04/16Page1

Installation,OperationandMaintenanceInstructionsIOM‐6A00IIA1/IIA

02‐15

Model6A00

InlineDeflagrationFlameArrestor

ChapterI

I.DESCRIPTIONANDAPPLICATION

Asautonomoussafetysystemsforintendeduseinhazardousareasthelistedtypescomplywiththe

requirementsoftheEuropeanDirective2014/34/EUandtheharmonizedstandardforflamearrestorsEN

ISO16852.

Thisdocumentappliestothefollowingtypesaccordingtothecharts1‐3.Thelimitvaluesofthemaximum

operatingpressurep0,themaximumoperatingtemperatureT0andthemaximumdistancetotheignition

sourceLumustbekept!

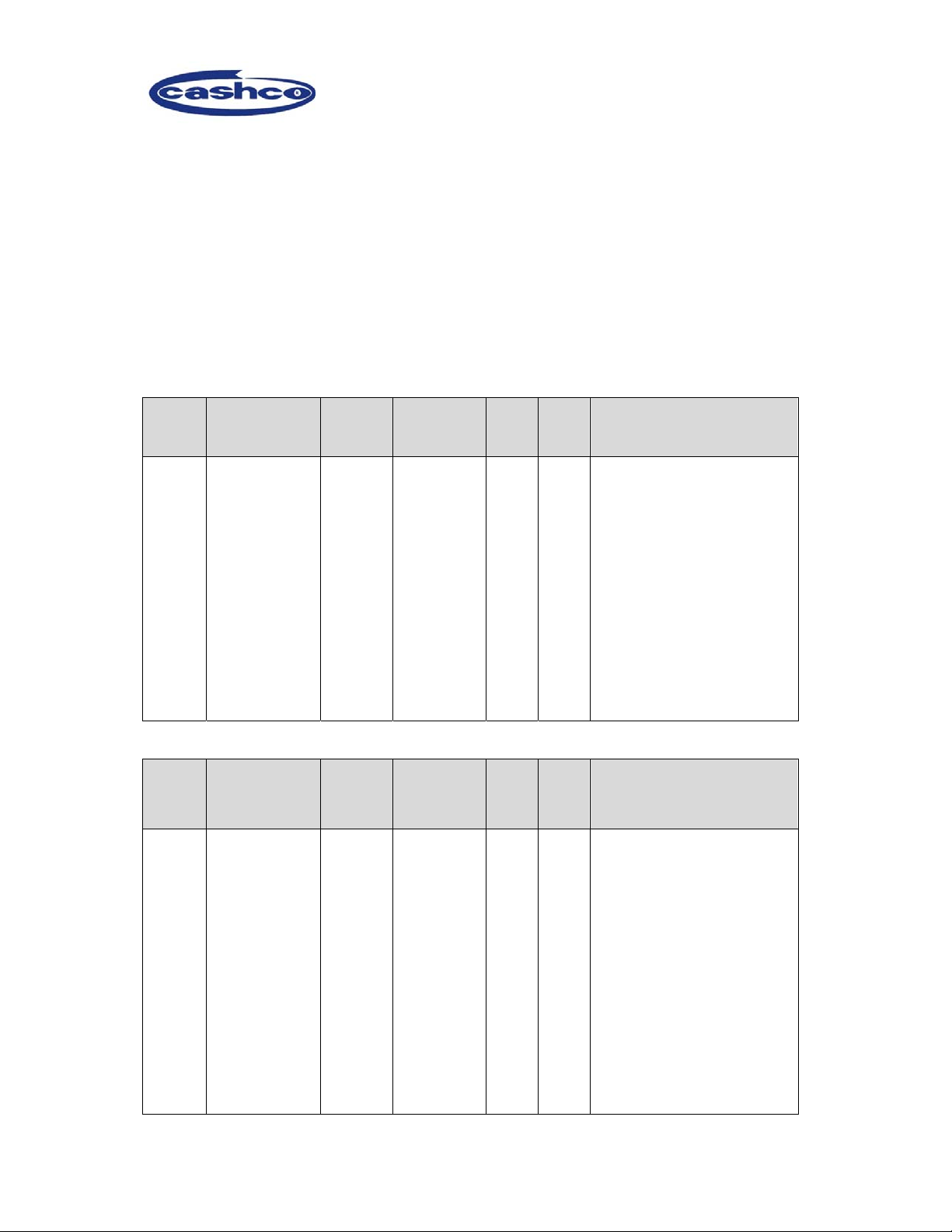

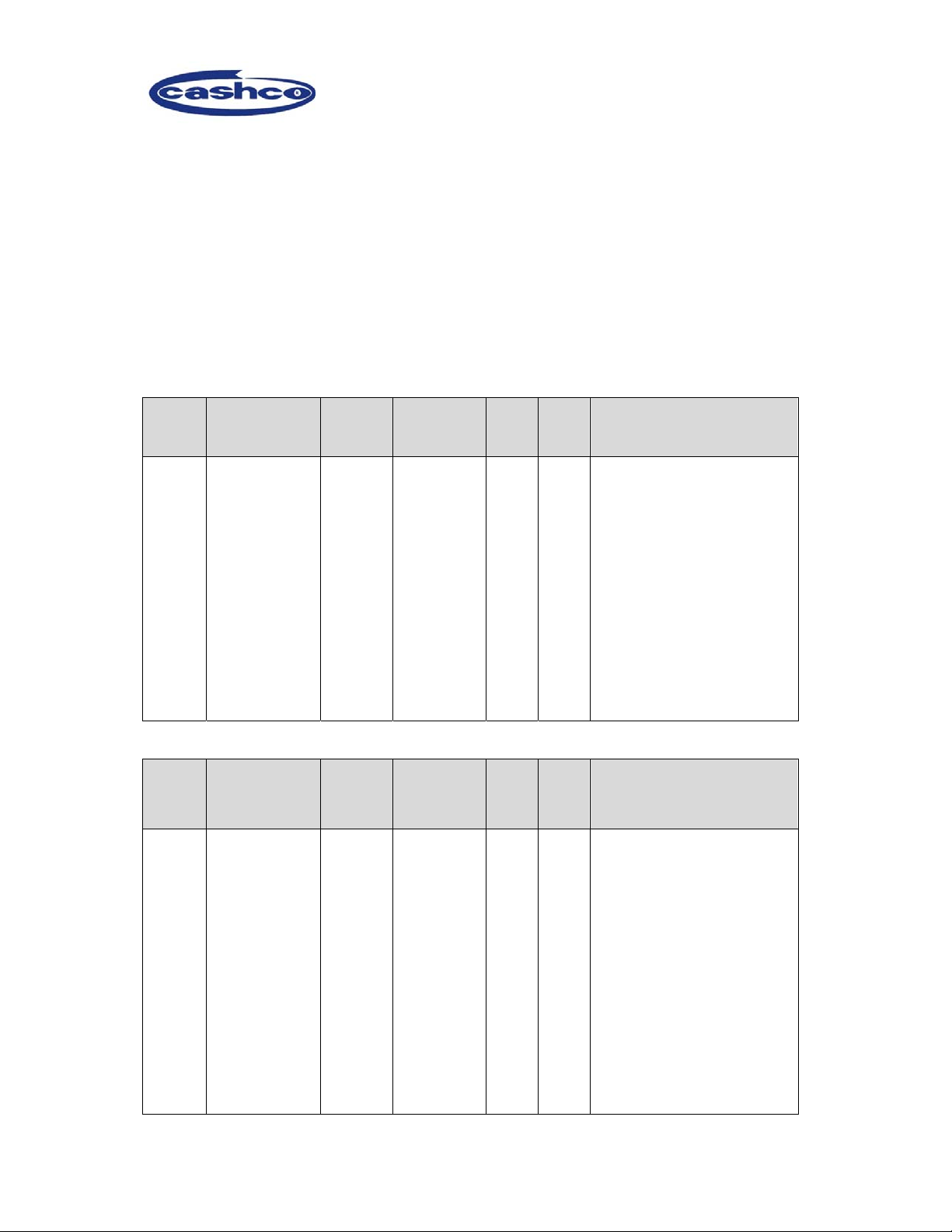

Ex‐Gr.

Pipesize

Type

p0

[kPa(abs.)]

T0

[°C]

Lu

[m]

EC‐typeexamination

certificate

IIA1

DN15(½")6A0A1110600,75

IBExU13ATEX2122X

DN20(¾")6A0B1110601,00

DN25(1")6A0C1110601,25

DN32(1¼")6A0K1110601,60

DN40(1½")6A0U1110602,00

DN50(2")6A0V1110602,50

DN65(2½")6A131110603,25

DN80(3")6A1B1110604,00

DN100(4")6A1K1110605,00

DN125(5")6A1T1110606,25

DN150(6")6A1U1110607,50

DN200(8")6A2211106010,0

Chart1:TypesofexplosiongroupIIA1(MESG>1,14mm)protectagainstdeflagrationandenduranceburning

Ex‐Gr.

Pipesize

Type

p0

[kPa(abs.)]

T0

[°C]

Lu

[m]

EC‐typeexamination

certificate

IIA1

DN20(¾")6A0B6160601,00

IBExU13ATEX2148X

DN25(1")6A0C6160601,25

DN32(1¼")6A0K6160601,60

DN40(1½")6A0U6160602,00

DN50(2")6A0V6160602,50

DN65(2½")6A136160603,25

DN80(3")6A1B6160604,00

DN100(4")6A1K6160605,00

DN125(5")6A1T6160606,25

DN150(6")6A1U6160607,50

DN200(8")6A2261606010,0

DN250(10”)6A2A61606012,5

DN300(12")6A2H61606015,0

Chart2:TypesofexplosiongroupIIA1(MESG>1,14mm)protectagainstdeflagrationandshorttimeburning

maximumtimeofstabilizedburning1minute