CHP Extra 300S User manual

Chip Hyde Products

34% Competition Series Extra 300S ARF

ASSEMBLY MANUAL

Copyright 2005 - Chip Hyde Products

Distributed by:

Chip Hyde Products Phone: (520)-458-1414

Visit the Web: www.chiphyde.com

&

Aeroworks Phone: (303) 366-4205

Fax: (303) 366-4203

Visit the Web: www.aero-works.net

E-mail: [email protected]

Warning

An R/C aircraft is not a toy! If misused, it can cause serious bodily harm and damage to property.

Fly only in open areas, preferably AMA (Academy of Model Aeronautics) approved flying sites,

following all instructions included with your radio and engine.

2

Contents of Manual

Cover page

Introduction

-Intended Use

-Warranty

Kit Contents

-Parts

-Hardware Bags

Building Instructions

-Beginning Construction

-Wing Assembly

-Elevator Servo Installation

-Stab and Elevator Assembly

-Rudder Servo Installation

-Cowl Mounting

-Motor Standoffs

-Motor Installation

-Cowl Air Lets Inlets

-Landing Gear and Skirt Installation

-Wheel Pant Installation

-Wing Attachment

-Canopy Installation

-Throttle Servo

-Belly Pan Installation

-Muffler Installation / Canister

-Fuel Tank Installation

Control Throws

C.G.

Flying

3

Introduction

Before starting the assembly process of your new 34% Extra 300S ARF, Please read through the assembly

manual carefully, and inspect all parts and hardware for imperfections or damage.

The competition series Extra 300S is a highly aerobatic airplane designed and sold by world-renowned

aerobatic RC pilot Chip Hyde who is a multiple USA National, World and TOC champion. This plane is fully

capable of both precision aerobatics and extreme 3-D aerobatics.

The Extra features rapid assembly due to plug-on wings and plug-on stabs that not only make it quick, but

easy and accurate to construct. The wings and stabilizers slide onto pre-fitted tubes and are aligned by pre-installed

anti-rotation pins. There is a minimal amount of gluing and drilling required to complete the assembly. This greatly

reduces the time to assemble and get you to the flying field.

The Extra can be disassembled and broken down into two wing panels, two stabilizer halves and a fuselage

to facilitate transportation in almost any size of vehicle. The larger the vehicle, the less you will need to remove!

Assembly at the field is greatly simplified with easy access to the inner fuse wing retention and. One ball-

wrench, a flat blade screw driver, a couple of minutes of assembly and a tank of 2-cycle gas will get you into the air.

The plane is designed for gas motors in the 100-cc category. The recommended motor is the DA 100 that is

shown in the assembly instructions. The final choice of power plant is left up to the builder.

A computer radio is recommended for the Extra. This is primarily so the Pilot can take advantage of the full

capabilities of this plane.

Intended use

This plane should not be regarded as a toy. This is an advanced aerobatic plane and is recommended for pilots who

are well beyond the trainer-stage and are comfortable with flying at least an aerobatic sport plane.

Warranty

It is important to notify Chip Hyde Products of any damage or problems with the

model immediately. If you wish to return this aircraft for any reason a 15% restock fee will

be charged to the customer. In addition the customer is responsible for all return shipping

cost and all prior shipping cost will not be refunded. Parts will be exchanged/replaced once

the original item is returned at the owner’s expense.

If you have any problems, contact CHP at (520)-458-1414

CHP cannot insure the skill of the modeler and can not direct the builder during the

construction or use of this aircraft, therefore, will not be accountable for any property

damage, bodily injury or death caused by this aircraft.

The purchaser/operator accepts all responsibility of any and

all structural or mechanical failures.

4

Kit Contents

Parts:

Canopy - unpainted

2 x Wings

2 x Ailerons

2 x Stabs

2 x Elevators

1 x Fin

1 x Rudder

1 x Fiberglass cowl

1 x Fuselage

1 x Front Hatch cover

1 x Rear Hatch cover

1 x Rear Hatch cover bottom plate

1 x 1.5” Aluminum wing-tube

1 x .5” Carbon Stab tube

1 x 10.5” x 1/4" Stab anti-rotation rod

1 x Polished Aluminum Landing gear

2 x Fiberglass Wheel pants

1 x Fiber Glass Canister tray

5

Hardware bags included:

Wheel bag

2 x wheels

2 x axles with nuts

4 x wheel collars with set screws

1 x anodized titanium tail wheel

4 x wood screws

2 x tail wheel steering springs

Landing gear

1 x tail wheel

6 x small wood screws

3 x medium wood screws

1 x tail wheel steering horn

2 x tail wheel springs

Wheel pant attachment bag

2 x wheel pant stiffeners

4 wood screws

Fuel tank and servo trays bag

1 x Fuel tank tray

2 x Rudder servo trays (different

sizes)

4 x aileron servo trays

2 x elevator servo trays

Control horn bag

8 x Anodized BB control horns

8 x 4-40 clevises

24 x Wood screws

Canopy screw bag

12 x small wood screws

Landing gear bolt bag

5 x machine screws

5 x split washers

Hatch cover screw bag

4 x machine screws

4 x flat washers

Wing attachments bag

2 x small front wood blocks

2 x large rear wood blocks

4 x anti rotation pins

4 x anti rotation pin locks

Cowl attachment bag

6 x machine screws

6 x blind nuts

Fillets bag

16 x small wood screws

2 x Upper landing gear fillets

2 x Lower landing gear fillets

2 x Cowl air lets

Screw bag

16 x small wood screws

4 x machine screws for stabs

6

Items needed to complete the Extra

100 cc Motor and Propeller

4" spinner

1 x 32 oz Fuel Tank (Gas)

Push rods

Ailerons - 4 x 2.5” pushrods

Elevators - 2 x 2.5” pushrods

Throttle -

Rudder - 1 x Heavy Duty Pull-pull 4-40 cable wires kit Dubro #

4 x aileron servos (100 Inch oz min)

2 x rudder servos (130 Inch oz min)

2 x elevator servos (150 Inch oz min)

1 x throttle servo (65 Inch oz high quality) Fast

Extension leads Wings - 2 x Y harnesses, 2 x 18”, 2 x 6”

Stabs - 2 x 36”, 2 x 12”

Throttle - 12”

Other - 2 x 12” battery extensions (depending on battery placement)

Receiver PCM

Receiver Battery

Ignition battery

2 x Charge Switches Heavy Duty

4 x 4-40 x 1/2” bolts and blind nuts for wheel pant retention.

Tools needed to complete:

Modeling knife

Electric hand drill and selection of bits

Masking tape

Phillips screwdriver (Small and medium)

Flat head screwdriver

Pliers

Allen wrenches USA and Metric.

Dremel sanding drum tool

Scissors

Wire Cutters

T pins

Ruler

Pen, pencil or fine tipped marker

Rubbing alcohol

Paper towels

Adhesives:

Thin CA

Medium CA

Thick CA

CA kicker (optional)

5 Minute epoxy

RC-56 canopy glue (optional)

7

Beginning Construction of the

Competition Series Extra 300S

TIGHTENING AND RE-SHRINKING THE COVERING

Open your kit slowly and take care not

to damage any parts of the kit. Remove all

parts from their plastic protective covers for

inspection. Before doing any assembly or

installation of any decals it is very important

to re-shrink or re-tighten the already applied

covering. Due to the shipping process, heat

and humidity changes from different

climates, the covering may become lose and

wrinkle in the sun. If you take the time to re-

tighten the covering, you will be rewarded

with a long lasting beautifully covered

model.

Using your covering iron with a soft

sock, gently apply pressure and rub in the

covering. If any bubbles occur, your iron

may be to hot, reduce heat and work slowly.

If bubbles persist, using a small pin, punch

holes in the bubble to relieve trapped air and

reheat.

After you have tightened up the

covering, it is time to start the assembly of

your Extra 300S.

8

WING ASSEMBLY

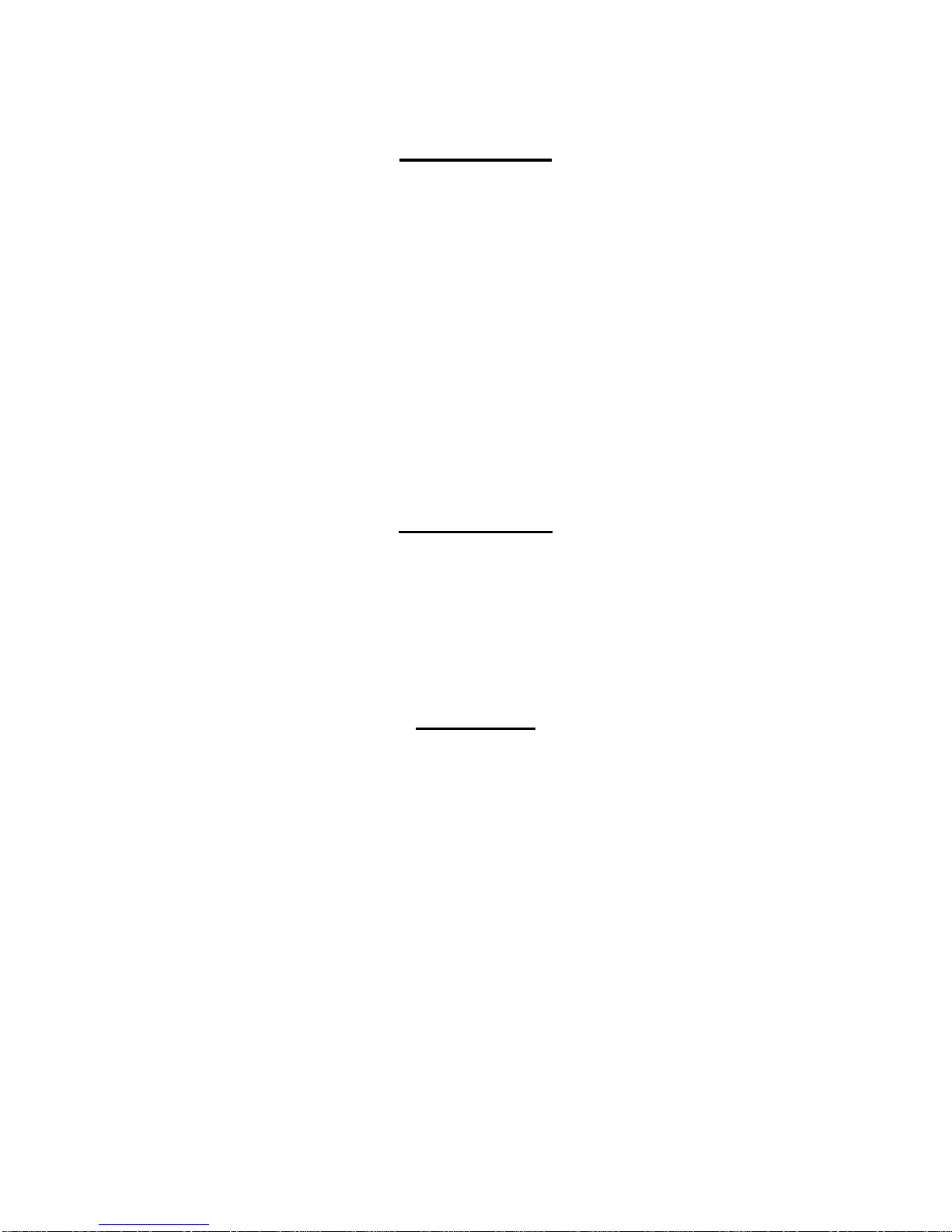

1) Locate the pre cut hinge slots in the

wing and aileron. The model comes

with CA style hinges pre installed, but

not glued into the control surfaces. We

have used the provided CA hinges with

no problems. Hinge ailerons by first

pushing a T pin through the center of all

CA hinges. Make sure that slot in hinge

runs perpendicular to hinge line. This

allows CA to wick to the back of the

hinges.

Hinge Slot

2) Next, slide hinges into aileron slots, then

slide aileron onto wing making sure all

hinges go into their slot. Also, keep the

hinge line as tight as possible.

3) Be sure to leave a 1/16” gap between the

wing and the aileron at the root end to

avoid binding.

9

4) Next, place 4-6 drops of thin CA on

each side of all hinges. We also

recommend using a clear covering to

seal all control surfaces.

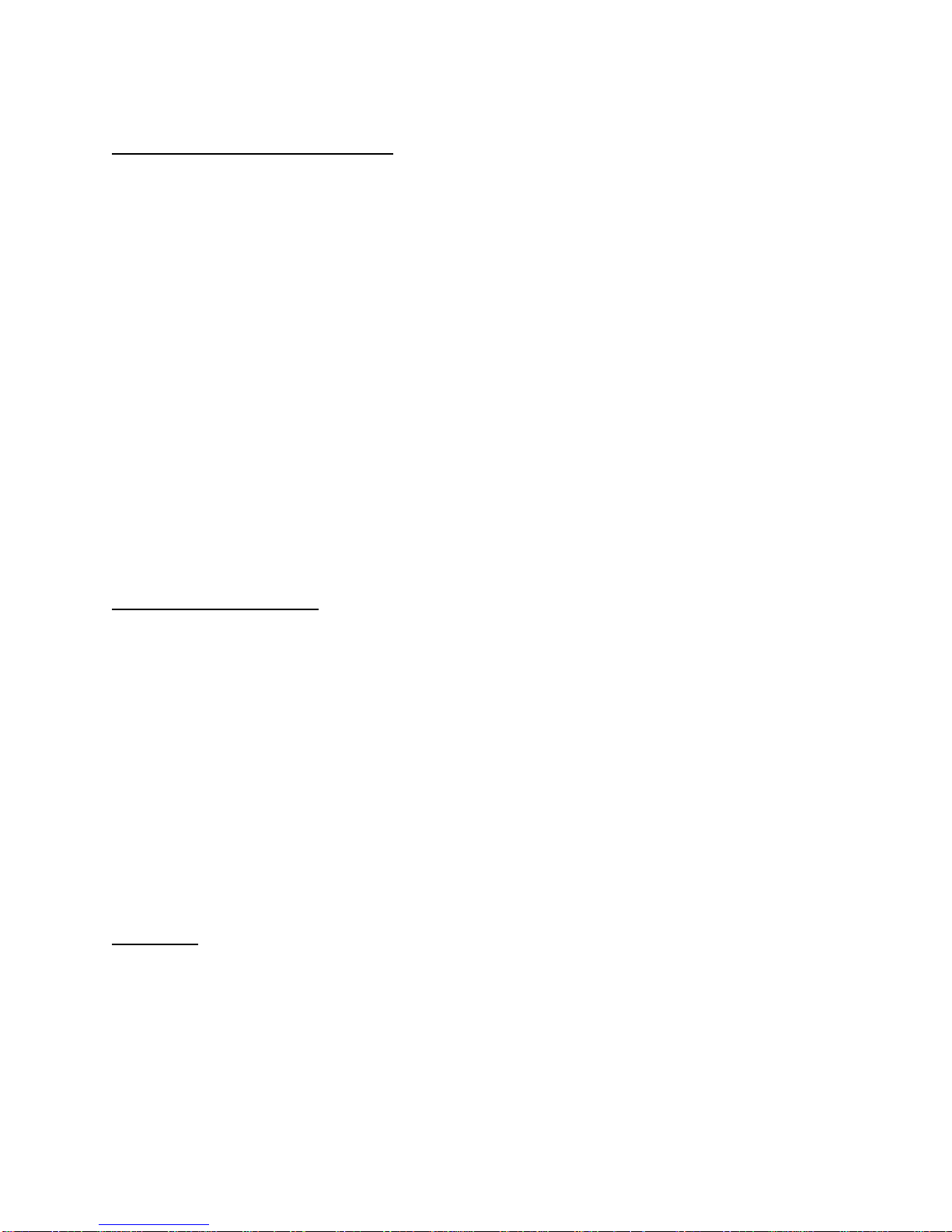

5) Locate servo locations on bottom side of

wings. Note: the pre cut slots in the

Extra are for the new Futaba 9152

servos. These servos are a little bigger

than standard size therefore, if you are

using standard size servos, we have

provided laser cut servo trays that can

easily be glued into place to

accommodate standard servo size.

6) If using the provided standard sized

servo trays, simply glue in place on top

of the pre-existing tray with either CA

or epoxy. Make sure the tray is all the

way down sitting flat against the pre-

existing tray.

10

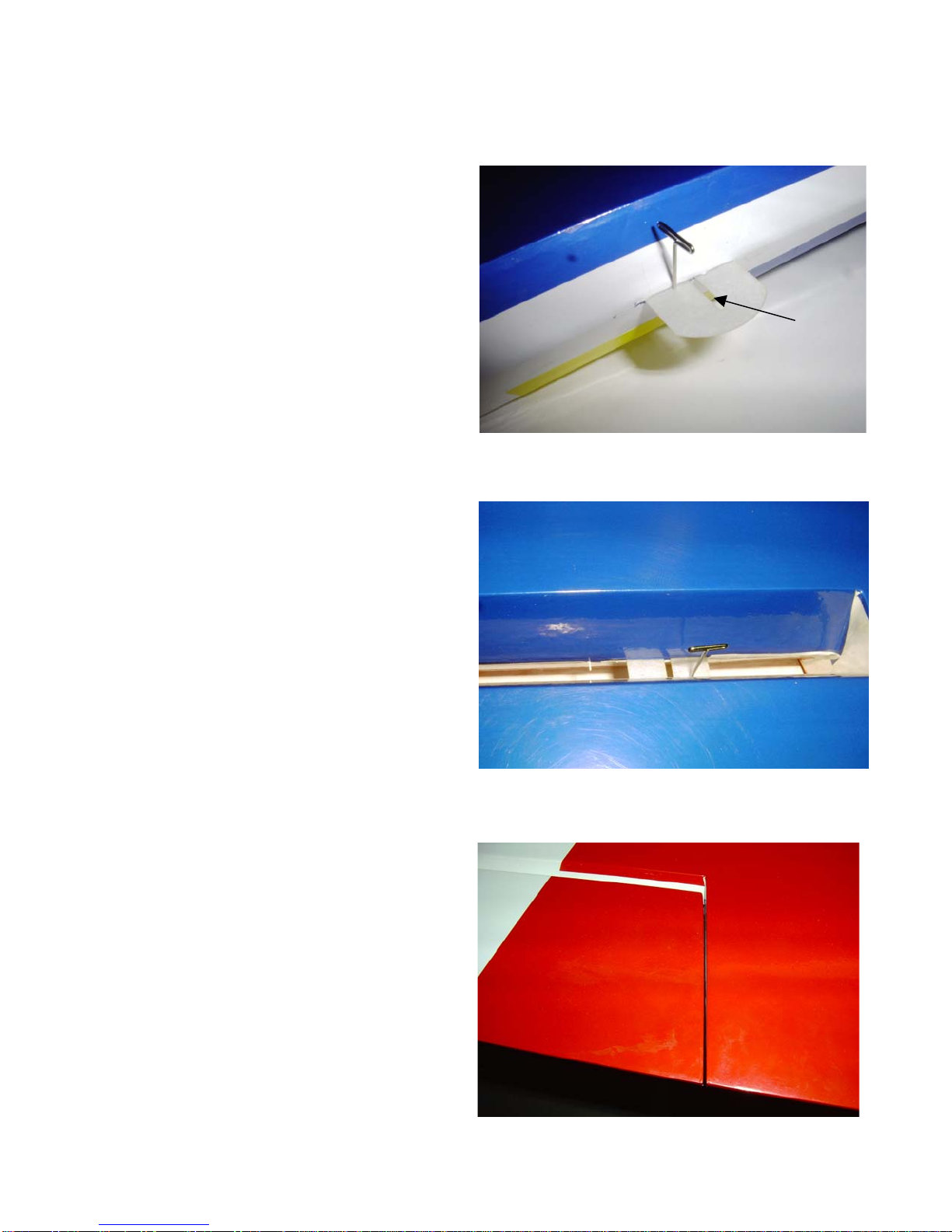

7) Attach servo extension leads to your

servos, it will be necessary to use a “Y”

harness and an 18” extension in order to

connect the two servos together and

have enough wire to exit the root of the

wing. It is important to secure the servo

connectors with tape, wire or after

market clip to be certain the leads do not

disconnected. Tie the pre-installed nylon

string to your servo wire and pull the

servo wire through the wing.

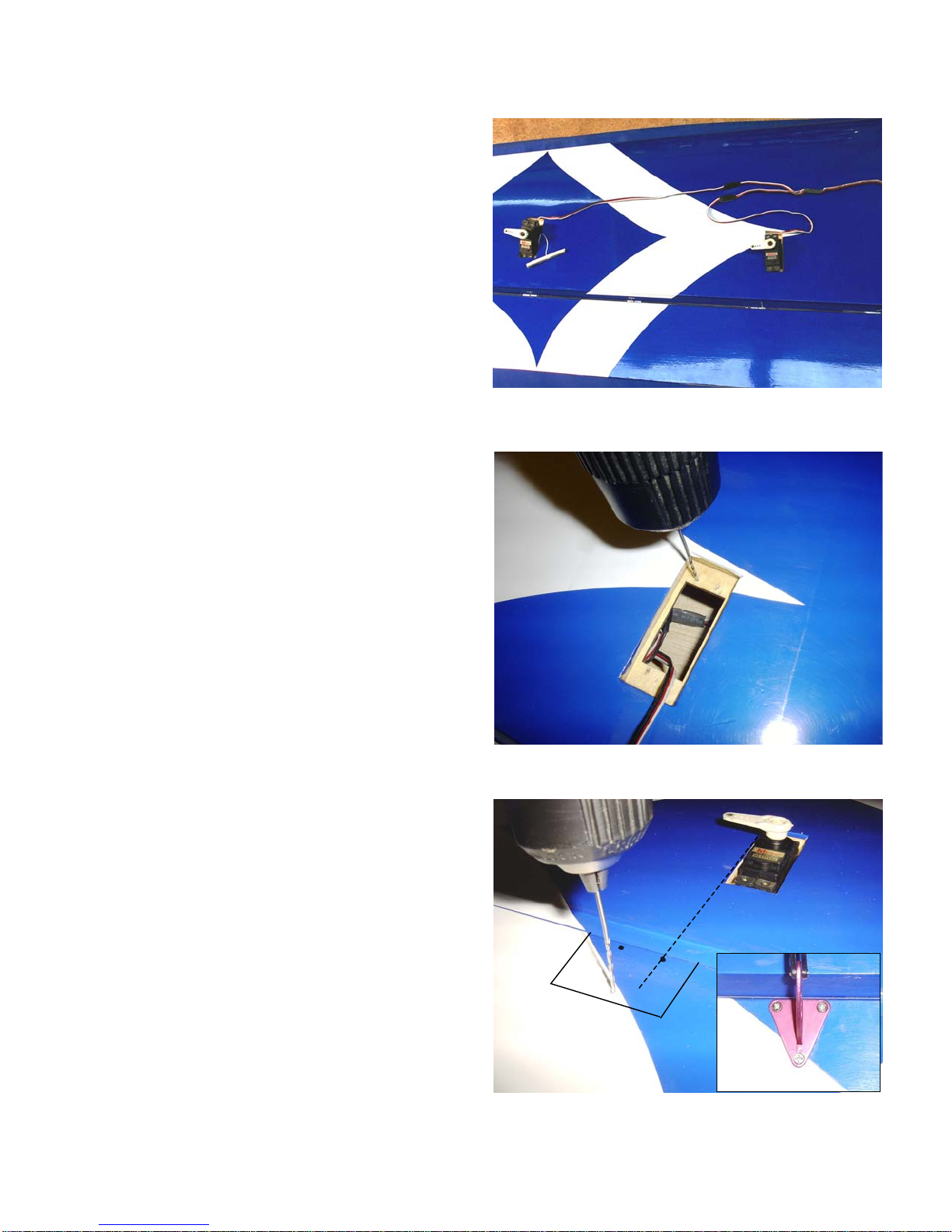

8) Test fit servos into wing so that output

shaft is toward leading edge of wing.

Mark locations for servo screws, remove

servo, and drill 1/16” pilot holes for

servo screws then harden the holes with

thin CA.

9) Reinstall servo and screw into place.

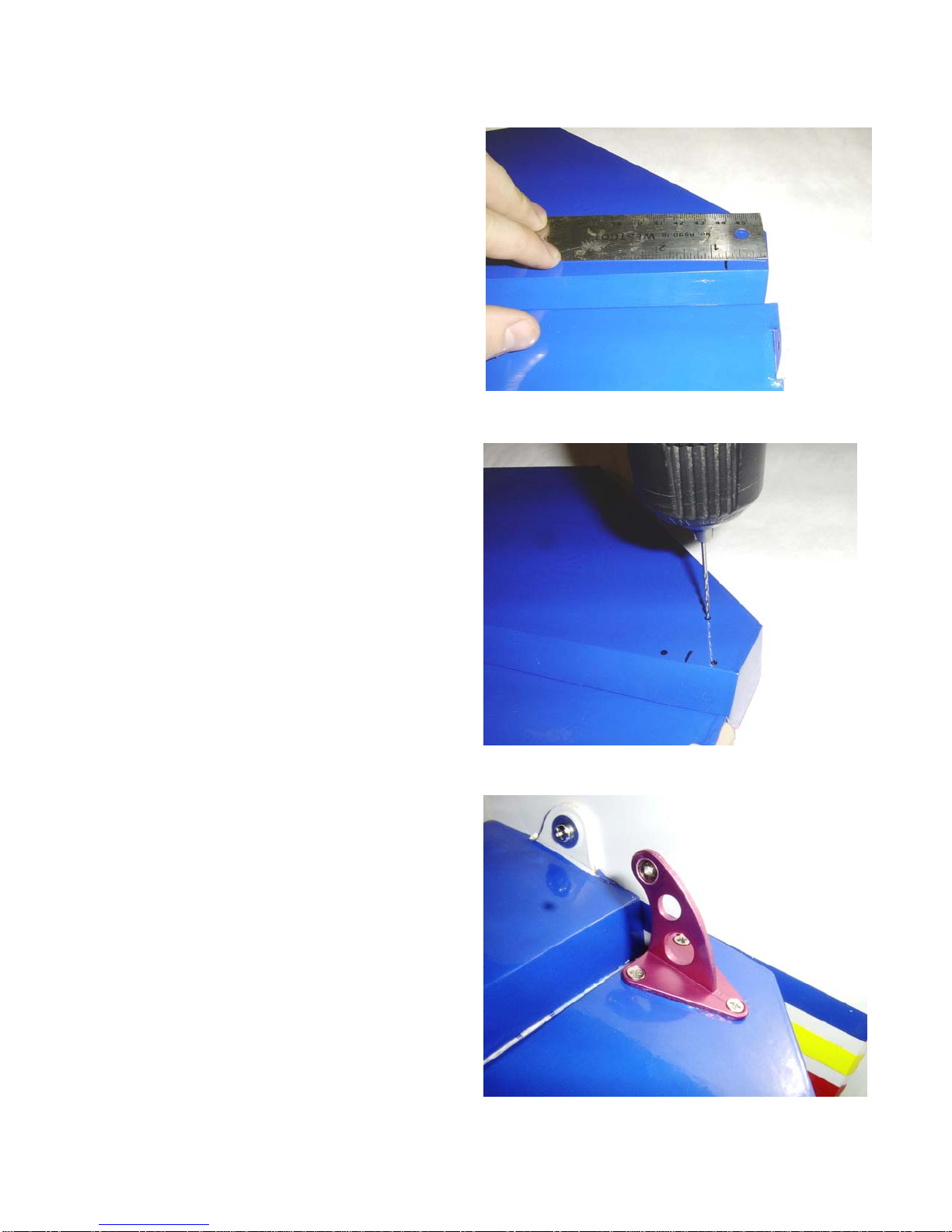

Use a ruler to mark a line on the aileron

even with the outboard edge of the servo

opening. Make sure this will be on top

of the hard wood plate in the aileron that

you can see though the covering. Now,

align the control horn so that the front

inboard hole is centered on your mark

and the front of the control horn is flush

with the leading edge of the aileron.

Mark the hole locations of the control

horn drill with a 1/16” bit.

11

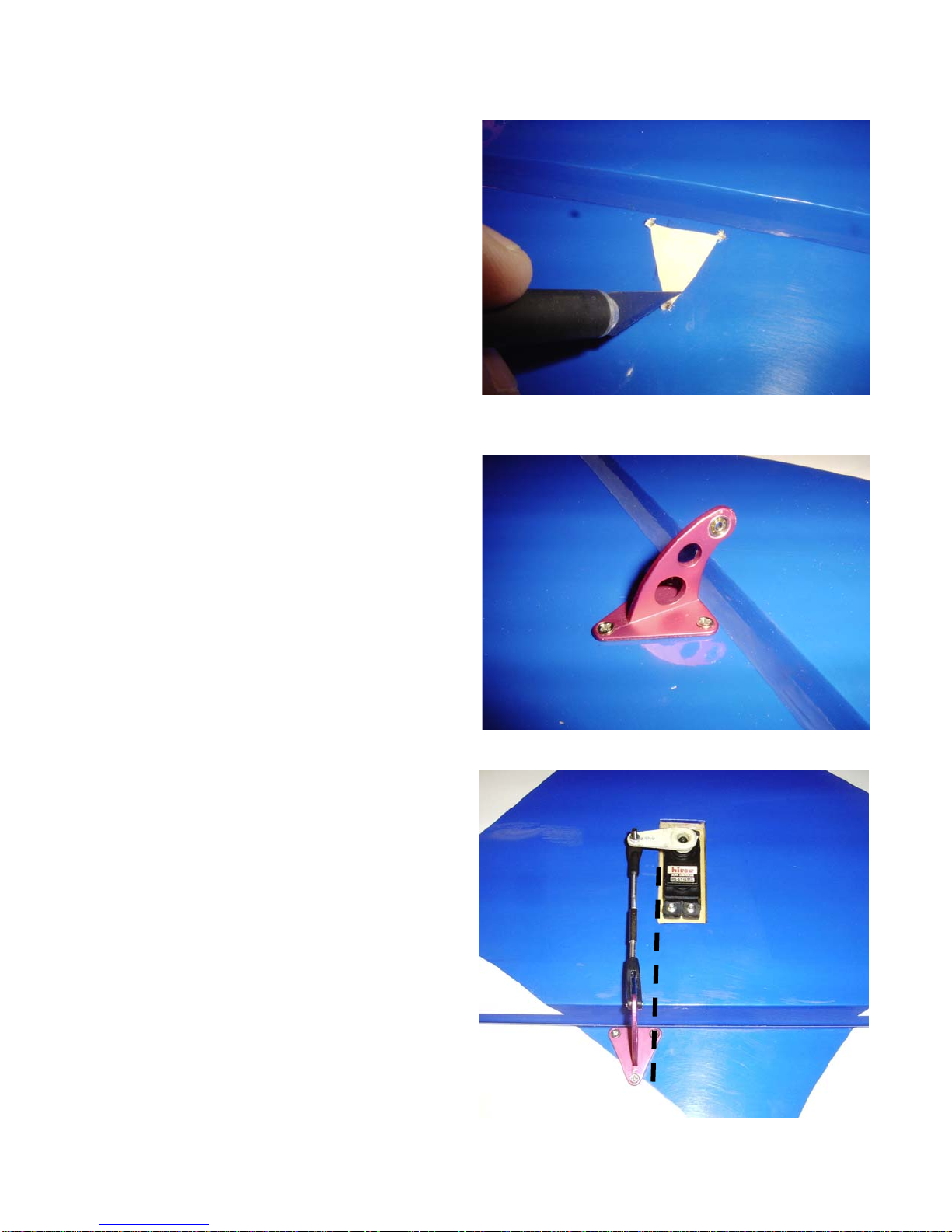

10) Now cut out the covering in a triangle

shape from your control horn screw

holes. Put a drop of thin CA in each of

the three holes to harden them. Next,

rough up the bottom of the control horn

with some sand paper so that glue will

stick to it better.

11) Now apply a thin layer of medium CA

to the bare wood in the triangle, position

control horn in place, and use three of

the provided screws to permanently

mount control horn.

12) If you are setting your plane for 3D style

flying, we recommend using larger after

market servo arms ( 1 ¼” to 1 ½”). The

pushrod selection has been left up to the

builder due to personal preference.

Special note: Remember to center all

servos prior to connecting linkages to

servo. This will eliminate any binding

when the radio is turned on.

12

ELEVATOR SERVO INSTALLATION

Note: As in the servo slots in the wings, the servo slots for the elevator servos are cut for

the new Futaba 9152 servos. Again, these servos a slightly bigger than standard size

servos, and therefore, we have provided standard size servo trays to accommodate a

standard servo. If you are using the new Futaba 9152 servos, install them as you

normally would making sure that the output shaft is toward the tail of the airplane and

the servo is as low in the slot as possible. If you are using a standard sized servo,

there are two methods of installation that this manual will illustrate. We leave it to

the builder to determine which way suits you best.

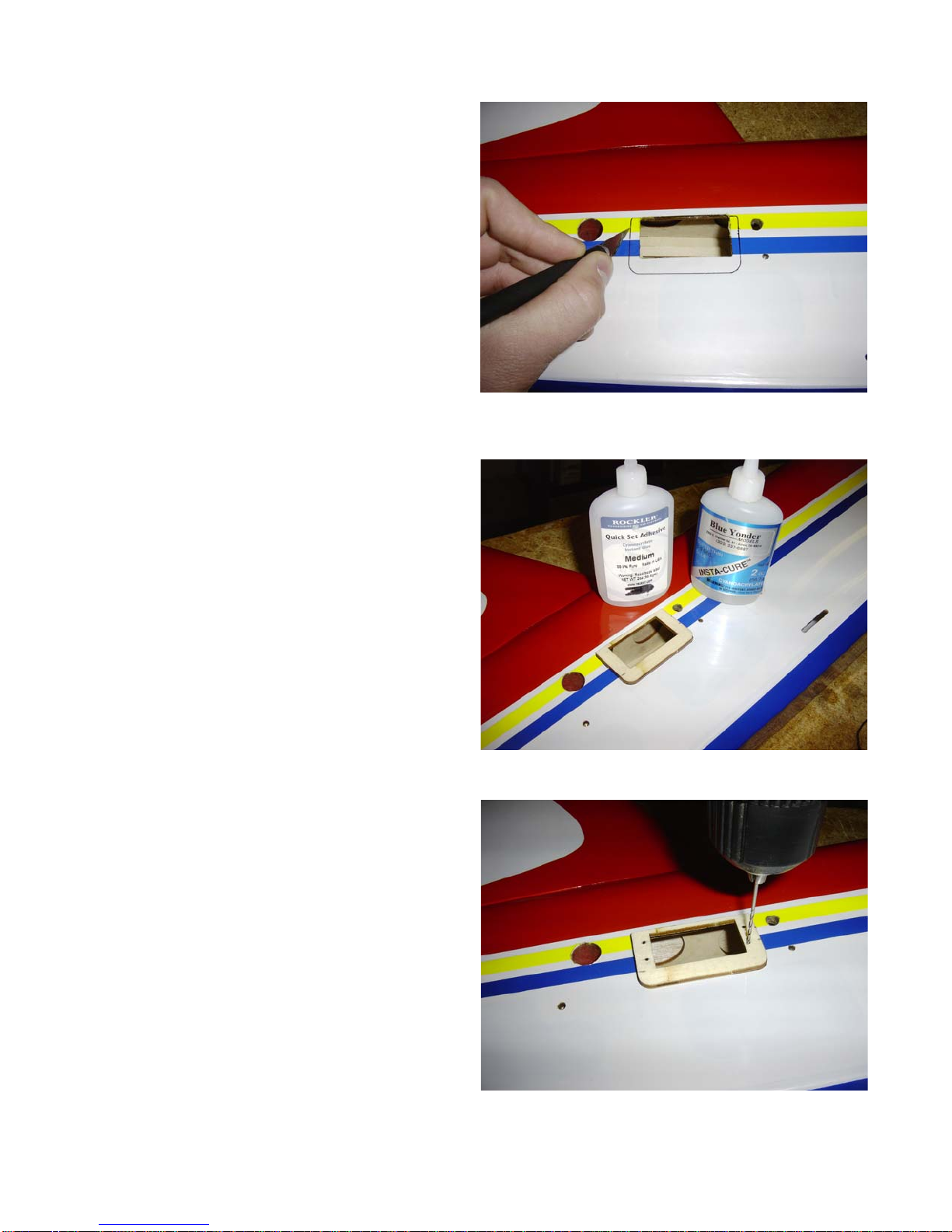

FOR ALL SERVOS: Gather the two stabs

and elevators, your two elevator servos, the

stab tube, two standard sized servo trays

(only if using standard servos), and the

aluminum stab anti rotation dowel. Use a

Xacto knife to remove the covering over the

holes in the stab and fuse for the stab

attachment bolts.

STANDARD SERVO METHOD #1

1) Test fit one servo into one of the

provided trays. Drop servo and tray into

the pre-cut slot in fuse making sure that

the output shaft of the servo is toward

the tail of the airplane and the thinner

side of the tray is toward the top of the

airplane.

Thin Side

Top

13

Align tray to fuse

Bottom Edge

TOP

2) Slide the servo and tray as far toward

the bottom of the slot as possible.

Remove elevator from stab. Insert stab

tube and anti rotation dowel into one

stab and test fit the stab by sliding it

onto the airplane (on the same side as

your servo and tray).

3) We found it necessary to remove 1/8” of

material from the top (thin side) of the

servo tray. This gives the stab enough

clearance to fit tight against the fuse.

To

p

Old New

4) Line up the inside bottom edge of the

servo tray with the inside bottom edge

of the servo slot in the fuse. Hold in

place and trace the out side edge of the

servo tray onto the fuse.

14

5) Use an Xacto knife to remove the

covering 1/16” to the inside of the line.

This is going to allow a good bond when

gluing the tray to the fuse.

6) Note: Before you glue the tray to the

fuse, you may want to cover the top and

sides of the tray with white ultra cote or

paint it. Glue the tray to the fuse with

CA. Make sure that plate is glued

securely.

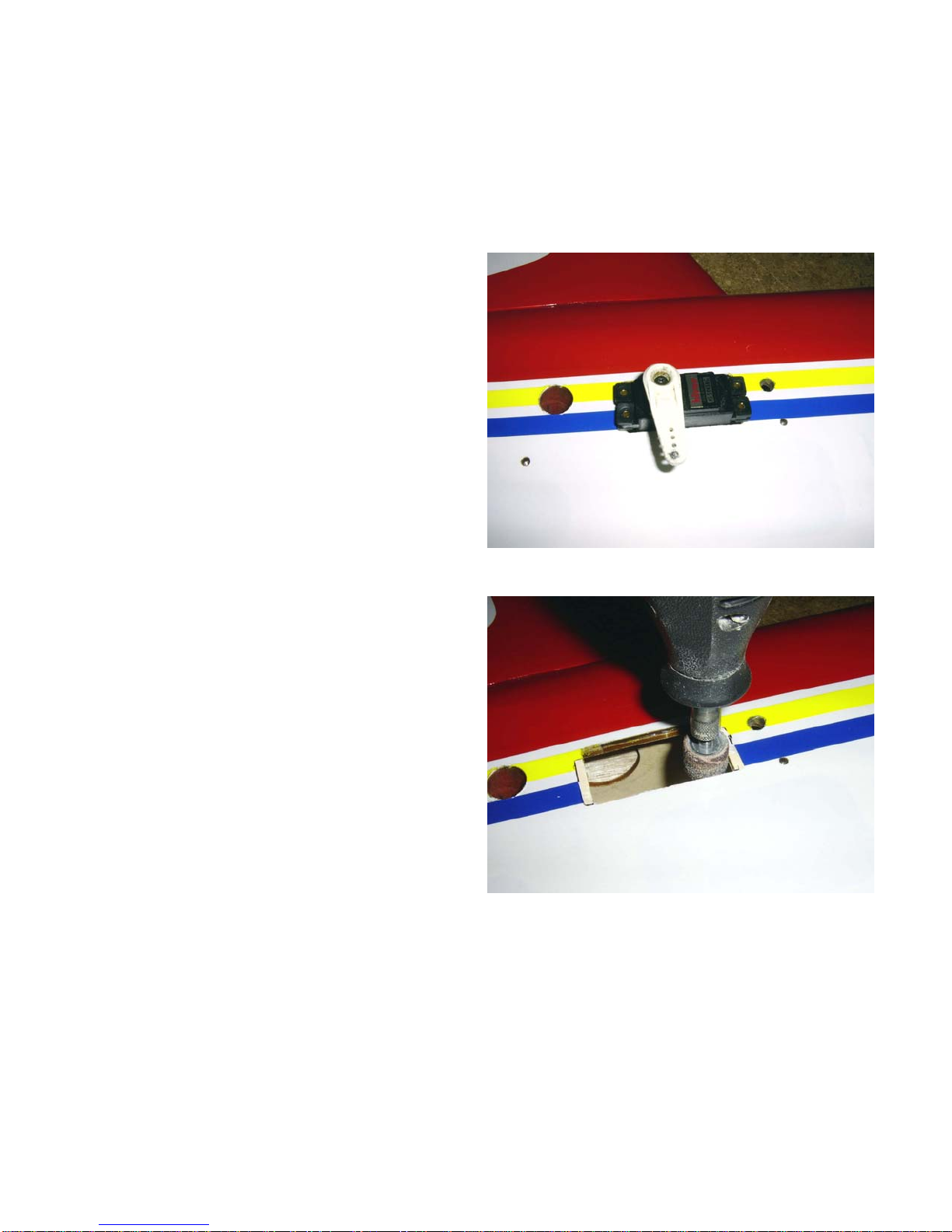

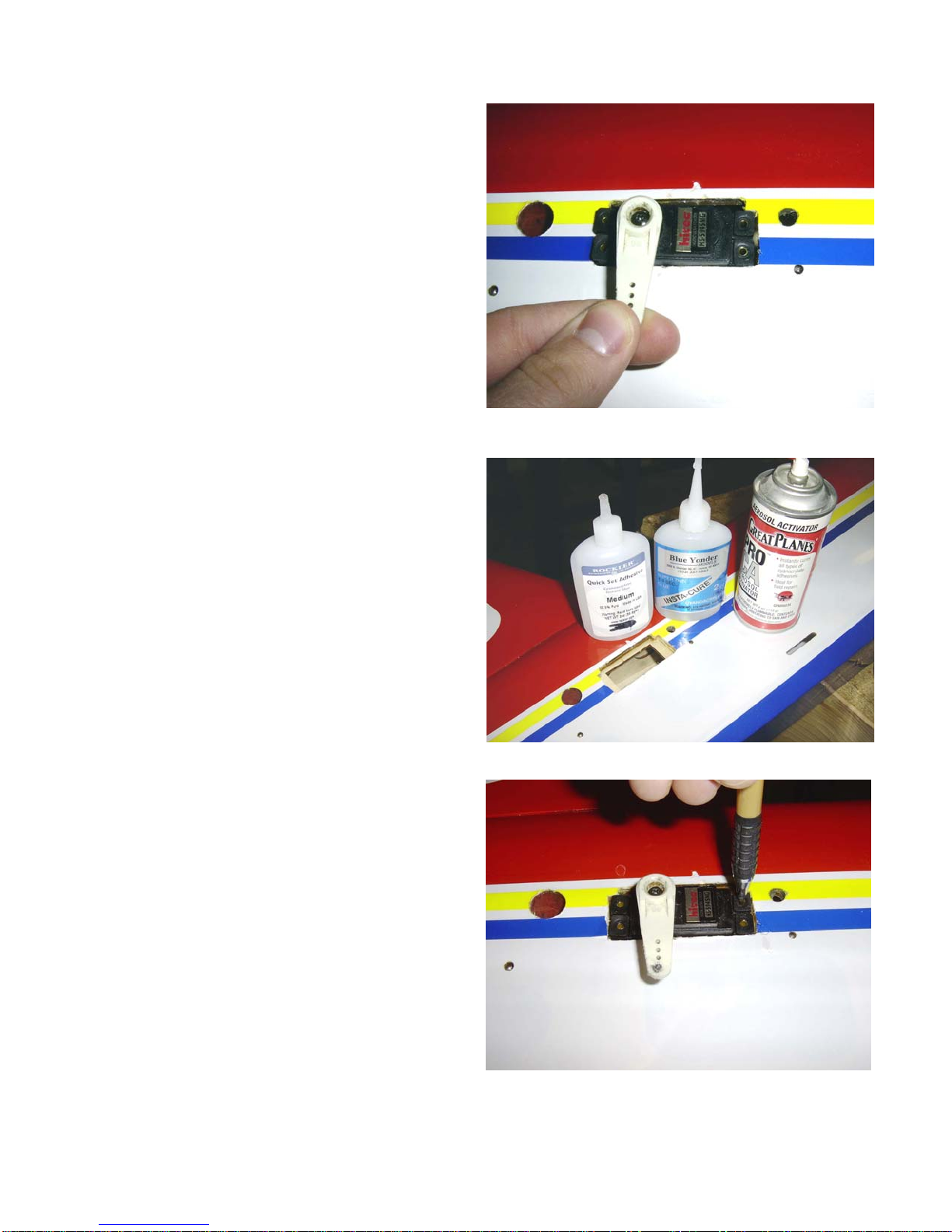

7) Mark locations for the servo screws.

Drill a 1/16” pilot hole at the marked

locations. Harden these holes with thin

CA. Secure servo to fuse with servo

screws. Remember to keep the servo

output shaft toward the tail of the

airplane. Repeat steps 1-7 for other

side.

15

STANDARD SERVO METHOD #2

The second method mounts the standard size servo plate to the inside of the fuse. This requires

using a Dremel tool to enlarge the pre-existing servo slot in the fuse.

1) Test fit the servo in the fuse. Center the

servo in the slot both front to back and

up and down.

2) Trace the outline of the servo onto the

fuse side. Use a Dremel tool to enlarge

the existing servo slot to the required

size of the servo (the line you just

made). DO NOT MAKE THE HOLE

BIGGER THAN IT NEEDS TO BE!

16

3) Test fit the servo into the new slot to

make sure the servo fits all the way

inside the hole you have made.

4) Slide the standard sized servo tray into

the fuse and hold up in place from

behind (use the other elevator servo slot

hole to get your fingers into the fuse and

hold in place). Center the tray under the

slot you made. Make sure that there is

enough room for the servo screws to

attach to on each side. Glue the plate in

place with CA. Make sure the tray is

glued securely.

5) Fit the servo into the fuse. Make sure

the servo sits flat against the servo tray.

Mark the locations of servo screws and

drill pilot holes with a 1/16” bit. Again

harden the holes with thin CA

17

6) Repeat steps 1-5 to other side before

securing the servo in slot to allow you to

hold the tray in position again. Once

both plates are installed securely, attach

servos to fuse with servo screws making

sure the servo output shaft is toward the

tail of the airplane.

STAB AND ELEVATORS ASSEMBLY

1) Hinge elevators in the same manner as

the ailerons. Be sure to keep the hinge

line as tight as possible while allowing

maximum throw.

2) Also be sure to leave at least 1/16” gap

between the boost tab and the stab to

avoid binding.

18

3) Next we will mount the control horn.

On the bottom of one of the elevators,

measure ¾” from the root end. This

mark is the centerline of the control

horn.

4) Next, Line the control horn up with the

leading edge of the elevator and center

the control horn over the line you just

made. Mark screw locations and drill

1/16” pilot hole.

5) Cut out triangle of covering, rough up

the bottom of the control horn, glue and

screw control horn to elevator the same

as for the ailerons. Repeat above steps

for other elevator.

19

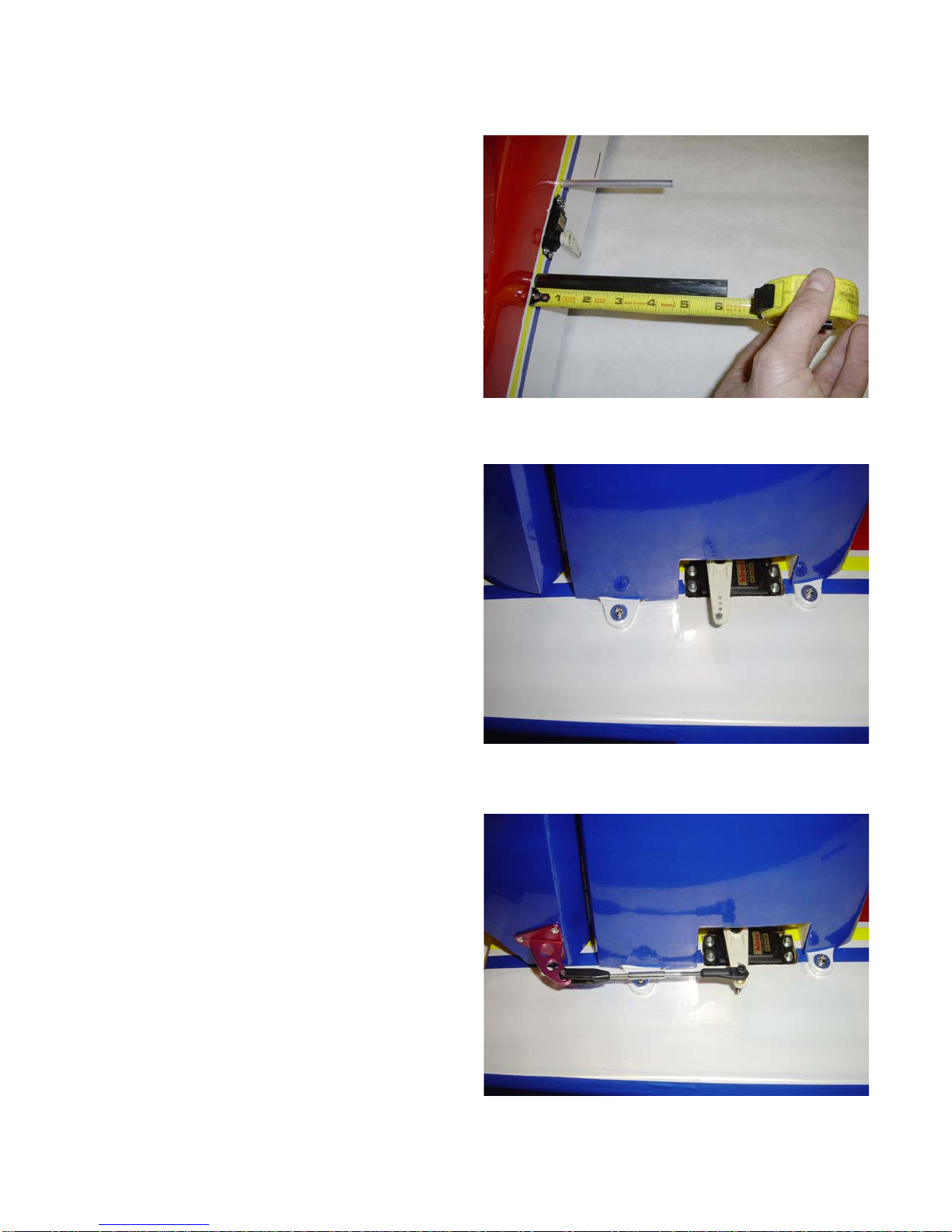

6) Slide stab tube and stab anti rotation

dowel though fuse. Use ruler to center

both tube and dowel in the fuse

7) Slide one stab on to stab tube and dowel.

Measure to make sure tubes have not

moved. Collect the 4 bolts from the

screw bag. These screws are used to

attach the stab to the fuse. Use two of

the bolts to secure stab to fuse. Make

sure to use locktite on threads to keep

from loosening. Repeat steps to attach

other stab to fuse.

8) If you are setting up the plane for 3D

style flying, we recommend using larger

after market 1 ½”servo arms. The

pushrod selection has been left up to the

builder due to builder’s preference.

Special note: Remember to center all

servos prior to connecting linkages to

servo. This will eliminate any binding

when the radio is turned on. The control

rod in the picture was made using a 4-40

threaded rod threaded at one end, a 4-40

threaded coupler and a 4-40 swivel ball

link.

20

Table of contents

Popular Toy manuals by other brands

Eduard

Eduard F-14A exterior Assembly instructions

Miniature Scenery

Miniature Scenery Fascinating Fences instructions

Eduard

Eduard F-100F Aassembly Instructions

Great Little Trading

Great Little Trading L5172 quick start guide

Learning Resources

Learning Resources Minute Math Electronic Flash Card user manual

Fisher-Price

Fisher-Price W9737 instruction sheet