CHOWEL WELCOM 600P User manual

OM-W600P-0410(E)

RESISTANCE WELDING CONTROLLER

WELCOM 600P

USER MANUAL

CHOWEL CORPORATION

WELCOM 600P

CHOWEL CORPORATION - 1 -

Please, read carefully this manual for safe

and efficient use of the welding controller

The information in this manual is the possession of the chowel, it is subject to change without notice.

And this manual can be changed also without the notice.

CHOWEL is registered trademark of the CHOWEL CORPORATION.

CHOWEL FIRST FACTORY

395-3 MOKNAE-DONG, DANWON-GU

ANSAN-CITY, GYEONGGI-DO, KOREA

TEL 82-31-494-2511

FAX 82-31-495-2515

CHOWEL SECONDARY FACTORY

598 SUNGGOK-DONG, DANWON-GU

ANSAN-CITY, GYEONGGI-DO, KOREA

TEL 82-31-493-9911

FAX 82-31-495-2518

COPYRIGHT CHOWEL CORPORATION ©2002

FIRST PRINTING, February, 2003

PRINTED IN REPUBLIC OF KOREA

WELCOM 600P

CHOWEL CORPORATION - 2 -

IMPORTANT

Read first this manual before operate this welding controller. In some case, failure to follow the

instructions manual can lead to control or machine damage. In other cases failure to follow

instructions can lead to injury, or death of personnel.

This manual explains some instructions depends on the level of danger as follows.

DANGER

If shows readers where people will be hurt if procedures are not followed properly.

WARNING

If shows readers where people may be hurt if procedures are not followed properly

CAUTION

If shows readers where machinery may be damaged or economic loss can occur, or

people may be hurt if procedures are not followed properly.

RISK OF ELECTRIC SHOCK

It shows readers where people will be struck by an electric shock if procedures are not

followed properly.

WELCOM 600P

CHOWEL CORPORATION - 3 -

READ FIRST

To use this welding controller in safety, the operator should follow industry standards and safety

senses whenever working on, or near the weld machine.

In some case, failure to follow the warning instruction can lead to control or machine damage. In other

cases failure to follow these instruction can lea to injury, or death of personnel. Some examples of safe

practices are listed below. These examples are not to be considered a comprehensive listing of safety

practices. Always use safety senses when working with any type of machinery.

DANGER

During electrical power is ON, this welding controller is charged with high voltage electricity. Turn

electrical power OFF before open the door.

In the case the door is opened as it is not turn OFF can lead to injury by an electric shock, or death of

personnel.

WARNING

In some case failure to follow these instructions as follows can lead to control damage or injury of

personnel.

Ensure that control / machine is connected to the correct voltage before turning electrical power ON.

Whenever power is ON, stand clear of moving parts. This practice should be used even if the

machine is not actually in use.

Before turning electrical power OFF, ensure that personnel are standing clear of moving parts that

are pneumatic or hydraulic powered.

Whenever electrical power is turned OFF, install a “lock-out” device at the main disconnect to

prevent power from being accidentally turned ON.

WELCOM 600P

CHOWEL CORPORATION - 4 -

CAUTION

Turn electrical power OFF before changing the tap switch at the weld transformer.

In the case failure to follow the instruction like a welding at changing the tap switch can lead to injury

to personnel.

Turn stop cock OFF before some piping work.

In the case failure to follow the instruction like the electrical circuit is splashed with cooling water can

lead to control damage.

CAUTION

Magnetic fileds

It should be borne in mind that welding machine generates intense magnetic fields.

Consequently, “Do not approach the secondary circuit” of the machine carrying on your person any

article that are likely to suffer damage. These include the following:

Any kind of magnetic card or badge, for example credit card, bank card, magnetic strip telephone card,

personal recognition cards, magnetic clocking-on cards, company permits, passes, etc.

Any kind of magnetic tape or media, for example cassette, video cassette, floppy disk, etc.

Any kind of delicate mechanism, for example electronic calculators, cameras, motion picture cameras,

television cameras, watches (especially mechanically driven ones).

WELCOM 600P

CHOWEL CORPORATION - 5 -

CONTENTS

Chapter 1. Installation of welder

§1. Cooling water handling .............................................................................................. 9

§2. Connection of power source and welding transformer ................................................ 10

§3. External I/O signal ..................................................................................................... 11

§4. Pilot input of binary method ....................................................................................... 16

Chapter 2. Programming

§1. Common program ...................................................................................................... 18

§2. Program for each pilot schedule number ..................................................................... 20

§3. Stepper program for each valve schedule number ....................................................... 23

Chapter 3. Indicator and Monitor data

§1. Panel indicator of I/O signal ....................................................................................... 25

§2. Monitor of internal data .............................................................................................. 28

Chapter 4. Fault detection

§1. Fault detection items .................................................................................................. 30

§2. Fault history ............................................................................................................... 33

Chapter 5. Special functions and usage

§1. Stepper control function ............................................................................................. 34

§2. Secondary cable break predict function ...................................................................... 36

§3. External input pilot .................................................................................................... 37

WELCOM 600P

CHOWEL CORPORATION - 6 -

Chapter 6. Operation sequence

§1. Basic operation sequence ........................................................................................... 40

§2. Fault, warning output sequence .................................................................................. 46

§3. Fault reset by pilot sequence ...................................................................................... 48

§4. Reweld at fault sequence ............................................................................................ 49

§5. Weld complete sequence at reset ................................................................................ 49

Chapter 7. DATA input and monitoring

§1. The normal window ................................................................................................... 51

§2. The fault window ....................................................................................................... 53

§3. Function select mode ................................................................................................. 53

Chapter 8. Troubleshooting

§1. External I/O checking ................................................................................................ 60

§2. Program checking ...................................................................................................... 63

Chapter 9. Exceptation

§1. Monitor content ......................................................................................................... 65

Reference

1. WELCOM 600P FAULT CODE TABLE ..................................................................... 67

2. WELCOM 600P DATA SHEET .................................................................................. 68

3. ELECTRICAL CONNECTION DIAGRAM OF WELCOM 600P ............................... 69

4. OUTSIDE VIEW OF WELDCOM 600P ..................................................................... 70

WELCOM 600P

CHOWEL CORPORATION - 7 -

● Attention, check point before operation and in operation

This control device is careful treatment because it is containing a backup battery internally to maintain

program data and monitor data at a power OFF.

1. Please avoid the place which to need the store of the long term is as follows.

1-1. the place which the high temperature and direct light

1-2. the place which the relative humidity is high

1-3. the place with an inflammable and attack gas

1-4. the place which a humidity change is extreme and the dew is formed

1-5. the place which the impact comes to add with the vibration

2. If disjoint and carry the P.C.B, it is careful about the subject following

2-1. To avoid the break of a backup battery, Do lest it should touch directly to aluimum sheet

2-2. To make lest the IC should be destroyed power-failure, do lest possible hand should touch to the

component of PCB.

2-3. To transport, use a vinyl packing paper to become a static electricity protect processing.

3. Check point before operation

3-1. The each connected part must be connected so that it is strong.

Exmple) a connection list of gift of an each part and a linking part of a cooling and high voltage

system

3-2. Cooling water and compressing air observe at this manual and must maintain so that is regular.

3-3. Remove the impurities of the AIR FILTER inside.

3-4. The change of an input power source is the toe in extreme place so that a welding condition unstable,

the rate of voltage change must link ±10% within.

3-5. The welding transformer installs in near to a power source (the fitness 30m within).

If it is far and goes the size from the transformer because of voltage change is strong and can not get

the setting current, it must do sufficient attention.

3-6. the place to give the equipment the vibration and which a surrounding temperature is over 40℃,a

corrosiveness and exploiveness gas must forbid an absolute install in dangerous place to happen.

WELCOM 600P

CHOWEL CORPORATION - 8 -

4. Check point in operation

4-1. After it confirm the existence over the safety of the equipment and check, must turn a power switch

ON.

4-2. It must provide suitable to a proper form power source to a welding power source.

4-3. It must work in the situation to provide cooling water.

4-4. The source of a compression air must be provided to the pressure to be determined.

4-5. If temperature is lesser than 0℃ the factory in the winter, it have the worry which cooling water

system is damaged, it must remove the cooling water completely to a compression air (a welding task

is completed).

4-6. The temperature of cooling water to be supplied must be lesser than 30℃.

And the cooling water pressure must be over 1kg/㎠ at a flowed-water.

4-7. At the secession from this equipment which is the short while among the task, it must turn a power

switch off.

WELCOM 600P

CHOWEL CORPORATION - 9 -

Chapter 1. Installation of welder

It expresses the sequence of the time to install the resistance welder control device in a task spot. It does not

confirm properly and to prevent the accident not to become the operation, apply necessarily this sequence.

§1.Cooling water handling

1-1. A conduit task

Confirm GUN, secondary cable, welding transformer, inside T/C thyristor cooling water conduit.

1-2. Cooling water flow-examination

Confirm sufficient cooling water givers cooling water flow examination and flows certainly at an each

region.

1-3. A conduit method check

Confirm the time to open shut and the door of the T/C unreasonable it skew to pull did not exist in the

conduit and a conduit fix is not touched at the electrode.

1-4. A seepage check

Many at a high voltage part danger is in the T/C inside, the linking part of conduit when the water

pressure is high, confirm sufficiently the seepage does not happen.

1-5. Flow switch check

In the case which flow switch of a flux checker purpose have been established, it use the

TESTER and do the action check.

1-6. The filth clearence

To prevent the leakage accident after cooling water examination finish, T/C with the inside to the

outside remove cooling water to overflow and remove the the filth to happen among a conduit task.

1-7. The fix of the body

To prevent the accident to be due fall of the body, it is certainly fixed to Bolt the device of the body.

WELCOM 600P

CHOWEL CORPORATION - 10 -

§2.Connection of power source and welding transformer

As it do a cable connection within the body at electric wire terminal, do in the sequence such as there.

2-1. The earth of the body

Earth a control device body certainly to prevent electric leakage accident.

2-2. The connection of transformer

Connect the transformer at the 01 terminal and 03 terminals according to inside the body connection

diagram.

2-3. the connection of power source

Connect the power source at the 01 terminal and 02 terminals according to inside the body connection

diagram.

2-4. the check of the connection

Probably wrong wirings of the connection do not exist or it is unreasonable ggug when have drawn the

cable or tight part does not exist or the clothing did not reach the edge of the support but confirm.

WELCOM 600P

CHOWEL CORPORATION - 11 -

§3. External I/O signal

As it marked function and action of outside connection terminal signal, Connect the wiring sothat you are

suitable to an utility purpose.

3-1. External input signal

All the inputs are designed for contact input.

PILOT INPUT1

The PILOT INPUT 1(BIT 0) signal is binary, initiate the sequence when it is turned from OFF to ON.

The case to be used a single pilot input operates to first welding condition.

Connect the pilot signal of welding sequence.

When not used, keep this signal open.

PILOT INPUT2

The PILOT INPUT 2(BIT 0) signal is binary, initiate the sequence when it is turned from OFF to ON.

The case to be used a single pilot input operates to first welding condition.

Connect the pilot signal of welding sequence.

When not used, keep this signal open.

PILOT INPUT4

The PILOT INPUT 4(BIT 0) signal is binary, initiate the sequence when it is turned from OFF to ON.

The case to be used a single pilot input operates to first welding condition.

Connect the pilot signal of welding sequence.

When not used, keep this signal open.

PILOT INPUT8

The PILOT INPUT 8(BIT 0) signal is binary, initiate the sequence when it is turned from OFF to ON.

The case to be used a single pilot input operates to first welding condition.

Connect the pilot signal of welding sequence.

When not used, keep this signal open.

PILOT INPUT16

The PILOT INPUT 16(BIT 0) signal is binary, initiate the sequence when it is turned from OFF to

ON.

The case to be used a single pilot input operates to first welding condition.

Connect the pilot signal of welding sequence.

When not used, keep this signal open.

WELCOM 600P

CHOWEL CORPORATION - 12 -

WELD ON/OFF INPUT

When this input signal is ON, the operation mode is WELD, and when off, TEST MODE.

In the test mode, if the pilot signal is set at ON, the sequence will be in the self-holding status.

Connect this signal to the weld sequence initiation signal.

When not used, keep signal short-circuited to ON.

EMERGENCY STOP

When this input signal is OFF, even if it is while the sequence is active, the weld time control will

stop immediately and the VALVE OUTPUT will be turned OFF.

Normally, connect this signal to the EMERGENCY STOP signal which is ON.

When not used, keep this signal short-circuited to ON.

COUNT RESET

When this signal is turn ON, only the counter that has completed counting is reset to 0 and the

COUNT UP OUTPUT is turned to OFF.

Note that this signal is neglected while the sequence is active.

Connect this signal to reset the counter.

When not used, keep this signal open.

STEEPER RESET

When this signal is turned ON, the step no. and the step counter are reset and the STEPPER

COMPLETE OUTPUT is turned OFF.

Connect this signal to the signal that resets the stepper.

Note that this signal is neglected while the sequence is active.

When not used, keep this signal open.

FAULT RESET

When this signal is turned ON, the FAULT OUTPUT is turned OFF, preparing for the next initiation.

Connect this signal to the FAULT OUTPUT release signal circuit.

Note that this signal is neglected while the sequence is active.

When not used, keep this signal open.

LEAK CHECK

Throgh a test weld to be set, it is an input function to check a secdonary cabel short.

If it turns ON, it do test weld in gun open state.

Care to ignore among the welding sequence.

INTERLOCK INPUT

When this signal is OFF at the time of weld initiate, the weld time starts. When it is turned ON, the

weld initation does not initiation until it is turned OFF.

To prevent the simultaneous weld by plural welders, connect this signal to a different control device

INTERLOCK OUTPUT signal.

When not used, keep this signal open.

WELCOM 600P

CHOWEL CORPORATION - 13 -

TRANSFORMER THERMO INPUT

When this signal is turned OFF, when the sequence is active, it is judged that the weld transformer is

overheated, and the fault is put out and the Timer unit comes to stop.

Connect this signal to the thermostat signal from the weld transformer.

When not used, keep this signal short-circuited to ON.

RETRACT ENABLE => “Chapter 5 §3. external input pilot”reference

Using the retract valve, it is an input signal to use the facility of the separate way(one step pressure).

When not used, keep this signal open.

EXT. PILOT ENABLE => “Chapter 5 §3. external input pilot”reference

It is useful signal while the case to input pilot signal to external FOOT switch or PALM switch.

When not used, keep this signal open.

FOOT/PALM => “Chapter 5 §3. external input pilot”reference

The case to use FOOT switch, operate ON with a FOOT switch common terminal.

The case to use PALM switch, operate OFF with a PALM switch common terminal.

When not used, keep this signal open.

An utility method of different a pilot input signal refer“Chapter 5 §3. external input pilot” reference.

3-2. External Output signals

For all the output signals, the semiconductor is used.

VALVE OUTPUT1

This is voltage output AC100V or DC24V for solenoid valve no.1.

Connect this signal to the solenoid valve.

When not used, keep this signal open.

VALVE OUTPUT2

This is voltage output AC100V or DC24V for solenoid valve no.2.

Connect this signal to the solenoid valve.

When not used, keep this signal open.

RETRACT VALVE OUTPUT1

This is voltage output AC100V or DC24V for RETRACT VALVE no.1.

Connect this signal to the solenoid valve.

When not used, keep this signal open.

WELCOM 600P

CHOWEL CORPORATION - 14 -

RETRACT VALVE OUTPUT2

This is voltage output AC100V or DC24V for RETRACT VALVE no.2.

Connect this signal to the solenoid valve.

When not used, keep this signal open.

WELD COMPLETE OUTPUT

This is a no-voltage A contact output which is turned ON when the sequence is completed and OFF

when all the PILOT INPUTS are turned off.

If the PILOT INPUTS are OFF at the end of the sequence, ON pulse of approx. 6 cycles will be put

out.

Connect this signal to the weld complete confirm input of the PLC, etc.

When not used, keep this signal open.

READY OUTPUT

This signal is a no-voltage A contact output which is turned ON when the following conditions are

ready for welding :

a. The SYSTEM indicator is ON.

b. The FAULT OUTPUT signal is OFF.

c. The WELD/NO WELD INPUT signal is ON.

d. The EMERGENCY STOP INPUT signal is ON.

Use this signal for preventing the work from flowing when the operation is in the TEST MODE.

When not used, keep this signal open.

COUNT UP

This is a no-voltage a contact output signal which is turned ON when the TOTAL WELD COUNTER

or EACH SCHEDULE WELD COUNTER reaches the set value.

Use this signal as general-purpose counter output signal for counting during the maintenance.

When not used, keep this signal open.

STEPPER COMPLETE

This is a no-voltage A contact output signal which is turned ON when the stepper operation of any

schedule completes.

Use this signal as alarm for the tip dressing or changing time.

When not used, keep this signal open.

FAULT OUTPUT

This is a no-voltage A contact output signal which is turned ON when some fault is detected.

Use this signal as an fault detect signal for welding result or the Timer unit.

When not used, keep this signal open.

WELCOM 600P

CHOWEL CORPORATION - 15 -

ALARM OUTPUT

This is a no-voltage A contact output signal which is turned ON when some alarm is detected.

This output signal does not affect the weld sequence operation.

Use this signal as an alarm signal to alarm the operators on the maintenance time.

When not used, keep this signal open.

SELECTABLE OUTPUT

This is a no-voltage A contact output signal which selects the output function by setting the program

accordingly.

When not used, keep this signal open.

INTERLOCK OUTPUT

This is a no-voltage A contact output signal which is turned ON immediately before the weld

initations in the weld mode and OFF upon the weld ends.

When not used, keep this signal open.

WELCOM 600P

CHOWEL CORPORATION - 16 -

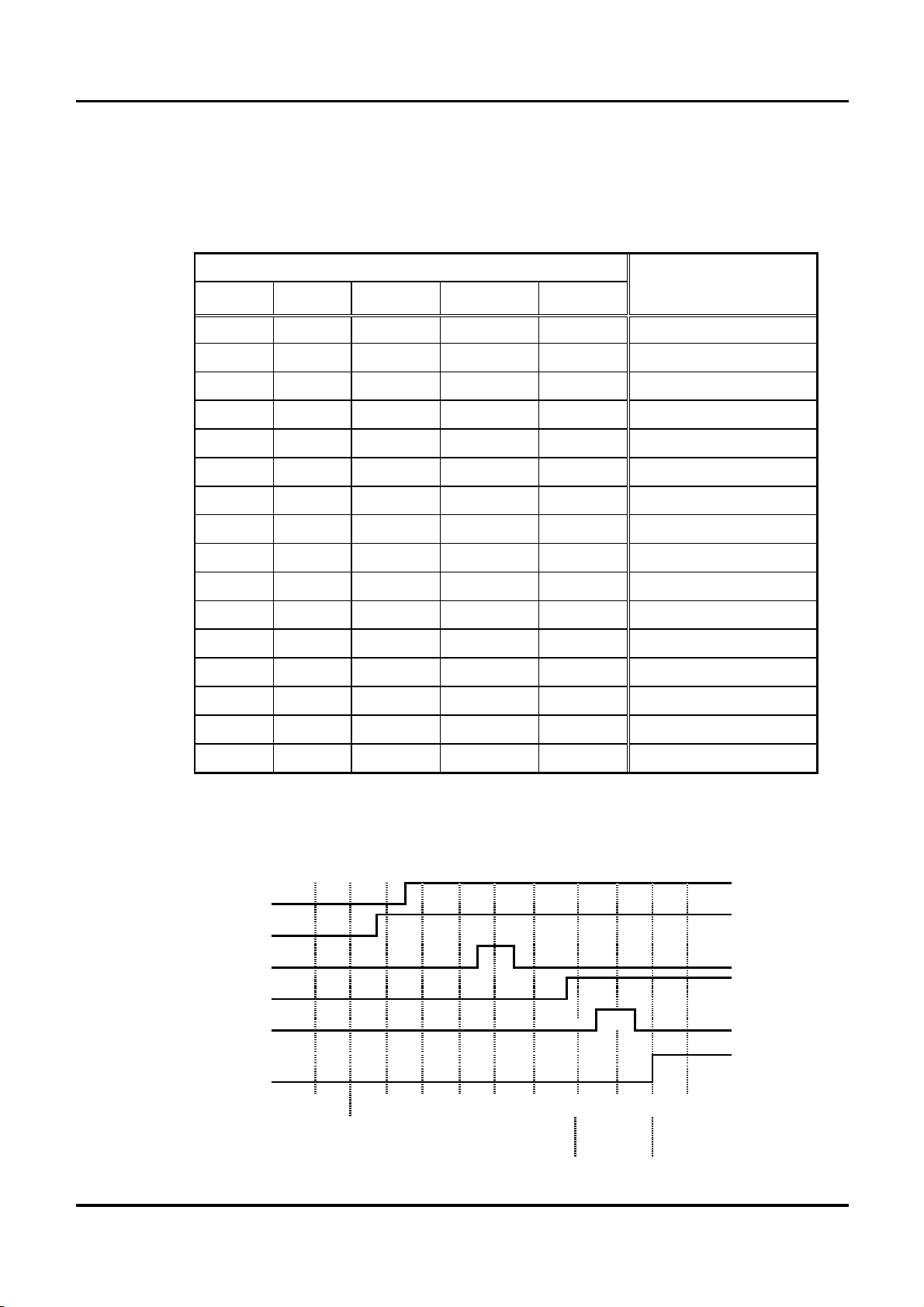

§4. PILOT INPUT of binary method

The PILOT INPUT signals are binary to enable many weld conditions enable to be selected. For the

combination of the PILOT INPUT signals and the schedule no., refer to the following table.

Only when three PILOT INPUT signals are coincided whith each other when checked and confirmed in

synchronization with the power supply the sequence will start.

PILOT INPUT signal Schedule No.

PILOT16

PILOT8

PILOT4 PILOT2 PILOT1

OFF OFF OFF OFF OFF NONE

OFF OFF OFF OFF ON 1

OFF OFF OFF ON ON 3

OFF OFF ON OFF ON 5

OFF OFF ON ON ON 7

OFF

OFF

ON OFF OFF ON 9

OFF ON OFF ON ON 11

OFF

ON

OFF

ON OFF ON 13

OFF ON ON ON ON 15

ON OFF OFF ON OFF 18

ON OFF ON OFF OFF 20

ON OFF ON ON OFF 22

ON ON OFF OFF OFF 24

ON

ON

OFF

OFF ON ON 26

ON ON ON OFF OFF 28

ON

OFF

ON ON ON ON 31

Power cycle

0

1

2 3 4

5 6 7 8 9

10

ON

PILOT INPUT 1

ON

PILOT INPUT 2

PILOT INPUT 4

OFF

PILOT INPUT 8

ON

PILOT INPUT 16

OFF

SEQUENCE

INITIATION

Schedule No.

None

None

3

3

7

3

11

27

11

11

WELCOM 600P

CHOWEL CORPORATION - 17 -

Chapter 2. Programming

Program the operation of the welding Timer unit, the weld condition and the constant of the welder to be

used.

Specify the program schedule common to all schedule with X0, and the SCHEDULE NO. and

VALVE/STEP NO. with X1 through X31.

Both the program data and the monitor data are arranged with X and Y addresses defined as shown in the

following chart.

COMM sch1 sch31

C-00

C-34

D-00

D-06

D-20

D-29

SCHEDULE MONITOR

N-00

N-19

SCHEDULE FAULT RECORD

SCHEDULE PROGRAM

A-00

A-38

Common

Program

area

B-00

B-19

STEPPER

Monitor

Area

B-20

B-29

Common

Monitor

area

M-00

M-29

Common

Error history

area

PROGRAM AREA

MONITOR AREA

STEPPER PROGRAM

WELCOM 600P

CHOWEL CORPORATION - 18 -

§1.Common program

This is a program common to all schedules and specified with X0.

Program the data common to all schedules.

1-1. Control constant program

Program the function and constant common the all the schedule.

A-00 LOW CURRENT LIMIT

Set the weld current drop detect level at 100% for the detection as specified.

A-01 HIGH CURRENT LIMIT

Set the weld current over detect level at 100% for the detection as specified.

A-04 BREAK DETECTION COUNTS

To improve the secondary cable disconnection detect precision, set the internal continuous detect

frequency until the signal is actually put out.

A-05 SHORT DETECTION CURRENT

Set the maximum allowable primary current at the weld gun release time to determine the

secondary cable short-circuit.

A-07 TOTAL WELD COUNT

Set the count up output target value of total weld counter common to all the schedule no.

1-2. Program of fault detect method

Set fault detection method among 0 (NEGLECT), 1 (FAULT), 2 (ALARM) to choose.

When detect fault, they become as follows the action according to the setting up.

a. NEGLECT : it do not a notice output, it is not have an influence on the control action.

b. ALARM : ALARM OUTPUT is turned ON, but not have an influence on the control action.

c. FAULT : FAULT OUTPUT is turned ON, the next pilot is stop.

A-20 LOW CURRENT DETECT

Set the detection action to detect the low current.

A-21 HIGH CURRENT DETECT

Set the detection action to detect the high current.

A-22 LOW VOLTAGE IN WELD

Set the detection action to detect the low voltage in weld.

A-23 SECONDARY CABLE BREAK

Set the detection action to detect th secondary cable break.

A constant current control is valid.

WELCOM 600P

CHOWEL CORPORATION - 19 -

1-3. Operation mode program

Set the operation modes common to all the schedule no. with 0(OFF), 1(ON).

A-30 SPEPPER RESET METHOD

Set the reset method for the step counter and weld counter to control the stepper.

For resetting the complete schedule only, set them at 0, and for resetting all schedule, set them at

1.

A-31 PULSE PILOT

If this is set at 0, the self-holding of the pilot input signal will not be made until the weld

initiations.

Input the pilot signal in pulse, for immediate self-holding, set this at 1.

A-32 FAULT RESET BY PILOT

If this is set at 0, initiation will not be made after the fault is put out until reset is made.

For automatic reset of the FAULT output by the next pilot input, set this at 1.

A-33 WELD COMPLETE AT FAULT

If this is set at 0, the WELD COMPLETE output signal after the abnormal end of the weld

sequence will not be turned on.

Set this at 1, to obtain the WELD COMPLETE output signal even in the case of abnormal

end of the weld sequence.

A-34 REWELD AT FAULT

If this is set at 0, the weld sequence will end in one time whether the weld current fault exists or

not.

Set this at 1, to make automatic reweld in the case where the LOW CURRENT fault,

EXTREMELY LOW CURRENT fault, SCR MISS FIRE due to the foreign substance between a

electrode tips, etc.

A-35 WELD COMPLETE AT FAULT RESET

If this is set at 0, the fault reset mode will resets the fault output only.

Set this at 1 to put out the WELD COMPLETE signal too, at the same time.

A-38 RETRACT PULSE PILOT

The case which the pulse input is used to the retract pulse pilot, this item is set at 1.

(Caution: when the retract ON/OFF switch and FOOT switch is ON, this item is able to use)

If this item is set at 0, the retract input is executed as the ON/OFF signal of the input.

Table of contents

Other CHOWEL Welding Accessories manuals

Popular Welding Accessories manuals by other brands

Argweld

Argweld PurgExtra User instructions

ESAB

ESAB A6 Mastertrac instruction manual

Wire wizard

Wire wizard NSW-20.4F-18B-2 Installation & operation manual

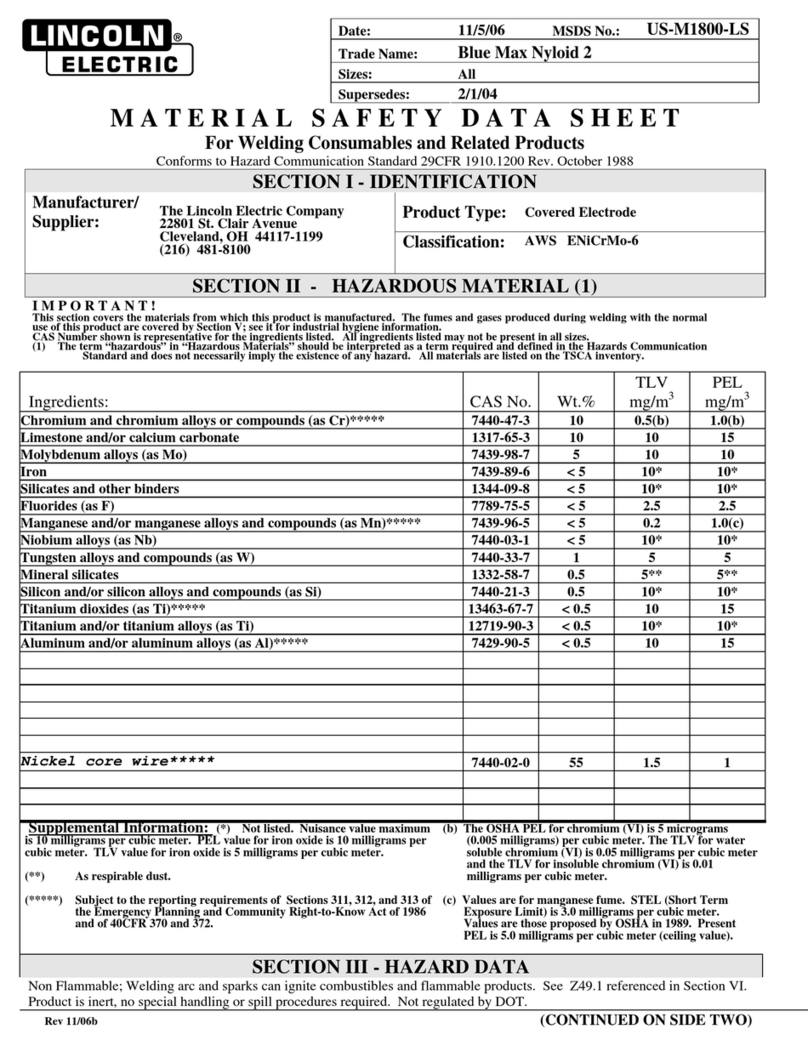

Lincoln Electric

Lincoln Electric K4168-1 Water Cooled 20-250-25R Operator's manual

Lincoln Electric

Lincoln Electric US-M1800-LS datasheet

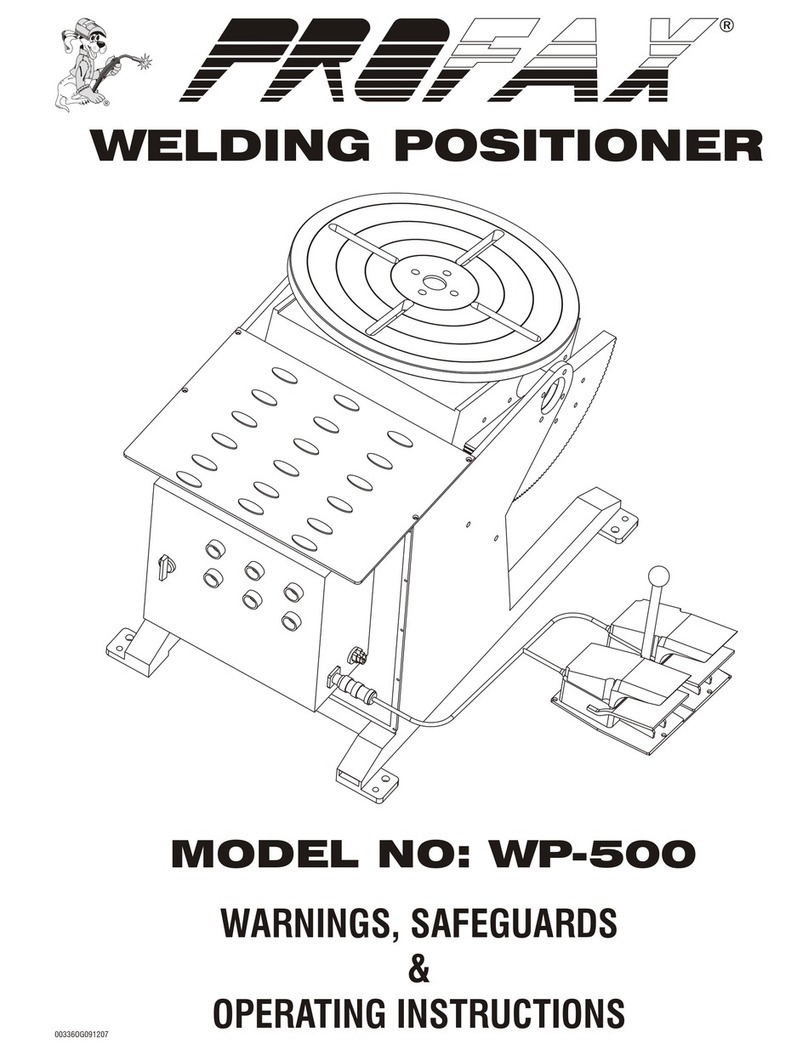

PROFAX

PROFAX WP-500 operating instructions