CHWS PRORAPID User manual

CHWS PRORAPID

SEMI INSTANTANEOUS DHW GENERATOR

Installation Manual

Operation & Maintenance Manual

2| INSTALLATION MANUAL PRORAPID

PF

PR

PHE

CONTROLLER

I

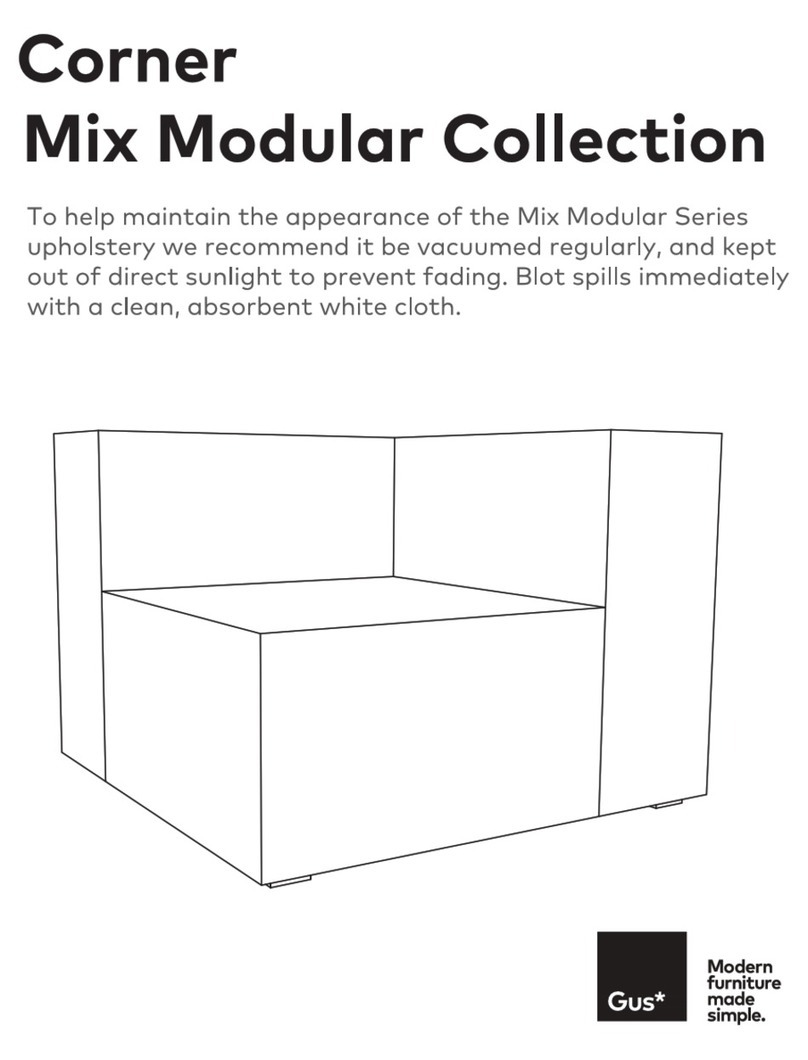

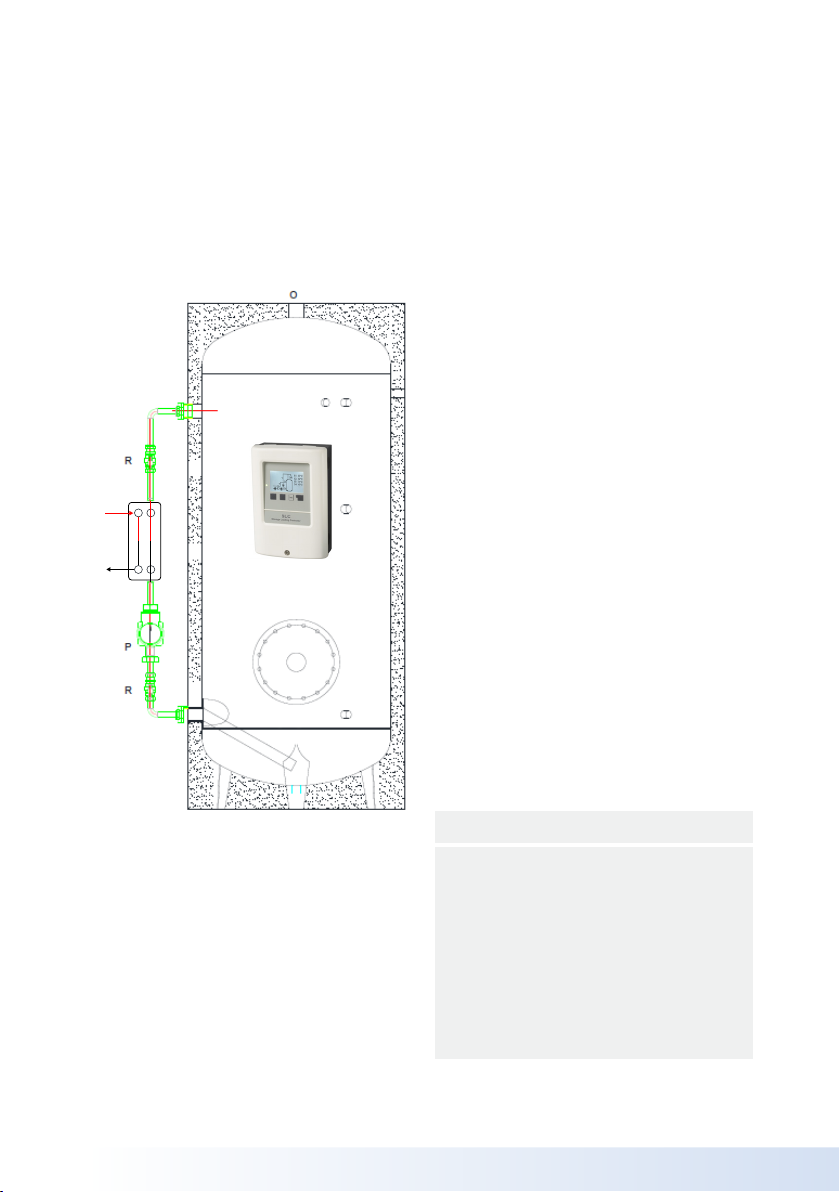

CHWS ProRapid

Semi Instantaneous DHW Generator

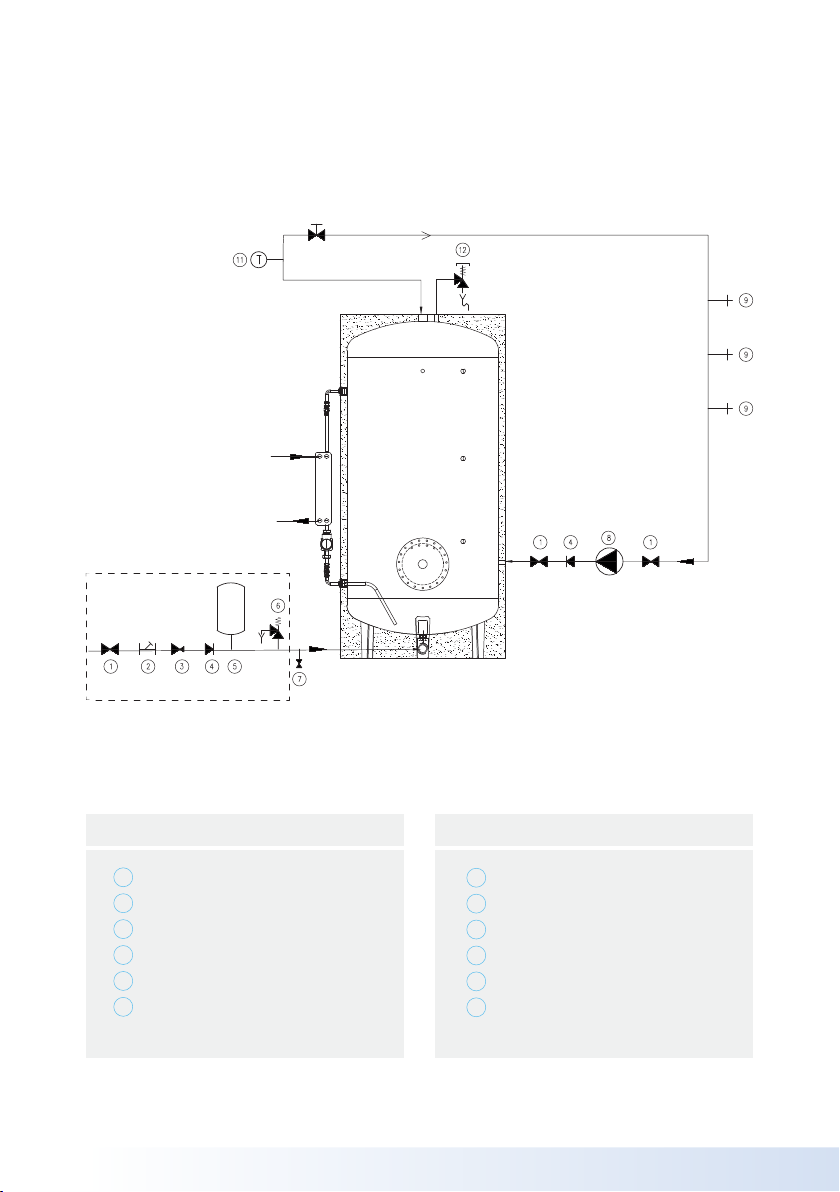

General Layout

Sanitary hot water outlet

Inlet cold water

Plate Heat Exchanger

Circulation pump

Isolating valve

Water recirculation

Primary return

Primary ow

Controller

Key

O

I

PHE

P

R

WR

PR

PF

C

Fig. 1

3

INSTALLATION MANUAL PRORAPID |

Instructions For Use

General Information

This instruction manual is a part of the

product, check that it is always supplied

with the CHWS ProRapid DHW generator.

Carefully read the instructions contained

in this chapter as they provide important

information on the usage of the unit.

Keep this manual for future reference if the

CHWS ProRapid DHW generator is sold or

transferred to a dierent owner or leaving

the unit where installed, please make sure

that this manual always accompanies the

CHWS ProRapid DHW generator so as it

can be used for reference by the new owner

or installation expert.

Important: This CHWS ProRapid Hot

water generator has to be used to produce

hot sanitary water, in accordance with its

technical features of performance and

power, by thermal exchange with a heating

water supply (t ≤ 100°C) max.

Any dierent usage for the CHWS ProRapid

Hot water generator is forbidden, do not

clean the CHWS ProRapid Hot water

generator with corrosive or ammable liquids.

The use of electric adapters, extension

cords or socket sets is not recommended.

In case of damages to the electric cord turn

the power o and consult a professionally

qualied technician.

An electric manual is enclosed in the

appliance please observe the following

fundamental rules:

• Do not touch the appliance with parts

of the body which are wet, damp or in

bare feet

• Do not pull the electric wires

• Do not allow children or unqualied

persons to use the appliance

The manufacturer declines any responsibility

for damages caused by neglect of the

appliance or system. If the CHWS ProRapid

hot water generator is not used for long

periods of time, turn o thepower supply

and empty the unit.

Description

The CHWS ProRapid DHW generators is

manufactured in stainless steel and is able

to satisfy high requirements of sanitary hot

water. The automatic system of water mixing

will avoid temperature’ stratication the heat

storage is therefore higher. The external

stainless steel plate exchanger enables easy

maintenance and cleaning.

The system will reduce the potential for

Legionella growth in an eective way by

heating the stored contents and circulating

water through the entirety of the cylinder.

4| INSTALLATION MANUAL PRORAPID

Periodical Checks

Periodic checks of the units must be

performed by qualied personnel in order to

guarantee the appliance eciency

and correct system operation, regular

maintenance is recommended to ensure

optimum operational performance and

tomeet safety requirements.

In the event that problems do occur during

the hot water generation, turn it o and do

not attempt to repair it please consult a

qualied technician.

Important Information

These instructions must be read and

understood before installing, commissioning,

operating or maintaining the equipment.

Installation & Commissioning

Read this installation and commissioning

manual and where necessary refer to

appendix C before commencing, the

CHWS ProRapid semi instantaneous DHW

Generator is a controlled service as dened

in the latest edition of the building regulations

and should only be tted by a competent

person. Installation & Commissioning of

equipment by accredited agents or specialist

sub-contractors will ensure the equipment is

operating safely and eciently.

The installation should also be in

accordance with the British Standard Codes

of Practice, current Building Regulations,

, i.e. Health & Safety Document No. 635

(The Electricity At Work Regulations

1989), and the Water Supply (Water

ttings) Regulations, BS 5449:1990

Forced circulation hot water systems , BS

6700:2006 Design, installation, testing and

maintenance of services supplying water.

The relevant regulations are: England and

Wales – Building Regulation G3; Scotland

– Technical Standard P3; North Ireland –

Building Regulation P5.

Failure to install this appliance correctly

could lead to prosecution and will invalidate

the guarantee.

It is in your own interest and that of safety to

ensure that the law is complied with.

5

INSTALLATION MANUAL PRORAPID |

Installation Instructions

General Information

This instruction manual is an integral and

essential part of the product check that it is

always furnished with the CHWS ProRapid

DHW generator.

Carefully read the instructions contained

in this chapter as it provides important

information for the correct and safe

installation and use of the appliance.

After the installation please deliver this

manual to the user. The installation and

start-up operations must be performed by

professionally qualied technicians having

the specic skills required in the heating

system sector.

The manufacturer declines responsibility for

any damage to persons or property caused

by a faulty installation or start up.

Important: This appliance should be used

only for the purpose mentioned any otheruse

is improper and therefore dangerous. Before

performing any operation on the appliance,

turn o the electric power supply and close

the water supply tap.

The use of any electric component involves

the observance of the following fundamental

rules:

• Always turn o the electric power

supply switch before touching any

electrical connection

• Do not touch the appliance with parts

of the body which are wet, damp or in

bare feet

• Do not pull the electric wires

• Do not expose the appliance to

atmospheric conditions

• Do not leave the appliance on when

not in use always turn the water and

electric supplies o.

Start Up

Before starting up the CHWS ProRapid

DHW generator, check that the unit is not

damaged if in doubt, do not use it and

contact CHWS Ltd.

The transport and positioning of the

appliance should be carefully performed

with the proper lifting hook. Avoid banging

or forcing the control board and the

insulation. The installation should be

performed in a suitable environment.

The CHWS ProRapid is suitable for

operating at 6 bar working pressure both for

sanitary and heating purposes. In the event

that the hydraulic pressure is higher than 6

bar, insert a pressure reducer in the

sanitary water supply.

Always cover both the sanitary hot

water and the heating water pipes with

an insulating coating according to the

regulations in force.

6| INSTALLATION MANUAL PRORAPID

Packaging components (plastic bags, etc.)

are potential danger and should not be left

within the reach of children.

The electrical safety of the equipment is

achieved when correctly connected to an

ecient grounding system performed

according to the regulations in force. This

fundamental safety requirement must be

veried.

If in doubt, request installation of the

electrical system by professionally qualied

personnel. CHWS Ltd declines responsibility

for damages caused by neglecting

grounding the system.

Gas, hydraulic and heating pipes cannot

be used as grounding. Serious damages to

pipes may occur within a short period of time.

The use of electric adapters, extension

cords or socket sets is not recommended.

Each appliance must be connected to the

electrical system by using a double-pole

switch according to the regulations in force.

The use of any component run by electrical

power involves the observance of the

following fundamental rules:

• Always turn o the electric power

supply switch before touching the

electrical connections

• Do not touch the appliance with parts

of the body which are wet, damp or in

bare feet

• Do not pull the wiring

• Do not expose the appliance to

atmospheric conditions (rain, sun, etc.)

Loading System

In case the external temperature is very low,

keep the temperature of the room where the

CHWS ProRapid DHW generator is installed

over 0°C when the hot water generator is

not in use, in order to avoid bursting due to

frost damage (the warranty does not cover

damages due to frost).

Fill the CHWS ProRapid by using the

hydraulic system check that the sanitary

water safety valve and the drain work

properly. Before lling the heating circuit with

water, clean the system carefully in order to

remove dirt and any residual substance that

may cause scale or damage.

Operation

Before turning the system on check that:

• The pipe connections are completely

sealed

• The system is equipped with safety

devices and controls according to the

regulations in force.

• The hot water pipes are insulated.

7

INSTALLATION MANUAL PRORAPID |

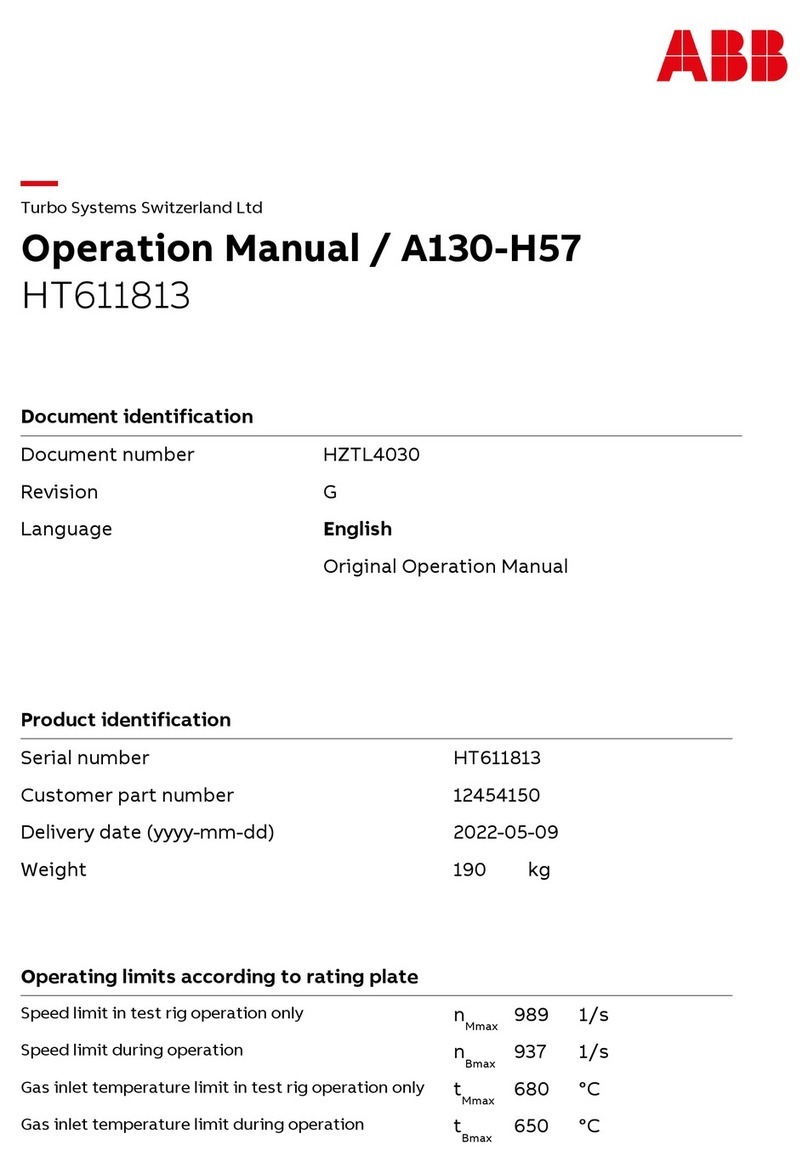

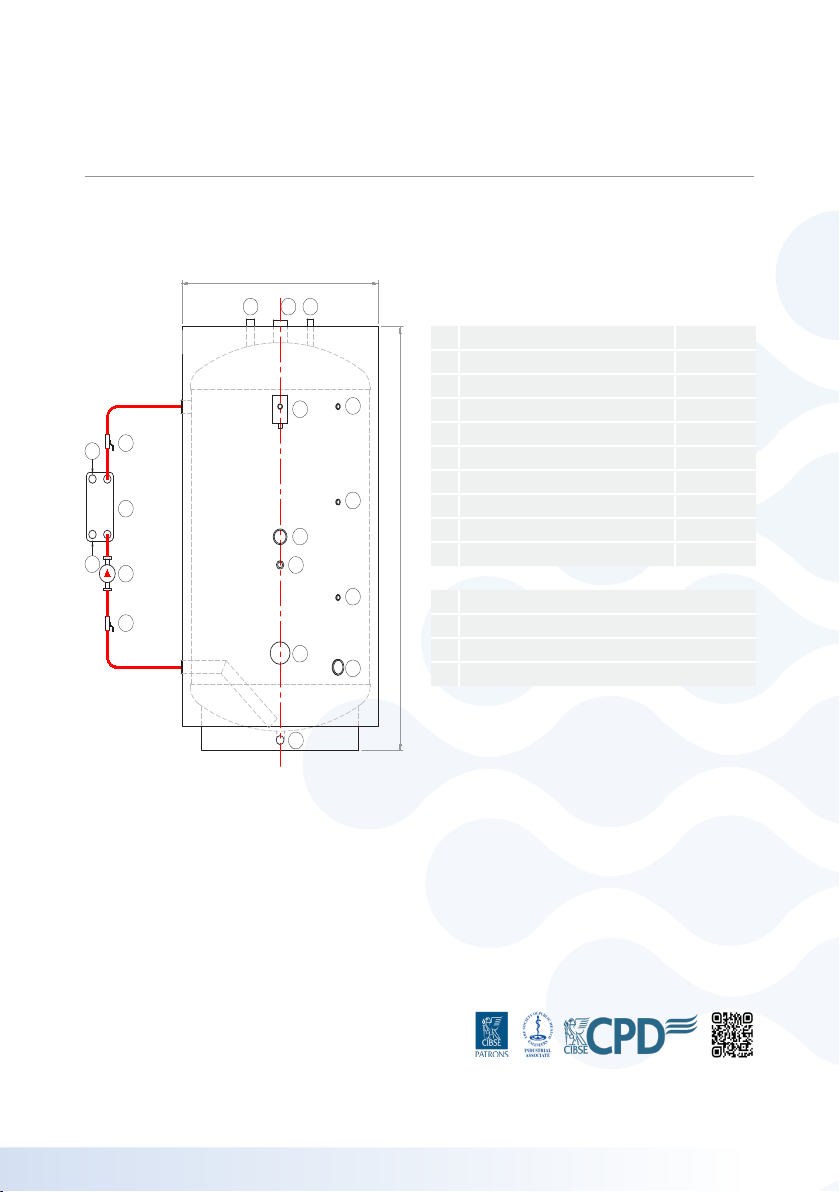

ProRapid - Semi Instantaneous DHW Generator

COMMERCIAL HOT WATER SOLUTIONS LTD

The Hive, Weston-super-Mare. BS24 8EE, United Kingdom

rapid/tps/feb2021/v1

A

B

5 43

6

6

6

10

9

8

7

D

1

A

B

C

A

2

2

Connections

1 Drain

2 Primary Connections

3 DHW Outlet

4 Temperature & Pressure Relief Valve

5 Anti-Vac Valve

6Sensor Tappings (x3)

7 Electrical Immersion Tapping

8 DHW Return

9Inspection Hatch / Electrical Immersion

10 Cold Water Inlet

A Isolation Valve

B Charging Pump

C Brazed Plate Heat Exchanger

D Control Panel

Drawing correct at time of publishing, some minor changes in design may occur which will not aect performance.

8| INSTALLATION MANUAL PRORAPID

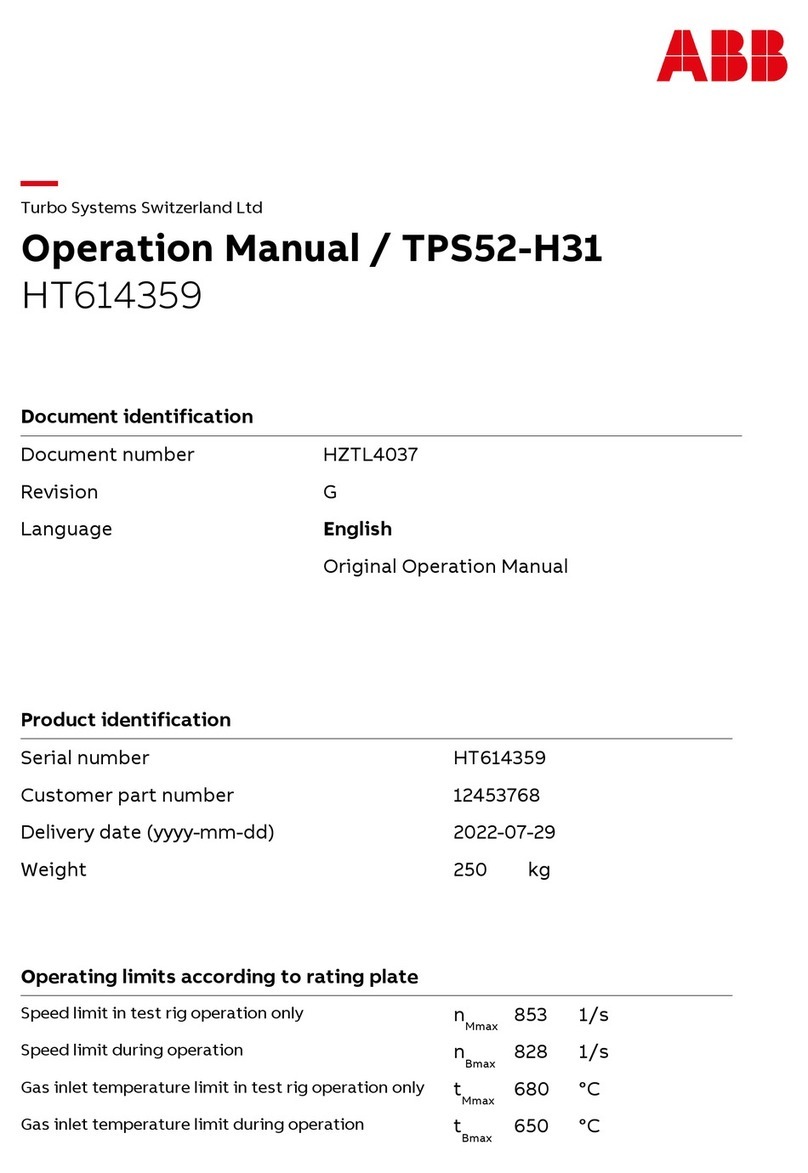

UNVENTED KIT

COLD WATER INLET

LTHW RETURN

LTHW INLET

HOT WATER DHW OUTLET

SECONDARY RECIRCULATION

Appendix C

Drain

Circulation pump (optional)

Draw-o points

Service stop valve

Temperature gauge (optional)

T&P valve

Isolating valve

Strainer

Pressure reducing valve

Non return valve

Expansion vessel

Safety relief valve

Key

1

2

3

4

5

6

7

8

9

10

11

12

9

INSTALLATION MANUAL PRORAPID |

Maintenance Instructions

General Instructions

Read carefully the instructions contained

in this chapter as they provide important

indications on the use and maintenance

of the appliance. Before performing any

operation on the CHWS ProRapid DHW

generator, turn o the electric power supply

switch and close the water supply valve.

The use of any component which is

electrically supplied entails the close

observance of the following fundamental

rules:

• Always turn o the electric power

supply switch before touching any

electrical connection

• Do not touch the appliance with parts

of the body which are wet, damp or in

bare feet

• Do not pull the wiring

• Do not expose the appliance to

atmospheric conditions

Substitute parts or accessories of the

appliance with original spare parts only. Do

not leave the appliance on when not in use.

Always turn the water and electric supply

switches o.

Emptying The CHWS ProRapid

DHW Hot Water Generator

Remove the electric supply and close the

cold water supply and empty the CHWS

ProRapid DHW generator by opening the

valve at the bottom of the tank. In case a

vacuum circuit breaker was not inserted in

the sanitary water circuit, insure that a valve

is open at the top of the vessel to vent the

vessel and avoid a damaging vacuum.

Troubleshooting

In case the heat exchange is not heating

suciently, the cause can be:

• The boiler power is not sucient

• The circulation of heating water is

not sucient because of a faulty or

undersized pump

• The temperature of the heating water

entering the ProRapid Plate Heat

exchanger is too low

• The temperature of the sanitary water is

too low or the temperature is too high

• The ProRapid is overused in

comparison with its performance

• Calcium deposits or other deposits in

the heat exchanger

The above listed causes must be veried by

professionally qualied personnel.

10 | INSTALLATION MANUAL PRORAPID

Warranty conditions for

ProRapid® cylinders

General warranty

CHWS Ltd will within a period of 5 years

from the date of purchase of the vessel,

supply a new and replacement cylinder of

the equivalent size and quality if the cylinder

is proved to be leaking or corroding due

to faulty manufacture or material defects.

Claims must be validated by CHWS Ltd who

will also have sole discretion on the validity

of any claim.

Components supplied by CHWS Ltd with

the cylinder will carry their manufacturers

warranty of 1 year. CHWS Ltd will repair

or replace any of these components that

have failed due to manufacturing or material

defects within that 1-year period. The

validity of any claim for faulty components

will be decided by the manufacturer of

that component.

Cylinder warranty

• The warranty on the ProRapid range

of products applies only to cylinders/

vessels supplied for use with sanitary/

drinking water.

• The products covered are the

ProRapid® models.

• CHWS Ltd will provide a 5 Year

warranty on the products as stated in

clause 2 as above.

• The warranty will only apply subject to

observance of the following conditions:

1. The cylinder should be installed in

accordance with the manufacturer’s

installation instructions

2. The cylinder should be installed in

accordance with National and Local

Building Regulations and observing all

relevant installation regulations at the

time of installation.

3. The cylinder is only used for the

purpose it was designed for, that being

the heating and storing of sanitary/

drinking water.

4. The design water temperatures or

pressure values displayed on the

cylinder data plate are not exceeded

during use at any time.

5. The cylinder is installed in a suitable

area that is not in a damp or corrosive

environment

6. In hard water areas, suitable water

conditioning or softening equipment

should be installed to condition the

sanitary water prior to heating. The

acceptable level of water hardness

is between 0 - 0.4 on the Langelier’s

Index of water measured at the

cylinder’s working temperature.

11

INSTALLATION MANUAL PRORAPID |

7. The cylinder should be periodically

maintained in accordance with the

manufacturers servicing schedule

which will include keeping any

sacricial anodes installed into the

cylinders serviceable.

8. Damage to the cylinder by an

external factor, misuse, neglect (this

includes frost damage), unauthorised

modications or attempts to repair

any leak or defect (other than by an

authorised and approved service

engineer) will invalidate any claim.

9. ALL claims must be authorised

by CHWS Ltd before any work or

replacement of defective components

takes place.

Limitations of warranty

CHWS Ltd will supply free of cost

replacement cylinders and components

including delivery to the original delivery

address of the cylinder. CHWS Ltd will not

accept any charges for the cost of labour,

installation or any other associated costs

with the installation of the replacement

cylinder or ancillary component.Claims must

be validated by CHWS Ltd who will also

have sole discretion on the validity of

any claim.

12 | INSTALLATION MANUAL PRORAPID

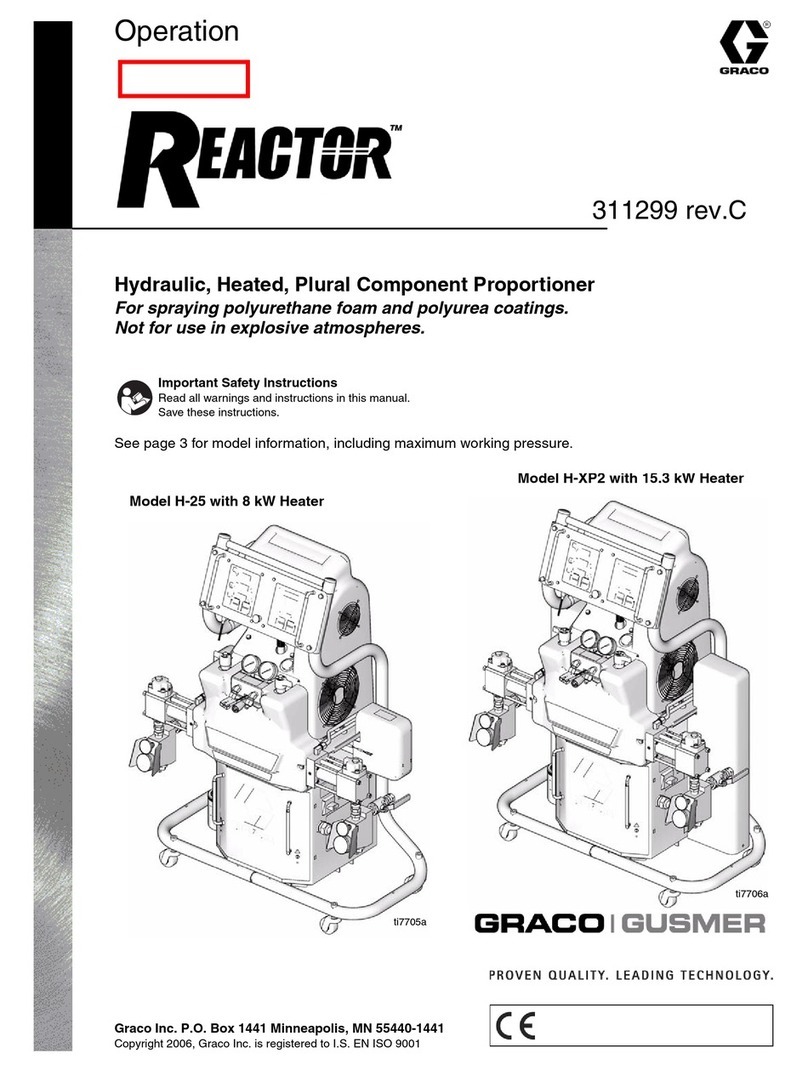

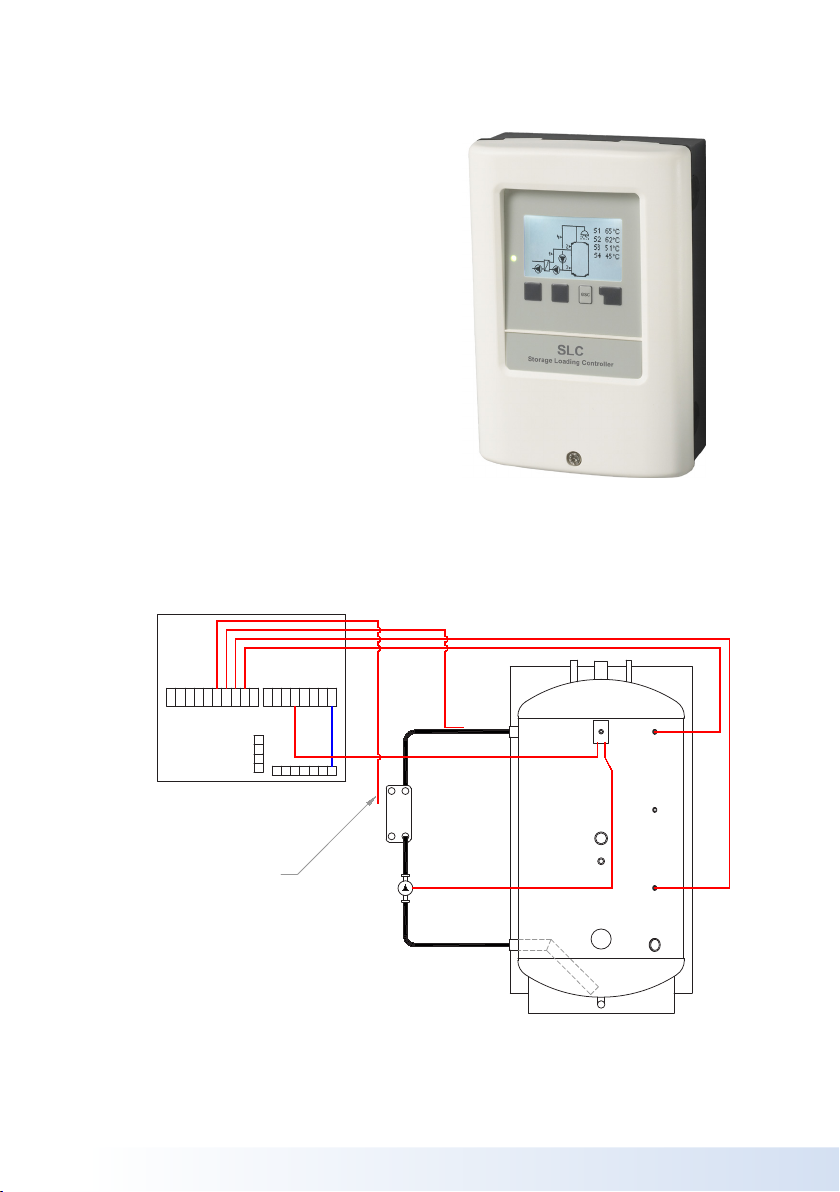

+ S6 V2 V1 S5 S4 S3 S2 S1 - R4 R4i R3 R2 R1 L N

NN

NN

NN

N

E

E

E

E

CIRCULATING

PUMP

HEAT

EXCHANGER

SLC CONTROLLER

PRO-RAPID VESSEL

PT1000 PROBE

WIRED AS SHOWN TO PRO-RAPID CONTROLLER

AND LEFT COILED FOR INSTALLER TO FIT

ONTO PIPEWORK

Storage Loading

Controller SLC

Installation and operating

instructions

Read carefully before installation,

commissioning and operation.

13

INSTALLATION MANUAL PRORAPID |

Safety Instructions

EU-Conformity

By axing the CE mark to the unit the

manufacturer declares that the SLC

conforms to the following relevant safety

regulations:

• EU low voltage directive 2014/35/EU

• EU electromagnetic compatibility direc-

tive 2014/30/EU conforms.

Conformity has been veried and the

corresponding documentation and the EU

declaration of conformity are kept on le by

the manufacturer.

General instructions

Please read carefully!

These installation and operating instructions

contain basic instructions and important

information regarding safety, installation,

commissioning, maintenance and the

optimal use of the unit. Therefore these

instructions must be read and understood

completely by the installation technician/

specialist and by the system user before

installation, commissioning and operation of

the unit.

This unit is an automatic, electrical Storage

Loading Controller. Install the unit only in dry

areas and under the ambient conditions

described in “Specications”.

The valid accident prevention regulations,

VDE regulations, the regulations of the

local power utility, the applicable DIN-EN

standards and the installation and operating

instruction of the additional system

components must also be observed.

Under no circumstances does the unit

replace any safety devices to be provided by

the customer!

Installation, electrical connection,

commissioning and maintenance of the

device may only be carried out by an

appropriately trained specialist. Users: Make

sure that the specialist gives you detailed

information on the function and operation of

the unit. Always keep these instructions in

the vicinity of the unit.

The manufacturer does not take over any

liability for damage caused through improper

usage or non-compliance of this manual!

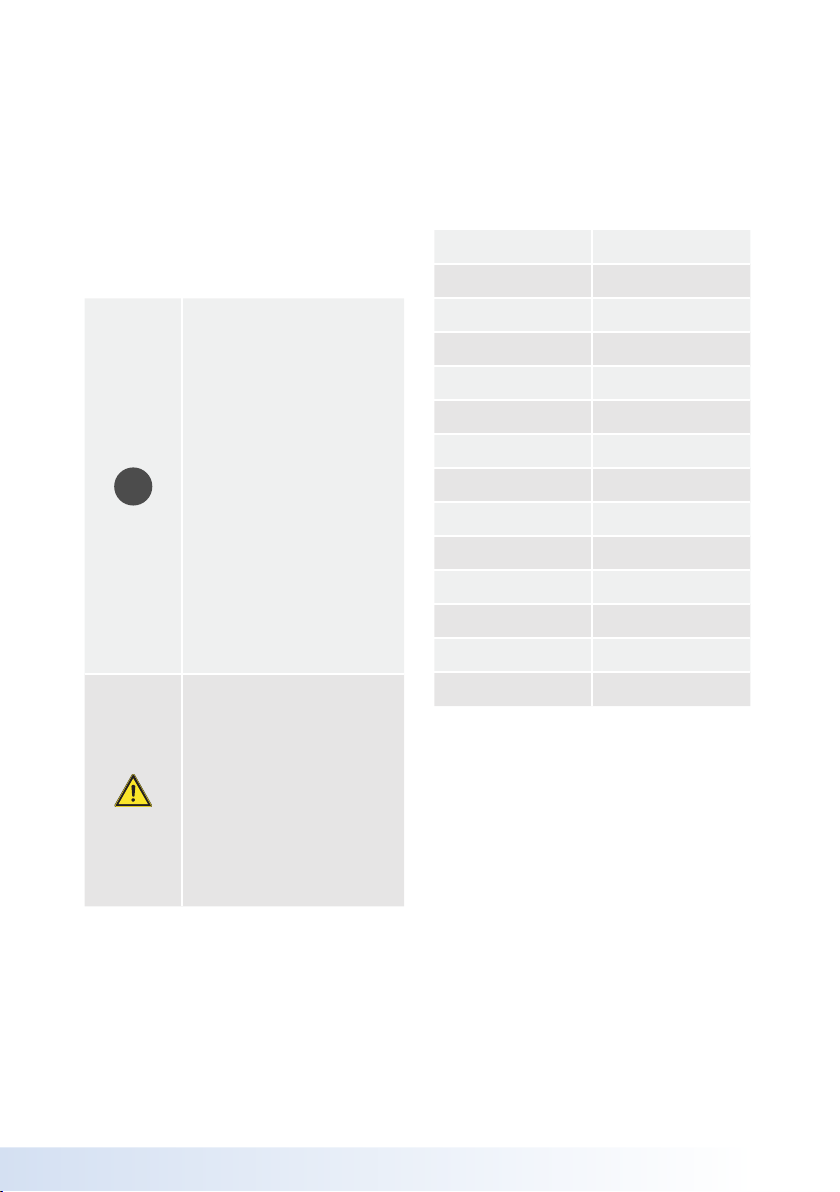

14 | INSTALLATION MANUAL PRORAPID

Danger Failure to observe

these instructions can result

in electrocution.

Danger Failure to observe

these instructions can result

in serious damage to health

such as scalding or life-

threatening injuries.

!

Caution Failure to observe

these instructions can result

in destruction of the unit or

the system, or environmen-

tal damage.

Caution Information which

is especially importation for

the function and optimal use

of the unit and the system.

Explanation of Symbols

Changes to the Unit

• Changes, additions to or conversion of

the unit are not permitted without writ-

ten permission from the manufacturer.

• It is likewise forbidden to install ad-

ditional components that have not been

tested together with the unit.

• If it becomes clear that safe operation

of the unit is no longer possible, for

example because of damage to the

housing, turn the Unit o immediately.

• Any parts of the unit or accessories

that are not in perfect condition must

be exchanged immediately.

• Use only original spare parts and ac-

cessories from the manufacturer.

• Markings made on the unit at the fac-

tory must not be altered, removed or

made illegible.

• Only the settings described in these

instructions may be set using the Unit.

Changes to the unit can

compromise the safety and

function of the unit or the

entire system.

Warranty and Liability

The Unit has been manufactured and

tested with regard to high quality and safety

requirements. The warranty and liability shall

not include, however, any injury to persons

or material damage that is attributable to

one or more of the following causes:

• Failure to observe these installation and

operating instructions.

• Improper installation, commissioning,

maintenance and operation.

• Improperly executed repairs.

• Unauthorised structural changes to the

unit.

15

INSTALLATION MANUAL PRORAPID |

• Use of the device for other than its

intended purpose.

• Operation above or below the limit

values listed in the ‚Speci cations‘

section.

• Force majeure.

Disposal and Pollutants

The unit conforms to the European RoHS

2011/65/EU for 2011/65/EUthe restriction of

the use of certain hazardous substances in

electrical and electronic equipment.

Under no circumstances

may the device be

disposed of with the

normal household waste.

Dispose of the unit only at

appropriate

collection points or ship

it back to the seller or

manufacturer.

16 | INSTALLATION MANUAL PRORAPID

Description Slc

Specications

Electrical specications:

Power supply 100 - 240VAC, 50 - 60 Hz

Power consumption / standby 0,5W - 2,5W/ X

Internal fuse 1 2A slow blow 250V

Protection Class IP40

Protection Class II

Overvoltage category II

Degree of pollution category II

Inputs/Outputs

Sensor inputs 6 -40 °C ... 300 °C

Outputs mechanical relay 3

mechanical relay R1 - R3 460VA for AC1 / 460W for AC3

0-10V/PWM output V1 - V2 for 10 k Ω working resistance 1 kHz, level 10 V

Max. cable length

Flow sensors <3m

0-10V/PWM <3m

mechanical relay <10m

Permissible Ambient Conditions

for controller operation 0 °C - 40 °C, max. 85 % rel. humidity at 25 °C

for transport/storage 0 °C - 60 °C, no moisture condensation

permitted

Other Specications and Dimensions

Housing design 2-part, ABS plastic

Installation methods Wall installation, optionally panel installation

Overall dimensions 163 mm x 110 mm x 52 mm

Aperture installation dimensions 157mm x 106mm x 31mm

Display completely graphic display 128 x 64 dots

Real Time Clock RTC with 24 hour power reserve

Operation 4 entry keys

17

INSTALLATION MANUAL PRORAPID |

Terminal: Connection for:

S1 Storage top

S2 Storage bottom

S3 Plate outlet temp

S4* Primary Flow Temperature

S5 Not used

V1 Not used

V2 Not used

S6 Not used

+ 12V Power supply

VFS1 Not used

VFS2 Not used

The connection of the ground wire is

made at the lower gray terminal

block.

CAN Not used

Terminal: Connection for:

S1 Neutral conductor N

S2 Phase conductor L

S3 240vac Switch Live Burner

S4* Not in use

S5 Not in use

V1 Secondary pump live

The neutral conductor N must be

connected to the N terminal block.

The PE protective conductor must be

connected to the PE metal terminal block!

Installation

Electrical Terminals

Low voltages

max. 12 VAC / DC

Mains voltages

100 - 240 VAC, 50 - 60 Hz

18 | INSTALLATION MANUAL PRORAPID

Before working on the unit, switch o the power supply and secure it against

being switched on again! Check that there is no power owing! Electrical

connections may only be made by a specialist and in compliance with the

applicable regulations. The unit may not be put into operation if there is

visible damage to the housing, e.g. cracks.

The unit may not be accessible from behind.

Low-voltage cables such as temperature sensor cables must be routed

separately from mains voltage cables. Feed temperature sensor cables only

into the left-hand side of the unit, and mains voltage cables only into the

right-hand side.

The customer must provide an all-pole disconnecting device, e.g. an

emergency heating switch.

The cables being connected to the unit must not be stripped by more than 55

mm, and the cable jacket must reach into the housing just to the other side of

the strain relief.

Cable Installation

1. Unscrew cover screw completely.

2. Carefully pull upper part of housing

from lower part. During the removal, the

brackets are released as well.

3. Set upper part of housing aside. Do not

touch the electronics.

4. All terminals are “spring cage” type

terminals. To open the terminal use a

terminal screw driver to push in the

spring and insert your cables. It is

recommended to use “boot lace” type

connections.

5. Once all cabling is completed, check

that no mains voltage cables have been

installed on the low voltage side.

6. Put on the cover and screw cover

completely.

Electrical Connection

19

INSTALLATION MANUAL PRORAPID |

Before working on the unit, switch o the power supply and secure it against

being switched on again! Check that there is no power owing! Electrical

connections may only be made by a specialist and in compliance with the

applicable regulations. The unit may not be put into operation if there is

visible damage to the housing, e.g. cracks.

The unit may not be accessible from behind.

Low-voltage cables such as temperature sensor cables must be routed

separately from mains voltage cables. Feed temperature sensor cables only

into the left-hand side of the unit, and mains voltage cables only into the

right-hand side.

The customer must provide an all-pole disconnecting device, e.g. an

emergency heating switch.

The cables being connected to the unit must not be stripped by more than 55

mm, and the cable jacket must reach into the housing just to the other side of

the strain relief.

Installing the Temperature Sensors

The controller operates with Pt1000

temperature sensors which are accurate

to 1 °C, ensuring optimal control of system

functions.

!

If desired, the sensor cables

can be extended to a

maximum of 30 m using a

cable with a cross-section

of at least 0.75 mm².

Ensure there is no contact

resistance! Position the

sensor precisely in the area

to be measured! Only use

immersion, pipe-mounted

or at-mounted sensors

suitable for the specic

area of application with the

appropriate permissible

temperature range.

Low-voltage cables such as

temperature sensor cables

must be routed separately

from mains voltage cables.

Feed temperature sensor

cables only into the left-

hand side of the unit, and

mains voltage cables only

into the right-hand side.

Temperature Resistance Table for

Pt1000 Sensors

°C Ω

-20 922

-10 961

0 1000

10 1039

20 1077

30 1116

40 1155

50 1194

60 1232

70 1270

80 1308

90 1347

100 1385

20 | INSTALLATION MANUAL PRORAPID

Operation

Display and Input

The display‘s (1), extensive text and

graphical mode, enables simple, almost self-

explanatory, operation of the controller.

The LED (2) lights up green when the

primary pump is switched on (automatic

mode). The LED (2) lights up red when

operating mode‚O‘ is set. The LED (2)

ashes quickly red when an error is present.

Entries are made using 4 keys (3+4), to

which contextual functions are assigned.

The ‚esc‘ key (3) is used to cancel an entry

or to exit a menu. If applicable, a request

for conrmation appears to save the made

changes.

The function of the other 3 keys (4) is shown

in the display right above the keys. The

right-hand key generally has a conrmation

and selection function.

The graphics mode appears if not key is

pressed for 2 minutes or after exiting the

main menu with ‘esc’.

Hitting the “esc” key in the graphics mode

takes you directly to the main menu.

Exit main menu

2. Statistics

1. Measurements

OK

Pump (rotates when active)

Storage / buer

Temperature Sensors

Heat exchanger

Further symbols can be found

in the special functions

Key

+/-

Yes/No

About

Back

Ok

Conrm

/

Increase / decrease values

Scroll menu down / up

agree / reject

further information

to the previous display

Conrm selection

Conrm setting

Examples for key settings:

58ºC

55ºC

100%

16.0| min

Table of contents

Other CHWS Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Genmitsu

Genmitsu PROVerXL 4030 CNC user manual

Pfeiffer Vacuum

Pfeiffer Vacuum HIPACE 700 P operating instructions

Vector

Vector OPT1-FC-HTNV-VC operating instructions

Oxford Instruments

Oxford Instruments MicrostatHe user manual

Eaton

Eaton Airflex WCB Series Installation, operation and maintenance

Montanari

Montanari RQ 200 manual