Chrontel CH7034B Supplement

AN-B013

Application Notes

206-1000-013 Rev1.4, 06/30/2020 1

Chrontel

PCB Layout and Design Guide for CH7034B HDTV/VGA/LVDS Encoder

1.0 INTRODUCTION

Chrontel CH7034B is specifically designed for a portable system that requires connections to LCD display, High

Definition Television (HDTV) or RGB (VGA) monitor. With its advanced video encoder, flexible scaling engine and

easy-to- configure audio interface, the CH7034B satisfies manufactures’ product display requirements and reduces their

cost of development and time-to-market.

This application note focuses only on the basic PCB layout and design guidelines for CH7034B HDTV/VGA/LVDS

encoder. Guidelines in component placement, power supply decoupling, grounding, input /output signal interface are

discussed in this document.

The discussion and figures that follow reflect and describe connections based on the 88-pin QFN package of the

CH7034B. Please refer to the CH7034B datasheet for the details of the pin assignments.

2.0 COMPONENT PLACEMENT AND DESIGN CONSIDERATIONS

Components associated with the CH7034B should be placed as close as possible to the respective pins. The following

discussion will describe guidelines on how to connect critical pins, as well as describe the guidelines for the placement

and layout of components associated with these pins.

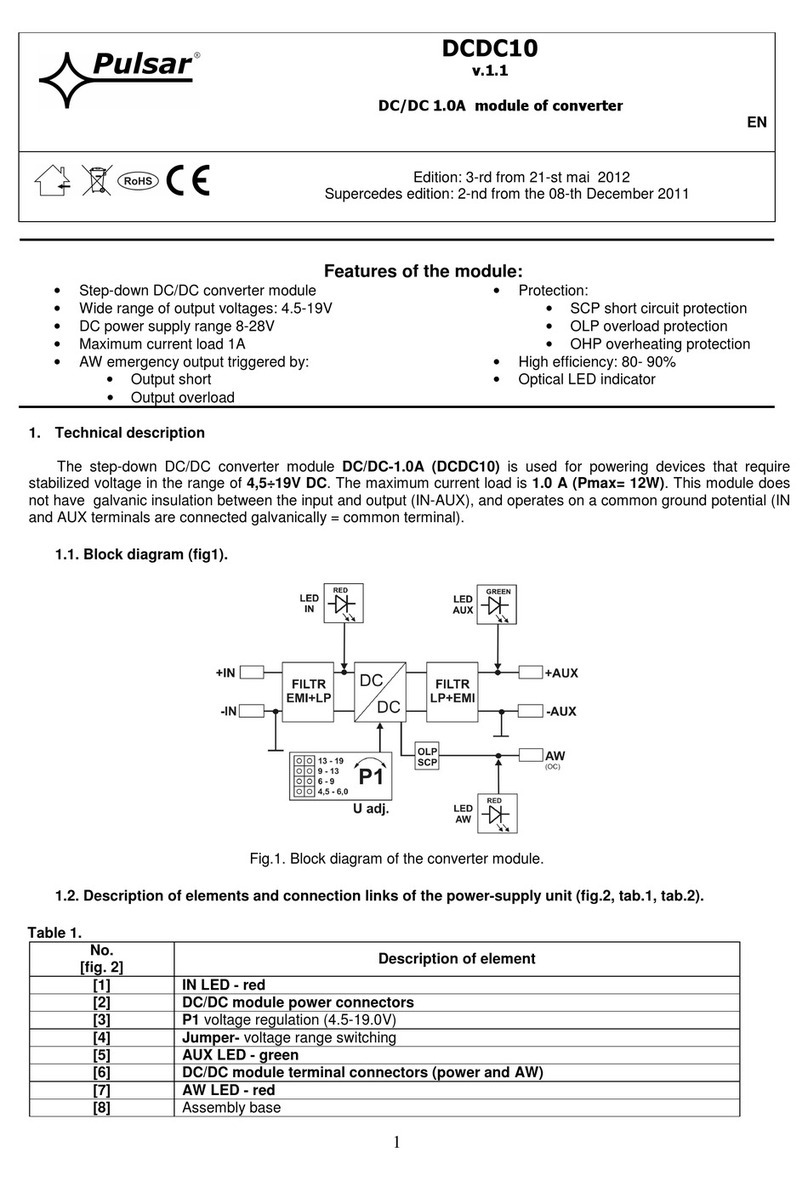

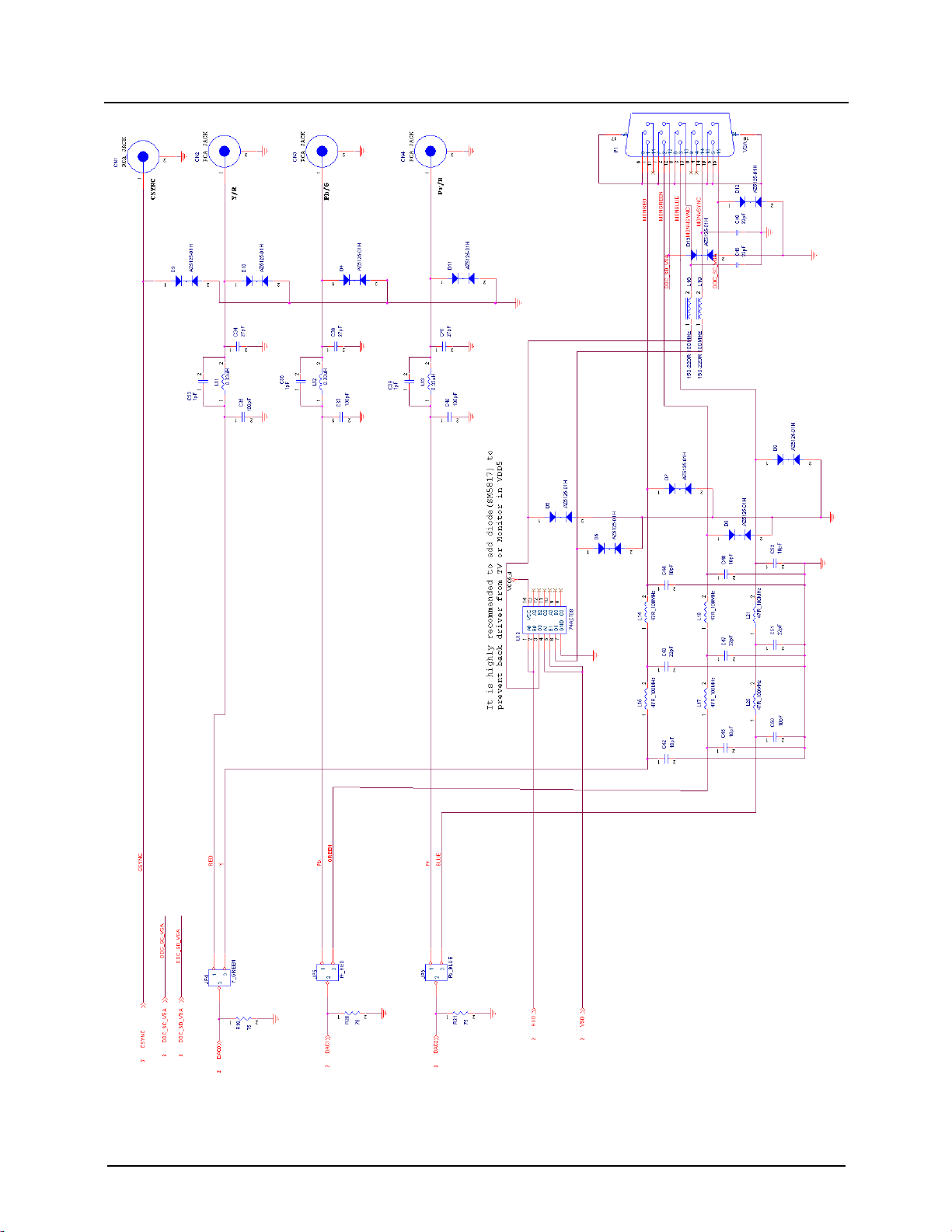

2.1 Power Supply Decoupling

The optimum power supply decoupling is accomplished by placing a 0.1μF ceramic capacitor to each of the power

supply pins as shown in Figure 1. These capacitors (C1, C2, C4, C5, C7, C8, C10, C11, C13, C14, C16, C18, C19, C22)

should be connected as close as possible to their respective power and ground pins using short and wide traces to

minimize lead inductance. Whenever possible, a physical connecting trace should connect the ground pins of the

decoupling capacitors to the CH7034B ground pins, in addition to ground vias.

2.1.1 Ground Pins

The analog and digital grounds of the CH7034B should be connected to a common ground plane to provide a low

impedance return path for the supply currents. Whenever possible, each of the CH7034B ground pins should be

connected to its respective decoupling capacitor ground lead directly, then connected to the ground plane through a

ground via. Short and wide traces should be used to minimize the lead inductance. Refer to Table 1 for the Ground pins

assignment.

2.1.2 Power Supply Pins

The power supply include AVDD, AVDD_DAC, VDDH, AVDD_PLL, VDDIO, DVDD, VDDMQ, VDDMS.

Refer toTable1 for the Power supply pins assignment. Refer to Figure 1 for Power Supply Decoupling.

CHRONTEL AN-B013

2 206-1000-013 Rev1.4, 06/30/2020

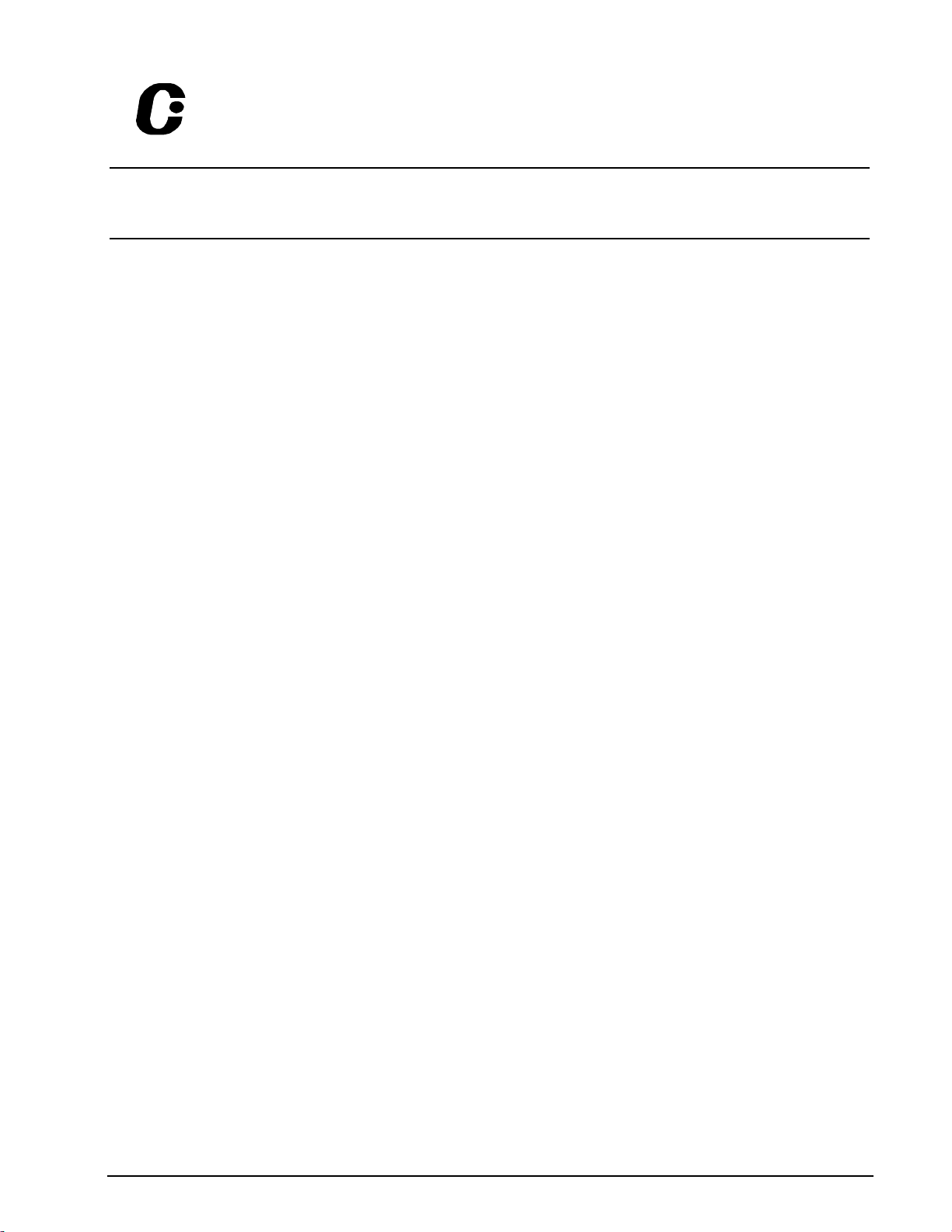

Table 1: Power Supply Pins Assignment of the CH7034B (QFN)

Pin Assignment

#Of Pins

Type

Symbol

Description

30,41

2

Power

VDDH

LVDS Power Supply (3.3V)

10,42

2

Power

DVDD

Digital Power Supply (1.8V)

23,46

2

Power

AVDD

Analog Power Supply (3.3V)

73, 77

2

Power

AVDD_DAC

DAC Power Supply (3.3V)

71

1

Power

AVDD_PLL

PLL Power Supply (1.8V)

53,61

2

Power

VDDMQ

SDRAM output buffer power supply (3.3V)

9,60

2

Power

VDDMS

SDRAM device power supply (3.3V)

33,38

2

Ground

VSSH

LVDS ground

83

1

Power

VDDIO

IO power supply (1.8-3.3V)

45

1

Ground

DGND

Digital ground

22,47

2

Ground

AGND

Analog ground

75, 79

2

Ground

AGND_DAC

DAC ground

70

1

Ground

AGND_PLL

PLL ground

52,62

2

Ground

GNDMQ

SDRAM output buffer ground

59,11

2

Ground

GNDMS

SDRAM ground

1 2

L8 47R100MHz

1 2

L1 47R100MHz

AVDD_PLL

C10

0.1uF C11

0.1uF

AVDD

C12

10uF

1 2

L2 47R100MHz

1 2

L3 47R100MHz

1 2

L4 47R100MHz

C16

0.1uF

C6

10uF

VDDMS

C18

10uF

VDDIOVDDIO

DVDD

C9

0.1uF

C8

0.1uF

VCC3_3

C7

10uF

C21

0.1uF

C22

10uF

C15

0.1uF

C13

10uF

C5

0.1uF

C17

0.1uF

QFN

VDDIO

83

DVDD 10,42

VDDMQ

53,61

VDDMS 9,60

AVDD 23,46

AVDD_PLL 71

VDDH

30,41

DGND 45

GNDMQ

52,62

GNDMS 11,59

AGND 22,47

AGND_PLL 70

VSSH

33,38

AGND

22,47

AVDD_DAC

73,77

AGND_DAC

75,79

U1

CH7034

C4

0.1uF

VCC1_8

C3

0.1uF

C2

0.1uF

C1

10uF

VCC3_3

AVDD_DAC

VDDMQ

VDDHVDDHVDDHVDDHVDDHVDDHVDDHVDDH

C14

0.1uF

C20

0.1uF

C19

10uF

1 2

L5 47R100MHz

1 2

L6 47R100MHz

1 2

L7 47R100MHz

Figure 1: Power Supply Decoupling and Distribution

Note: All the Ferrite Beads described in this document are recommended to have an impedance of less than 0.05 Ω

23 Ωat 25MHz & 47 Ωat 100MHz. Please refer to Fair Rite part #2743019447 for details or an equivalent part can be

used for the diagram.

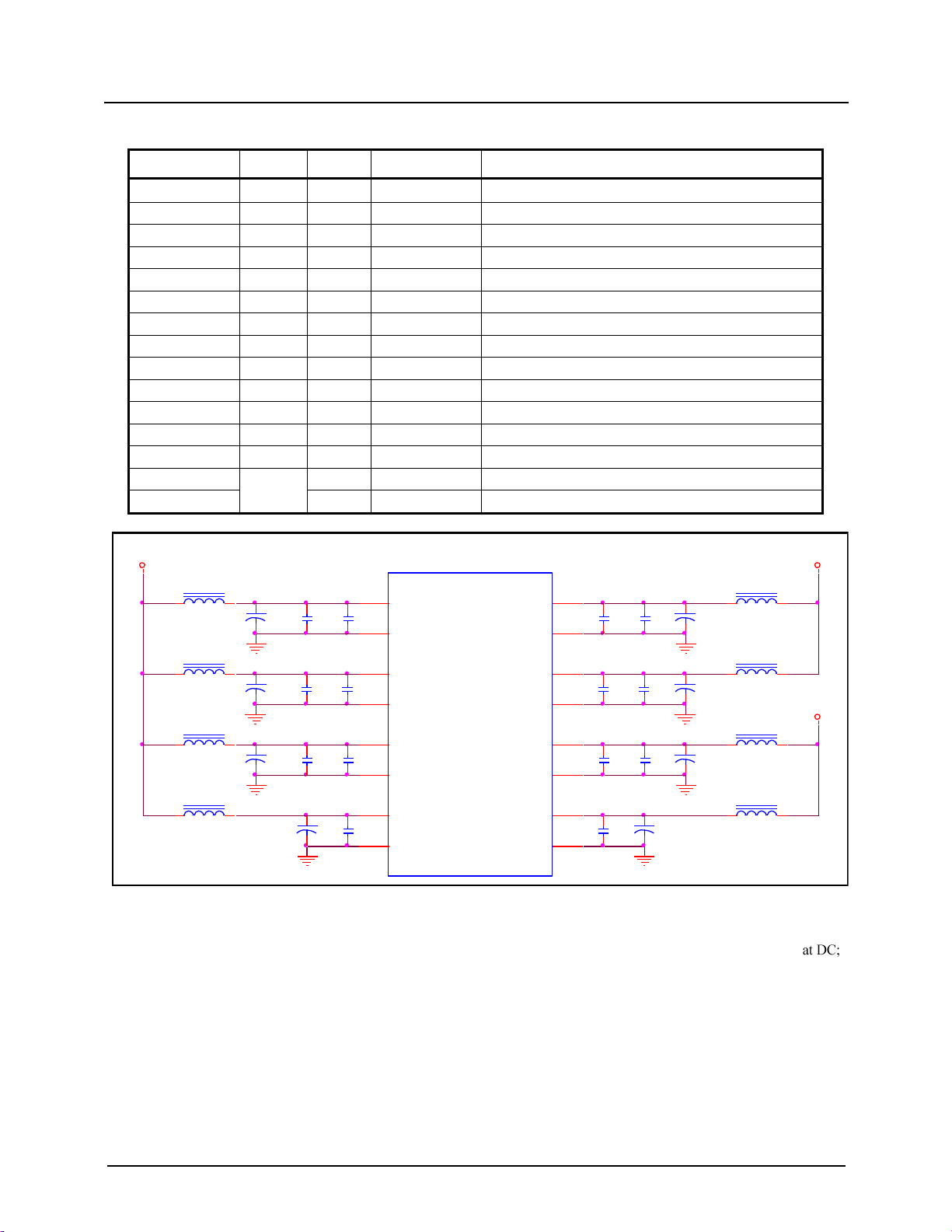

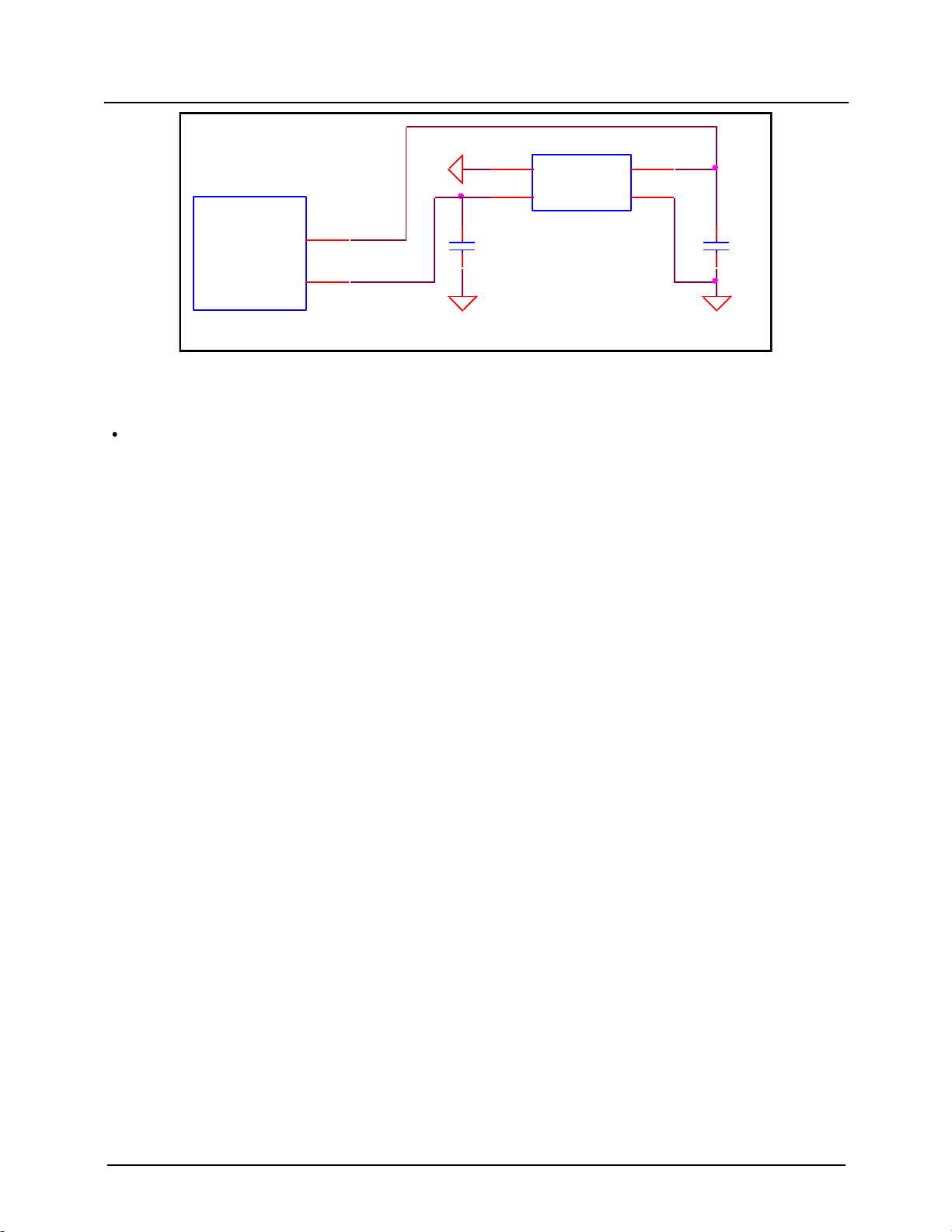

2.1.3 On chip power-on reset function’s sequence

Power-on reset sequence shown in the Figure 2, should be refer to for design target of generating the ResetB signal

to CH7034B by onboard RC delay. Otherwise, the Power-on Reset Function maybe not work, and the Registers can

NOT be reset to the default values. For hard ware circuit, please refer to 2.3 RESETB.

CHRONTEL AN-B013

206-1000-013 Rev1.4, 06/30/2020 3

Figure 2: Power-on Reset Function’s Sequence on board

ResetB signal is generate by system global reset. In this case, the power supply should be valid and stable for at least

20ms before the reset signal is valid. The pulse width of valid reset signal should be at least 100us. Otherwise, the

chip can’t work well. The timing is shown in Figure 3.

Figure 3: Power-on Reset Function’s Sequence on board

2.2 Internal Reference Pins

• ISET pin

<9ms

AVDD

Other

Powers

ResetB

>20ms

AVDD

Other

Powers

ResetB

>100

us

CHRONTEL AN-B013

4 206-1000-013 Rev1.4, 06/30/2020

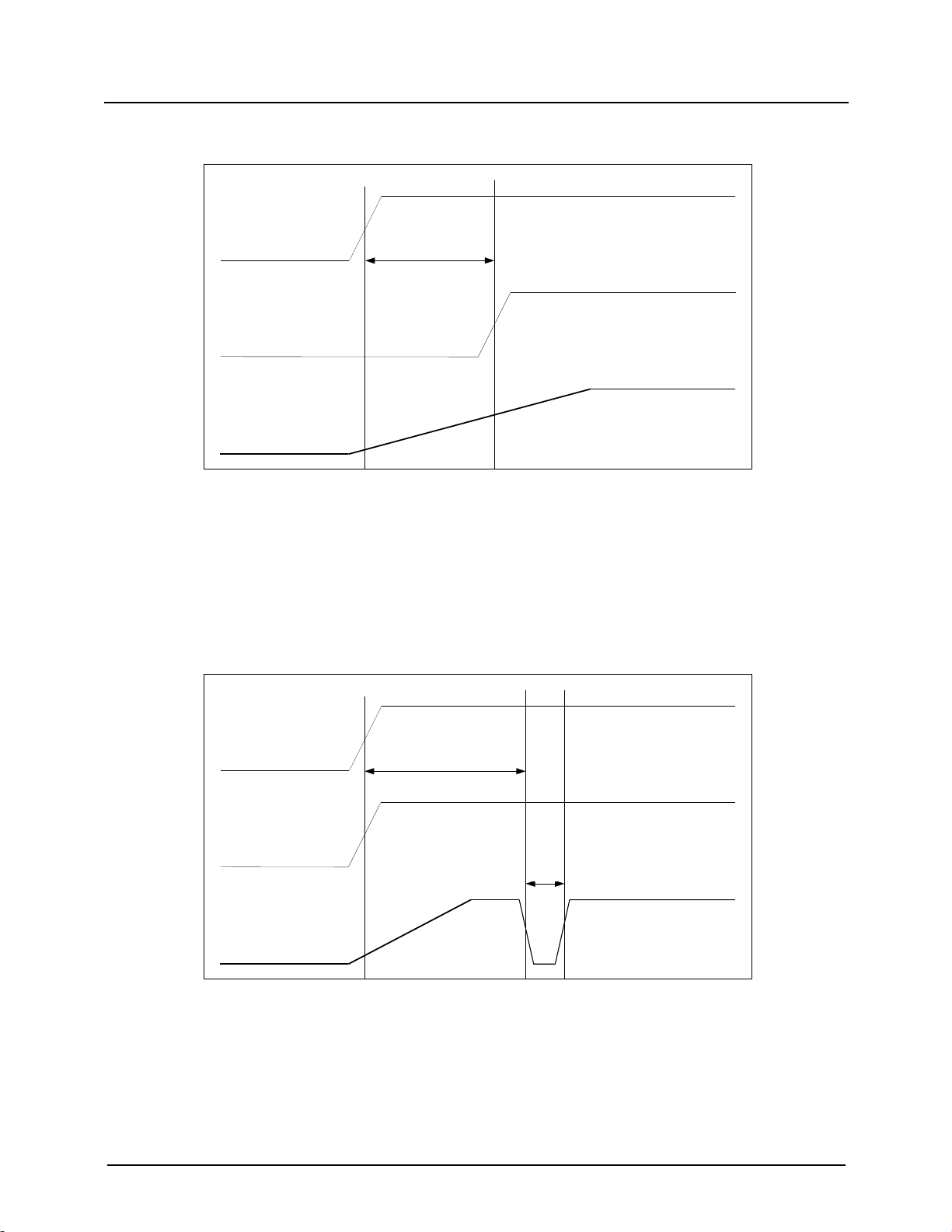

This pin sets the DAC current. A 1.2K ohm, 1% tolerance resistor should be connected between this pin and

AGND_DAC as shown in Figure 4. This resistor should be placed with short and wide traces as near as possible to

CH7034B.

R16

1.2K(1%)

ISET 80

AGND_DAC 79

U1

CH7034

QFN

Figure 4: ISET pin connection

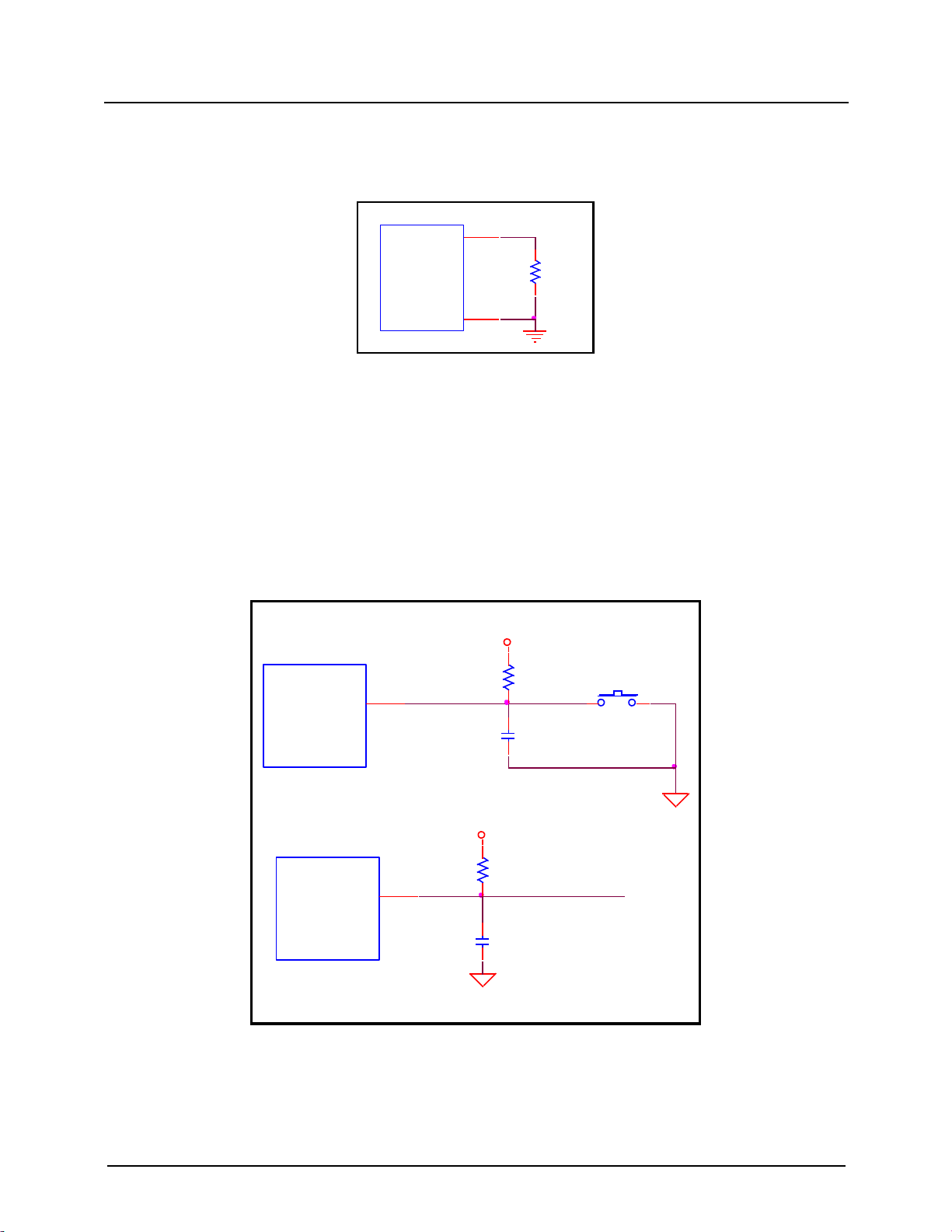

2.3 General Control Pins

• RESETB

This pin is the chip reset pin for CH7034B QFN. RESETB pin, which is internally pulled-up, places the device in

the power on reset condition when this pin is low. A power reset switch can be placed on the RESETB pin on the

PCB as a hardware reset for CH7034B QFN or connect to the system’s global reset as shown in Figure 5. When the

pin is high, the reset function can also be controlled through the serial port.

Global reset

U1

RESETB 7

AVDD

SW1

P8058SS-ND

ResetB

C1

0.1uF

R1

1M

U2

RESETB 7Global ResetResetB

AVDD

C2

0.1uF

R2

1M

On board reset

Figure 5: RESETB pin connection

• XI/FIN and XO

CH7034B has capability to accept external crystal with frequencies from 2.3 MHz to 64 MHz.

CHRONTEL AN-B013

206-1000-013 Rev1.4, 06/30/2020 5

QFN

U3

CH7034 XI/FIN 68

XO 67

X1

535-9118-1-ND (27 MHz)

GND

4

P1

1GND 2

P2 3

XI/FIN

XO

C2

18pF

12

C1

18pF

12

Figure 6: Crystal Pins

Reference Crystal Oscillator

CH7034B includes an oscillator circuit that allows a predefined-frequency crystal to be connected directly.

Alternatively, an externally generated clock source may be supplied to CH7034B. If an external clock source is used,

it should have CMOS level specifications. The clock should be connected to the XI pin, and the XO pin should be

left open. The external source must exhibit ±20ppm or better frequency accuracy, and have low jitter characteristics.

If a crystal is used, the designer should ensure that the following conditions are met:

The crystal is specified to be predefined-frequency, ±20 ppm fundamental type and in parallel resonance (NOT

series resonance). The crystal should also have a load capacitance equal to its specified value (CL).

External load capacitors have their ground connection very close to CH7034B (Cext).

To be able to tune, a variable capacitor may be connected from XI to ground.

Note that the XI and XO pins each has approximately 10 PF (Cint) of shunt capacitance internal to the device. To

calculate the proper external load capacitance to be added to the XI and XO pins, the following calculation should

be used:

Cext = (2 x CL) - Cint - 2CS

Where

Cext = external load capacitance required on XI and XO pins.

CL= crystal load capacitance specified by crystal manufacturer.

Cint = capacitance internal to CH7034B (approximately 10-15 pF on each of XI and XO pins).

CS= stray capacitance of the circuit (i.e. routing capacitance on the PCB, associated capacitance of crystal holder

from pin to pin etc.).

In general,

CintXI = CintXO = Cint

CextXI = CextXO = Cext

Such that

CL= (Cint + Cext) / 2 + CSand Cext = 2 (CL- CS) - Cint=2CL- (2CS+ Cint)

Therefore CLmust be specified greater than Cint /2 + CSin order to select Cext properly.

CHRONTEL AN-B013

6 206-1000-013 Rev1.4, 06/30/2020

After CL(crystal load capacitance) is properly selected, care should be taken to make sure the crystal is not

operating in an excessive drive level specified by the crystal manufacturer. Otherwise, the crystal will age quickly

and that in turn will affect the operating frequency of the crystal.

For detail considerations of crystal oscillator design, please refer to AN-06.

2.4 Serial Port Control for CH7034B

• SPC and SPD

SPD and SPC function as a serial interface where SPD is bi-directional data and SPC is an input only serial clock. In

the reference design, SPD and SPC pins are pulled up to +1.8V ~ +3.3V with 6.8 kΩresistors as shown in Figure 7.

• SPCM and SPDM

SPCM and SPDM can automatically load firmware from external EEPROM . In the reference design, SPDM and

SPCM pins are pulled up to +3.0V ~ +3.5Vwith 6.8 KΩresistors as shown in Figure 7.

Note: CH9904 hard wire address should be 57h.

• DDC_SC and DDC_SD

DDC_SC and DDC_SD are used to interface with the DDC of VGA. This DDC pair needs to be pulled up to 5V

through resistors (Refer to Figure 7).

R5

6.8K R7

6.8K

R6

6.8K

SPDM

R9 10K

R8

6.8K

1 2

SPCM

U2

CH9904

GP1

1

GP2

2

GP3

3

GND

4SPD 5

SPC 6

WE 7

VCC 8

R9

6.8K

1 2

VCC3_3VCC3_3

C1

0.1uF

12

VCC3_3

U1

CH7034

SPDM

69 SPCM

72

SPD

55 SPC

54

DDC_SD

64 DDC_SC

63

SPD

R1

6.8K

12

SPC

R2

6.8K

1 2

VCC3_3

QFN

DDC_SC and DDC_SD connect to VGA connector.

The resistor(R3and R4) value according to the capactive Loading.

It is highly recommended to add diode(SM5817) to prevent back

driver from TV or Monitor in VDD5

SPCM and SPDM for autoload

D14

SM5817

VDD5

R4

1.8K

1 2

R3

1.8K

1 2

VDD5_d

Figure 7: Serial Port Interface: SPCM, SPDM and SPC, SPD pins of CH7034B

2.5 Input Pins

CHRONTEL AN-B013

206-1000-013 Rev1.4, 06/30/2020 7

Data Inputs

CH7034B can accept up to 24 data inputs, as shown in Figure 8, from a digital video port of a graphics controller.

The swing is defined by VDDIO (1.2 ~ 3.3V).

Unused Data input pins should be pulled low with 10kΩresistors or shorted to Ground directly.

H/V Sync Pins

The horizontal/vertical sync pins can be used as inputs as shown in Figure 8.

DE/CSB

The DE/CSB pin is used as a data input indicator (Refer to Figure 8). When the pin is high, the input data is active.

When the pin is low, the input data is blanking.

If DE/CSB is not used, it can be left open or pulled down to the Ground.

GCLK

The GCLK input is the clock signal input to the device for using with the H, V, DE and D [23:0] data.

QFN

D[0]

29

D[1]

28

D[2]

27

D[3]

26

D[4]

25

D[5]

21

D[6]

20

D[7]

19

D[8]

18

D[9]

17

D[10]

16

D[11]

15

D[12]

14

D[13]

13

D[14]

12

D[15]

8

D[16]

6

D[17]

5

D[18]

4

D[19]

3

D[20]

2

D[21]

1

D[22]

88

D[23]

87

V

85 H/WEB

86

GCLK

82

DE/CSB

84

Controller

Graphics

Figure 8: CH7034B Data Input Pins

2.6 Miscellaneous Pins

•IRQ

This pin should be connected with graphic controller directly.

2.7 Video Output

CHRONTEL AN-B013

8 206-1000-013 Rev1.4, 06/30/2020

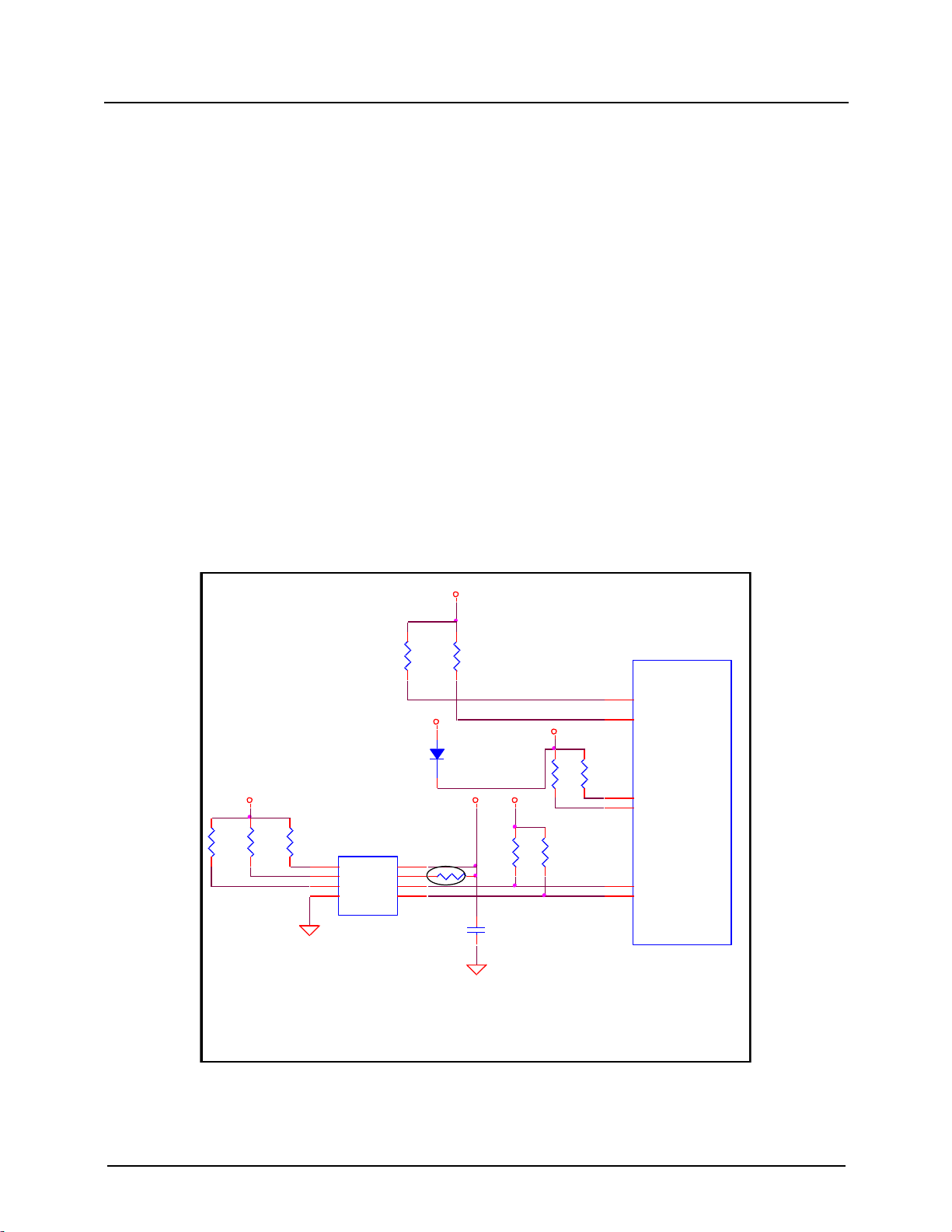

YPbPr and RGB+ Csync output

CH7034B supports both RGB+Csync and HDTV YPbPr output format. The resolution is from 480P to 720P and

1080i and 1080P. In RGB+Csync output format, the Csync high level is the same with AVDD power supply. Csync

pin is a COMS push-pull output pin, customer can use other circuit to change is high level to 0.7V or other voltage

level according to different Receivers. ( Refer to Figure 9)

VGA output

VGA standard output signal level of Hsync and Vsync is more than 2.4V. CH7034B Hsync and Vsync output signal

level is same with AVDD power supply. Customer can use 74ACT08 (AND GATE) to pull high this signal level to

5V(recommend to add the diode).. It is recommended but not necessary. ( Refer to Figure 9)

CHRONTEL AN-B013

206-1000-013 Rev1.4, 06/30/2020 9

R39 75

12

C46

10pF

12

MONHSYNC

MONRED

C48

22pF

12

C49

10pF

12

JP6

Y_GREEN

12

3

C51

10pF

12

L20

47R 100MHz

12

JP7

Pr_RED

12

3

JP8

Pb_BLUE

12

3

C52

22pF

12

L21

47R 100MHz

12

C53

10pF

12

MONVSYNC

CSYNC1

R40 75

12

It is h i ghly r ecommen d to add the dio de in power

supply of 74ACT08, it can prevent the back drive

from TV or Monitor

U5A 74ACT08

A1

B2

Y

3

DAC01

U5B 74ACT08

A4

B5

Y

6

DAC11

DAC21

VSO1

HSO1

Pr

BLUE

RED

Y

Pb

GREEN

MONGREEN

MONBLUE

L17

47R 100MHz

1

2

L18

47R 100MHz

1

2

C47

22pF C50

22pF

L19

150-220R100MHz

1

2

L16

150-220R100MHz

1

2

C43

10pF

12

C44

22pF

12

CSYNC CN1

RCA JACK

1

2

L12

0.33uH

12

C37 1pF

12

C39

27pF

12

C38 100pF

12

C40 1pF

12

L13

0.33uH

12

C41 100pF

12

C42

27pF

12

CN3

RCA JACK

1

2

CN4

RCA JACK

1

2

C34 1pF

12

R38 75

12

C36 100pF

12

L11

0.33uH

12

CN2

RCA JACK

1

2

C35

27pF

12

Y/R

Pr/B

Pb/G

D1

AZ5125-01H

12

C45

10pF

12

P1

VGA

11

22

33

44

55

66

77

88

99

10 10

11 11

12 12

13 13

14 14

15 15

16

16 17 17

L15

47R 100MHz

1

2

L14

47R 100MHz

1

2

CSYNC

D2

AZ5125-01H

12

D3

AZ5125-01H

12

D4

AZ5125-01H

12

D5

AZ5125-01H

12

D6

AZ5125-01H

12

D7

AZ5125-01H

12

D8

AZ5125-01H

12

D9

AZ5125-01H

12

MONSCL

D10

AZ5125-01H

12

MONSDA

D11

AZ5125-01H

12

Figure 9: CH7034B YpbPr, RGB+Csync and VGAoutput

Note: In order to minimize the hazard of ESD, a set of protection diodes (AZ5125-01H) are highly recommendedfor

each DAC and Sync Output.

CHRONTEL AN-B013

10 206-1000-013 Rev1.4, 06/30/2020

2.8 LVDS Output

The LVDS output signals are LDCx* and LDCx. The LVDS is a differential interface with a nominal swing 200mV.

The following rules applies to the signals:

1. Keep traces as short as possible.

2. Make these traces have 100 ohm differential impedance.

3. Trace widths should be 5 mils.

4. Intra Pair spacing (spacing between the “+” and “-” pairs) should be 7mils.

5. Inter Pair spacing (spacing between one differential pair and another) should be a minimum of 20 mils.

6. Difference in trace lengths between “+” and “-” pairs should be within 5mils.

7. Difference in trace lengths among Inter pairs should be within 10mils.

8. “+” and “-” pairs should be routed in parallel.

2.9 Important Design Considerations

• LVDS Power

Close attention must be paid to the power supplied to the LVDS backlight and the LVDS panel. Power requirements

may differ from panel to panel. Please check the panels’ power and backlight voltage specifications.

ENABLK(pin58) and ENAVDD(pin57) of the CH7034B can be used as control signal to turn on the power to the

LVDS backlight and the LVDS logic circuitry.

• PWM

PWM can be used to control the backlight luminance level. The duty cycle of pwm wave can varies between 0 and 1

with a step of 1/255 and the frequency of PWM wave can be 100Hz, 200Hz, 2KHz, 4KHz, 16KHz, 32KHz, 64KHz,

and 128KHz via register setting.

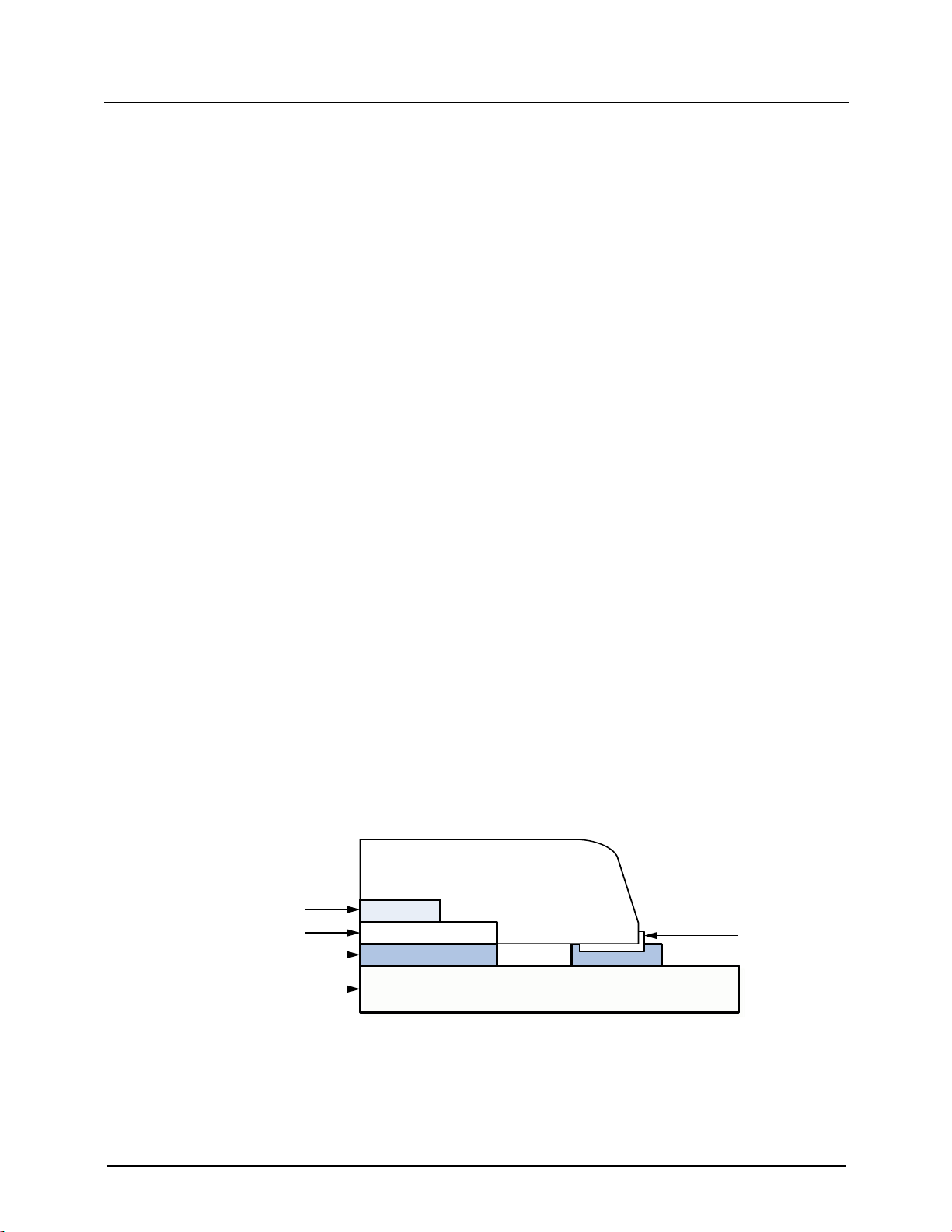

2.10 Thermal Exposed Pad Package

The CH7034B is available in 88-pin QFN package with thermal exposed pad package. The advantage of the thermal

exposed pad package is that the heat can be dissipated through the ground layer of the PCB more efficiently. When

properly implemented, the exposed pad package provides a means of reducing the thermal resistance of the

CH7034B.

Careful attention to the design of the PCB layout is required for good thermal performance. For maximum heat

dissipation, the exposed pad of the package should be soldered to the PCB as shown in Figure 10.

Die

Exposed Pad

Solder

PCB

Pin

Figure 10: Cross-section of exposed pad package

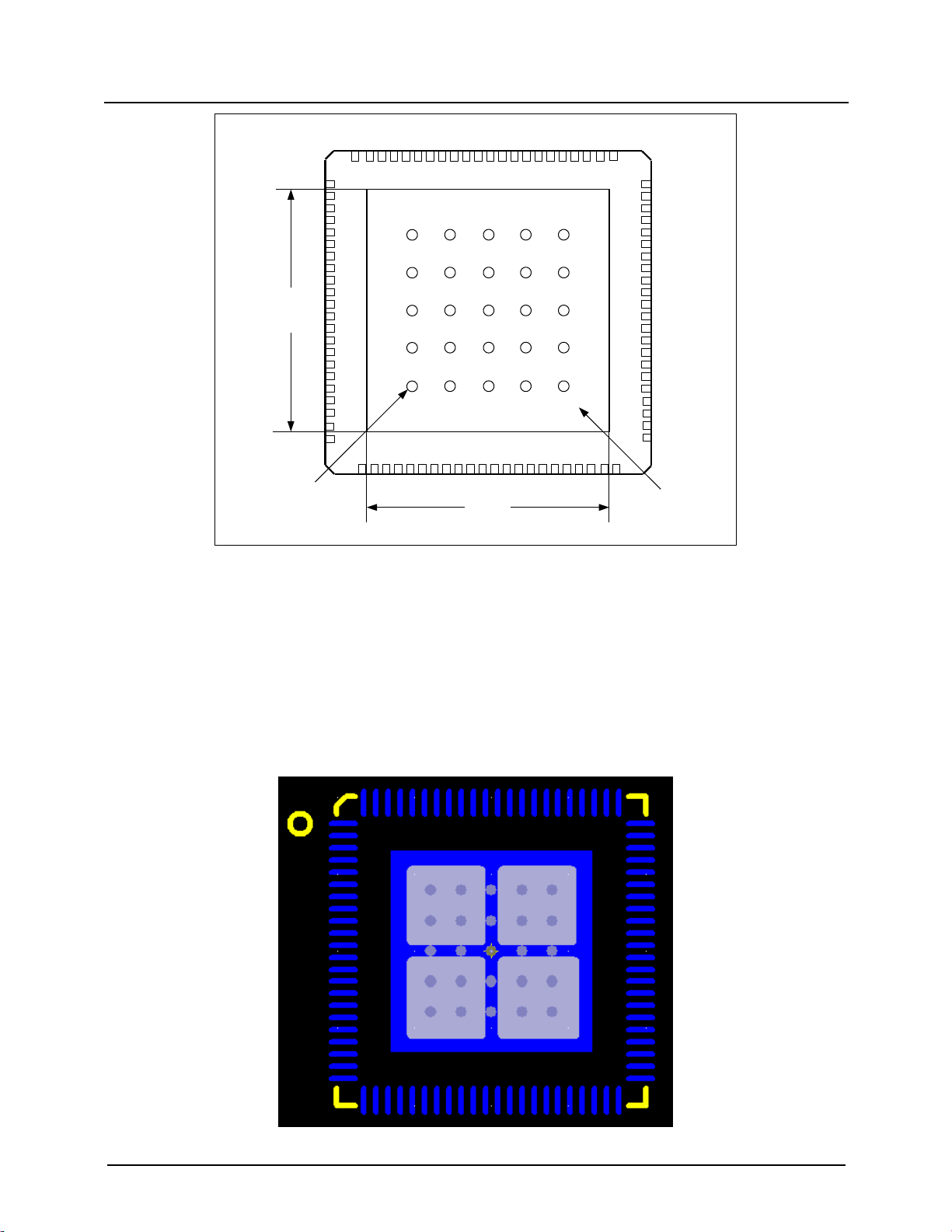

Thermal pad dimension is from 6.6mm to 6.9mm (min to max), 6.6mm x 6.6mm is the minimum size recommended

for the thermal pad, and 6.9mm x 6.9mm is the maximum size. The thermal land pattern should have a 5x5 grid

array of 1.0 mm pitch thermal vias connected to the ground layer of the PCB. These vias should be 0.3mm in

diameter with 1 oz copper via barrel plating. Please refer to Figure 11.

CHRONTEL AN-B013

206-1000-013 Rev1.4, 06/30/2020 11

6.6 mm

6.6 mm Exposed Pad

land pattern

Thermal Via Array

(5x5) 1 mm Pitch

0.3 mm diameter

Figure 11: Thermal Land Pattern

When applying solder paste to the thermal land pattern, the recommended stencil thickness is from 5 to 8 mils.

Thermal resistance was calculated using the thermal simulation program called ANSYS.

2.11 QFN Package Assembly

For the assembly process, it is important to limit the amount of solder paste that is put under the thermal pad. If too

much paste is put on the PCB, the package may float during assembly. Compared with the solder mask of thermal

pad, the paste mask should be shrank to70%~80%. Figure 12 shows a paste mask pattern in gray for the thermal

pad.

Figure12: Thermal Pad Paste Mask Pattern

CHRONTEL AN-B013

12 206-1000-013 Rev1.4, 06/30/2020

3.0 REFERENCE DESIGN EXAMPLE

The figures below are the reference schematic of CH7034B, which is provided here for design reference only. Please

contact Chrontel Applications group if necessary. Table 3 provides the BOM list for the reference schematic.

3.1 Reference Schematic

CHRONTEL AN-B013

206-1000-013 Rev1.4, 06/30/2020 13

(a) QFN Package

CHRONTEL AN-B013

14 206-1000-013 Rev1.4, 06/30/2020

(b) YpbPr, RGB+Csync and VGA output

CHRONTEL AN-B013

206-1000-013 Rev1.4, 06/30/2020 15

ENABLK_Panel2 ENABLK_panel R23 0

Open LDI Connector, Please reference your Panel Spec

JE1

OpenLDIConnector

A0M

1

A0P

19

A1M

2

A1P

20

A2M

3

A2P

21

CLK1M

4

CLK1P

22

A3M

5

A3P

23

ShieldGND

6

reserved

24

reserved

7

reserved

25

reserved

8

reserved

26

reserved

9

DDCpwr gnd

27

DDC/SCL

10

DDC/SDA

28

+5VdcDDC pwr

11

USB pwr gnd

29

USB+

12

USB-

30

+5Vdc USB pwr

13

ShieldGND

31

A4M

14

A4P

32

A5M

15

A5P

33

A6M

16

A6P

34

A7M

17

A7P

35

CLK2M

18

CLK2P

36

PWM_Panel2

ENAVDD_Panel2 ENAVDD_Panel

R22 0

R25 0

PWM_panel

LDC0*2 LDC02

LDC12 LDC1*2

LDC22 LDC2*2

LLC2 LLC*2

It is highly recommended to use VDD5_d, the diode

can prevent the back driver from Panel

R24 0

VCC5_d VDD_DDC_5VVDD_DDC_5V

(c) Output

CHRONTEL AN-B013

16 206-1000-013 Rev1.4, 06/30/2020

3.2 Reference Board Preliminary BOM

Table 3: CH7034B Reference Design BOM List

Item

Quantity

Reference

Part

1

11

D3, D4, D5, D6, D7, D8, D9, D10, D11, D12, D13

AZ5125-01H

2

1

D14

SM5817

3

19

C1,C2, C4, C5, C6, C7, C10, C12, C13, C15, C16,

C18, C20, C21, C23, C24, C26, C27, C32

0.1uF

4

9

C3, C8, C9, C11, C14, C17, C19, C22, C25

10uF

5

3

C33, C36, C39

1pF

6

8

C30, C31, C42, C44, C45, C48, C50, C52

10pF

7

2

C28, C29

18pF

8

5

C43, C46, C47, C49, C51

22pF

9

3

C35,C37,C40

100pF

10

3

C34,C38,C41

27pF

11

1

JP3

Header 4

12

1

JP2

Header 20x2

13

5

JP1, J1, J2 ,JP4, JP5, JP6

Header 3

14

4

CN1, CN2, CN3, CN4

RCA

15

12

L1, L2, L3, L4, L5, L6, L7, L8, L9, L10, L16, L19

FB

16

3

L11, L12, L13

0.33uH

17

6

L14, L15, L17, L18, L20, L21

47R_100M FB

18

1

P1

VGA

19

9

R1, R2, R3, R4, R5, R10, R11, R26, R27

6.8 k Ω

20

9

R15, R22, R23, R24, R25, R29, R30, R31, R32

0 Ω

21

1

R12

1M Ω

22

1

R18

1.2 k Ω(1%)

23

2

R6, R17

10 k Ω

24

3

R13, R16, R28

4.7 k Ω

25

1

R14

33 Ω

26

3

R19, R20, R21

75 Ω

27

2

R26, R27

1.8K

28

1

SW1

P8058SS-ND

29

1

U1

CH9904

30

1

U2

CH7034BA

31

2

U3, U4

SI4953

32

1

U12

74ACT08

33

1

X1

535-9118-1-ND (27MHz)

34

4

Q1, Q2, Q3, Q4

2N7002

35

1

JE1

OpenLDI Connector

CHRONTEL AN-B013

206-1000-013 Rev1.4, 06/30/2020 17

4.0 REVISION HISTORY

Table 4: Revisions

Rev. #

Date

Section

Description

1.0

05/24/2010

All

Initial release

1.1

03/10/2011

Add DDC pin

Add DDC pin for LVDS output

PWM

Add the frequency of PWM wave can be 16KHz, 32KHz, 64KHz, and

128KHz via register setting.

1.2

07/12/2011

2.1

2.3

2.4

2.10

3.1

3.2

Add power on sequence

Modify figures and add GPIO pin

Modify figure

Thermal Exposed Pad Package

Modify reference schematic

Modify BOM list

1.3

08/31/2011

2.1

2.3

2.4

2.7

3.1

3.2

Update power on sequence

Update figures and description

Update figures and description

Update figures and description

Update reference schematic

Update BOM list

1.4

06/30/2020

2.11

Disclaimer

Update the QFN package assembly

CHRONTEL AN-B013

18 206-1000-013 Rev1.4, 06/30/2020

Disclaimer

This document provides technical information for the user. Chrontel reserves the right to make changes at any time

without notice to improve and supply the best possible product and is not responsible and does not assume any

liability for misapplication or use outside the limits specified in this document. CHRONTEL warrants each part to be

free from defects in material and workmanship for a period of one (1) year from date of shipment. Chrontel assumes

no liability for errors contained within this document. The customer should make sure that they have the most recent

data sheet version. Customers should take appropriate action to ensure their use of the products does not infringe

upon any patents. Chrontel, Inc. respects valid patent rights of third parties and does not infringe upon or assist others

to infringe upon such rights.

Chrontel PRODUCTS ARE NOT AUTHORIZED FOR AND SHOULD NOT BE USED WITHIN LIFE SUPPORT

SYSTEMS OR NUCLEAR FACILITY APPLICATIONS WITHOUT THE SPECIFIC WRITTEN CONSENT OF

Chrontel. Life support systems are those intended to support or sustain life and whose failure to perform when used

as directed can reasonably expect to result in personal injury or death.

Chrontel

www.chrontel.com

E-mail: sales@chrontel.com

2020 Chrontel - All Rights Reserved.

Table of contents

Other Chrontel Media Converter manuals

Popular Media Converter manuals by other brands

Aus Electronics Direct

Aus Electronics Direct AA6180 user manual

Cross Technologies

Cross Technologies 3115-21-109 instruction manual

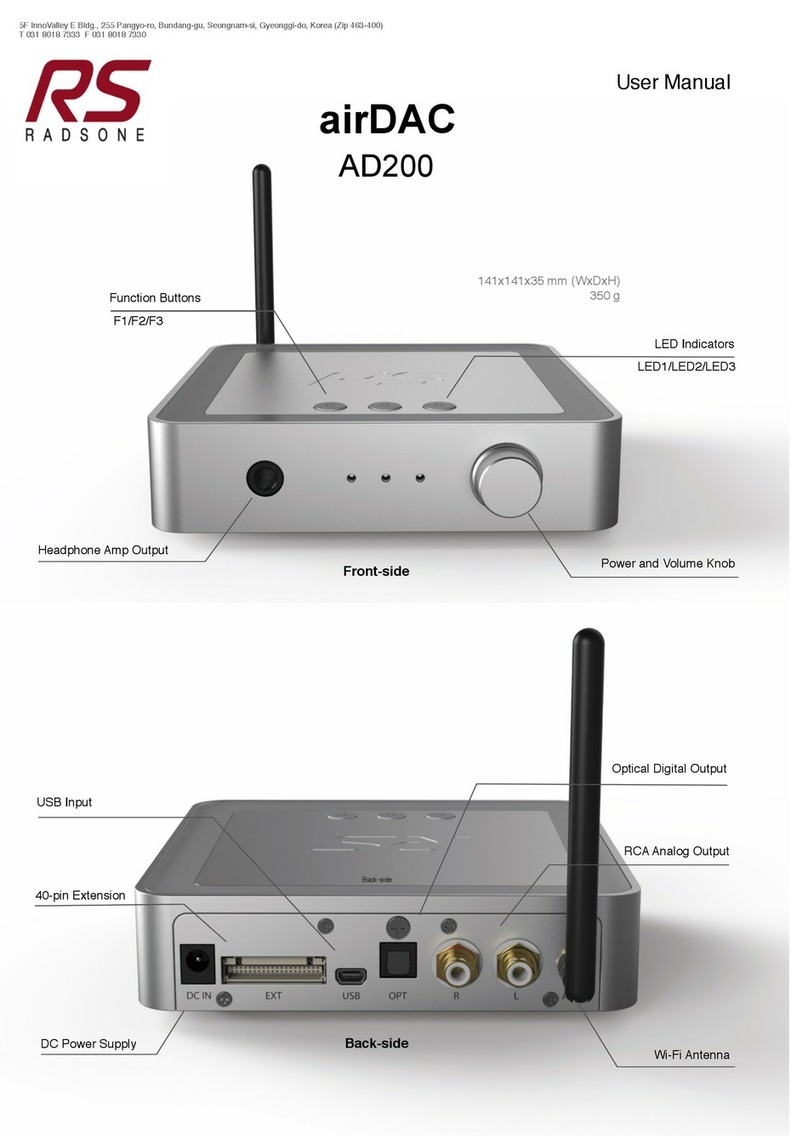

Radsone

Radsone airdac AD200 user manual

Omnitron Systems

Omnitron Systems iConverter 8878-27 user manual

Fostex

Fostex VC-8 owner's manual

Stahl

Stahl 9721/13-11 Series operating instructions