Cod. 006.0001.2020

16/11/2021 V.2.1

Discovery 220T Evo/VRD Evo

Discovery 300T Evo/VRD Evo

9

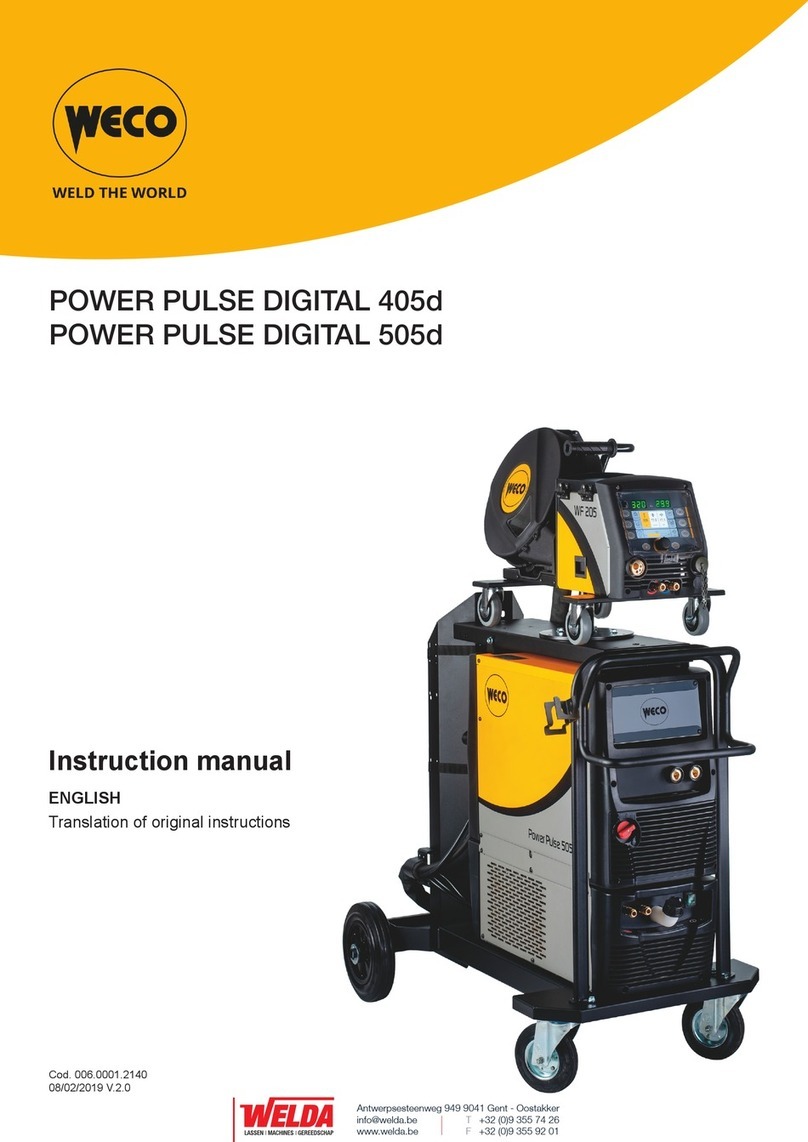

2.5 PREPARING FOR TIG WELDING

NOTE: For the cooler to power source assembly procedure refer to the cooler instruction

manual.

1. SettheweldingpowersourceON/OFFswitchto“O”(unitde-energized).

2. Plugthepowercableplugintoamainssocketoutlet.

3. Connectthegashosefromtheweldinggascylindertothereargassocket.

4. Open the cylinder gas valve.

5. Choosetheelectrodebasedonthetypeofmaterialandthicknessoftheworkpiecetobewelded.

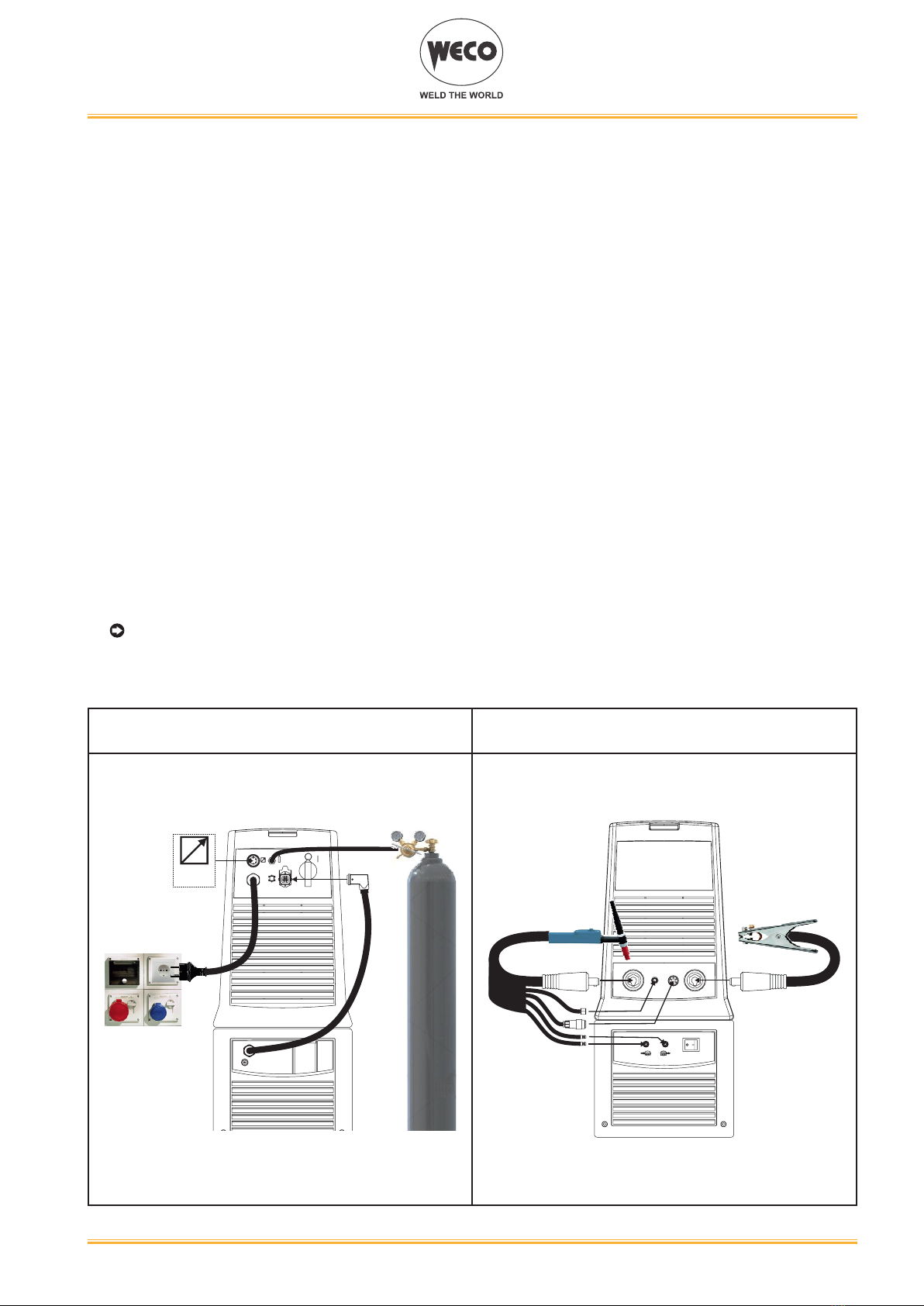

6. Insert the electrode in the TIG torch.

7. Connectthetorchplugtotheweldingsocketonthebasisofthepolarityrequiredbythetypeof

electrode in question.

8. Connecttheplugofthegroundclamptotheweldingsocketonthebasisofthepolarityrequired.

9. Connectthegashosefromtheweldingtorchtothefrontgassocket.

10.ConnecttheweldingtorchconnectortotheTIGtorchsignalsconnector.

11.Connecttheearthclamptotheworkpiecebeingprocessed.

12.SettheweldingpowersourceON/OFFswitchto“I”(unitpowered).

13.Selectthefollowingweldingmodeontheuserinterface:DCTIG

14.Pressthetorchtriggerwiththetorchwellclearofanymetalparts.Thisservestoopenthegas

solenoidvalvewithoutstrikingtheweldingarc.

15.Usetheowcontrolvalvetoadjusttheowofgasasrequiredwhilethegasisowingout.

16.Settherequiredweldingparametervaluesontheuserinterface.

Whentheremotecontrolpedalisconnectedandtherelativelockingscrewistightenedtheweld-

ingcurrentwillvaryinrelationtothepressureexertedonthepedal.

Thesystemisreadytostartwelding.

REAR VIEW FRONT VIEW

(polarity for tungsten electrode)

REMOTE

CONTROL