chromasens allPIXA evo 10k User manual

allPIXA evo camera | Manual

CD40195

R01 / 2020-0214

PMA_CHR_CD40195_R01_allPIXA_evo_UserManual.docx 2

Table of Contents

1General information 5

1.1 About Chromasens 5

1.1.1 Contact information 5

1.1.2 Support 5

1.2 Firmware and software version in this manual 6

1.3 List of abbreviations 6

1.4 Definitions 7

1.5 Scope of supply of the allPIXA evo camera 8

1.6 Design of a line scan camera system 9

2Specifications and definitions 10

2.1 Camera highlights 10

2.2 Feature Reference 11

2.3 Technical specification 12

2.4 Mechanical specification 13

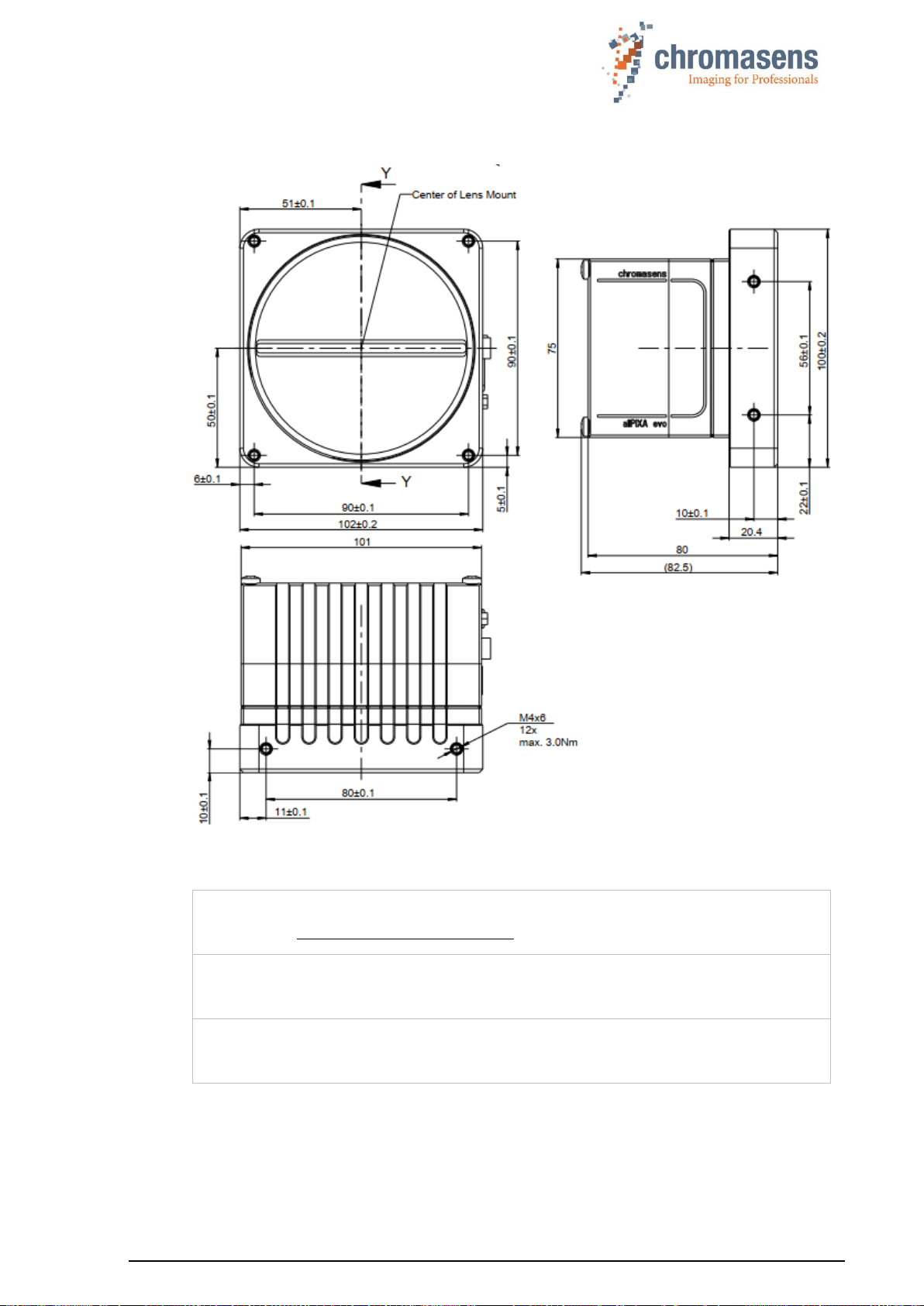

2.4.1Mechanical dimensions of the allPIXA evo 10k camera 13

2.4.2 Mechanical dimensions of the allPIXA evo 15k camera 14

2.5 Sensor alignment and orientation 15

2.6 Adapter and accessories 16

2.6.1 Lenses, adapters and mounts 16

2.6.2 Cooling kit 16

2.6.3 Environmental requirements 17

3Safety 18

3.1 Depiction of safety instructions 18

3.2 Basic safety regulations 18

3.3 Safety instructions on the allPIXA evo camera 19

3.4 Purpose / applications 19

3.5 Staff requirements 20

3.6 Organizational measurements 20

3.7 Safety instructions for maintenance / cleaning 20

3.8 Maintenance and cleaning of the allPIXA evo camera 21

3.8.1 Cleaning intervals 21

3.8.2 Cleaning process 21

3.9 Disposal 21

4allPIXA evo –basic functionality 22

4.1 Basic design of the allPIXA evo camera 22

4.2 Design of the allPIXA evo camera line scan sensor 23

4.3 The allPIXA evo camera line scan sensor pixel arrangement 24

4.4 Spectral sensitivity of the allPIXA evo camera line scan sensor 24

4.5 Image processing 26

4.5.1 Digital image processing 26

4.6Black-level correction and shading (flat-field) correction 27

4.7 White balancing with a closed-loop control 28

PMA_CHR_CD40195_R01_allPIXA_evo_UserManual.docx 3

4.8 Setting concept 29

4.8.1 Available user sets 29

4.8.2 Data format 29

4.8.3 Restoring the factory default 29

4.9 SphinxLib API 29

5Installing the allPIXA evo camera 31

5.1 Interface and status LED 31

5.1.1 Power supply 32

5.1.2 Micro-USB 32

5.1.3 SFP+ connectors 32

5.1.4 Status LED 32

5.1.5 Digital IO port 33

5.1.6 LVCMOS and RS422 levels 34

5.2 Trigger/IO and Encoder wiring 34

5.2.1 Using a light barrier –Start condition only 35

5.2.2 Using a light barrier –Start and stop condition 35

5.2.3 Using line trigger input 36

5.2.4 Using an encoder 36

5.3 Mechanical installation 37

5.4 Thermal links / cooling 37

5.5 Preventing installation errors 38

5.5.1 Conveyor belt tracking 38

5.5.2 Perpendicularity of the sensor to the direction of transport 38

5.5.3 Rotation around the longitudinal axis of the line scan sensor 39

5.5.4 Rotation around the transverse axis of the line sensor 40

5.6 Electrical installation 40

5.7 Connecting the camera to the PC 42

5.8 Updating the firmware of the allPIXA evo camera 43

5.9 Camera system setup –first steps 44

5.10 Installing the camera 44

6Working with GCT 45

6.1 Installing GCT 45

6.2 Connecting the camera 46

6.3 Grabbing images 46

6.3.1 Activating the filter driver 46

6.3.2 Setting image parameters 47

6.4 Updating the firmware 48

6.5 Downloading firmware components 48

6.6 Flat field correction: Creating a shading reference (PRNU) 49

6.7 Flat field correction: Creating a black-reference (DSNU) 50

6.8 Plotting function 51

6.9 Detail view of an image 53

6.10 Camera features 53

6.10.1 User level 53

6.10.2 Feature data types 54

6.11 Other functions 54

PMA_CHR_CD40195_R01_allPIXA_evo_UserManual.docx 4

6.11.1 Starting / stopping test mode 54

6.11.2 Saving camera features to a text file 54

7Camera system set-up 55

7.1 Installing the camera 55

7.2 Starting up the system 56

7.3 Adjusting the camera to the environment (camera calibration) 56

7.4 Synchronizing cameras: Master and Slave operation 58

7.4.1 Set up the cameras for master-slave synchronization 58

7.4.2 Connect master and slave camera(s) 59

7.4.3 Digital I/O port pin connection for master and slave camera 59

8Troubleshooting and Support 61

8.1 Returning material (obtain an RMA number) 61

8.2 Camera status identification by the camera status LED 61

8.3 Camera overheating protection 62

8.4 Before contacting Chromasens technical support 62

9Appendix 64

9.1 EC conformity declaration 64

9.2 Camera system design / lens selections 65

9.2.1 Calculating the object-to-image distance 65

9.2.2 Calculating the distance rings (tubes) for the allPIXA evo camera 66

9.2.3 Calculating the integration time 67

PMA_CHR_CD40195_R01_allPIXA_evo_UserManual.docx 5

1 General information

1.1 About Chromasens

The name of our company, Chromasens, is a combination of 'Chroma' which means color, and

'Sens' which stands for sensor technology.

Chromasens designs, develops and produces high-quality and user-friendly products:

◼Line scan cameras

◼Camera systems

◼Camera illumination systems

◼Image acquisition systems

◼Image processing solutions

Today, Chromasens GmbH is experiencing steady growth and is continually penetrating new

sales markets around the globe. The company's technologies are used, for example, in products

and for applications such as book and document scanners, sorting systems and inspection

systems for quality assurance monitoring.

Customers from all over the world of a wide range of industrial sectors have placed their trust in

the experience of Chromasens in the field of industrial image processing.

1.1.1Contact information

Chromasens GmbH

Max-Stromeyer-Str. 116

78467 Konstanz

Germany

Phone: +49 (0) 7531 / 876-0

Fax: +49 (0) 7531 / 876-303

Email: info@chromasens.de

HP: www.chromasens.de

1.1.2Support

Should you ever have problems with the allPIXA evo camera that you cannot solve by yourself,

please look into this manual for additional information, check the troubleshooting chapter 8,

contact your local distributor, or send us an e-mail.

Chromasens GmbH

Max-Stromeyer-Str. 116

D-78467 Konstanz

Germany

Phone: +49 (0) 7531 / 876-500

Fax: +49 (0) 7531 / 876-303

Email: support@chromasens.de

HP: http://www.chromasens.de/en/support

Visit our website at http://www.chromasens.de which features detailed information on our

company and products.

PMA_CHR_CD40195_R01_allPIXA_evo_UserManual.docx 6

1.2 Firmware and software version in this manual

This document refers to the following version:

Camera: Packet 1.18

The recent version may have additional functions. Therefore, contact the Chromasens support.

1.3 List of abbreviations

Abbreviation

Meaning

Explanation

CCM

Color conversion matrix

The CCM supports the conversion from for

example RGB to sRGB or any user-defined

conversion

Corona II

LED illumination

Chromasens product

DSNU

Dark signal non-

uniformity

Irregularity in the dark image

GenICam

Generic interface for

cameras

Generic programming interface for industrial

cameras administered by the European

Machine Vision Association

www.emva.org

LED

Light emitting diode

-

PRNU

Photo response non-

uniformity

Difference in sensitivity of the individual pixels

ROI

Region of interest

-

RS485

ANSI standard defining the electrical

characteristics of drivers and receivers for use

in serial communications systems.

SFNC

Standard Feature Naming

Convention

Document of the GenICam standard, which

provides feature names for common camera

features.

VSync

Vertical synchronization

Frame signal for an image (corresponds to

FVAL: frame valid)

PMA_CHR_CD40195_R01_allPIXA_evo_UserManual.docx 7

1.4 Definitions

Chromasens

Other used definitions

Explanation

Black-level

correction

Background subtraction,

Offset correction

Corrects the dark offset for each

pixel (DSNU)

Trigger Delay Lines

Image start delay

Delay of the image’s beginning,

as a number of lines, from the

beginning of the trigger condition

to the beginning of the image

Shading correction

brightness correction,

White-level correction,

PRNU correction

Corrects brightness

inhomogeneities resulting from

lens, light and non-uniformity of

sensor pixels (PRNU)

Flat-field correction

Corrects dark offset and

brightness inhomogeneities

RGB line distance

Line shift,

Line distance,

Spatial correction,

ImageCalibrationLineDistance

The tri- or quad-linear sensor has

individual pixel lines for (gray, )

red, green and blue. Inside the

camera, the spatial differences

are corrected.

White balancing

Setting the operation point

White balancing ensures that a

reference white is kept stable in

an image with color temperature

or brightness changes of the

illumination. This can be done in a

single setup process or in a

continuous process.

White reference

White reference position

The white reference is a physical

patch in the field of view of the

camera that can be used for a

camera-internal white balancing

by adjusting the gain values.

PMA_CHR_CD40195_R01_allPIXA_evo_UserManual.docx 8

1.5 Scope of supply of the allPIXA evo camera

Check your device upon delivery to ensure that it is undamaged and complete.

The following components are supplied with the allPIXA evo camera:

◼allPIXA evo camera packaging

Check the packaging for damage, which may have occurred during transport.

◼allPIXA evo camera

Check the camera for damage, which may have occurred during transport.

The rating plate is located on the rear of the allPIXA evo camera. It shows the camera

resolution and the serial number.

◼Additionally ordered and supplied accessories

Lens adapters, extension rings, lenses and other accessories are not included in the

standard scope of delivery. These items must be ordered separately as accessories.

Check additionally ordered accessories for completeness and for damage, which may have

occurred during transport.

Read this manual carefully before using the camera, contacting your local partners or the

Chromasens support.

Should there be any questions left, do not hesitate to contact your local partner or us.

We would be pleased to be of assistance to you.

PMA_CHR_CD40195_R01_allPIXA_evo_UserManual.docx 9

1.6 Design of a line scan camera system

The following figure demonstrates the basic setup of a typical line scan camera system:

Figure 1: Design of a line scan camera application

The following components are necessary in a typical line scan camera application:

Component

No.

Line scan camera: An allPIXA evo camera, which scans the image line by line

and communicates with the PC (5).

1

The optical system: Optical lenses with tubes and mounts with an adjusted

focusing

2

Illumination: The illumination system lights up the information carrier/scan area

on the passing object. The Chromasens Corona II illumination system is an ideal

supplementary option for the allPIXA evo camera.

3

Illumination controller: Controls and monitors the illumination unit. The

Chromasens Corona II illumination (3) has integrated temperature/voltage

sensors which can be read out with the XLC4 controller. By use of the XLC4

controller, the illumination unit can be monitored and kept stable.

4

Fiber optic cable and suitable network card in the PC: The image data are

sent to a PC using one or two fiber optic cables. (6).

5

PC: The PC system performs subsequent processing of the image data and can

optionally control the illumination system (3 + 4).

6

Speed detection: The speed of the object / conveyor belt can be detected by an

optional incremental encoder. The encoder can be connected to the allPIXA evo.

7

Conveying unit: The conveying unit moves the scanned object past the allPIXA

evo camera.

8

Power supply: Both, the allPIXA evo camera and the illumination system, require

a suitable power supply.

9

PMA_CHR_CD40195_R01_allPIXA_evo_UserManual.docx 10

2 Specifications and definitions

The allPIXA evo camera family is available in the following maximum resolutions:

◼10,240 pixels

◼15,360 pixels

The allPIXA evo camera comprises all functions required for supplying images with the same

color, brightness and resolution of each operational area.

The allPIXA evo camera is especially suitable for inspection systems requiring a very high speed

and a consistently high color quality.

The camera is compliant with the GigE Vision 2.0 specification which defines the communication

interface protocol for any GigE Vision device. The device description of the camera is contained

in an XML file. For more information for GigE Vision see: https://www.emva.org/standards-

technology/genicam.

The camera can be connected to the PC either with a single copper or fiber cable or with two

cables using Link Aggregation.

Continuous white balancing is possible during image acquisition to ensure optimum color

quality. In addition, offset and shading correction ensure the balance of different color pixel

sensitivities (DSNU and PRNU) as well as the illumination process.

The design was fully revised during development of the housing, which is impressively tough

but offers several screw-mounting options. Take notice that the wide range of adapter options

makes the installation simple for users.

The standard mount connections M72x0.75 for the 10k camera, or M95x1.0 for the 15k camera,

respectively, permit to use all commercially available standard lenses. In addition, special

adapters are available that permit to connect Chromasens accessories.

2.1 Camera highlights

◼Quadlinear color line scan camera (quadlinear CMOS line scan sensor)

◼5,6 µm pixel size

◼High accuracy sensor alignment

◼GigE-Vision-compliant (GigE-Vision 2.0)

◼3 x 8 bits color information on the output side; RGB spatial compensation in the camera

(also sub-pixel correction, patented)

◼ROI mode (one ROI selectable)

◼Continuous white balancing maintains a constant image brightness and color irrespective

of the temperature and service life of the illumination system

◼Incremental encoder port on the camera; this ensures simple handling and less

programming work

◼Flat field correction, fully automatic calculation internally in the camera

◼Gamma correction, brightness and contrast controller, separate for each channel

◼Robust metal housing

◼Standard mount connections M72x0.75 for the 10k camera, or M95x1.0 for the 15k

camera, respectively

◼Special adapters permit to use Chromasens accessories

◼Internal test image generator

◼Area scanning with variable image lengths based on trigger inputs (light barriers)

PMA_CHR_CD40195_R01_allPIXA_evo_UserManual.docx 11

2.2 Feature Reference

For detailed information on camera controls refer to the allPIXA evo Features Reference, which

is available on the Chromasens website. It describes the standard and advanced camera

controls for GigE Vision. Please make sure that you always refer to the feature reference that

matches the firmware version used.

PMA_CHR_CD40195_R01_allPIXA_evo_UserManual.docx 12

2.3 Technical specification

Sensor

Quad linear CMOS color line sensor

Pixel size

5,6 µm x 5,6 µm (5,6 µm pitch)

Line spacing

11,2 µm between R-G and G-B

Spectral sensitivity

360 nm to 960 nm

Resolution

10240 / 15360px x 4 lines

Output

Single/Dual 10 GigE

GigE Vision® 2.0 compliant

Maximum line rate - camera internal

mono: up to 71 kHz |RGB: up to 3 x 71 kHz

Maximum line rate in ROI mode

(1 ROI available)

depend on ROI size

RGB and mono: up to 71 kHz

Maximum line rate color: output

Data rate over 10 GigE depend on network system

Single 10 GigE:

10240 pixels: up to 40 kHz

15360 pixels: up to 26 kHz

Dual 10 GigE (Link aggregation)

10240 pixels: up to 48 kHz, see Note

15360 pixels: up to 32 kHz, see Note

Maximum line rate mono: output

Data rate over 10 GigE depend on network system

Single 10 GigE

10240 pixels: up to 71 kHz

15360 pixels: up to 71 kHz

Data format

3 x 8 bit color mode or

1 x 8 bit mono mode

Trigger mode

Off / On

Frame Start / Frame Active / Line Start

Interface

2 x SFP+ (copper and fiber connectors)

Other interfaces

Power supply (6 pin Hirose, male)

External IO (15 pin HD D-Sub, female)

USB 2.0 (Micro-USB)

Camera mount

M72x0.75 for allPIXA evo 10k,

M95x1.00 for allPIXA evo 15k,

Adapters to Chromasens accessories available

Certifications

CE, FCC compliant, RoHS

Power supply

12 to 24 VDC +/- 10%; 1A@24V

Housing temperature

0°C to 60°C; 32°F to 140°F

Housing dimensions

10k: L = 102 mm, H = 76 mm, D = 82 mm

15k: L = 102 mm, H = 101 mm, D = 82 mm

Weight

<0.9 kg

NOTE

The allPIXA evo maximum line frequencies over 10 GigE depend on network

hardware and configuration. Please note that only Windows Server supports

Link Aggregation (LAG) for Dual 10 GigE 10. Windows 10 do not support LAG.

NOTE

The power consumption may be up to 1 ampere@24V. It is recommended to

provide a power supply with 24VDC/1amp or with higher possible power

consumption.

PMA_CHR_CD40195_R01_allPIXA_evo_UserManual.docx 13

2.4 Mechanical specification

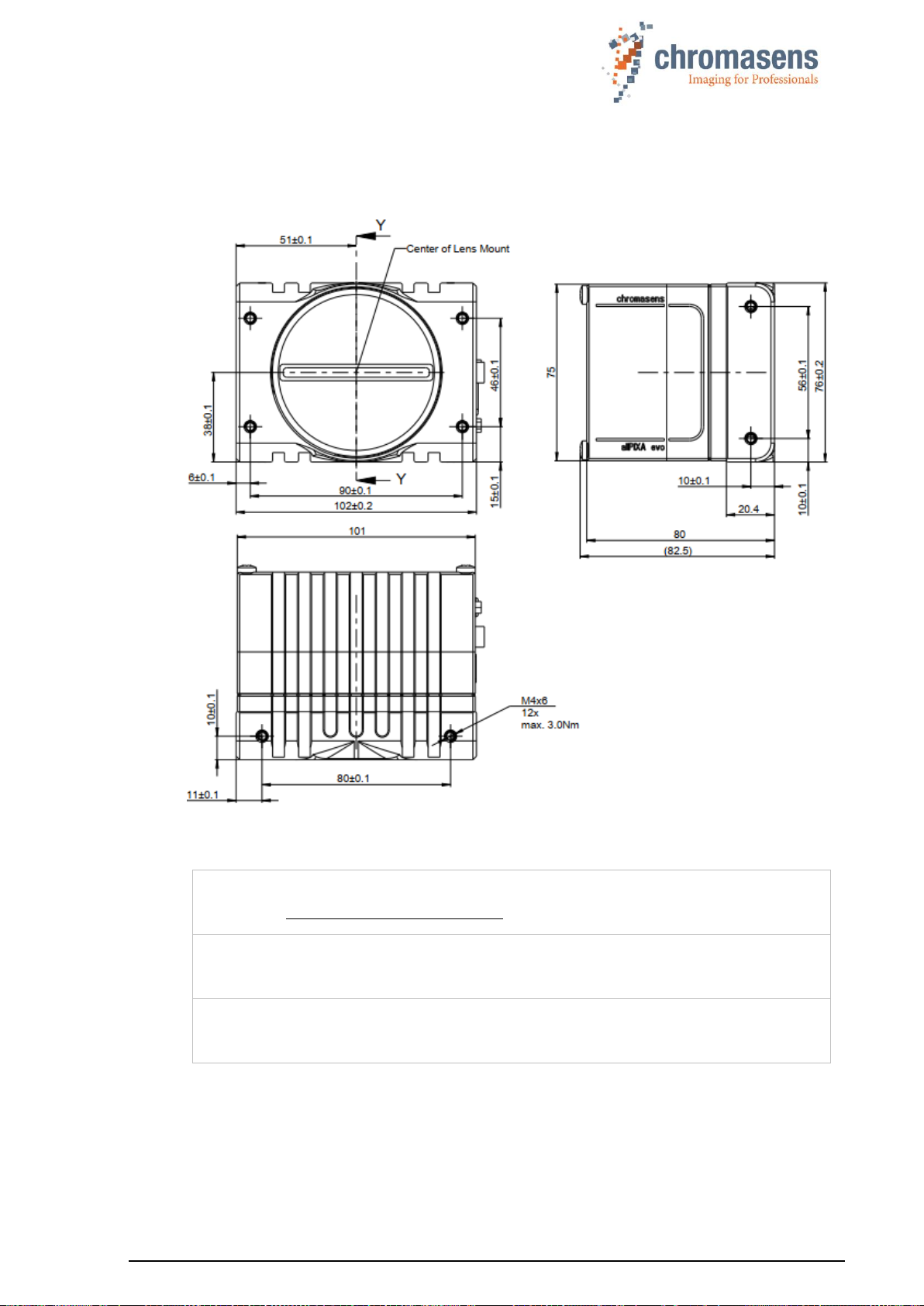

2.4.1Mechanical dimensions of the allPIXA evo 10k camera

Figure 2: Mechanical dimensions of the allPIXA evo 10k camera

NOTE I

Drawings and 3D-CAD-models are available on our homepage

http://www.chromasens.de/user

NOTE II

The shown position of the sensor surface is given as resulting optical value

including lengthening of the sensor glass. For more details, see section 2.5.

NOTE III

For information about the XYZ coordinate system and sensor alignment, see

section 2.5.

PMA_CHR_CD40195_R01_allPIXA_evo_UserManual.docx 14

2.4.2Mechanical dimensions of the allPIXA evo 15k camera

Figure 3: Mechanical dimensions of the allPIXA evo 15k camera

NOTE I

Drawings and 3D-CAD-models are available on our homepage

http://www.chromasens.de/user

NOTE II

The shown position of the Sensor surface is given as resulting optical value

including lengthening of the sensor glass. For more details, see section 2.5.

NOTE III

For information about the XYZ coordinate system and sensor alignment, see

section 2.5.

PMA_CHR_CD40195_R01_allPIXA_evo_UserManual.docx 15

2.5 Sensor alignment and orientation

Sensor orientation and alignment in viewing from the front side of the camera. For a detailed

mechanical drawing, see section 2.4.

First pixel of sensor lines:

Left side

Color lines orientation:

Blue: top

Green: center

Red: bottom

Sensor alignment:

Position:

X: < +/- 100 µm

Y: < +/- 100 µm

Z: < +/- 100 µm

Rotation about:

Y: < +/- 0.1 °

Z: < +/- 0.1 °

Planarity of sensor surface:

< +/- 0.50 µm

Sensor window:

Thickness: 1.1 mm

Refraction index 1.5

Optical path extension: 0.37 mm

Figure 4: Sensor alignment

Sensor alignment is an important issue for:

•Adjusting multi-camera systems

•Replacing cameras

•Mechanical design of the mounting system for the camera

First pixel

X

Y

Z

PMA_CHR_CD40195_R01_allPIXA_evo_UserManual.docx 16

2.6 Adapter and accessories

2.6.1Lenses, adapters and mounts

Chromasens offers a large variety of accessories which are designed to provide maximum

flexibility and to get most out of the camera.

For the allPIXA evo cameras, special adapters are available that permit to use the accessories

of the allPIXA pro cameras.

You can find the complete list of all accessories including descriptions and detailed drawings in

the login area of our website at www.chromasens.de/user.

NOTE

For more information about accessories, refer to the corresponding accessories

catalogue.

2.6.2Cooling kit

To dissipate heat and thus reduce the housing temperature, a special cooling kit is available

that can be fixed to the camera, on the side and / or on top or bottom:

Figure 5: Cooling Kit for the allPIXA evo cameras

The distance of the mounting holes of the allPIXA evo housing are the same as for the allPIXA

wave camera. Therefore, the cooling kit of the allPIXA wave can be used:

Description

Identification No.

Pos.

allPIXA wave Cooling Kit B100

CP000540

01

PMA_CHR_CD40195_R01_allPIXA_evo_UserManual.docx 17

2.6.3Environmental requirements

Value

Temperature for camera operation

See section 2.3 for the allowed housing

temperature

Air humidity during camera operation

20% - 85% relative air humidity,

non-condensing

Storage / transport temperature

-20 ºC - +85 ºC; -4 °F - +185 °F

Protection category

IP50

General ambient conditions

Operation

IEC 721-3-3:IE33

Transport

IEC 721-3-2:IE21

Storage

IEC 721-3-1:IE11

NOTE:

You should use thermal conductive mounting (for example direct attachment

on metal frame) to decrease temperature and for improved camera

performance. See also section 5.4.

PMA_CHR_CD40195_R01_allPIXA_evo_UserManual.docx 18

3 Safety

3.1 Depiction of safety instructions

Safety-relevant information is indicated in this manual as follows:

WARNING

Indicates a potentially hazardous situation or task, which, if not avoided,

could result in serious injury or death.

CAUTION

Indicates a potentially hazardous situation or task, which, if not avoided,

may result in minor or moderate injury.

Indicates a potentially hazardous situation or task, which, if not avoided, could

result in damage to the product or the surrounding environment.

3.2 Basic safety regulations

The basic safety regulations always observe the following:

◼Do not attempt to install the device or start operation before you have read all supplied

documentation carefully and have understood its contents.

◼Safe and correct operation of the device requires correct and appropriate transport, storage,

mounting and installation as well as careful operation and maintenance.

◼Operation of the allPIXA evo camera device is only permitted if it is in a faultless and safe

condition. If a fault or defect occurs, the allPIXA evo camera, the machine, or the system in

which the allPIXA evo camera is installed, must be stopped immediately, and the responsible

person must be informed.

◼Modifications and extensions to the allPIXA evo camera are only permitted if the prior written

consent of Chromasens GmbH is obtained. This applies in particular to modifications and

extensions which can negatively affect the safety of the allPIXA evo camera.

◼Compliance with the ambient conditions described in this manual is essential.

PMA_CHR_CD40195_R01_allPIXA_evo_UserManual.docx 19

3.3 Safety instructions on the allPIXA evo camera

Risks from hot surfaces

The body of the allPIXA evo camera heats up during operation.

Do not touch hot surfaces without suitable protective gloves. Always allow

hot surfaces to cool down before carrying out any work on the unit.

Electric voltage hazard

The allPIXA evo camera runs with electric power. Before any work is carried

out on the allPIXA evo camera, be aware to disconnect the mains cables.

Make sure that the device is safely isolated from the power supply!

Risk of electrostatic discharge

The allPIXA evo camera contains components and units which are sensitive

to electrostatic charge.

Observe all precautionary measures for handling electrostatically sensitive

equipment.

Make sure that allPIXA evo camera, its corresponding tools, its equipment,

and the knowledge of the person who is handling it have the same electrical

potential.

3.4 Purpose / applications

◼The allPIXA evo camera is designed for machines and systems which are used for

commercial and industrial applications.

◼The owner of the machine or system in which the allPIXA evo camera has been installed is

responsible for compliance with relevant safety regulations, standards and directives.

Commissioning of the allPIXA evo camera is only permitted if the machine or system, in

which the camera is installed, complies with the safety regulations and standards of the

country in which the allPIXA evo camera runs.

◼The owner of the machine or system with the installed allPIXA evo camera must verify the

suitability of the allPIXA evo camera for its intended use.

◼Safety regulations of the country in which the device is used must be complied with it.

◼The allPIXA evo camera may only be connected or used as described in this manual.

◼The allPIXA evo camera must be set up and installed in compliance with the instructions

contained in this manual.

PMA_CHR_CD40195_R01_allPIXA_evo_UserManual.docx 20

3.5 Staff requirements

◼The system owner must ensure that all persons working on the system are trained for the

required work and have read and understood this manual. This applies particularly to the

employees who only work occasionally with the allPIXA evo camera, for example, during

commissioning and maintenance work.

◼Work on the electrical installation of the system may only be carried out by a qualified

electrician or persons who have undergone the necessary electrotechnical training under

the supervision of a qualified electrician, in compliance with applicable electrotechnical

regulations.

◼Be aware that only suitably trained and qualified persons are permitted to work with the

allPIXA evo camera. Such persons are qualified to work with the allPIXA evo camera device

if they are familiar with its assembly, installation, care, and all necessary precautionary

measures.

◼Assignments and responsibilities of the staff charged with operation, commissioning,

maintenance, and repair must be clearly defined and specified by the owner of the device

in which the allPIXA evo camera is installed.

3.6 Organizational measurements

◼The instruction manual must be stored safely in the vicinity of the camera in operation.

◼Information contained in this manual must be integrated into the documentation of the

device in which the allPIXA evo camera is installed.

◼The allPIXA evo camera and all connected peripheries must be checked regularly for visible

external damages.

3.7 Safety instructions for maintenance / cleaning

◼Before any service or maintenance work is carried out, the responsible staff has to be

informed.

◼Deadlines and intervals for regular inspections must be complied with.

◼Before maintenance is started, the allPIXA evo camera must be isolated from the power

supply.

◼Due to the risk of fire, devices such as radiators, heaters, or lighting equipment must be

allowed first to cool down.

◼Only technicians of the Chromasens GmbH are permitted to open or slacken screws or

housing sections of the allPIXA evo camera.

◼Necessary repairs may only be carried out by Chromasens GmbH.

◼Cleaning of the device is only allowed with a soft, lint-free cloth and Isopropanol (optional).

◼To avoid damages, the camera should only be transported in its original packaging.

This manual suits for next models

1

Table of contents

Popular Machine Vision System manuals by other brands

Advantech

Advantech VPS-3100 user manual

AXIOMTEK

AXIOMTEK RSC101 Series user manual

CIS

CIS VISION:mini VCC-G21X31ACL Product specification & operational manual

PhaseOne

PhaseOne RP1 1600 installation manual

TKH

TKH SVS-Vistek MotionBLITZ Cube6 manual

Daheng Imaging

Daheng Imaging MERCURY GigE Series user manual