Chrysler 160 Instruction manual

Other Chrysler Automobile manuals

Chrysler

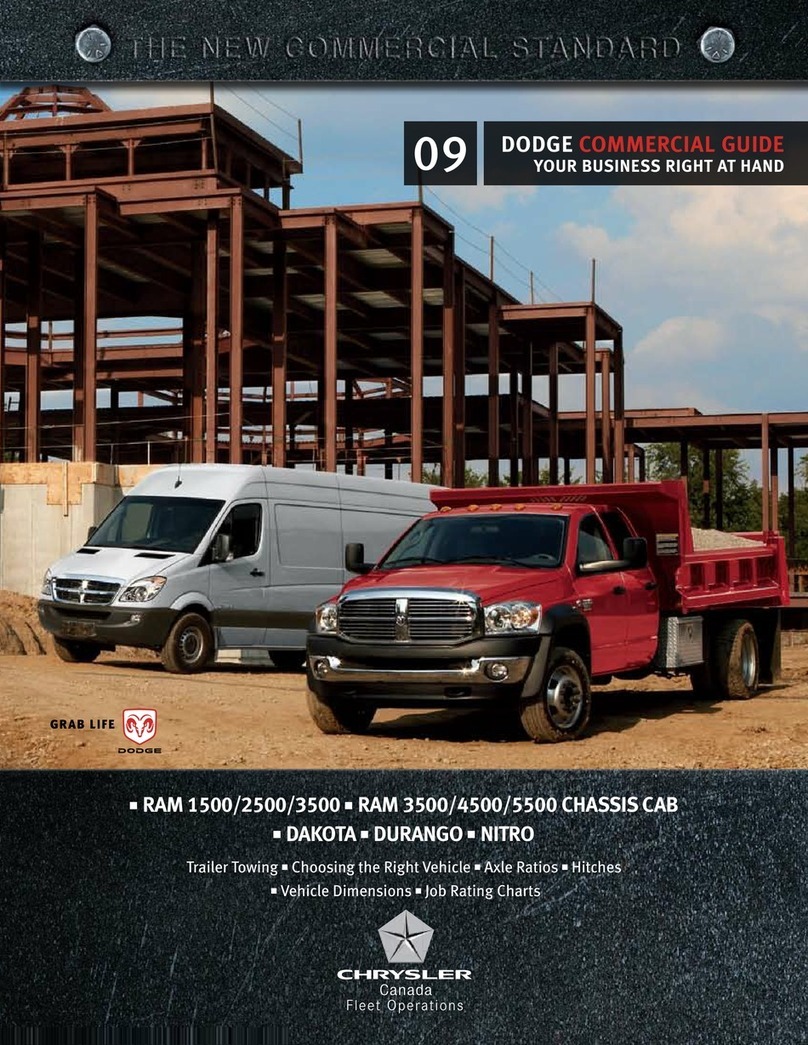

Chrysler RAM 1500 User manual

Chrysler

Chrysler 300 C 2009 User manual

Chrysler

Chrysler Pacifica 2022 User manual

Chrysler

Chrysler 2006 Town and Country User manual

Chrysler

Chrysler Dodge Grand Caravan 2014 Installation guide

Chrysler

Chrysler Caliber SRT4 User manual

Chrysler

Chrysler Town and Country User manual

Chrysler

Chrysler 200 Convertible 2014 User manual

Chrysler

Chrysler PACIFICA HYBRID 2023 User manual

Chrysler

Chrysler 200 Convertible User manual

Chrysler

Chrysler Pacifica 2020 User manual

Chrysler

Chrysler Pacifica Hybrid 2018 User manual

Chrysler

Chrysler 300 Touring RWD 2010 User manual

Chrysler

Chrysler Sebring Convertible 2010 User manual

Chrysler

Chrysler Sebring Convertible 2010 User manual

Chrysler

Chrysler 300 SRT8 2012 User manual

Chrysler

Chrysler 2010 Sebring User manual

Chrysler

Chrysler 300 Touring RWD 2010 User manual

Chrysler

Chrysler Town & Country 2014 User manual

Chrysler

Chrysler 300 2013 User manual