Sundstrom SR 590 User manual

Other Sundstrom Welding Accessories manuals

Sundstrom

Sundstrom SR 591 User manual

Sundstrom

Sundstrom SR 591 User manual

Sundstrom

Sundstrom SR 590 User manual

Sundstrom

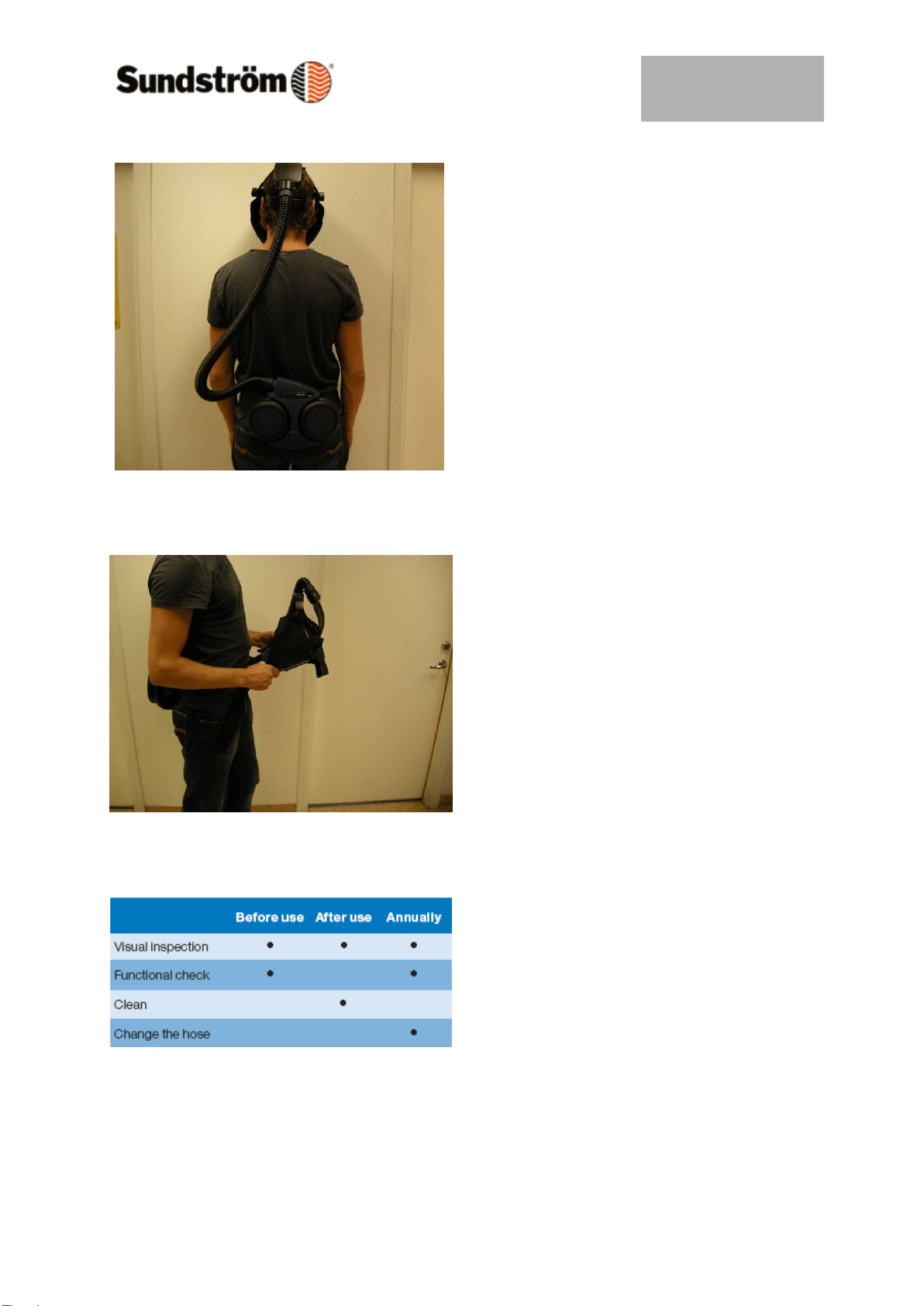

Sundstrom SR 592 User manual

Sundstrom

Sundstrom SR 591 User manual

Sundstrom

Sundstrom SR 584 User manual

Sundstrom

Sundstrom SR 584 User manual

Sundstrom

Sundstrom SR 592 User manual

Sundstrom

Sundstrom SR 592 Technical manual

Sundstrom

Sundstrom SR 590 User manual

Popular Welding Accessories manuals by other brands

Lincoln Electric

Lincoln Electric LT-7 Tractor Technical specifications

Cornwell Tools

Cornwell Tools MMWC1 Operator's manual

Dohle

Dohle ExOn2A operating instructions

Nederman

Nederman Fume Eliminator FE 840/2500/P150 user manual

3M

3M Speedglas 9100 Series user manual

Miller Electric

Miller Electric OM-842 owner's manual

Miller

Miller A-200 Series owner's manual

Abicor Binzel

Abicor Binzel ABIMIG WT Series operating instructions

Miller

Miller MIGmatic M-25 owner's manual

Tregaskiss

Tregaskiss TOUGH GUN TT3 Reamer owner's manual

Abicor Binzel

Abicor Binzel xFUME PRO Original operating instructions

Sealey

Sealey SR20.V2 instructions