Chromalox DirectConnect User manual

1

Installation and

Operating Instructions

Chromalox DirectConnectTM

High Voltage Converter System

PK526

Doc Rev: 13 AUG 2022

Software Rev 2.60

2

Table of Contents

A: INTRODUCTION AND SAFETY................................................................................................................3

B: RECEIPT, HANDLING, STORAGE and INSTALLATION....................................................................6

C: COMMISSIONING......................................................................................................................................11

D: OPERATION...............................................................................................................................................12

E: INSPECTION and MAINTENANCE........................................................................................................16

FASTENER TORQUES..................................................................................................................................18

ANNEX 1: HMI SCREENS............................................................................................................................19

ANNEX 2: ARC CONTROL SHROUD........................................................................................................38

3

A: INTRODUCTION AND SAFETY

The DirectConnectTM Converter System

manual uses this symbol to alert personnel

to potential hazards that may damage the

equipment.

The DirectConnectTM Converter System

manual uses this symbol to alert personnel

to potential hazards that may cause injury

or death.

__________________________________________________________________________

1...General

1.1 Scope

This manual provides instructions for receiving, handling, storage, installation, startup

(commissioning), operation, and maintenance (including troubleshooting) of Chromalox High

Voltage Converter Systems designed and built to IEC or UL standards.

__________________________________________________________________________

2...Introduction

2.1 Key Safety Practices

ALL PERSONNEL WORKING

ON HIGH VOLTAGE

ELECTRICAL EQUIPMENT

MUST ADHERE TO ALL

NATIONAL AND LOCAL REGULATIONS,

CODES, AND STANDARDS.

ONLY SUITABLY QUALIFIED AND

EXPERIENCED PERSONS, WHO ARE

FAMILIAR WITH THIS EQUIPMENT, AND

THE WORK THEY ARE TO DO, SHOULD

CARRY OUT INSTALLATION,

COMMISSIONING, OPERATION, OR

MAINTENANCE OF THIS CONVERTER

SYSTEM AND THE ASSOCIATED

HEATER.

SUCH PERSONS SHALL ADHERE TO

PROPER HIGH VOLTAGE SAFETY

PROCEDURES, INCLUDING THE USE OF

APPROPRIATE PERSONAL

PROTECTIVE EQUIPMENT (PPE).

FAILURE TO ADHERE TO ANY OF THE

ABOVE MAY RESULT IN EQUIPMENT

DAMAGE, OPERATING LOSSES,

INJURY, OR DEATH. CHROMALOX

WILL NOT BE LIABLE FOR FAILURE TO

ADHERE TO ALL GOVERNING

REGULATIONS, CODES, STANDARDS,

SITE PROCEDURES AND INFORMATION

GIVEN IN THIS MANUAL.

IF IN DOUBT, CONTACT CHROMALOX.

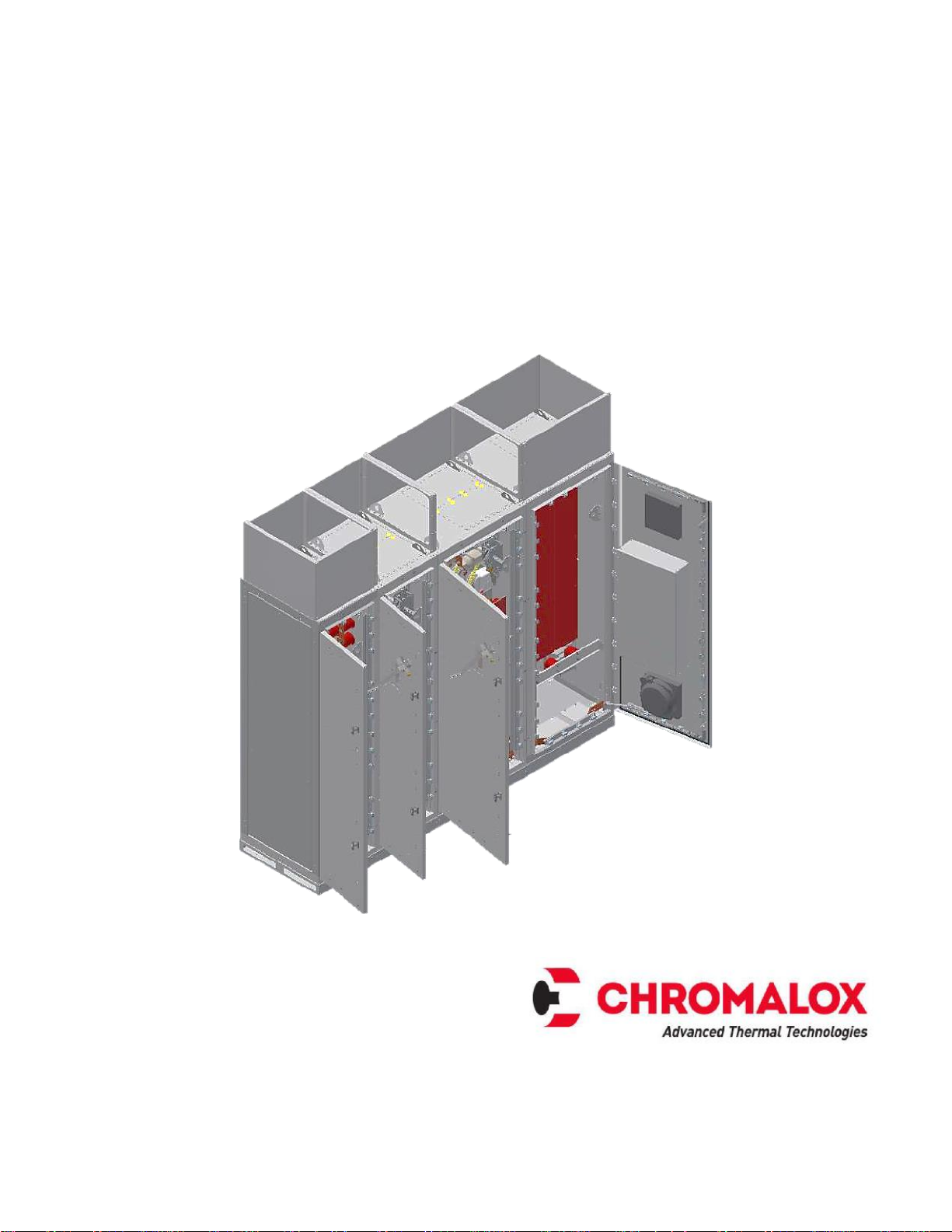

2.2 Description

An MV DirectConnectTM Converter System will

be made up of multiple ‘Sections’.

The primary load control element is the three-

phase line-commutated semiconductor (SCR)

power ‘Converter’ section. This contains three

SCR ‘Stacks’, each with three pairs of SCRs

connected in series. Each pair of SCRs is

mounted in ‘anti-parallel’ so that one SCR can

control the current flowing in one direction, and

the other can control it when the current is

flowing in the opposite direction.

The Converter section also contains an output

voltage monitoring VT, three load current CTs,

and a CT connected around all three phases to

measure residual current leakage to earth

[ground]. It will usually also contain the MV

Load Terminals, though these could be

supplied in a separate section. The Converter

switches the supply voltage in such a way as to

control (reduce) the amount of voltage that

reaches the heater to provide the heating

needed.

Power for the Converter is fed from the

‘Controller’ section. This contains an MV

Disconnector Switch, fully rated Type E MV

fuses, an MV Contactor, Inductors, and an input

voltage monitoring VT. It can also contain a

power supply Control Power Transformer

(CPT), and the MV Supply Line terminals.

Cooling for the Converter stacks is provided by

a door mounted fan (for NEMA 1), or a side

mounted Heat Exchanger (for NEMA 4). The

Inductors, which are connected in circuit

between the Contactor and the SCR stacks,

limit the rate of rise (di/dt) of current flowing into

the SCRs.

If the incoming MV supply line terminals are not

mounted in the Controller section, a separate

‘Direct-on-Line’ (‘DOL’) section will be provided

for these terminals.

If multiple Heaters are to be fed from a

Converter, and separate switching control is

required for each Heater, ‘Load Switching’

section(s) will be provided, each with up to two

Contactors, and associated load terminals.

If the total Heater load exceeds the maximum

that can be supplied by the Converter, the

Converter System will be equipped with

additional ‘Stepper’ sections that work in

sequence with the Converter to ramp the

Heater load up to the level required. ‘Stepper’

sections each have a Disconnector Switch, MV

fuses, and output Power and Dry-out

Contactors.

LV control is mounted in a separate ‘LV

Compartment’ that is mounted on the front door

of the Converter.

The doors for the various sections, and for the

Low Voltage compartment can be locked closed

using key locks provided in the door handle.

The Disconnector Switches mentioned above

each provide an isolation gap between the

Supply/Line power and the associated

Heater(s). They can be padlocked open. A

window is provided for each Disconnector so

that its status can be verified visually.

The Disconnector and the Heater junction

box(s) can be equipped with a key inter-locking

system intended to prevent opening of certain

compartments until specific conditions are met.

For example, the Heater junction box lock may

be equipped with a key that is captured in the

Disconnector Switch mechanism and is not

released until the Disconnect Switch is open.

Secondary compartmentalization may be

provided, in which the Disconnector(s) is

segregated in its own compartment within the

Controller or Stepper section. This

compartment has its own door, and with this

door closed, in some regions / applications, if

the Disconnector is open access to the

associated MV fuses mounted in that section, is

possible for replacement with MV power still

connected to the primary side of Disconnector.

Appropriate PPE must be worn. However, it is

strongly recommended that, if at all possible,

the main incoming supply be switched off and

locked off upstream of the Converter System

before such work is carried out.

2.3 General Safety Principles

All connections should be considered energized

until proven to be de-energized, and until every

possible precaution has been taken to ensure

that they stay de-energized until work is

complete.

Suitable visible warning devices should be

placed around the Converter Systems, at a

suitable distance from the equipment, if work is

necessary when the System is still live.

Components inside the Converter System may

stay physically hot for some time after supply

has been switched off. SCR snubber

capacitors will self-discharge in less time that is

needed to remove the red-board covers.

2.4 De-energizing, and Earthing /

Grounding

BEFORE WORKING INSIDE

THE EQUIPMENT, CONFIRM

THAT ALL POWER HAS BEEN

TURNED OFF, LOCKED OFF,

AND PREFERABLY EARTHED

[GROUNDED] AT ALL POINTS OF LOW

AND HIGH POTENTIAL, ON BOTH THE

SUPPLY LINE AND LOAD SIDE

CIRCUITS, AS REQUIRED / PERMITTED

BY ALL CODES AND STANDARDS.

Never assume: Use a properly rated voltage

sensing device to verify that power is off.

The Disconnector Switches mentioned above

provide an isolation gap between the Supply

Line power and the associated Heater(s). They

can be padlocked open. A window is provided

so that its status can be verified visually.

NOTE: INCOMING POWER SUPPLIES,

TERMINALS, AND CONNECTIONS TO THE

DISCONNECTOR SWITCHES ARE STILL

LIVE WHEN THE DISCONNECTOR IS OPEN

The Disconnector and the Heater junction

box(s) can be equipped with a key inter-locking

system intended to prevent opening of certain

compartments until specific conditions are met.

For example, the Heater junction box lock may

be equipped with a key that is captured in the

Disconnector Switch mechanism and is not

released until the Disconnect Switch is open.

The VTs and CPT mentioned in the

descriptions above will all back feed high

voltage onto the MV circuits if an auxiliary LV

control is connected to their secondary(s).

Therefore, care must be taken when connecting

any test equipment to the LV circuits, and the

voltage free status of the MV circuits must be

verified by testing, and preferably ensured by

connecting a cable from each circuit to the

earth / ground before any work starts.

2.5 Design Purpose

This equipment was specifically designed for its

intended purpose and should not be used for

any other application without a complete re-

evaluation by the manufacturer. The operator

should ensure these instructions are kept with

the equipment to prevent any use for which the

equipment has not been designed.

2.6 Complete System

The Chromalox DirectConnectTM system is

comprised of both a Chromalox MV

Converter System and a Chromalox MV

Heater. One may not be employed without

the other. All written and implied warranties

are voided if one DirectConnectTM

component is used without the other.

2.7 Startup/Commissioning

All Chromalox DirectConnectTM MV Converter

Systems MUST be commissioned by

Chromalox Service Personnel. All written and

implied warranties are voided if non-Chromalox

Service personnel are utilized for

DirectConnectTM System commissioning.

__________________________________________________________________________

6

B: RECEIPT, HANDLING, STORAGE and INSTALLATION

3...Receiving & Handling

3.1

Care should be exercised when moving

Converter Systems as they are heavy and can

tip over. Do to attempt to handle systems

without securing properly and using only proper

equipment capable of handling heavy loads.

3.2

When first received, inspect for shipping and

handling damage. Proceed only if there is no

visible damage.

3.3

Ensure that lifting equipment can handle the

weight of the system.

3.4

Keep the system secured to prevent distortion

of the frame during moving and to minimize

tipping.

3.5

Exercise care during any movement and

placement operations to prevent falling or

unintentional rolling or tipping.

_________________________________________________________________________

4...Storage

4.1.1. Any system that is not installed and

energized immediately should be stored in a

clean, dry space where a uniform temperature

prevents condensation. It should be stored in a

heated building with adequate air circulation

and protected from dirt, pollutants (especially

conductive dust, salt laden air, and Hydrogen

Sulfide), water, rodents, insects and mold. The

system should be stored off the ground. Doors

should never be left open.

4.1.2. Shipping containers are temporary

protective covers. The system should not be

stored outdoors for more than 24 hours. If the

system must be stored outdoors for longer

periods it must be protected from the outdoor

elements with appropriate coverings.

4.2 Short Term Storage

4.2.1. In non-humidity-controlled environments,

the anti-condensation heaters (if fitted) must be

energized, equivalent temporary heating

sources must be provided, or desiccant must be

used to prevent condensation on interior

surfaces.

4.2.2. Electronic components can be damaged

if stored at low temperatures. If the system is to

be stored in an environment of less than 0oC

[32of], the internal heaters (if fitted) must be

energized, or equivalent temporary heating

sources must be provided.

4.2.3. Unless the system is designed for use in

direct sunlight, it should be stored away from

direct sunlight, or be suitably covered.

4.2.4. Once the system is taken out of storage,

all desiccant, internal packing, caps, plugs,

wrappings, etc. must be removed just prior to

the equipment being placed into operation.

4.3 Long Term Storage

4.3.1. For long term storage, in addition to the

above precautions, it is recommended that the

entire system should be heat sealed in plastic

barrier bags with the proper amount of

desiccant included.

Converter Systems in long term storage should

be inspected periodically for any signs of

deterioration.

4.4 All written and implied warranties

are voided if these storage guidelines

above are not followed.

__________________________________________________________________________

7

5...Installation

Precautions & Warnings

READ AND UNDERSTAND

SECTION A ABOVE BEFORE

CARRYING OUT THE WORK

DETAILED BELOW

5.1 Preparations

5.2.1. The Heater skid & Converter System

should be adequately protected against

mechanical damage, extreme temperatures and

other adverse environmental conditions.

5.2.2. Ensure that all precautions are taken

regarding the weight of the equipment. Lifting

equipment should have capacity for the given

weight.

5.2.3. The foundation must be sufficiently

strong to withstand the load of equipment and

should be flat.

5.2.4. Converter Systems should be inspected

for foreign material, and the entire system

should be cleaned before startup.

5.2.5. General safety precautions listed in the

plant safety procedures should be closely

complied with to prevent injury to personnel or

damage to equipment.

5.2.6. Ensure that personnel responsible for site

safety and others in the vicinity are aware that

work is being undertaken and required post

warning notices. Ensure that the appropriate

PPE and clothing is worn. Take all required

precautions if working at above ground level.

5.2.7. Where possible hazards have been

eliminated or reduced as far as is reasonably

practicable by design, but the additional

warnings listed below should be followed to

ensure continued safe use

5.2. Mechanical Installation

5.2.1 Converter Systems are shipped on heavy

duty pallet(s) and can be lifted and moved using

forklift trucks, or heavy-duty rollers.

5.2.2 Converter Systems may be shipped in

one or more Transport Units / Shipping

Sections. Each section is equipped with lifting

angles allowing the System or Transport Unit to

be removed from the pallet. All four lifting

angles in the corners of the System should be

used.

For outdoor installations these lifting angles

should be removed, and the fasteners should

be replaced. Sealing washers, shipped with the

System, should be installed under the heads of

the fixing screws before reassembly. Do not

discard the lifting angles. They may be needed

for lifting or moving the System in the future.

5.2.3 All lifting should comply with local codes.

In particular, if lifting chains are used, they

should be attached individually to each lifting

eyes (i.e. not in a loop run through 2 or more

lifting eyes), and there should be an angle of at

least 45 degrees between the lifting chain and

the roof of the Converter System.

On IEC Systems, if adequate space is not

available above the Converter System for a

lifting crane to be used, and access will be

available behind the System once installed, the

plinth front and rear bottom plates may be

removed, and a fork truck or palette truck(s)

may be used to move the System into place.

Very great care must be taken if this form of

movement has to be used to avoid damage to

the plinths. The front and rear bottom plates

must be replaced once installed as they form a

key part of the structural integrity of the base.

5.2.4 Typically a minimum of 300mm [1ft] is

necessary to the sides and rear of the

Converter System for cooling, and 1.8m [5.9ft]

is necessary at the front to allow enough space

for personnel to pass in front of an open door.

The ceiling above Systems that are not Arc-

Resistant must be at least 2.5m [8.2ft] above

the floor to allow 300mm [1ft] of space above

the roof for cooling.

IEC Arc Resistant Converter Systems are for

internal use only. The ceiling above these

Systems must be at least 4.4m [14.4ft] above

the floor to allow 2m [6.6ft] of space above the

roof for explosive products to exit.

Do not install Arc Resistant Systems below

catwalks or other elevated access routes.

To ensure that water does not enter the System

from below, adequate drainage should be

provided around the System, and in cable

trenches. Cable ducts should be sealed.

Avoid exposure to salt air, hydrogen sulfide,

excessive dust, dripping water, falling dirt, or

other similar conditions.

The equipment is not designed for seismic

shock, or nuclear radiation hazards.

5.2.5. Once the Converter System is in place, it

should be secured to the foundation by suitable

means. On IEC Systems, the plinth front and

rear bottom plates may be removed to access

the plinth mounting holes. These plates must

be replaced once the System is secured as

they form a key part of the structural integrity of

the base. On UL Systems, access to mounting

holes can be found inside the enclosures.

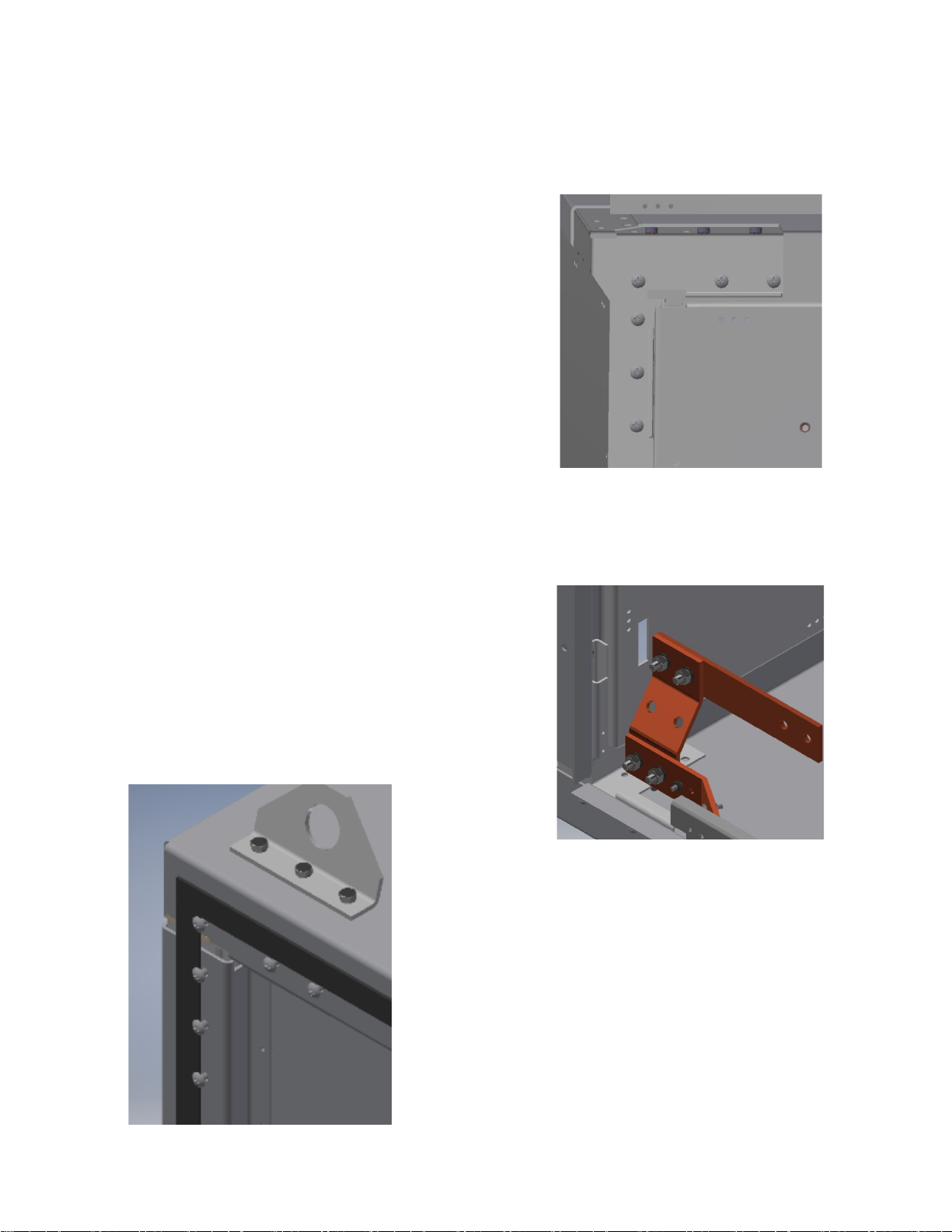

5.2.6 If IEC Converter System are supplied in

shipping sections that have to be assembled

together on site, the fasteners that are to be

used to secure the shipping sections together,

will be fastened to the left hand section of the

each shipping section at the shipping split.

There will be 24 such fasteners plus any

associated washers at each shipping split, 6 per

corner as shown below. Tighten the screws to

71lbs in [8.0 Nm].

IEC sections must be brought together, and the

fasteners (and any associated washers) must

be installed from the inside of the section to the

left of the slit through into holes where the

fasteners were originally installed.

The ground bar link that connects the ground

bars in the IEC sections either side of the

shipping spilt will be mounted such that it faces

into the section.

It should be detached from the vertical copper

stub that it is attached to, turned through 180

degrees, and reassembled such that it passed

through the slot in the adjacent steelwork.

It should be reconnected to the vertical stub it

was removed from, and to the equivalent

vertical stub in the section to the left of the

shipping split with the hardware provided.

Tighten the nuts 19.4lbs ft [26.3 Nm].

Consult the schematic diagram(s) and

reconnect all LV wires at the interconnection

terminal blocks or plugs and sockets provided

at the split, and all the MV power cables.

5.2.7 On Arc-resistant IEC sections the

additional parts used to create the arc shroud

(that guides arc products exiting from the top of

the system upwards) may be shipped

separately, the instructions given in Annex 2

should be followed to assemble it on site. The

shroud for each section consists of 4 parts plus

all the fixing screws required. If rear access to

the System is not possible, the rear and side

pieces of the shroud should be assembled to

the enclosure before the System is placed in its

final position.

When complete, the shroud should form a wall

around the top of the Converter System.

Partitions between parts of the shroud above

different sections have large opening in them to

give arc products the maximum amount of

space to expand into. It is important that all

fasteners between parts of the shroud, and

between shroud parts and the enclosure top are

in place and securely tightened.

5.3 Cabling

ACCESS TO THE CABLE TERMINATIONS

SHOULD ONLY BE MADE WHEN THE

POWER FEEDS ARE ALL TURNED OFF,

LOCKED OFF AND PREFERABLY EARTHED

/ GROUNDED.

5.3.1 Incoming MV cable terminals are mounted

in the Controller section, or DOL section, and

provide easy termination of incoming power

wiring. Space is provided for the spreading,

bending, and termination of over-size cables if

these are needed to minimize voltage drops.

Follow instruction provided by the cable or

cable termination manufacturer.

The DOL and Controller doors are

locked/bolted closed, and the Controller door

cannot be opened if the Disconnector is not

open.

The incoming power cable gland plate is

mounted on the base, or roof, in line with the

cable terminations.

5.3.2 Outgoing MV cable terminals are mounted

in the Converter and/or Load Switching section,

and any Stepper sections, and provide for easy

termination of power wiring from the Converter

System to the Heater(s). Plenty of space is

provided for cable bending, and termination.

Follow instruction provided by the cable or

cable termination manufacturer.

The Converter, Load switching, and Stepper

Sections are key locked, and the Converter

door is blocked closed if the Disconnector is

closed.

The outgoing power cable gland plate is

mounted on the base, or roof, in line with the

cable terminations.

5.3.3 Incoming and outgoing LV cable terminals

are mounted in the LV compartment on the

Converter front door. The main control board

and all Temperature and Over-temperature

controls are also located in the LV

compartment. This compartment is segregated

from High Voltage and can be opened without

de-energizing the main power if local codes

permit. All required PPE should be worn.

The LV compartment door is key locked.

An LV cable gland plate is mounted on the

base, or roof, to the right of the power cable

gland plate.

__________________________________________________________________________

10

C: COMMISSIONING

6...Commissioning

Precautions & Warnings

READ AND UNDERSTAND

SECTION A ABOVE BEFORE

CARRYING OUT THE WORK

DETAILED BELOW

6.1 Before Powering Up

Chromalox takes great pride in knowing that we

have provided to you a product of premium

quality and workmanship. We have taken every

precaution to ensure that your equipment

arrives safe and secure.

However, shock, vibration and temperature

changes during shipping can cause some

components to become loose.

Wiring and Connections:

Since electrical wiring and mechanical

connections may be loosened during shipment,

before first energizing the Converter System,

inspect wiring for damage and repair or replace

if needed.

Inspect for loose electrical and mechanical

connections. Tighten or replace defective

crimp-style lugs. Re-solder loose solder

connections. Tighten or replace all loose or

missing hardware –see page 17 for fastener

torque values.

6.2 Electrical Testing

Check that Supply Line cable connections to

the Converter System match phasing rules for

the site.

Disconnect Lightening Arresters if fitted.

Remove all fuses from VTs and CPTs. Label

these so that they can be correctly placed back

into service.

Close the Disconnector.

Simulate a closed Contactor by shorting each of

the Contactor Vacuum Interrupters (VI) using a

slim wire connected between the terminals at

each end of each VI.

Carry out Power Frequency (Hi-pot) tests to

ensure that there is no hidden damage in the

insulation system as follows:

Perform a phase to phase Power Frequency

(Hi-pot) test, across the Supply Line terminals.

Perform a phase to earth / ground Power

Frequency (Hi-pot) test, from each Supply Line

terminal to the enclosure.

Perform a phase to phase Power Frequency

(Hi-pot) test, across the Load terminals.

Perform a phase to earth / ground Power

Frequency (Hi-pot) test, from each Load

terminal to the enclosure.

System Max

Voltage kVac

Factory Test

Voltage kVac

Site Test

Voltage kVac

7.2

20

16

The voltage should be raised gradually to the

Site Test voltage, then kept at that voltage for 1

minute, then reduced gradually to zero.

Remove the wires connected between the

terminals at each end of the contactor VIs.

Replace all fuses in VTs and CPTs.

.

__________________________________________________________________________

D: OPERATION

7...Startup and Operation

Precautions & Warnings

READ AND UNDERSTAND

SECTION A ABOVE BEFORE

CARRYING OUT THE WORK

DETAILED BELOW

7.1 Theory of Operation

The controls system uses a PLC to

automatically control the Heater output to meet

the 0-100% process demand signal (generated

internally or customer supplied). There are 2

control methods: Full SCR, and SCR w/Trim.

In a full SCR system, the power output to the

heaters is controlled using solid state SCRs

(Silicon Controlled Rectifiers). If the process

demand signal is at 50% (12 mA demand), the

SCRs would be “gated” into conduction to allow

50% of the available power to be sent to the

heater. Full SCR systems with multiple heater

circuits all operate at the same demand level,

they are not staged. For example, a 3 SCR

system with a process demand of 45% will

trigger all 3 SCR’s at 45%.

In an SCR w/Trim system, the first load utilizes

an SCR, while all remaining loads are

controlled by a contactor. The PLC looks at the

process demand and calculates how many

contactor loads need energized, and what the

final SCR output will need to be. Some stepper

systems may use different sized loads.

In either mode, this power proportioning is

controlled by one of two methods: Zero

Crossover, or Phase Angle.

Zero Crossover Control

Zero Crossover control (ZC) proportions the

amount of power to the load by supplying full

sine waves of power to the load for a short

period, then supplying no power for a short

period, this sequence repeating. The ratio of on

to off periods determines the average power to

the load. This is accomplished by gating the

SCR switches into conduction at the zero volt

point on the sine wave, resulting in much lower

harmonic distortion & EMI. The ZC control is

based on a 1 second time base so in the 50%

demand example, the SCR switches would be

conducting full Sine of power for ½ second and

no power for ½ second resulting in 50% of the

available power being delivered to the load.

This is the control mode used in normal

operation of the Heater.

Phase Angle Control

Phase Angle control (PA) gates the SCRs into

conduction at various angles of the incoming

sine wave. Given a 50% demand, the SCR

switches would be gated into conduction at 90

degrees in the positive sine wave, and again in

the negative sine wave. This type of control is

very precise but can cause harmonic distortion

issues, so it is restricted to use in the Dryout

Mode only unless manually selected by the

operator. When PA is manually selected, the

main HMI screen will flash an indicator to alert

that PA is active.

Slow Start Mode

In Slow Start mode (SS), zero crossover is

used to start up to gradually increase the power

over a 100 second interval, until either 100%

output is achieved, or the ramping output

reference equals the power demand. This

mode is selectable.

Dry-out Mode

The Dry-out Mode (DM) feature, is used to “dry

out” Heaters that may have accumulated

moisture during long periods without power

applied. Phase Angle firing mode is used to

limit the voltage applied to the elements. This

is required in HV heating systems due to the

large amount of energy that can be delivered in

a single burst. As a Heater that contains

significant moisture could be damaged by full

voltage, DM helps to minimize this risk.

Note that in SCR w/Trim systems, the

Converter is used to dry-out the heater attached

to the Stepper before it is connected to the

supply line power.

Dry-out can be accomplished in two ways:

13

Manual: If Manual Dry-out is selected from the

HMI, the system will dry out the selected Heater

until it is turned off from the HMI.

Automatic: The Automatic Dry-out mode utilizes

feedback from the residual current monitoring

system, comparing the residual current with a

preset value from the HMI. If this preset is

exceeded, the controller will enter automatic

dry-out mode and stay in that mode for the

number of minutes set on the HMI.

If the system is unable to dry-out a Heater after

the programmed number of attempts, the

affected Heater will be disabled, and the HMI

will display a dry-out fault condition.

In both dry-out modes, the maximum output is

set using the HMI, up to a maximum of 20%. If

the process demand signal is lower than the

Max setting on the HMI, the lower of the two

signals will be used to avoid damaging the

process.

7.2 Electrical Interlocks

There are seven basic electrical interlocks that

will disable the Converter output:

Sheath or Flange Temperature Over-temp

(OTC). The System can be equipped with

multiple Over-temp Limit Controllers to protect

the heater from failure. The OTC(s) indicate

both an ALARM and a TRIP condition on the

HMI. The ALARM condition is a warning and

will self-reset when the temperature falls to a

safe value. The TRIP condition must be

manually reset (via HMI or remote input), after

the temperature has lowered back to a safe

value.

Residual leakage current. If the leakage current

exceeds the trip point set on the relay, the relay

will signal the PLC to trip the MV Contactor to

disable the affected load. The relay must be

manually reset (via HMI or remote input), and

the alarm condition cleared before the heater

can be re-enabled.

The disconnector switch auxiliary contact must

show that the disconnector switch is closed for

each load before the heater can be energized.

The Blown Fuse Auxiliary contact must show

that the MV fuses are all intact before the

heater can be energized.

The local and external E-Stop circuits must be

made before starting.

Any remote permissive inputs must be

energized.

Each SCR is controlled by a firing card that has

an alarm contact that must be clear, indicating

the SCR is not overheating.

7.3 HMI Screens - General

The HMI screens have a navigation bar across

the bottom. This menu stays visible for most

screens making navigation between screens

easy, the leakage current screen being the only

exception.

When the Converter System is first energized, it

is important to set up the HMI using the SETUP

screen before using any of the control screens.

The following sections show screens that are

used in normal operation only. See ‘Annex A’

for more detailed explanations, and for

additional set-up, dry-out, and diagnostic

screens.

14

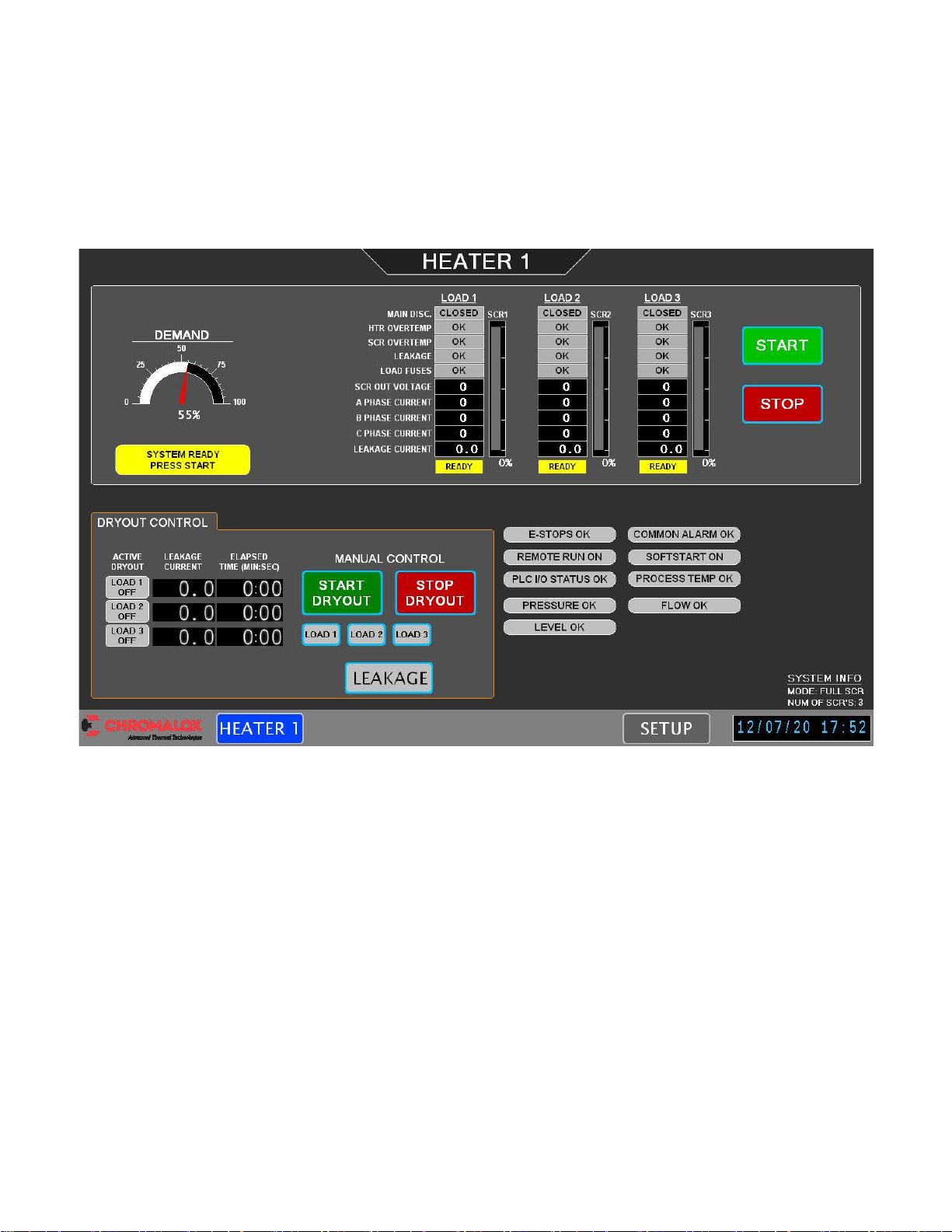

7.4 HMI Screens

The HEATER screen shows an overall view of the system, displaying system demand, permissive

signals, measured output voltages, phase currents, leakage currents, and status for each heater load.

This screen also displays DRYOUT control, as well as START/STOP functionality. The following shows

an example of a 3 SCR system in AUTO mode, with the demand coming from a temperature controller or

remote demand signal. The system is shown READY, pressing the START button would energize the

heater. System permissive signals and indications (E-stop, Common Alarm, etc..) are shown on the

bottom right. Some indications (Pressure, Flow, etc.) may not apply to all systems.

15

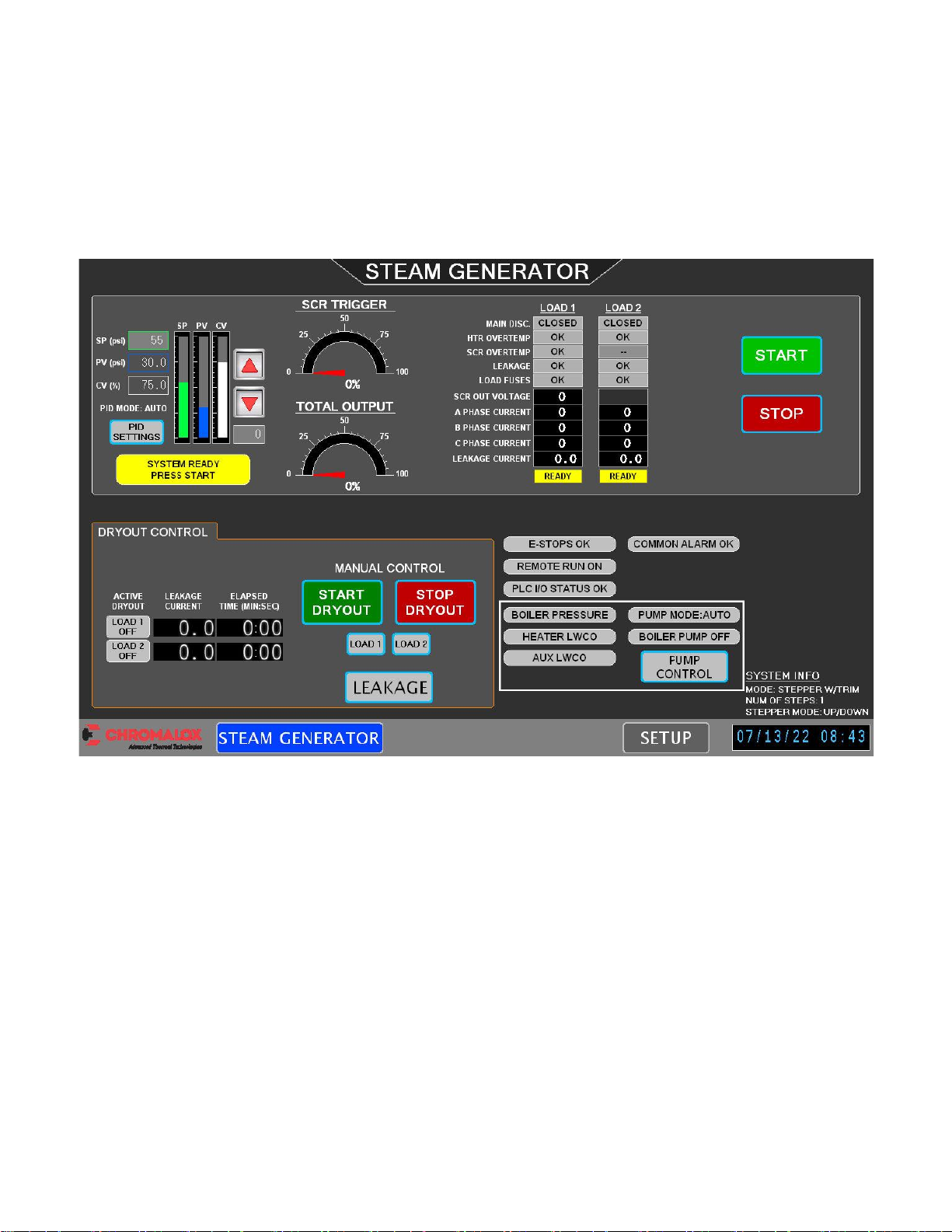

7.5 HMI Screens (Steam Generator Systems)

The STEAM GENERATOR screen shows an overall view of the system, displaying system demand,

permissive signals, measured output voltages, phase currents, leakage currents, and status for each

heater load. This screen also displays DRYOUT control, as well as START/STOP functionality. The

following shows an example of a 2 circuit Stepper system with an internal PID loop in AUTO mode. The

system is shown READY, pressing the START button would energize the heater. System permissive

signals and indications (E-stop, Common Alarm, etc..) are shown on the bottom right. Steam Generator

specific signals are shown in the white border (Pressure status, Pump Status, Low Water Cutoff).

____________________________________________________________________________

16

E: INSPECTION and MAINTENANCE

8...Inspection & Maintenance

Precautions & Warnings

READ AND UNDERSTAND

SECTION A ABOVE BEFORE

CARRYING OUT THE WORK

DETAILED BELOW

8.1 Monitoring

Any one of the following will prevent the

Converter starting:

•MV Disconnector open

•Emergency Stop engaged

•Remote Run off

If any of the following goes into a fault condition

the MV Contactor will be turned off.

•MV Fuses

•Over-temp monitors

•Ground / Earth Fault monitors

•Firing Circuit

Determine and rectify the cause of the fault

before making any attempt to re-energize the

Converter System.

8.2 Preventive Maintenance

Preventive maintenance consists of

inspections, tests and cleaning of equipment at

scheduled intervals. It helps detect and correct

conditions that could cause equipment

malfunction. The scheduled maintenance

instructions in this manual are intended to

enhance and form part of the site’s planned

maintenance program.

Preventive Maintenance Schedule

The schedule for conducting preventive

maintenance depends usage and site

conditions.

Unless the site has a known environmental risk,

it is recommended that maintenance be carried

out annually until experience allows the

schedule to be adjusted.

If the site has a known environmental risk, it is

recommended that maintenance be carried out

every six months until experience allows the

schedule to be adjusted.

It is recommended that the maintenance

interval should never exceed 5 years.

Enclosure Exterior

Inspect the Converter System’s exterior:

a. Inspect fan air inlet and air exhaust filters

and replace if necessary.

b. Touch up all chipped paint with primer and

paint. Remove any corrosion with sandpaper.

Enclosure Interior

Before accessing the interior of the System, it is

important to remove any materials from the

outside surface that may enter the System.

a. Wipe off all dust, and moisture from the

exterior surface of the door and surrounding

enclosure frame with a lint-free cloth.

b. Remove oil, and grease from the exterior

surface of the door and surrounding

enclosure frame with an alcohol-free

cleaner.

Clean and inspect the System interior:

a. Remove loose dust and dirt with a vacuum

cleaner.

b. Wipe off all moisture, and all remaining

dust, and dirt with a lint-free cloth.

c. Remove any sticky residues with a dry, lint-

free rag, using an alcohol-free cleaning

solvent.

d. Inspect for evidence of dripping water or

liquids falling on equipment parts. If found,

determine the cause and correct.

e. Inspect for rust on metal parts. Repair or

replace if found.

f. Inspect for signs of insect or animal

damage. Remove any spider’s webs.

g. Inspect for signs of mold.

h. Inspect for hydrogen sulfide corrosion (black

marks on plating) on conductive parts and

electrical contacts. Repair or replace if

found.

j. Inspect for salt corrosion on metal parts and

electrical contacts. Repair or replace if

found.

k. Inspect for partial discharge erosion on

insulators (signs of tracking on insulating

surfaces). Determine the cause of the

17

discharge, and repair or replace if found.

Replace insulators that have been

compromised by tracking.

l. Inspect for signs of overheating. If found,

determine the cause and correct. Repair or

Replace damage parts.

m. Inspect for worn or broken parts. If found,

determine if there is an underlying cause,

the repair or replace.

n. Inspect door gaskets and replace if worn

and/or deteriorated. Repair or replace if

found.

p. Make sure that moving parts move freely

and do not stick. Lubricate if necessary.

r. Inspect for signs of foundation damage or

movement.

Lubrication

Oil door hinges and latches with light machine

oil.

The Disconnector mechanism moving parts

should be lubricated every five years with

ISOFLEX TOPAS NB 52.

If necessary, Disconnector contact knifes

should be lubricated with ISOFLEX TOPAS

NCA 52.

The Contactor should not be lubricated.

Exercise Mechanisms

After lubrication, exercise the hinges, latches

and Disconnector mechanism to ensure free

movement. Close the Controller door to

exercise the Disconnector mechanism.

8.3 Wiring and Connections

Check wiring and connections:

a. Inspect wiring for wear, fraying, damage,

and evidence of overheating. Replace if

needed.

b. Inspect for loose electrical and mechanical

connections.

Replace damaged lugs.

Re-solder loose solder connections.

Replace all loose or missing hardware.

Tighten all connections. Special care

should be taken to ensure that all power

and earth / ground connections are fully

tight –see page 17 for fastener torque

values.

8.4 Contactors

Vacuum Contactor are sealed units and require

very little maintenance. Refer to contactor

manufacturer manual included in the document

package for maintenance instructions.

8.5 Converter SCR Stacks

SCR Stacks and associated electronics boards

and wiring harnesses are designed for long

trouble-free operation. Refer to Chromalox for

maintenance instructions.

8.3 Fault and abnormal Conditions

Indications

MV Fuse Blown

If any of the main MV power fuses open, the

blown fuse trip bar will open one or more micro-

switches. The CONTROL screen (see above)

gives a fuse open alarm. Following all safety

precautions detailed above; determine the

cause of the blown fuse and replace.

When removing a fuse, rotate the fuse body

slightly to help ease the fuse ferrule out of the

fuse clip. If necessary, lubricate the fuse clips

with Mobil® 28 red grease as the fuse is

rotated. Coat replacement fuses with this

grease to ease future removal.

Over-temp Fault

If any of the Over-temperature controllers trip, it

will be indicated in red as “OTC TRIP”. Run

mode can only be activated after the

overtemperature is cleared and reset.

Residual Current Fault

A residual current monitoring relay monitors

leakage current and sends the measured value

to the PLC. If the leakage current is above the

preset limit, the residual current relay will

energize, and the affected load will shut off. The

CONTROL screen will indicate a fault condition.

Firing Card

If an SCR heatsink overtemp is detected the

CONTROL screen will indicate the fault

condition.

Contactor Fault

If a Contactor is energized but no status is

received, a timer will begin. If this timer

18

completes, the system will stop, and the HMI

will indicate the fault.

Contactor Welded

If a Contactor is released but the status

remains, a timer will begin. If this timer

completes, the system will stop, and the HMI

will indicate the fault.

8.7 Testing

Conduct Power-Frequency (Hi-pot) tests to

clause 6.2.

8.4 Renewal Parts

See spares list supplied separately.

________________________________________________________________________

FASTENER TORQUES

All Torques +/- 10%

M5 Torx Head Thread Rolling Screws 19 lbs-in [2.1Nm]

M5 Stainless Steel Screws 19 lbs-in [2.1Nm]

M5 Nuts for Securing Steelwork 56 lbs in [6.3 Nm]

M6 Hex Nuts for Securing Ground Bars 52 lbs-in [5.8 Nm]

M6 Truss Head Stainless Steel Screws 71 lbs-in [8.0 Nm]

M6 Hex Head Bolts for Securing Gland Plates 95 lbs-in [10.7 Nm]

M6 Pan Head Screws for Securing Door Lock Guides 95 lbs in [10.7 Nm]

M6 Nuts for Securing Steelwork 95 lbs in [10.7 Nm]

M8 Hex Nuts for Securing Contactor Cable Lugs & Copperwork Joints 9.4ft lbs [12.7Nm]

M8 Hex Head Bolts for Securing the VTs, CPT, Contactor & Lifting Angles 19.2 lbs-ft [26 Nm]

M10 Hex Nuts for Securing Inductor and SCR Cable Lugs & Fuse Copperwork 19.4 lbs ft [26.3Nm]

M10 Hex Head Nuts for Securing Ground Bars 19.4 lbs-ft [26.3 Nm]

M10 Hex Head Bolts for Securing the Moldings to the Sub-Panels 38 lbs-ft [52 Nm]

M12 Hex Head Bolts for Securing the Disconnector 66 lbs-ft [90 Nm]

19

ANNEX 1: HMI SCREENS

The following pages give a full description of all the screens available on the HMI for full SCR systems.

Note that actual layout may vary slightly.

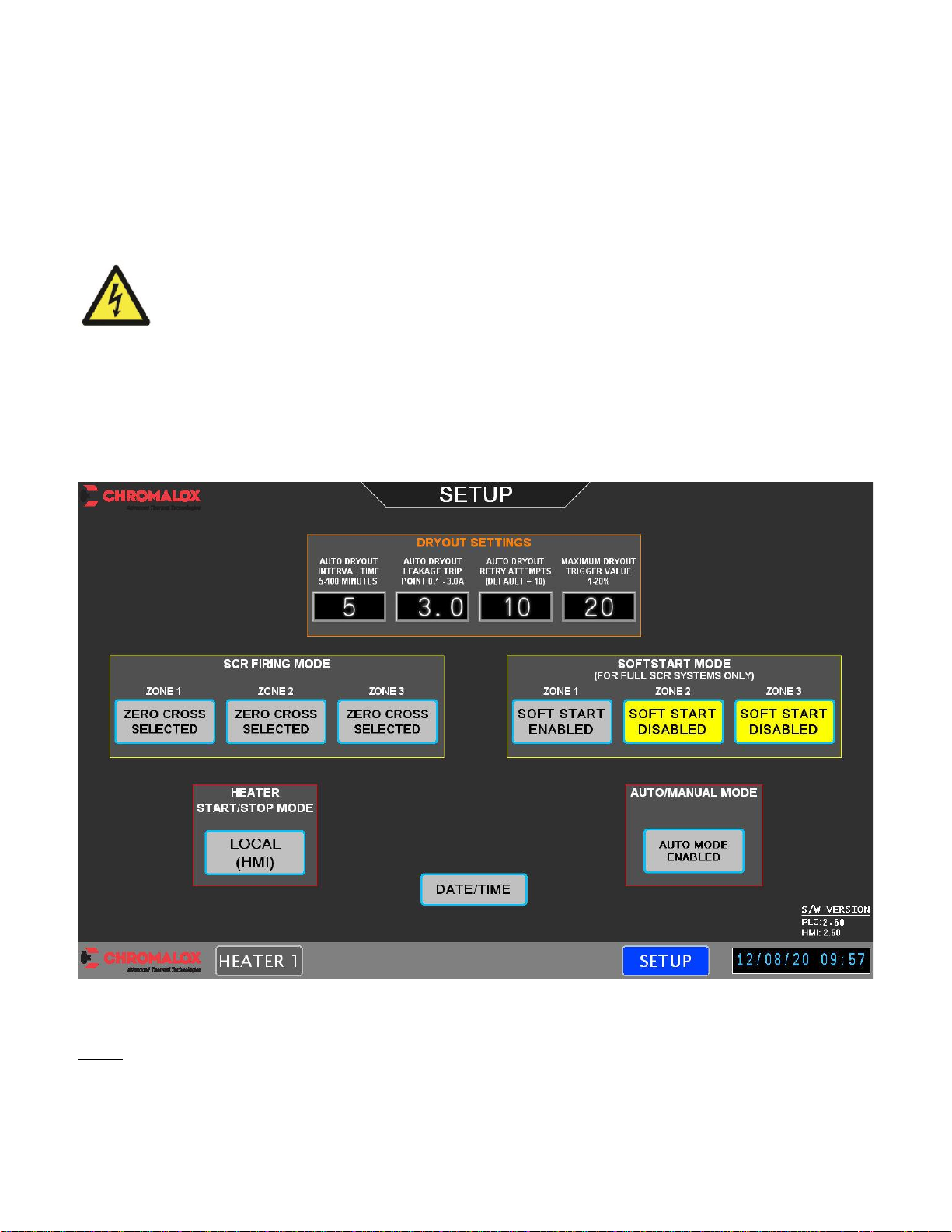

A1.1 Set-Up Screen

NOTE: The Low Voltage Section should be checked and verified, and the following settings

should be set before energizing the High Voltage

Energize the Low Voltage Supply.

Touch (SETUP)

The SETUP screen is used to configure dry-out settings, select between Auto/Manual mode, enable

Phase Angle or Zero Cross firing, toggle local/remote mode, and update the Date/Time.

Full SCR System

Notes:

“AUTO DRYOUT INTERVAL TIME”: This configures how long an Auto-Dryout cycle will run. This is

selected in minutes.

20

“AUTO DRYOUT LEAKAGE TRIP POINT”: This is the amount of leakage current (Amps) that will

trigger and Auto-Dryout sequence. The maximum allowed is 3.0A.

“AUTO DRYOUT RETRY ATTEMPTS”:If the number of dry-out attempts for an element reaches

this number and the element is still not dry, dry-out will be disabled for this load, preventing any

further dry-out cycles, and a ‘Dry-out Fault’will be indicated on the HMI.

“MAXIMUM DRYOUT TRIGGER VALUE”: The maximum dry-out trigger % is restricted to a

maximum of 20% of full load current to avoid heater damage and to limit harmonics caused by Phase

Angle firing.

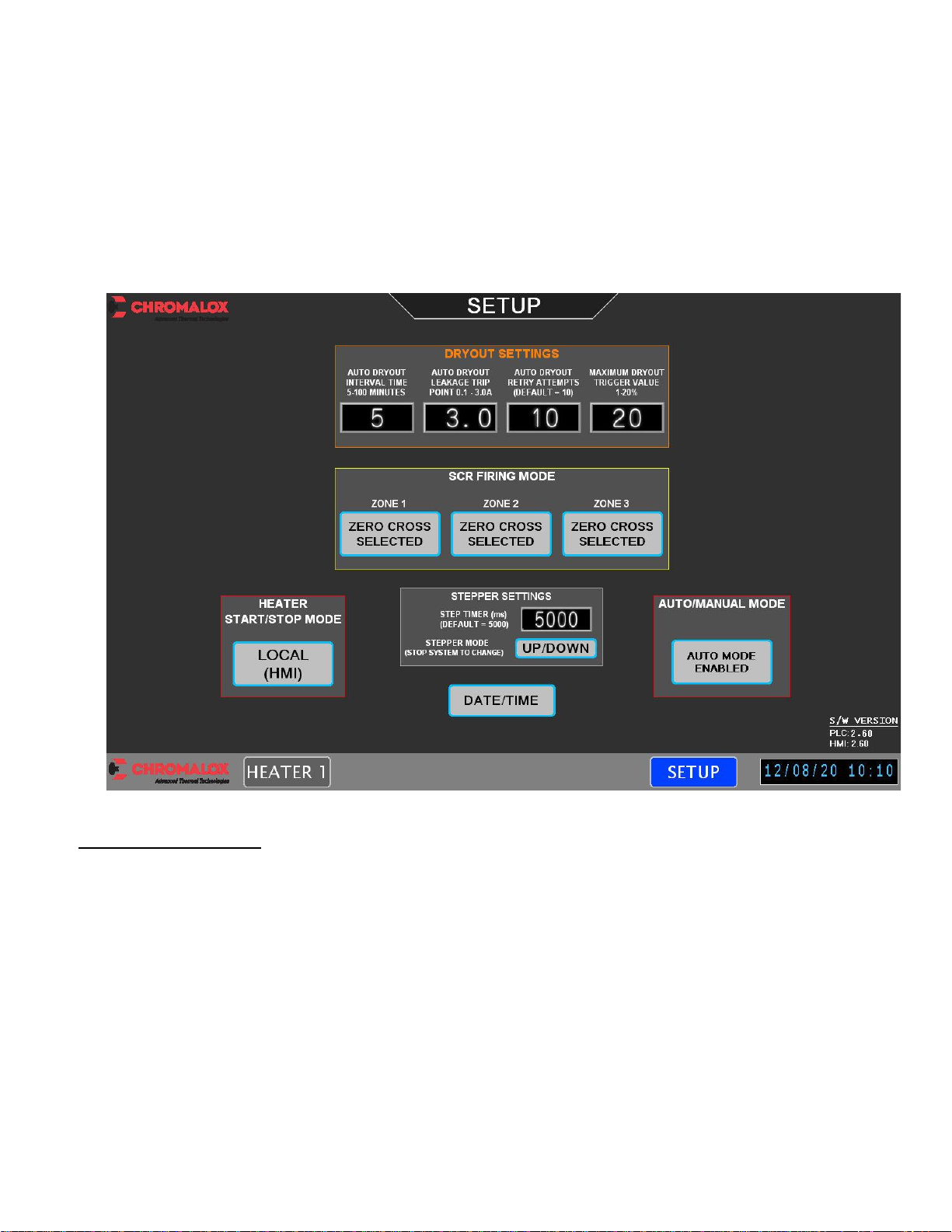

SCR Stepper System

Stepper w/Trim Settings:

“STEP TIMER (ms)”: This adjusts the time between steps when the system is turning on to meet the

initial demand. Once the demand is met, this time is automatically reduced to allow quicker tracking

of the demand signal.

“STEPPER MODE”: Two modes exist in stepper systems: Up/Down and Circular. These modes

determine which loads are stepped on/off as demand goes up/down.

In Up/Down mode, the first load will always be the first to turn on and last to turn off.

In Circular mode the system tracks the loads to help spread out the time that each load is energized.

If load 3 is the first load energized, it will be the first load to turn off. Note: Circular mode is not

available in Progressive Stepper systems.

Other manuals for DirectConnect

1

Table of contents