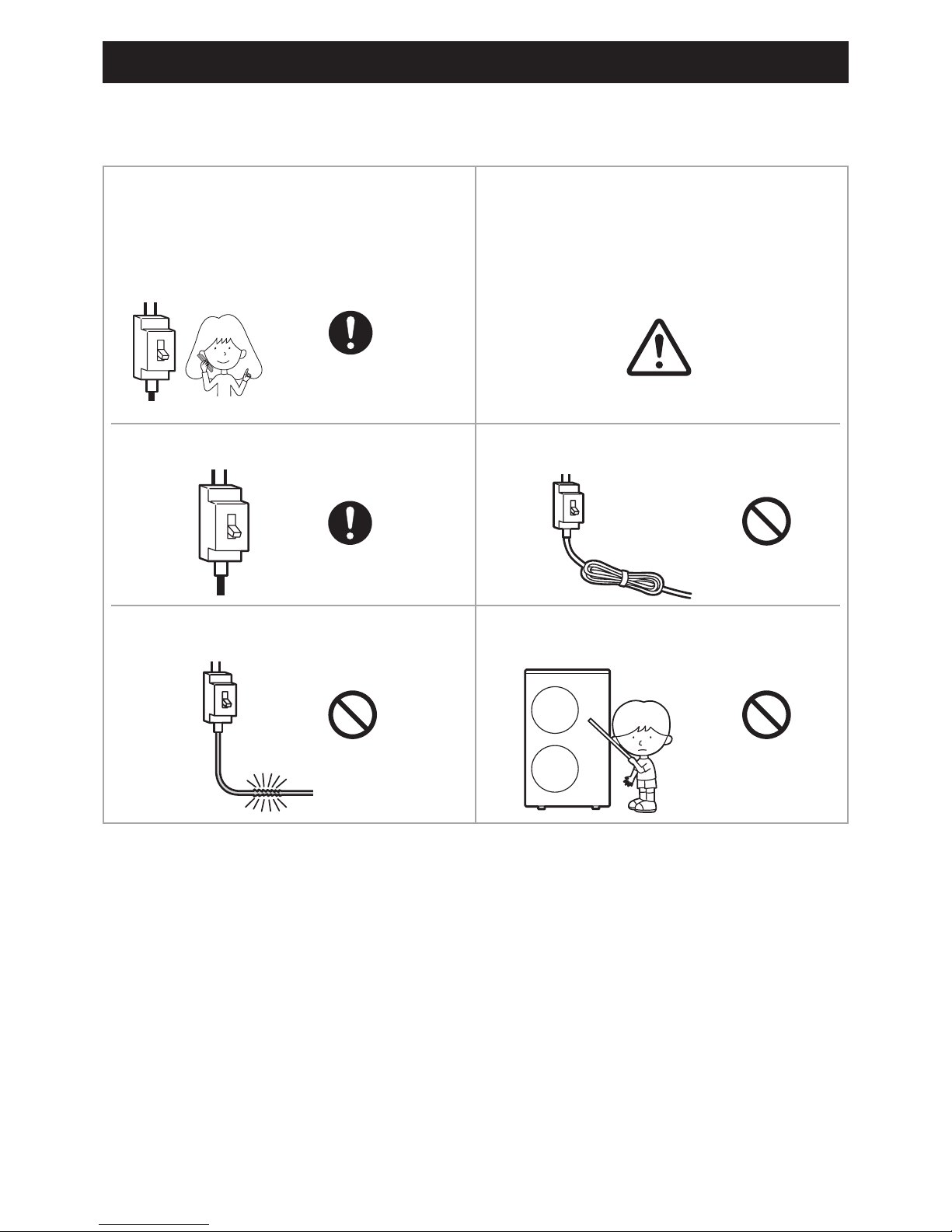

Use the voltage 230V. Do not use the power supply

cable in a bundle.

Take care not to damage the

power supply cable.

Do not insert objects into the air

inlet or outlet.

GB

Prohibition

1

2

MODE

ON

/

OFF

TIMER

ON

/

OFF

CAUTION

Strict

Enforcement

Prohibition Prohibition

Prohibition Prohibition

Prohibition

GB

Prohibition

1

2

MODE

ON

/

OFF

TIMER

ON

/

OFF

CAUTION

Strict

Enforcement

Prohibition Prohibition

Prohibition Prohibition

Prohibition

GB

Prohibition

1

2

MODE

ON

/

OFF

TIMER

ON

/

OFF

CAUTION

Strict

Enforcement

Prohibition Prohibition

Prohibition Prohibition

Prohibition

When an anomaly is detected, as

a burning smell, immediately stop

the power supply by isolating on

the main switch of the electrical

panel.

This unit must not be used by

children or people with reduced

physical, sensory or mental

capabilities, or lack of experience

and knowledge, unless they are

supervised.

GB

Prohibition

1

2

MODE

ON

/

OFF

TIMER

ON

/

OFF

CAUTION

Strict

Enforcement

Prohibition Prohibition

Prohibition Prohibition

Prohibition

PROHIBITION

GB

Prohibition

1

2

MODE

ON

/

OFF

TIMER

ON

/

OFF

CAUTION

Strict

Enforcement

Prohibition Prohibition

Prohibition Prohibition

Prohibition

PROHIBITION

STRICT

ENFORCEMENT

GB

Prohibition

1

2

MODE

ON

/

OFF

TIMER

ON

/

OFF

CAUTION

Strict

Enforcement

Prohibition Prohibition

Prohibition Prohibition

Prohibition

GB

Prohibition

1

2

MODE

ON

/

OFF

TIMER

ON

/

OFF

CAUTION

Strict

Enforcement

Prohibition Prohibition

Prohibition Prohibition

Prohibition

GB

Prohibition

1

2

MODE

ON

/

OFF

TIMER

ON

/

OFF

CAUTION

Strict

Enforcement

Prohibition Prohibition

Prohibition Prohibition

Prohibition

PROHIBITION

CAUTION

6

1. Responsibility and recommendations

-

Prohibition

STRICT

ENFORCEMENT

Prohibition Prohibition

Prohibition

Prohibition Prohibition

Prohibition

Hight temperature

Connect the earth wire. Use an exclusive power source

with a circuit breaker.

Do not install the unit in the

place with any possibility of

inammable gas leakage around

the unit.

Do not allow the unit to be

exposed to vapor or oil steam.

Do not stop the operation

by turning off the circuit breaker.

Check good condition

of the installation stand.

Do not pour water into the unit

for cleaning.

Do not place animals or plants

in the direct path of the air ow.

-

Prohibition

STRICT

ENFORCEMENT

Prohibition Prohibition

Prohibition

Prohibition Prohibition

Prohibition

Hight temperature

-

Prohibition

STRICT

ENFORCEMENT

Prohibition Prohibition

Prohibition

Prohibition Prohibition

Prohibition

Hight temperature

Do not place any objects

on or climb on the unit.

Note for draining water.

The maximum temperature for the circulating

water is approximately 60°C. Take care to

avoid burns when draining the water.

-

Prohibition

STRICT

ENFORCEMENT

Prohibition Prohibition

Prohibition

Prohibition Prohibition

Prohibition

Hight temperature

HIGH TEMPERATURE

Do not try to repair or

reconstruct by yourself.

Do not extend power supply cable

or connect incorrectly.

GB

Prohibition

1

2

MODE

ON

/

OFF

TIMER

ON

/

OFF

CAUTION

Strict

Enforcement

Prohibition Prohibition

Prohibition Prohibition

Prohibition

PROHIBITION

GB

Prohibition

1

2

MODE

ON

/

OFF

TIMER

ON

/

OFF

CAUTION

Strict

Enforcement

Prohibition Prohibition

Prohibition Prohibition

Prohibition

PROHIBITION

GB

Prohibition

1

2

MODE

ON

/

OFF

TIMER

ON

/

OFF

CAUTION

Strict

Enforcement

Prohibition Prohibition

Prohibition Prohibition

Prohibition

PROHIBITION

GB

Prohibition

1

2

MODE

ON

/

OFF

TIMER

ON

/

OFF

CAUTION

Strict

Enforcement

Prohibition Prohibition

Prohibition Prohibition

Prohibition

PROHIBITION

GB

Prohibition

1

2

MODE

ON

/

OFF

TIMER

ON

/

OFF

CAUTION

Strict

Enforcement

Prohibition Prohibition

Prohibition Prohibition

Prohibition

PROHIBITION

GB

Prohibition

1

2

MODE

ON

/

OFF

TIMER

ON

/

OFF

CAUTION

Strict

Enforcement

Prohibition Prohibition

Prohibition Prohibition

Prohibition

PROHIBITION

GB

Prohibition

1

2

MODE

ON

/

OFF

TIMER

ON

/

OFF

CAUTION

Strict

Enforcement

Prohibition Prohibition

Prohibition Prohibition

Prohibition

PROHIBITION

GB

Prohibition

1

2

MODE

ON

/

OFF

TIMER

ON

/

OFF

CAUTION

Strict

Enforcement

Prohibition Prohibition

Prohibition Prohibition

Prohibition

PROHIBITION

GB

Prohibition

1

2

MODE

ON

/

OFF

TIMER

ON

/

OFF

CAUTION

Strict

Enforcement

Prohibition Prohibition

Prohibition Prohibition

Prohibition

PROHIBITION

STRICT

ENFORCEMENT

7

1. Responsibility and recommendations

GB

Prohibition

1

2

MODE

ON

/

OFF

TIMER

ON

/

OFF

CAUTION

Strict

Enforcement

Prohibition Prohibition

Prohibition Prohibition

Prohibition

If the same part of the body is

exposed to the oor heating for

a long time, it could cause low

temperature scalding.

GB

Prohibition

1

2

MODE

ON

/

OFF

TIMER

ON

/

OFF

CAUTION

Strict

Enforcement

Prohibition Prohibition

Prohibition Prohibition

Prohibition

PROHIBITION

Check personnel wears suitable personal protective equipment.

Verify the absence of damages caused by transport or movement of the

equipment and, immediately forward the claim to the supplier.

Dispose of the packing material in compliance with the local standards.

Do not lift the unit by inserting hooks in the side handles but use specic

equipment (lifting devices, trucks, etc.).

Do not rest liquid containers or other objects on the unit.

• Do not use this unit for any purposes other than Heating and Cooling.

• This appliance can be used by children aged from 8 years and above and persons

with reduced physical, sensory or mental capabilities or lack of experience and

knowledge if they have been given supervision or instruction concerning use of

the appliance in a safe way and understand the hazards involved. Children shall

not play with the appliance. Cleaning and user maintenance shall not be made by

children without supervision.

• The appliance is accessible to the general public.

8

1.2. Specications

Model

AEYC-0639U-CH AEYC-1039U-CH AEYC-1639U-CH

Type Heating and Cooling Monobloc Type

DC Inverter (Reverse cycle)

Power 1N ~ 230V 50Hz

Heating (*)

Capacity [kW] 6.0 10.0 16.0

Power Input [kW] 1.46 2.30 3.90

Running Current (MAX.) [A] 6.4(11.2) 10.2(17.5) 17.0(25.3)

COP 4.11 4.35 4.10

Cooling (*)

Capacity [kW] 5.0 8.0 16.0

Power Input [kW] 1.28 2.32 4.10

Running Current (MAX.) [A] 5.6(6.6) 10.1(11.6) 17.8(23.0)

EER 3.91 3.45 3.90

MAX. Pressure [MPa] 4.1

Refrigerant (R410A) [kg] 1.05 1.72 2.99

Dimentions & Weight (NET)

Height [mm] 675 882 1,418

Width [mm] 825 850 1,000

Depth [mm] 300 330 330

Weight [kg] 52 74 119

Temperature Range

Outdoor Temperature

Heating [°C] –20 to 43

Cooling [°C] 18 to 43 20 to 43 15 to 43

Inlet Water Temperature [°C] 18 to 55

Water Pressure [MPa] 0.1 to 0.3

• Specications are subject to change without notice.

(*) Rating condition Heating : Outdoor temperature DB/WB 7°C/6°C, Leaving water temperature 35°C

Cooling : Outdoor temperature 35°C, Leaving water temperature 18°C

• Acoustic Noise Information : The maximum sound pressure level is less than 70 dB (A).

According to IEC 704-1 and ISO 3744.

• If the air to water heat pump is operated under higher temperature conditions than those listed, the built-in protection circuit

may operate to prevent internal circuit damage. Also, during Cooling modes, if the unit is used under conditions of lower

temperatures than those listed above, it may freeze, leading to water leakage and other damage.

9

3. Installation

3.1 Notice for safety installation

CAUTION

• Please ask qualied installer to install this unit.

• Do not attempt to install this unit by yourself to avoid accidents such as electric shock, re and leakage of water.

• Before installing this unit, please read this notice for safety installation carefully and install properly and safely.

• Be sure to follow the safety articles mention of important details on safety.

• After nishing the installation, please check no defective points in the testing operation. Then, kindly explain to

the user about the directions and maintenance according to the operation manual.

• For product modication, the product and its specication may show slight differences from the description of this manual.

DANGER

• Be sure to install the unit in suitable place to hold the heavy weight. Lack of stability or imperfect installation may

cause injury due to the fall unit falling.

• Do not install to a place where there is any possibility of inammable gas leakage such as from LP gas cylinder

around the unit. Leaked inammable gas around the unit may cause a re.

• If the leaked refrigerant is exposed to re, poisonous gas may be generated.

• The entry of other gases, such as air, into the cooling circuit could cause an explosion and injuries.

WARNING

• At the time of installation of the unit or relocation, use only the designated refrigerant (R-410A) into refrigerant

circulating system (Refrigeration circuit). Other gas such as air in the refrigeration circuit may cause an explosion

and injury.

• Connect the unit with standard parts required. This installation manual describes the correct connections using

the installation set available from standard parts.

DANGER

• Installation work must be performed in accordance with national wiring standards by authorized personnel only.

• For the air to water heat pump to operate satisfactorily, install it as outlined in this installation manual.

• Also, do not use an extension cord.

• Do not turn on the power until all installation work is complete.

• Use designated parts or accessories to avoid accidents such as electric shock, re and leakage of water.

• Follow the local standards in electric works. Be sure to use an exclusive power source.

• Any shortage of electric circuit’s capacity or imperfect works may cause an electric shock and a re.

• Never touch electrical components immediately after the power supply has been turned off. Electrical shock may

occur. After turning off the power, always wait 5 minutes or more before touching electrical components.

• Be sure to x the power supply cable in connecting points of the terminal block correctly, Imperfection of the

connecting may cause overheating and a re.

• Be sure to install the wiring lid in a straight line. Imperfect wiring works may cause overheating, a re or electric

shock at the connecting point in the terminal block.

• Always connect earth wire.

Never connect the earth cable to gas tube, water supply pipes, lightning rod and earth cable of telephone.

Imperfect earth connection may cause electric shock.

• Install a circuit breaker. Lack of circuit breaker may cause electric shock.

CAUTION

• Be sure to complete a drainage works according to this manual.

• After installation, check that there are no defects in the test. Then kindly inform the user about instructions and

maintenance according to the user manual.

10

3. Installation

Minimum clearanceDimensions

3.2 Positioning and securing

327

57

388 54

R3/4(20A)

30015.3 42

825 73

675

580

122.5 122.5

43

Circulating water

return port

Circulating water

outgoing port

AEYC-0639U-CH

• Anchor the unit to the concrete with bolts (ø10 mm) and nuts rmly and level.

• In case the vibration may affect the house, use an anti-vibration mounts and x the unit securely.

Over 300mm

Over 600 mm

Over 100mm

Over 100mm

Over 600mm

AEYC-1039U-CH

882

850 24

R1(25A)

R1(25A)

25 330 38

480173

155540155

75 70

357

Circulating water

return port

Circulating water

outgoing port

AEYC-1039U-CH

Over 300mm

Over 600 mm

Over 100mm

Over 100mm

Over 600mm

AEYC-1639U-CH

680185

357

80 80

241000 3637 330

1418

205590205

Circulating water

outgoing port

Circulating water

return port

R1 1/4(32A)

R1 1/4(32A)

AEYC-1639U-CH

Over 300mm

Over 600 mm

Over 100mm

Over 100mm

Over 600mm

AEYC-0639U-CH

(Unit:mm)

11

3. Installation

SELECTION ON THE PLACE

• Consider a place where the noise and the air discharged to not affect neighbours.

• Consider a position protected from the wind.

• Consider an area that respects the minimum spaces recommended.

• Consider a place that does not obstruct the access to doors or corridors.

• The surfaces of the oor must be solid enough to support the weight of the unit and minimise the transmission of

vibrations.

DANGER

• Do not install where there is the danger of combustible gas leakage.

• If children may approach the unit, take preventive measures so that they cannot reach the unit.

• Install the unit in a place where it will not be inclined more than 5 °.

When installing the unit where it may exposed to strong wind, brace it securely.

Decide the mounting position with the customer as follows:

(1) Install the unit in a location which can withstand the weight of the unit and vibration. Please make sure it is

installed level.

(2) Provide the indicated space to ensure good airow.

(3) Do not install the unit near a source of heat, steam, or ammable gas.

(4) During heating operation, condensate water ows from the unit. Therefore, install the unit in a place where the

condensate water ow will not be obstructed.

(5) Do not install the unit where strong wind blows or where it is very dusty.

(6) Do not install the unit where people pass.

(7) Install the unit in a place where it will be free from being dirty or getting wet by rain as much as possible.

CAUTION

• When the outdoor temperature is 0°C or less, remove the drain pipe and use without it. If the drain pipe is used,

the drain water in the pipe may freeze in extremely cold weather.

• In the area with heavy snowfall, if the intake and outlet of unit is blocked with snow, it might become difcult to get

warm and it is likely to cause of the breakdown. Please construct a canopy and a pedestal or place the unit on a

high stand.

12

3. Installation

Air inlet is located in the left or in the back

Air inlet is located in the left or in the back

Air inlet is located in the left or in the back

Air outlet

Air outlet

Air outlet

The heat pump has various safety parts and an internal circulator (Pump1) for quick installation with the aid of a

few external components.

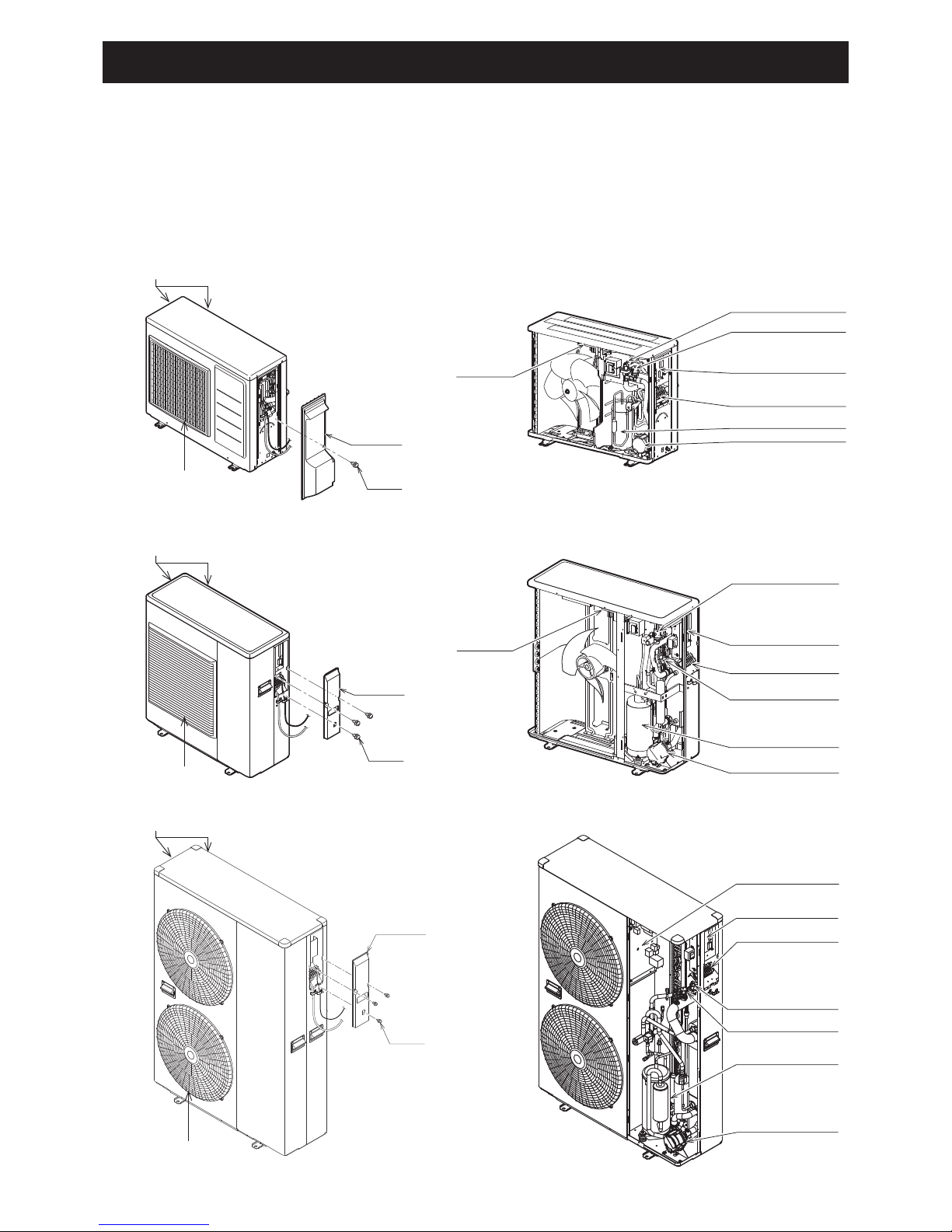

3.3 Main components

Wiring lid

Screw

AEYC-0639U-CH

AEYC-1039U-CH

AEYC-1639U-CH

PCB(Terminal)

Airpurge valve

Terminal block

Pump

Compressor

Pressure relief valve

PCB(Main)

Wiring lid

Screw

PCB(Terminal)

Airpurge valve

Terminal block

Pump

Compressor

Pressure relief valve

PCB(Main)

Wiringlid

Screw

PCB (Main)

PCB (Terminal)

Terminal block

Airpurge valve

Pump

Compressor

Pressure relief valve

13

3. Installation

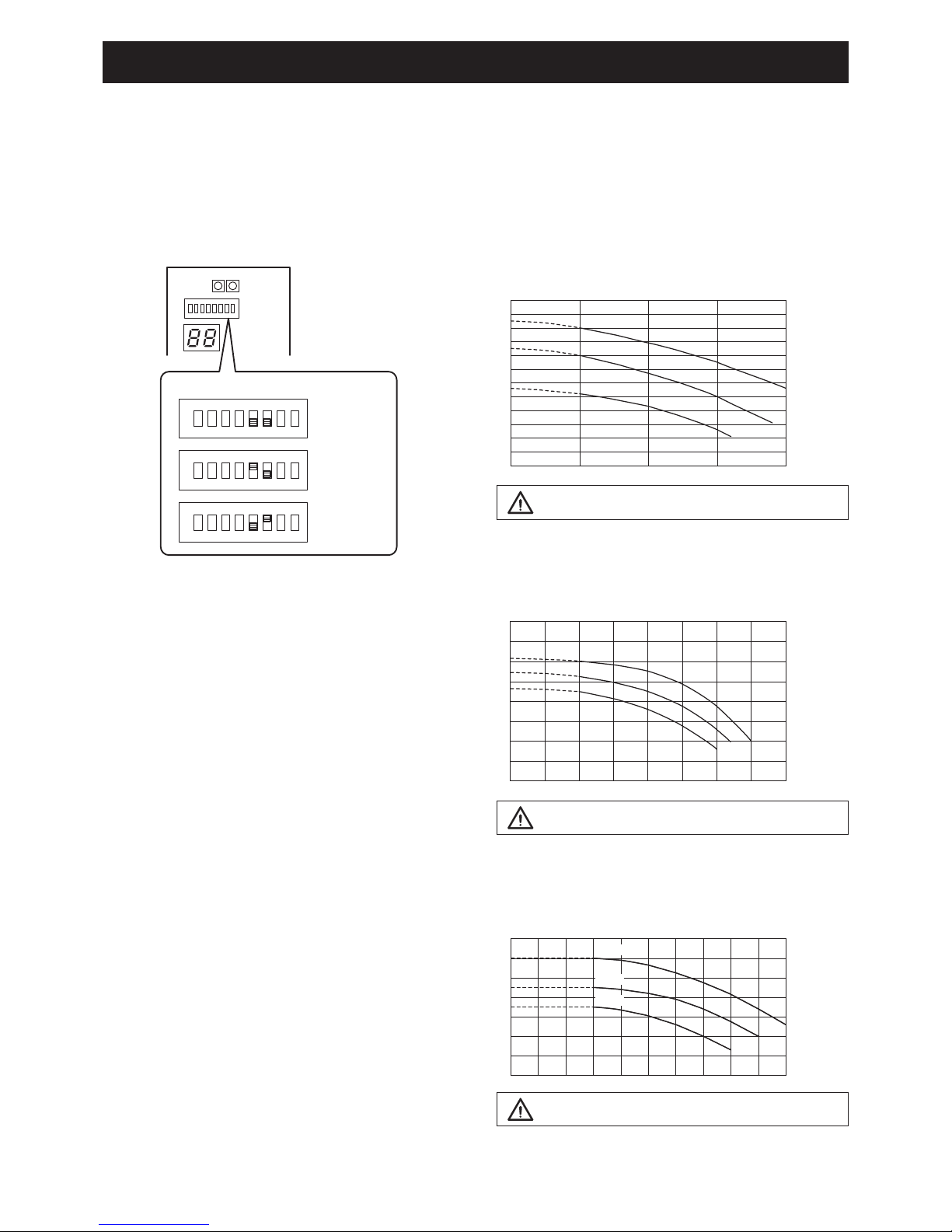

3.4 Pressures and quantity available at heat pump outlet

Main water pump in the unit has 3 levels of speed.

Factory default value is level 3.

Select dip switch 5 and 6 of DIP SW. on PCB(Terminal) to change the setting.

ON

4321 65 87

OFF

DIP SW.

Level 3

(Maximum)

ON

4321 65 87

OFF

Level 2

(Medium)

ON

4321 65 87

OFF

Level 1

(Minimum)

CAUTION

The quantity should not be less than 15L/min.

0

2

4

6

8

10

12

14

(m)

0 10 20 30 40

Level3

Level2

Level1

50(L/min)

AEYC-1639U

0

2

4

6

8

10

12

14

(m)

0 10 20 30 40

Level3

Level2

Level1

50(L/min)

0

1

2

3

4

5

6

7

8

(m)

0 105 20

15 25 30 35 40(L/min)

Level3

Level2

Level1

CAUTION

The quantity should not be less than 10L/min.

AEYC-1039U

0

1

2

3

4

5

6

7

8

9

10

11

12

(m)

0 5 10 15 20(L/min)

Level3

Level2

Level1

CAUTION

The quantity should not be less than 5L/min.

AEYC-0639U

14

3. Installation

Do not use the heat pump to treat industrial process water, swimming pool water or domestic water.

Set-up an intermediate heat exchanger for all the above cases.

CAUTION

• The quantity of water in the system must not be less than 30 litres

• If the quantity of water in the system is higher than 160 litres, use an additional Buffer tank

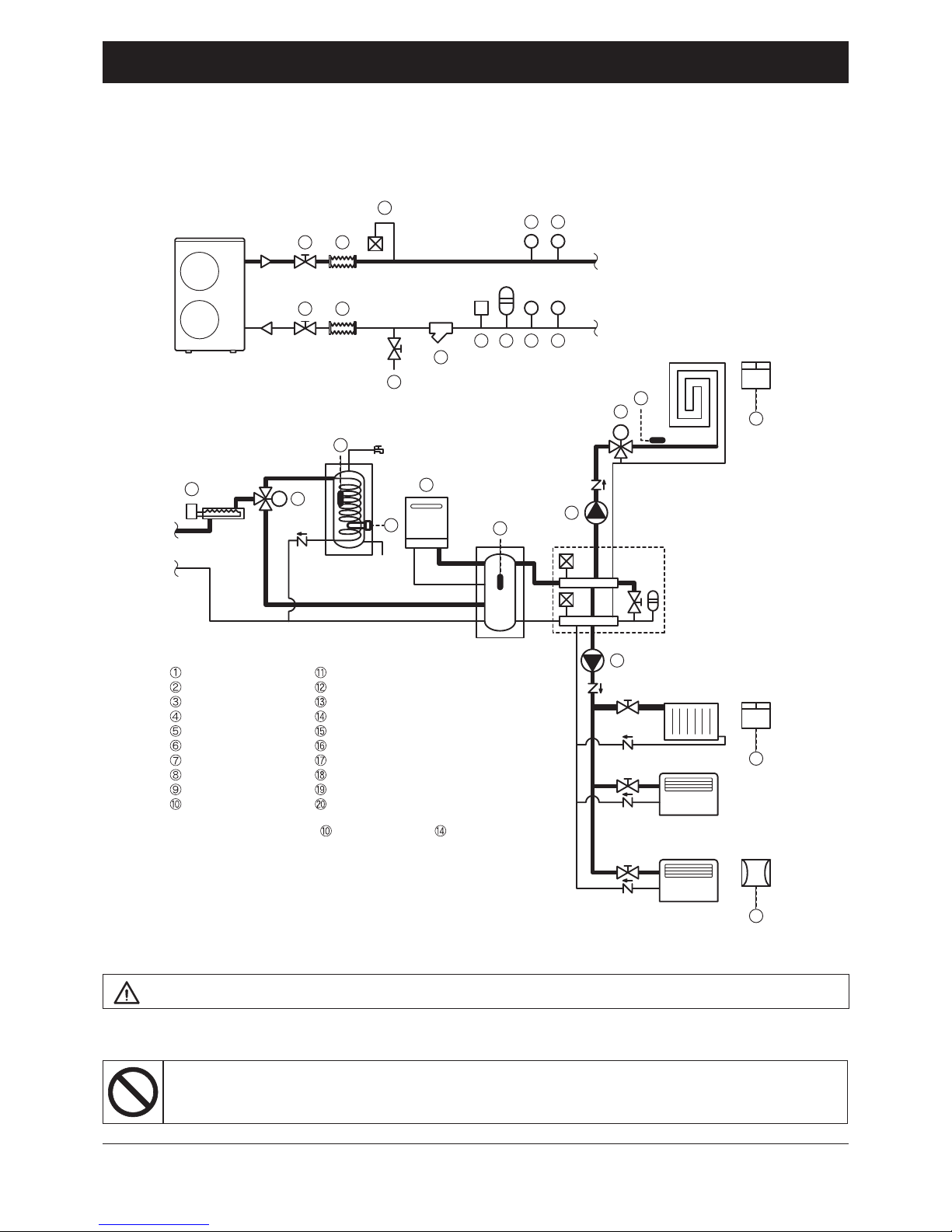

3.5 Water circuit connection

Buffer tank

Mani fold

Outlet

Inlet

DHW tank

M

Space Heating

Dehumidifier

M

Fan convector

Radiant panel

F P T

PT

12

12

3

89

89

6

5

7

4

11

13

14

12

10

15

19

17

18

16

16

19

20

Shut-off valve

Vibration damper joint

Air bleed valve

Fill/drain valve

Water line filter

Flow switch

Expansion vessel

Pressure gauge

Thermometer

Backup heater*

DHW 3way valve

DHW tank temperature probe

DHW Electric heater

EHS*

Buffer tank temperature probe

Additional water pump

Mixing valve

Mix water temperature probe

Remote controller

Humidity sensor

* Backup heater and EHS

cannot be used at same time.

HP unit

15

3. Installation

The hydraulic connections of heat pump 01, must be carried out using all necessary components and completed

with materials able to guarantee water seal of the threaded joints. The diagram typical of hydraulic circuit shows

applications in the air conditioning eld.

The hydraulic circuit must be completed following the recommendations below:

1. It is advised to include shut-off valves allowing isolation of the most important components of the system.

These valves, that can be ball, globe or buttery, must be dimensioned to allow the smallest load loss,

possible when in opening position.

2. The system must have drainage in the lowest points.

3. Air vents must be included in the highest points of the system.

4. Gauges and pressure couplings must be installed upstream and downstream of the pump.

5. All piping must be adequately insulated and supported.

6. The presence of solid particles in the water can obstruct the heater. Therefore, protect the exchanger using a

removable mesh lter. The gauge of the lter net must be of at least 10 meshes/cm2.

7. After system assembly ush and clean the whole system, paying particular attention to the state of the lter.

8. In cases where water must be cooled at temperatures below 5°C, of if the device is installed in areas subject to

temperatures below 0°C, it is essential to mix water with an adequate amount of monoethylene glycol inhibitor.

9. In the event of new installation or emptying of the circuit, preventively clean the system. In order to guarantee

good product operation, after every cleaning operation, water replacement or glycol addition, check the liquid is

clear, without visible impurities and the hardness is below 20°.

% Monoethylene glycol inhibitor 10% 20% 30% 40%

Freezing temperature * -4°C -9°C -15°C -23°C

Correction factor

Capacity 0,996 0,991 0,983 0,974

Power absorbed 0,990 0,978 0,964 1,008

Pressure drop 1,003 1,010 1,020 1,033

(*) The temperature values are indicative. Always refer to the temperatures given for the specic product used.

Hydraulic connections

Anti-freeze concentration in the system

16

3. Installation

Connection to the water circuit

1) Connect the water supply to a drain and ll valve.

2) Loosen the plug a little to take the air out of the circulating water pipe through the air purge valve. The plug

doesn't have to be removed. Be careful not to loose it.

3) Fill with water until the manometer indicates a pressure of approximately 2.0 bar. Remove air in the circuit as

much as possible using the air purge valves.

4) After the air is all purged from the system, tighten the plug again.

• Water connections must be made in accordance with diagram in the manual and on the unit, respecting the water

in-and outlet.

CAUTION

• Be careful not to deform the unit piping by using excessive force when connecting. Deformation of the piping can

cause the unit to malfunction.

If air, moisture or dust gets in the water circuit, problems may occur. Therefore, always take into account the

following when connecting the water circuit:

• Use clean pipes only.

• Hold the pipe end downwards when removing burrs.

• Cover the pipe end when inserting it through a wall so that no dust and dirt enter.

• Use a good thread sealant for the sealing of the connections. The sealant must be able to withstand the

pressures and temperatures of the system.

• When using non-brass metallic piping, make sure to insulate both materials from each other to prevent galvanic

corrosion.

• Because brass is a soft material, use appropriate tooling for connecting the water circuit. Inappropriate tooling will

cause damage to the pipes.

• The unit is the only to be used in a closed water system. Application in an open water circuit can lead to

excessive corrosion of the water piping.

Before continuing the installation of the unit, check the following points:

• The maximum water pressure is 3 bar.

• Make sure to provide a proper drain for the pressure relief valve to avoid any water coming into contact with

electrical parts.

• Air vents must be provided at all high points of the system. The vents should be located at points which are easily

accessible for servicing. An automatic air purge is provided inside the unit. Check that this air purge valve is not

tightened too much so that automatic release of air in the water circuit remains possible .

• Take care that the components installed in the eld piping can withstand the water pressure.

• Never use Zn-coated parts in the water circuit. Excessive corrosion of these parts may occur as copper piping is

used in the unit’s internal water circuit.

loosen

tighten

Air purge valve

Plug

Charging water

17

3. Installation

Piping insulation

The complete water circuit, including all piping, must be insulated to prevent condensation during cooling operation

and reduction of the cooling and heating capacity.

If the temperature is higher than 30°C and the humidity is higher than RH 80%, then the thickness of the sealing

materials should be at least 20 mm in order to avoid condensation on the surface of the sealing.

Be sure to insulate the pipes in order to prevent the water being frozen.

Anti-freeze function setting

PCB(Terminal)

ON

4321 65 87

OFF

DIP SW. position

If the circulation water is mixed with a certain quantity of inhibited monoethylene glycol, then the anti-freeze

function is not necessary.

To disable the anti-freeze function, access the PCB (Terminal) and set “Dip SW1” to OFF.

Remove the wiring lid to access the PCB (Terminal).

“Dip SW1” factory default setting is ON, so the anti-freeze function is enabled.

When Pump SW on the PCB (Terminal) is pressed, the water pump comes into operation to circulate water.

Each digital segment on the right side of the PCB (Terminal) lights up sequentially during pump operation.

The pump is stopped automatically after 10 minutes of operation. If air could not be released this way from the

water circuit, then press Pump SW again after the pump has stopped. If you want to stop the pump before it stops

automatically, press Pump SW again.

Display

Pump SW.

Water loading and air bleeding in the hydraulic circuit

• During lling, it might not be possible to remove all air in the system. Remaining air will be removed through the

automatic air purge valves during rst operating hours of the system. Additional lling with water afterwards might

be required.

• The water pressure indicated on the manometer will vary depending on the water temperature (higher pressure at

higher water temperature).

However, at all times water pressure should remain above 0.3 bar to avoid air entering the circuit.

• The unit might dispose some excessive water through the pressure relief valve.

• Water quality must be according to EN directive 98/83 EC.

NOTICE

18

3. Installation

• In case of using the drain elbow, attach it as illustrated.

• Do not attach the drain elbow in cold districts where the air temperature falls below zero continuously.

Frozen drain ice may cause obstruction to the fan.

Hose

Drain elbow

3.6 Electrical connections

All electrical connections made on site are solely the responsibility of the installer.

DANGER

Electrical shock may cause serious personal injury or death.

Electrical connections must only be performed by qualied personnel.

DANGER

• All cables and hydraulic components must be installed by a licensed technician and comply with all relevant

European and national standards.

• Ensure the power supply system complies with the national safety standards in force.

• The electrical wiring must be carried out according to the wiring diagram supplied with the unit, and the

instructions provided below.

• Turn off the power supply before making any connections.

• Ensure an effective grounding line is available.

• Be sure to use a dedicated electrical power supply system. Never use a power supply shared by another appliance.

• Check that the voltage and frequency of the electric system are those required.

• Ensure the impedance of the power supply line conforms to the electrical absorption of the unit specied on its

data plate.

• It is necessary to incorporate a main switch in the xed wiring or other means for disconnection having a contact

separation in all poles, in accordance with relevant local and national legislation.

• Emergency disconnect devices from the mains must allow for disconnection in accordance with the conditions of

overvoltage protection class III.

• Make sure to install a protective earth leakage device (30 mA). Failure to observe this warning may cause electric

shock.

• Make sure to establish a grounding line. Do not ground the unit by connecting it to a service pipe, a voltage

absorber or a phone line grounding block. Incomplete grounding may cause electric shock.

• Do not change the unit by removing safety devices or by-passing safety switches.

ATTENTION

• Properly connect the connecting cable to prevent damage to electrical components.

• Connection to the mains is of Y type, thus replacing the cable should only be done by the technical service in

order to prevent harm.

• For wiring, use specic cables and rmly connect them to terminals.

Attachment of drain elbow

19

3. Installation

Removing the wiring lid will give access to the electrical power supply terminal board of the heat pump and the

PCB (Terminal) for the external contacts and sensors connection.

WARNING

• The rated voltage of this product is 230 V a.c. 50 Hz.

• Before turning on, verify that the voltage is within the 207 V to 253 V range.

• Always use a dedicated circuit and install a dedicated receptacle to supply power to the air to water heat pump.

• Use a dedicated circuit breaker and receptacle matched to the capacity of the air to water heat pump.

(Install in accordance with standard.)

• Perform wiring work in accordance with standards so that the air to water heat pump can be operated safely and

positively.

• Install a dedicated leakage circuit breaker in accordance with the related laws and regulations and electric

company standards.

• The circuit breaker is installed in the permanent wiring. Always use a circuit that can trip all the poles of the wiring

and has an isolation distance of at least 3 mm between the contacts of each pole.

CAUTION

• The power source capacity must be the sum of the air to water heat pump current and the current of other

electrical appliances. When the current contracted capacity is insufcient, change the contracted capacity.

• When the voltage is low and the air to water heat pump is difcult to start, contact the power company to raise the

voltage.

CAUTION

• The unit complies with Voltage Fluctuations and Flicker (EN61000-3-11).

• The unit complies with Harmonic Current Emission (EN61000-3-12).

• The maximum permissible system impedance (Zmax) of the unit is 0.354 Ω(AEYC-1039U), 0.320 Ω(AEYC-

1639U).

The unit must be connected to a public supply of system impedance 0.354 Ω(AEYC-1039U), 0.320 Ω

(AEYC-1639U).

20

3. Installation

• Be sure to insert the cable cores

into the proper position of the

terminal block completely.

• Faulty wiring may cause not only

abnormal operation but also

damage to pc board.

• Fasten each screw sufciently.

• To check the complete insertion,

pull the cable slightly.

CAUTION

Peeling of the connecting cable's covering must be 10 mm.

If shorter, a defective contacting may occur.

If longer, a short circuit may occur.

Terminal block

Cable clamp

Connection diagrams

Unit side terminal

Power supply

Earth

NL

(N)(L)

1 2 3

Earth wire

Power supply cord

(N)(L)

3

2

1

L

POWER

N

ON

Reset

SW.

Pump

SW.

OFF

PCB

(TERMINAL)

3

4

2

1

Remote

Controller

1

2

3

4

5

6

7

17

18

19

20

21

22

23

Humidity

Sensor

COM

DHW Remote

Contact

ON/OFF

or

EHS Alarm

GND

24VAC

COM

Control

DHW

T.probe

OUTDOOR

T.probe

BUFFER

T.probe

Mix water

T.probe

3-way

mixing

valve

RS485 +

-

Dehumidifier

Alarm

Pump1

Pump2

Neutral

N.C.

Neutral

EHS

Heating

Cooling

mode

output

Phase

Signal

3-way

valve

8

9

10

11

12

13

14

Dual Set

Point

Control

Heating

Cooling

mode

Flow

switch

Night

mode

Low

tariff

RS485

GND

45

46

47

48

49

50

31

32

24

25

26

27

28

29

30

15

16

N

41

42

43

44

51

52

Electric

heater

10 mm 30 mm

Crimp-on terminal

Stripped wire :10mm

Sleeve

Terminal block

Crimp-on terminal

Sleeve

PCB(Terminal)

Circuit

breaker

Distribution

board

Be sure to use an exclusive power source with a circuit breaker.

Respecting the following designation, use cables whose wires size are more than the designated one in the table

below.

Power cord and circuit breaker shall be approved according to EN standard.

Supply cord must be approved in compliance with IEC60245 IEC57 (H05RN-F).

Peel ends of connecting cables in accordance with dimension in the diagram.

Use crimp-on terminals with insulating sleeves as illustrated in the diagram

below for connecting the wires to the terminal block or PCB(Terminal).

Stranded conductors shall not be soldered.

• Use a circuit breaker with a 3 mm clearance of air gap between the contacts.

Model Power supply cord(mm2)Breaker

capacity

MAX. MIN.

AEYC-0639U 2.0 1.5 16

AEYC-1039U 4.0 3.5 20

AEYC-1639U 5.5 4.0 32

This manual suits for next models

2

Table of contents

Other CHOFU Heat Pump manuals

Popular Heat Pump manuals by other brands

Envision

Envision NSKW 06 installation manual

Astral Pool

Astral Pool OPTIMA Series TECHNICAL MANUAL. START-UP AND OPERATION

ACPro

ACPro Q6SE X36 User's manual & installation instructions

alphainnoTec

alphainnoTec LWV 82R1/3 operating manual

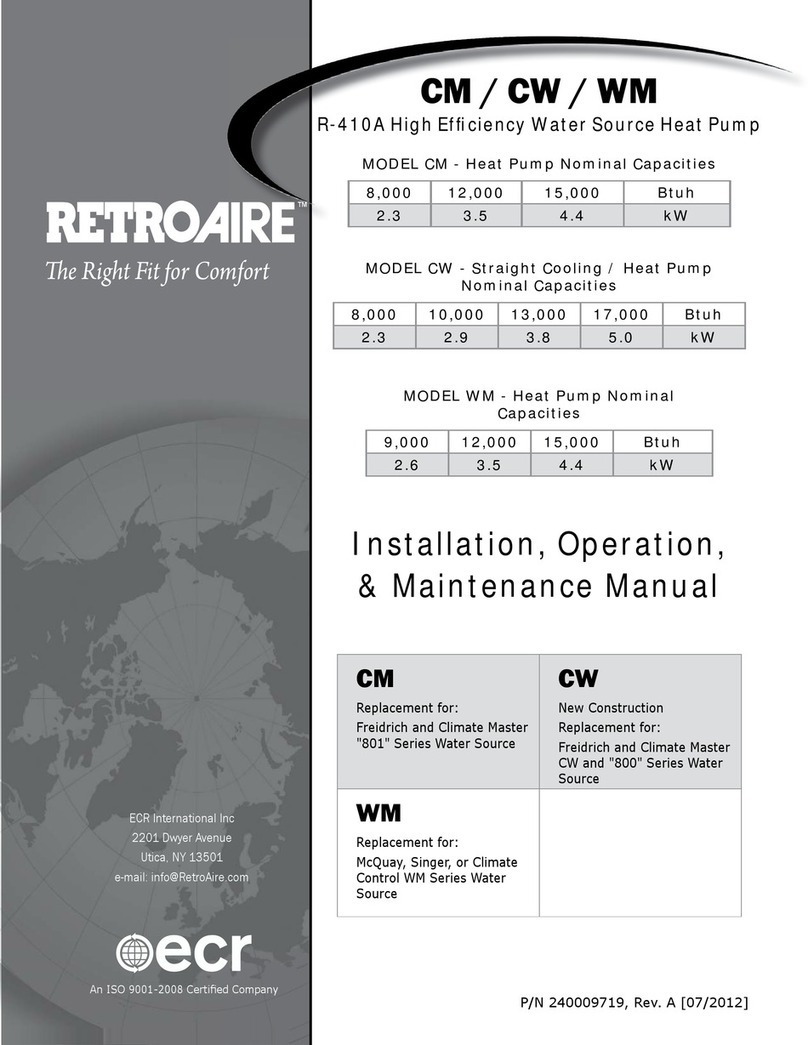

Retro Aire

Retro Aire CM Installation, operation & maintenance manual

euroline

euroline 38VAF installation instructions

Daikin

Daikin Altherma 3 R F Installer's reference guide

Calorex

Calorex Pro-Pac Series Owners & installation manual

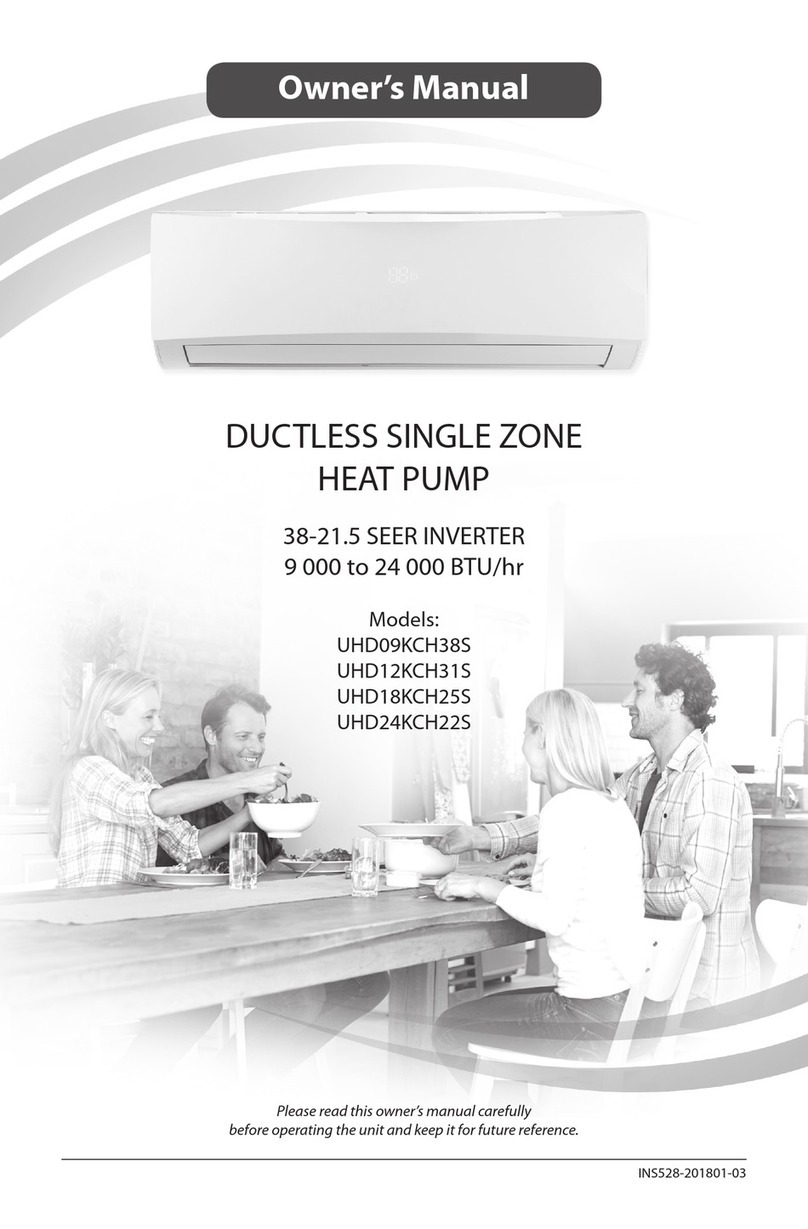

ACD

ACD UHD09KCH38S owner's manual

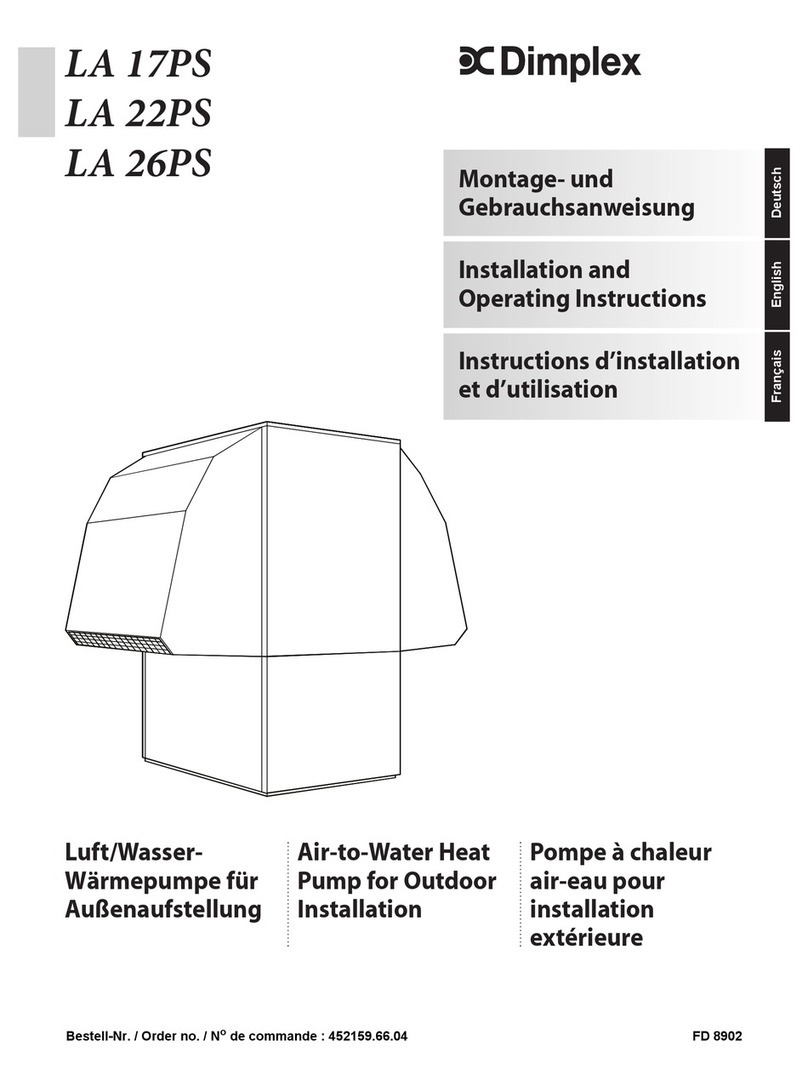

Dimplex

Dimplex LA 17PS Installation and operating instructions

Daikin

Daikin EKHBRD011ADV17 Operation manuals

Bosch

Bosch IDP Premium 18 SEER2 Series installation instructions