CHOWEL WELCOM-250Y User manual

MM-W250Y,Z-041117(E)

MAINTENANCE MANUAL

FOR

RESISTANCE WELDING CONTROLLER

(MODEL : WELCOM-250Y, WELCOM-250Z)

CHOWEL CORPORATION

WELCOM-250Y, Z MAINTENANCE MANUAL

CHOWEL - 2 -

MAINTENANCE MANUAL

FOR

RESISTANCE WELDING CONTROLLER

Important Safeguards

Read and understand the entire contents of this manual, with special

emphasis on the safety material throughout the manual, before installing, operating,

or maintaining this equipment. This equipment and this manual are for use only by

persons trained and experienced in the safe operation of welding equipment. Do not

allow untrained persons to install, operate or maintain this equipment. Contact your

distributor if you do not fully understand this manual.

WARNING

To guard against injury, the following basic safety precautions should be observed

in the instruction manual of the resistance welding controller

CHOWEL CORPORATION. Model : WELCOM-250Y, WELCOM-250Z

598, SUNGGOK-DONG, DANWON-GU, ANSAN-CITY,

KYUNGGI-DO, REPUBLIC OF KOREA

Copyright CHOWEL CORPORATION

ⓒ

1997

First Printing, March 1997 Printed in Korea

WELCOM-250Y, Z MAINTENANCE MANUAL

CHOWEL - 3 -

CHOWEL has developed this document for its licensees and customers. The information contained

herein is the property of CHOWEL and may not be copied, used, or disclosed to others without prior

written approval from CHOWEL and may not be copied, used, or disclosed to others without prior

written approval from CHOWEL. Users are cautioned that the material contained herein is subject to

change by CHOWEL at any time and without prior notice.

The information contained herein is the property of CHOWEL and shall not be reproduced in whole of in

part without prior written approval of CHOWEL. The information contained herein is subject to change

without notice and should not be constructed as a commitment by CHOWEL.

CHOWEL assumes no responsibility for any errors or omissions in this document.

☞Contact your sales agent for individual warranty coverage.

WHO DO I CONTACT?

CHOWEL CORPORATION

598, SUNGGOK-DONG, ANSAN-CITY,

KYUNGGI-DO, REPUBLIC OF KOREA

ZIP CODE : 425-110

PHONE : 82-31-493-9911 FAX : 82-31-495-2518

WELCOM-250Y, Z MAINTENANCE MANUAL

CHOWEL - 4 -

READ FIRST

To use this welding controller in safety, the operator should follow industry

standards and safety senses whenever working on, or near the weld machine.

In some case, failure to follow the warning instruction can lead to control or

machine damage. In other cases failure to follow these instructions can lead to

injury, or death of personnel.

Some examples of safe practices are listed below. These examples are not to be

considered a comprehensive listing of safety practices.

Always use safety senses when working with any type of machinery.

DANGER

During electrical power is ON, this welding controller is charged with high

voltage electricity. Turn electrical power OFF before open the door.

In the case the door is opened as it is not turn OFF can lead to injury by an

electric shock, or death of personnel.

WARNING

In some case failure to follow these instructions as follows can lead to control

damage or injury of personnel.

1. Ensure that control / machine is connected to the correct voltage before turning

electrical power ON.

2. Whenever power is ON, stand clear of moving parts.

This practice should be used even if the machine is not actually in use.

3. Before turning electrical power OFF, ensure that personnel are standing clear of

moving parts that are pneumatic or hydraulic powered.

4. Whenever electrical power is turned OFF, install a "lock-out" device at the

main disconnect to prevent power from being accidentally turned ON.

WELCOM-250Y, Z MAINTENANCE MANUAL

CHOWEL - 5 -

CAUTION

1. Turn electrical power OFF before changing the tap switch at the weld

transformer.

In the case failure to follow the instruction like a welding at changing the tap

switch can lead to injury to personnel.

2. Turn stop cock OFF before some piping work.

In the case failure to follow the instruction like the electrical circuit is splashed

with cooling water can lead to control damage.

CAUTION

Magnetic fields

It should be borne in mind that welding machine generates intense magnetic fields.

Consequently, “Do not approach the secondary circuit” of the machine carrying on

your person any article that are likely to suffer damage.

These include the following:

-Any kind of magnetic card or badge, for example credit card, bank card,

magnetic strip telephone card, personal recognition cards, magnetic clocking-on

cards, company permits, passes, etc.

-Any kind of magnetic tape or media, for example cassette, video cassette, floppy

disk, etc.

-Any kind of delicate mechanism, for example electronic calculators, cameras,

motion picture cameras, television cameras, watches (especially mechanically

driven ones).

RISK OF ELECTRIC SHOCK

It shows readers where people will be struck by an electric

shock if procedures are not followed properly.

WELCOM-250Y, Z MAINTENANCE MANUAL

CHOWEL - 6 -

CONTENTS

1. Specification of WELCOM-250Y,Z ······································· 7

2. Fault detection ······························································· 11

3. Circuit diagrams ····························································· 15

4. TB30 ·········································································· 31

5. RB10············································································ 34

WELCOM-250Y, Z MAINTENANCE MANUAL

CHOWEL - 7 -

1. Specification of WELCOM-250Y,Z

1-1 Voltage and Frequency

. Welding power supply : Single phase AC440±15%

50/60Hz Automatic selection

. Control power supply : Unnecessary due to be fed from a

voltage dropped welding power supply.

. Power consumption : 50VA (No working condition)

1-2 Environments

. Temperature : -5℃∼+ 50℃( 23℉∼122℉)

. Humidity : 90% or less without dewing

1-3 Cooling Condition

. Controller : Natural air cooled

. SCR : Water cooled

Temperature at water inlet : 30℃or less

(86℉or less)

Quantity of water : More then 5 liters per minute

(More then 1.321 gallons per minute)

Cooling water pressure : Max. 3Kgf/㎠

Resistively : More then 5000 ohms/centimeter

(More then 1969 ohms .inch)

1-4 Control Element : SCR size D

(900A / 1200V 100% duty cycle)

1-5 Current Control System : Synchronous phase control by SCR.

1-6 Weld current control method

. Constant current control : Loop control by primary current feedback

. Voltage compensation control : Open-loop control by measuring

welding power supply.

1-7 Control Range

. Firing angle control range : 20 - 135 degrees

. Pri, current control range : 50 - 1500amps (limit by SCR size)

. 2nd current control range : 2.0 KA - 25.5 KA

. Turn ration of transformer : 1.0 - 199.9

WELCOM-250Y, Z MAINTENANCE MANUAL

CHOWEL - 8 -

. Time range Initial squeeze time : 0 - 99 CYC

Squeeze time : 1 - 99 CYC

Up-slope time : 0 - 30 CYC

#1 weld time : 0 - 99 CYC

Down slope time : 0 - 30 CYC

#2 weld time : 0 - 99 CYC

Hold time : 1 - 99 CYC

Weld complete delay time : 0 - 99 CYC

Off time : 1 - 99 CYC

1-8 Input signals

. Pilot : 4 (14 schedule, binary 4 bit)

. Weld/No weld : 1

. Count reset : 1

. Stepper reset : 1

. Fault reset : 1

. External thermo : 1

. Input open circuit voltage 24V DC

. Input short circuit current 12mA

1-9 Output signals

. Gun valve : 2

Gun valve output capacity 24V DC, 0.5A

. Weld complete : 1a

. Count up : 1a

. Stepper complete : 1a

. Fault : 1a

. Alarm : 1a

. Contact load voltage AC130Vrms, DC170V(Cont.max.value)

. Contact load current 0.15A (Cont. max. value)

1-10 Stepper

. Stepper schedule : 14

. Number of step : 10 (Including #0 of first step)

. No. of weld count per step : 0 to 9999 (#0 : 1 to 9999)

. Current ratio : based on step #0 * 50% to 200%

. Stepper reset : Select completed stepper or all

stepper

WELCOM-250Y, Z MAINTENANCE MANUAL

CHOWEL - 9 -

1-11 Counter

. Total weld counter : 1 / 1 to 99,999,999

. Each schedule counter : 14 / 1 to 99,999,999

1-12 Fault detection

. Controller failure : Fault output

. Internal power failure : Fault output

. Internal parts failure : Fault output

. Low line voltage : Alarm output

. Illegal power frequency : Fault output

. Low voltage in weld : Fault output

. Memory data error : Fault output

. Current program error : Fault output

. No current : Fault output

. SCR short : Fault output

. 2nd cable break : Alarm output

. 2nd cable short : Fault output

. SCR over temperature : Fault output

. Extremely low current : Fault output

(Less then 50%)

. Low current : Fault output

. High current : Fault output

. Communication error : Fault output

. Undefined error : Fault output

1-13 Monitor

. Monitor according to each schedule

C.T input gain : 1 to 16 (2,880 to 180amp FS)

Weld power factor : 0 to 90 degree

Weld T/R margin : 0 to 99 %

Test current : 0 to 25,500 amp

Average test current : 0 to 25,500 amp

Times judged cable breaking : 0 to 9 times

Each schedule weld count value : 0 to 99,999,999

. Common monitor

#1 weld time : 0 to 99 CYC

#2 weld time : 0 to 99 CYC

Index no. : 0 to 255

WELCOM-250Y, Z MAINTENANCE MANUAL

CHOWEL - 10 -

Schedule no. : 1 to 14

Fault code : 0 to 99

Total weld count value : 0 to 99,999,999

Target control current, #1,#2 weld : 2.0KA to 25.5KA

Average Firing angle, #1,#2 weld : 20 to 150 degree

Average extinction angle, #1,#2 weld : 0 to 90 degree

Average conducting angle, #1,#2 weld: 0 to 180 degree

Average weld current, #1,#2 weld : 2.0KA to 25.5KA

Average power supply, #1,#2 weld : 75% to 125%

1-14 Fault recording function

. Fault code number : The lasts 10 per each schedule.

. Weld schedule number : The lasts 10 of fault schedule number.

1-15 Memory data maintenance

. Battery : Lithium battery

. Life time : More than 5 years

WELCOM-250Y, Z MAINTENANCE MANUAL

CHOWEL - 11 -

2. Fault detection

Fault is checked for at the time of power on, inactive status, start and

sequence end and alarm the detection according to its cause.

2-1 Fault detection items

The followings are the typical times, details and remedies of fault

for each fault code. Use them for troubleshooting.

. E01 CONTROLLER FAILURE

This fault is checked for when the power is turned on.

If the fault is fatal due to the detect of the memory I.C, output

to or communication with the external will be impossible.

If the controller failure indicator will be turned ON and the

communication to the external is impossible, replace the timer unit.

. E02 INITIAL POWER FAILURE

This fault is checked for when the power is turned on, and alarmed

immediately, if any.

This fault indicates that there is a trouble with the control power built

in the welding controller.

Replace the welding controller.

This fault can not be reset. To make sure of normal operation of

the new controller, turn ON the power again.

. E03 INTERNAL PARTS FAILURE

This fault is checked for when the power is turned on, and alarmed

immediately, if any.

This fault indicates that there is a trouble with some parts in the timer unit.

Replace the timer unit.

This fault can not be reset. To make sure of normal operation of

the new controller, turn ON the power again.

. E10 LOW LINE VOLTAGE

This fault is checked for when the power is turned on, and alarmed

immediately, if any.

This fault indicates that the weld line voltage dropped below the

lower limit for at least several second.

Check whether the weld line voltage matches up to the rated voltage or not.

WELCOM-250Y, Z MAINTENANCE MANUAL

CHOWEL - 12 -

. E11 ILLEGAL POWER FREQUENCY

This fault is checked for when the power is turned on, and alarmed

immediately, if any.

This fault indicates that the weld line frequency could not be

identified when the power is turn on.

Check whether the power supply is unstable or not.

Reset this fault by turning ON the power again.

. E12 LOW VOLTAGE IN WELD

This fault is checked for when the power is turned on, and alarmed

immediately, if any.

This fault indicates that the power has been shut OFF during the

welding or the drastic voltage drop was caused. Check whether

the weld during the power shut-off is defective or not.

. E20 MEMORY DATA ERROR

This error is checked for when the power is turned ON, and

initiation, and alarmed immediately, if any.

This error indicates that the data in the memory was destroyed

or is outside of the specified range.

Reset the whole area of the program and monitor whether it has

been used or not.

. E21 CURRENT PROGRAM ERROR

This error is checked for during the weld current control, and

alarmed when sequence ends.

This error indicates that the current set value excesses the controllable range

during the constant current control calculation processing.

Check whether the current and the weld transformer turns ratio

have been properly set or not.

. E30 NO CURRENT FAULT

This fault is checked for during the weld current control, and

alarmed when the sequence ends.

This fault indicates that the weld current was excessively low due to dirt

caught by the electrode tips or the thyristor failed in firing control.

Check whether there is dirt caught by the electrode tips or the initial

squeeze time is sufficient or not.

WELCOM-250Y, Z MAINTENANCE MANUAL

CHOWEL - 13 -

. E31 SCR SHORT

This fault is checked for always while welding is not active, and

alarmed immediately, if any.

This fault indicates that the thyristor came to be short circuited.

Replaced the thyristor and check whether the weld current is

above the rated current or not.

. E40 SECONDARY CABLE BREAK

This fault is checked for when the welding ends, and alarmed at the end of the sequence.

This fault indicates that the disconnection of the secondary cable is imminent.

The imminent disconnection is predicted based on the probability.

Before replacing the secondary cable.

Check the impedance again for the reconfirmation purpose.

. E41 SECONDARY CABLE BREAK

This fault is checked for when the secondary cable short circuit test is made,

and alarmed immediately, if any.

This fault indicates that the secondary cable is short circuited or almost short circuited.

Replace the secondary cable.

. E50 SCR OVER TEMPERATURE

This fault is checked for at the initiation, and alarmed

immediately, if any.

This fault indicates that the thyristor or the weld transformer is over temperature.

Check the duty factor and the temperature and flow of the coolant.

. E60 EXTREMELY LOW CURRENT

This fault is checked for during the weld current control ends,

and alarmed when the sequence ends.

This fault indicates that the weld current was excessively small.

Check the weld cable for disconnection the weld and the electrode for dirt.

. E61 LOW CURRENT

This fault is checked for during the weld current control ends,

and alarmed when the sequence ends.

This fault indicates that the weld current was below the low current limit level.

Check the weld cable for disconnection the weld and the electrode for dirt.

WELCOM-250Y, Z MAINTENANCE MANUAL

CHOWEL - 14 -

. E62 HIGH CURRENT

This fault is checked for when the weld current control ends,

and alarmed when the sequence ends.

This fault indicates that the weld current is above the high current limit level.

Check whether the weld current and the over current detect set

level have been set properly or not.

. E98 COMMUNICATION ERROR

This fault is always checked for, but the indication is made only in DSTB or DSRB and

the timer unit does not alarm this fault because it continues the control operation.

This fault indicates that there is a trouble with communication.

Check the communication connector and the communication cable for disconnecting.

. E99 UNDEFINED ERROR

This indicates the reserve code in which the fault codes are not classified or defined.

Record the operation status when this fault occurred and replace the welding controller.

2-2 If any of the followings is the case, the fuse may be blown.

a. When the power is turned ON, there is no I/O indication.

Check the primary protection fuse (F1) in the contactor for blowing.

b. When any schedule is activated, the valve indicator is turned on,

but the weld gun does not press at all.

Check the press circuit protection fuse (F1) in the printed

circuit board of the timer for blowing.

c. When the power is turned ON, neither T/B nor R/B indicates at all.

Check the T/B and R/B power protection fuse (F2) in the PCB

of the timer for blowing.

WELCOM-250Y, Z MAINTENANCE MANUAL

CHOWEL - 15 -

3. Circuit diagrams

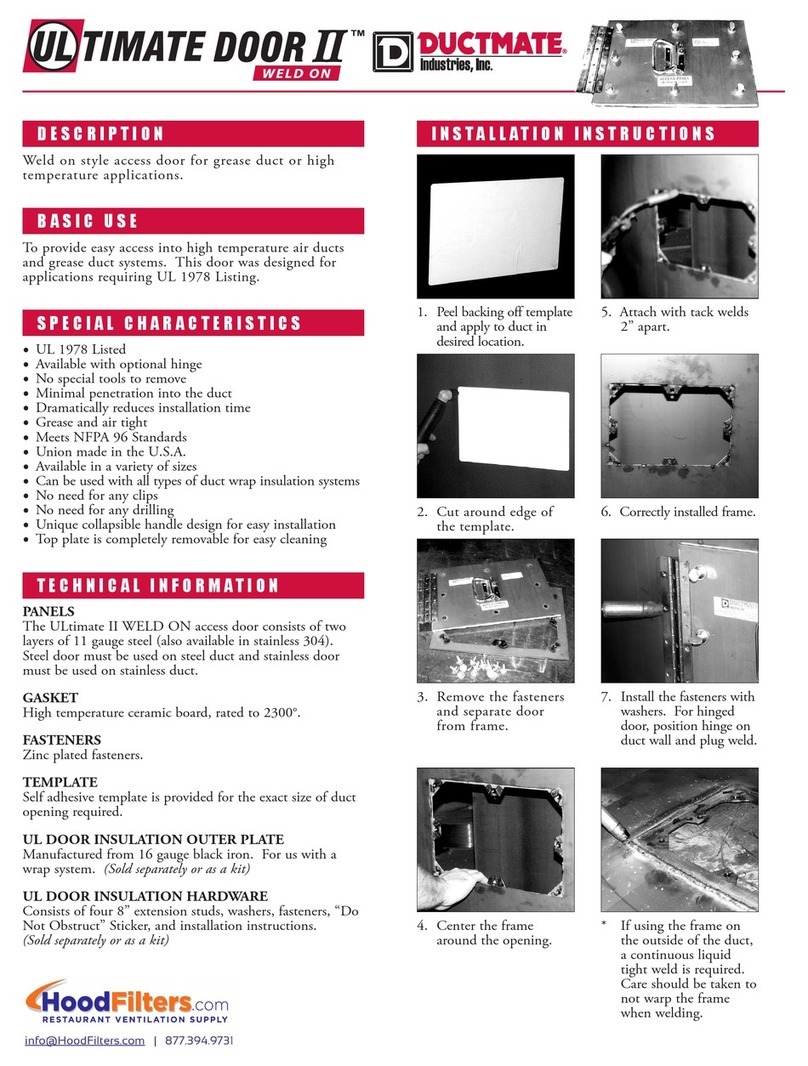

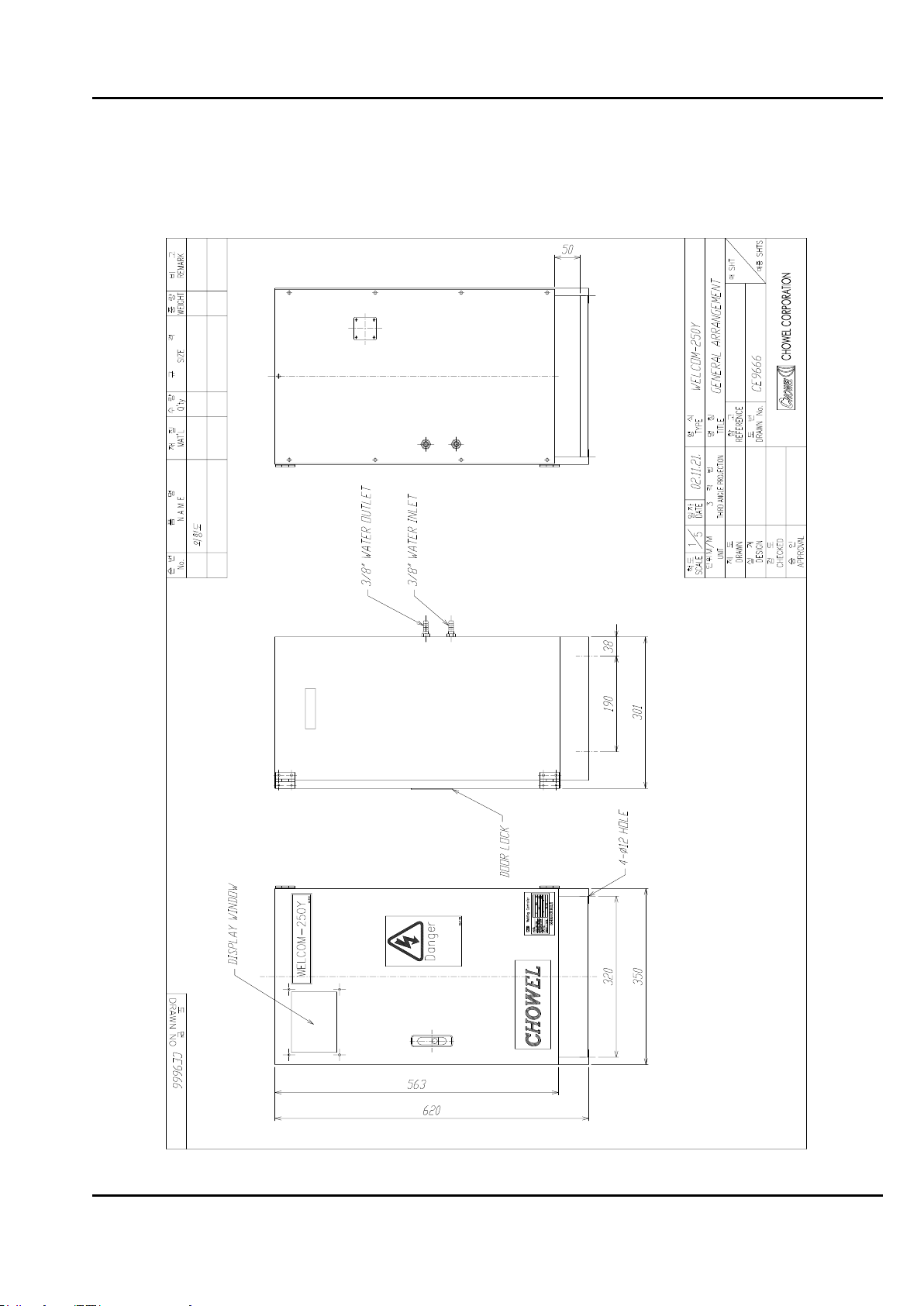

3-1 Layout diagram for WELCOM-250Y

WELCOM-250Y, Z MAINTENANCE MANUAL

CHOWEL - 16 -

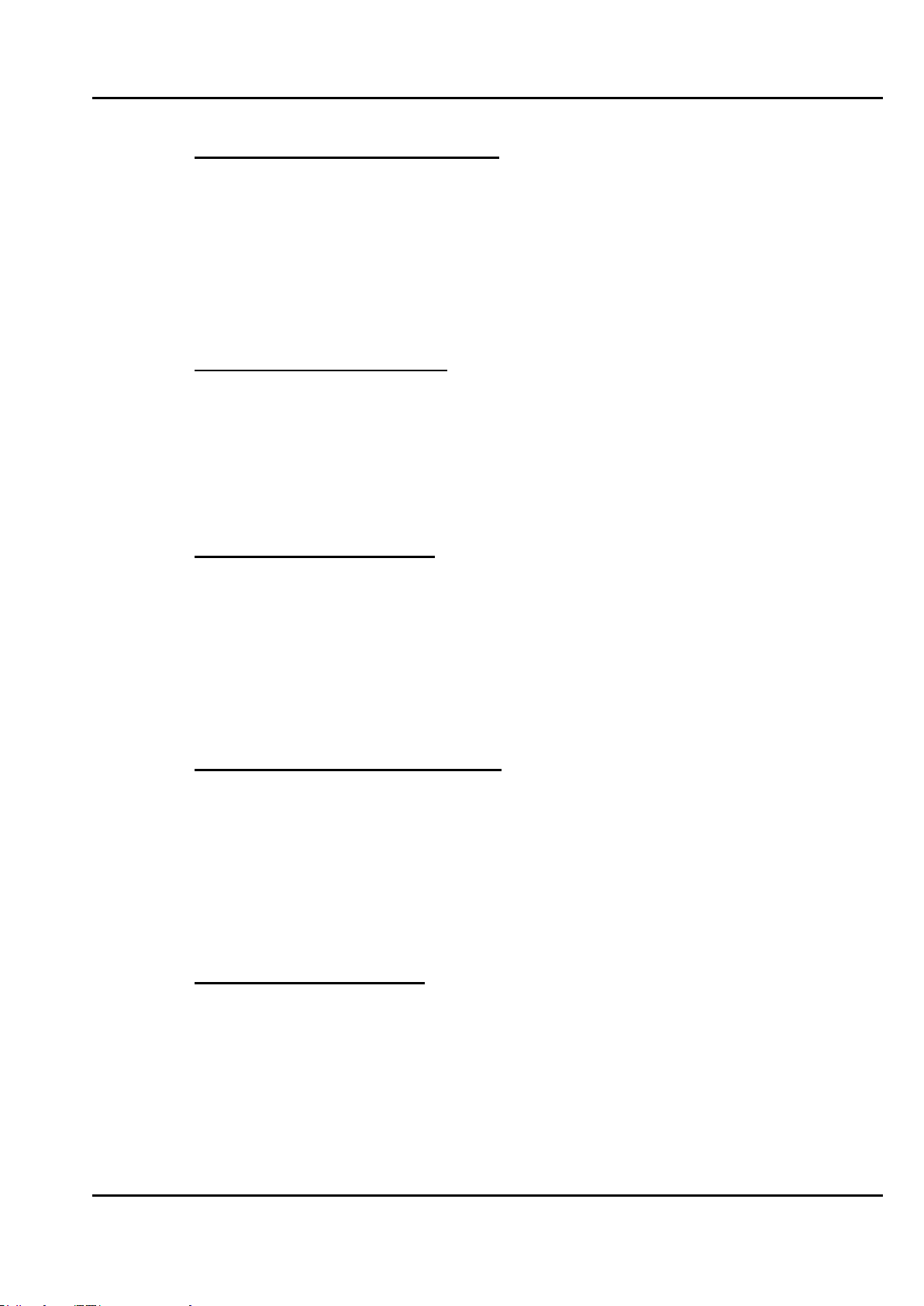

3-2 Layout diagram for WELCOM-250Z

WELCOM-250Y, Z MAINTENANCE MANUAL

CHOWEL - 17 -

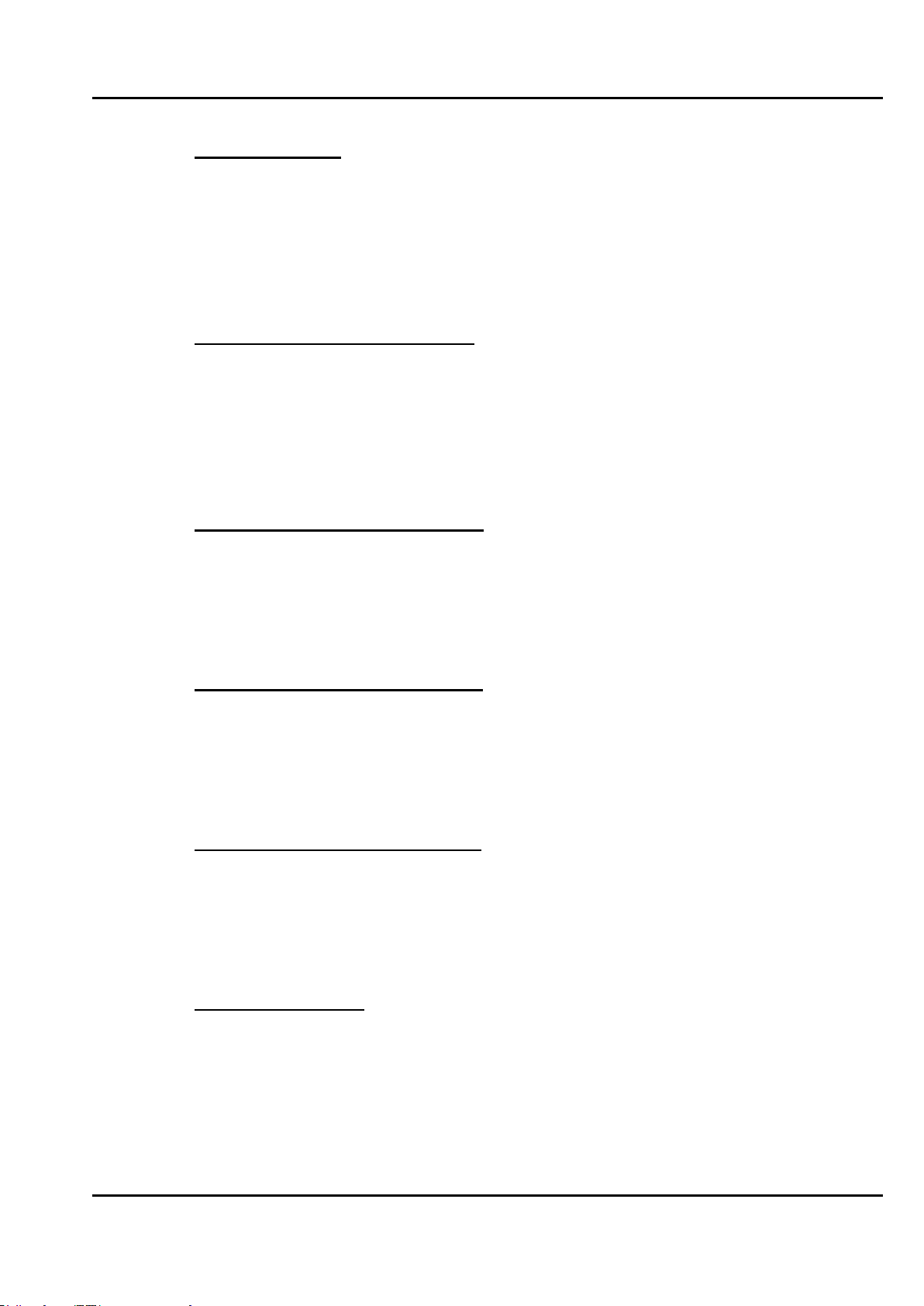

3-3 Timer unit and I/O display

WELCOM-250Y, Z MAINTENANCE MANUAL

CHOWEL - 18 -

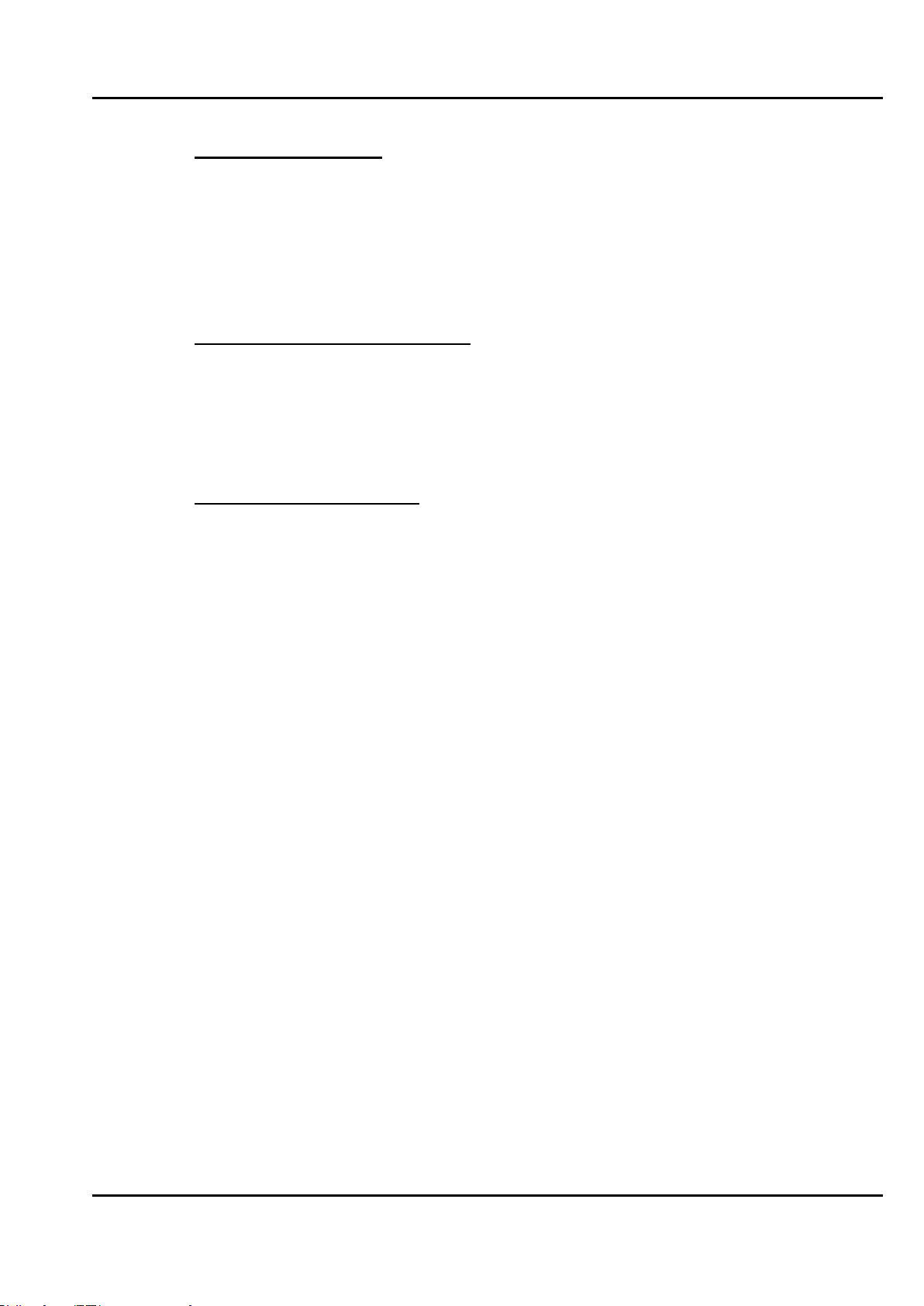

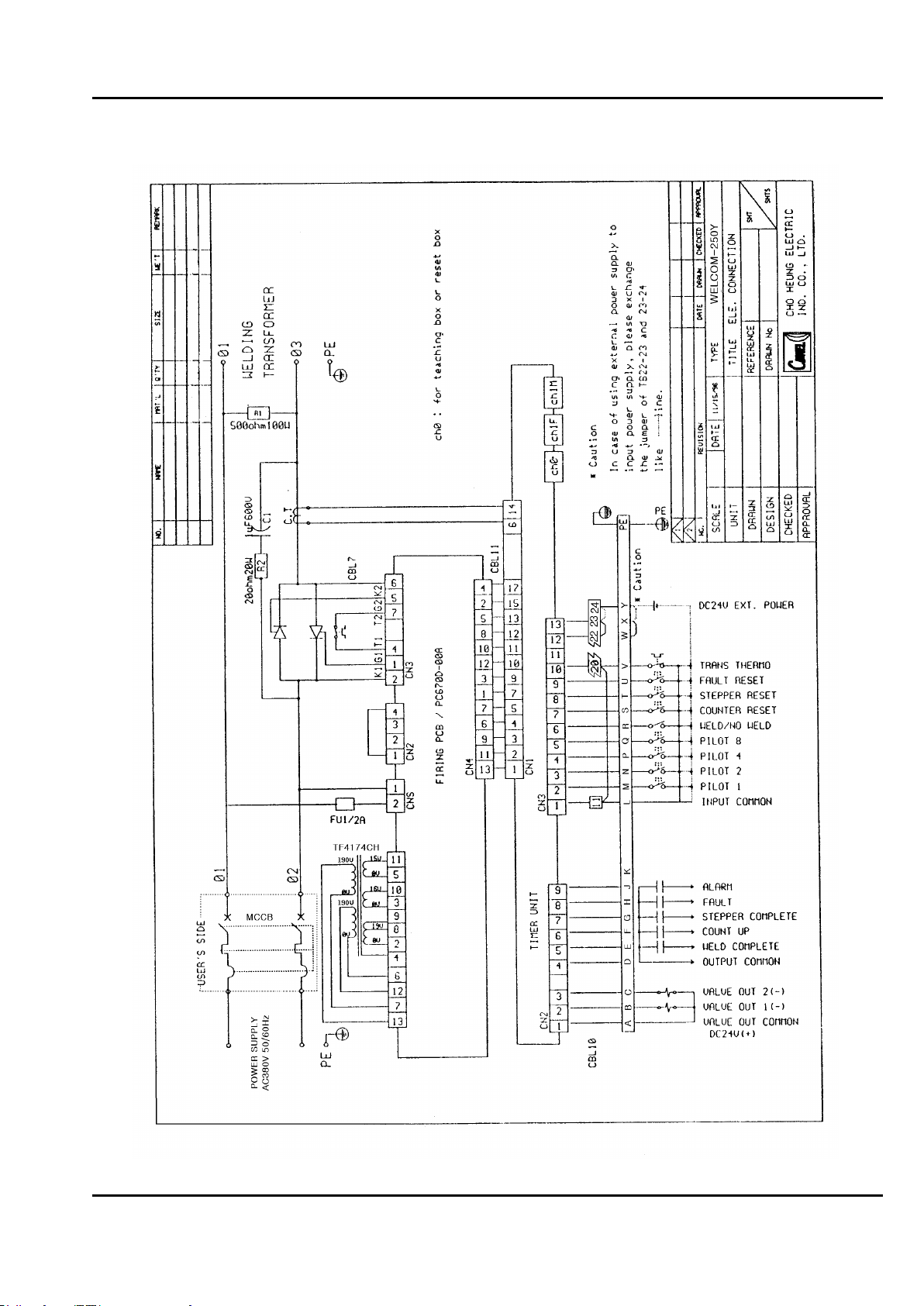

3-4 Electrical connection for WELCOM-250Y

WELCOM-250Y, Z MAINTENANCE MANUAL

CHOWEL - 19 -

3-5 Electrical connection for WELCOM-250Z

WELCOM-250Y, Z MAINTENANCE MANUAL

CHOWEL - 20 -

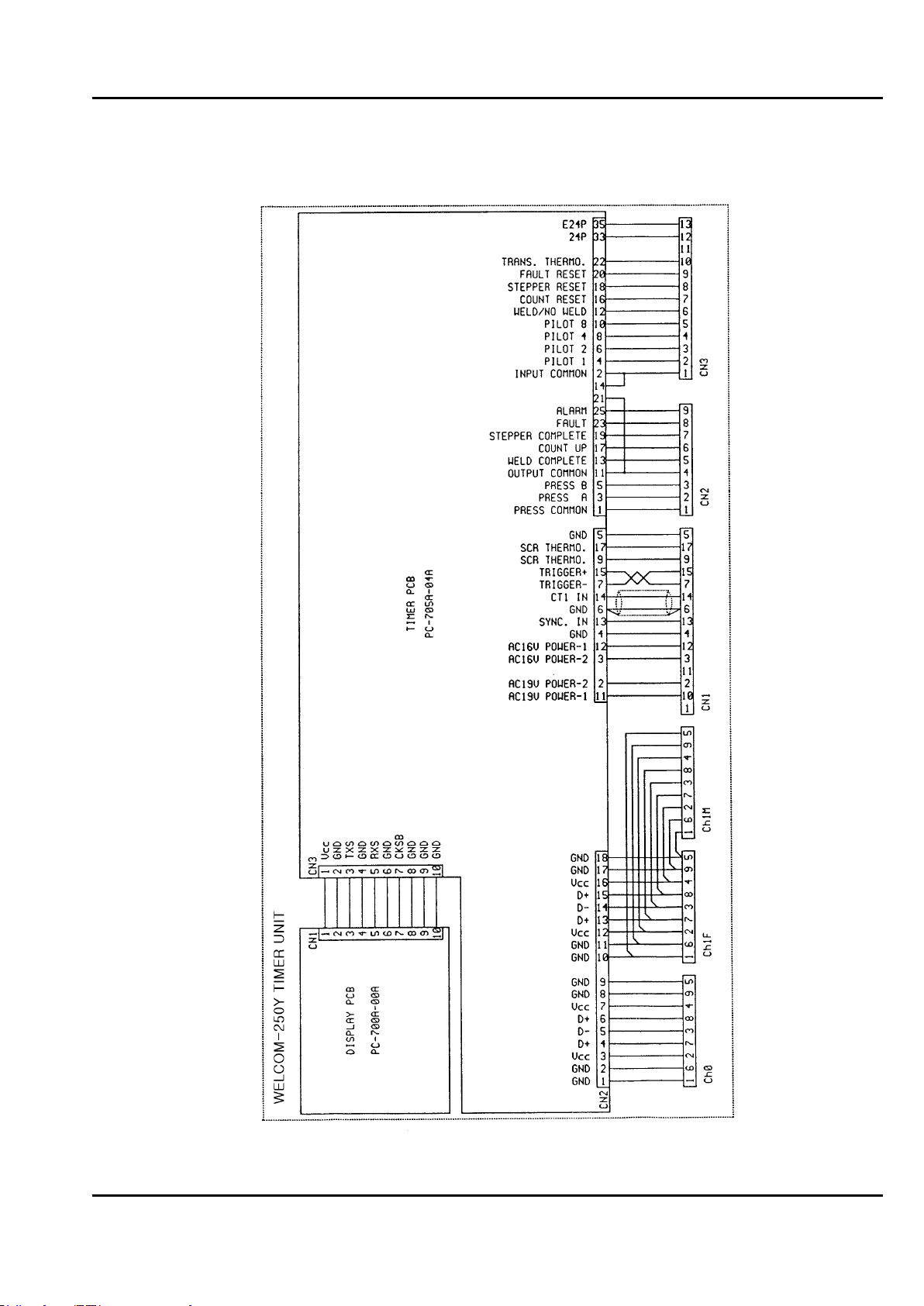

3-6 Connection diagram for WELCOM-250Y timer unit

This manual suits for next models

1

Table of contents

Other CHOWEL Welding Accessories manuals