CHWS Propak Thermal Series Instruction Manual

PROPAK THERMAL SERIES

Installation Manual

Operation & Maintenance Manual

2| OPERATION & MAINTENANCE MANUAL

Principal

CHWS Propak is a compact and highly

ecient DHW production system

incorporating a gasketed plate heat

exchanger, electrically actuated 3-port

control valve, safety relief valve, A-rated

ERP variable speed primary pumps with a

secondary pump supplied on the Propak

plus units.

The unit is complete with a full PID

controller and PT100 temperature sensor.

The motorized 3-port valve allows high

speed adjustment of the primary heat

input to match changes in secondary hot

water demand. The design maintains the

outlet temperature at the set point (default

60ºC) and consequently reduces the risk of

legionnaires disease within the system.

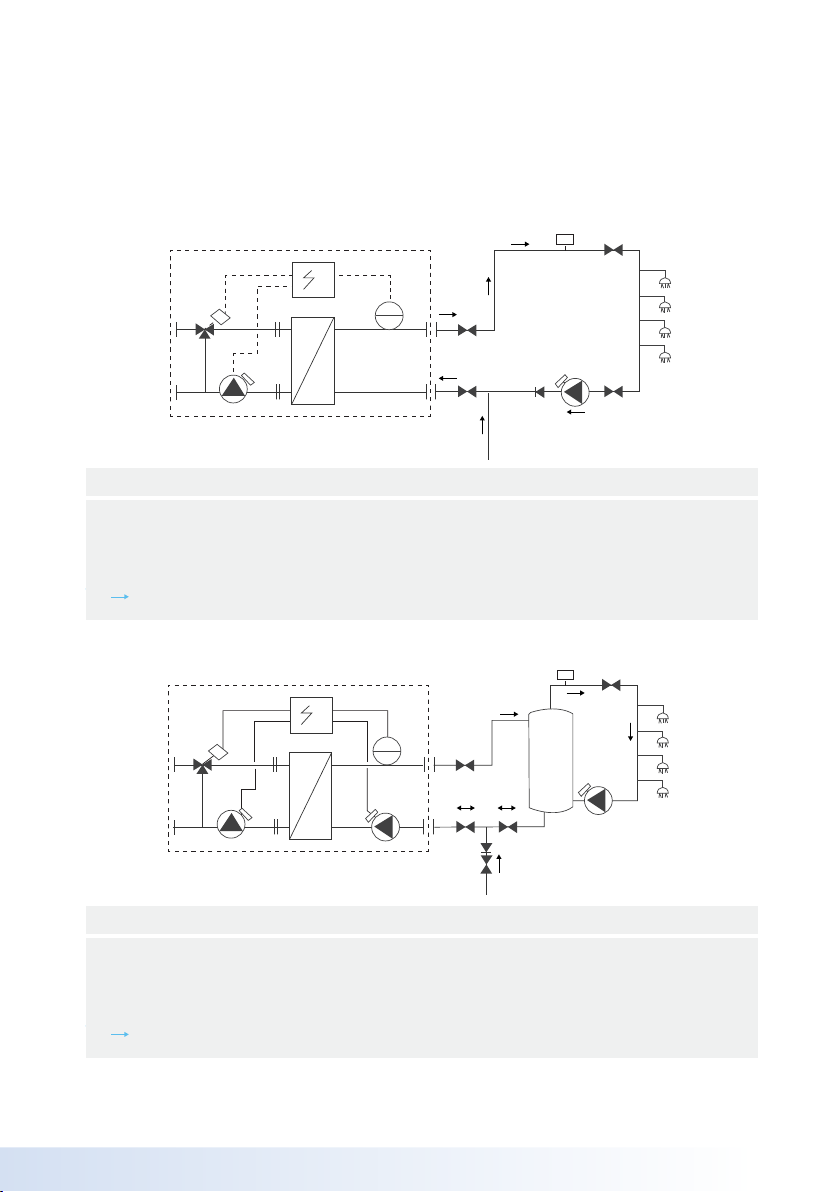

See schematic layout:

A) Propak Thermal Instantaneous

B) Propak Thermal Plus Semi-Instantaneous

Secondary Inlet

Secondary Outlet

Primary Inlet

Primary Outlet

Key

1

2

3

4

3

OPERATION & MAINTENANCE MANUAL |

Instantaneous Applications

1

2

C

E

F

G

3

LK

J

4

H

B

TT

1

A

D

AAV

1

2

C

E

G

G

3

J

G

B

TT

1

A

N

H

D

AAV

G

G

K

4

1

2

C

E

F

G

3

LK

J

4

H

B

TT

1

A

D

AAV

1

2

C

E

G

G

3

J

G

B

TT

1

A

N

H

D

AAV

G

G

K

4

Semi-Instantaneous Applications

Primary ow

Primary return

Cold mains feed

Secondary ow

DHW Flow direction

Key

1

2

3

4

Isolation valve

Isolation valve

Isolation valve

Secondary return pump

Automatic air vent

G

H

J

K

AAV

Heat exchanger

Primary pump

Control valve

Control panel

Temperature sensor

Isolation valve

A

B

C

D

E

F

Semi-Instantaneous Applications

Semi-Instantaneous Applications

Primary ow

Primary return

Cold mains feed

Secondary ow

DHW Flow direction

Key

1

2

3

4

Isolation valve

Buer vessel

Secondary return pump

Non-return valve

Automatic air vent

G

H

J

K

AAV

Heat exchanger

Primary pump

Control valve

Control panel

Temperature sensor

Secondary shunt pump

A

B

C

D

E

F

4| OPERATION & MAINTENANCE MANUAL

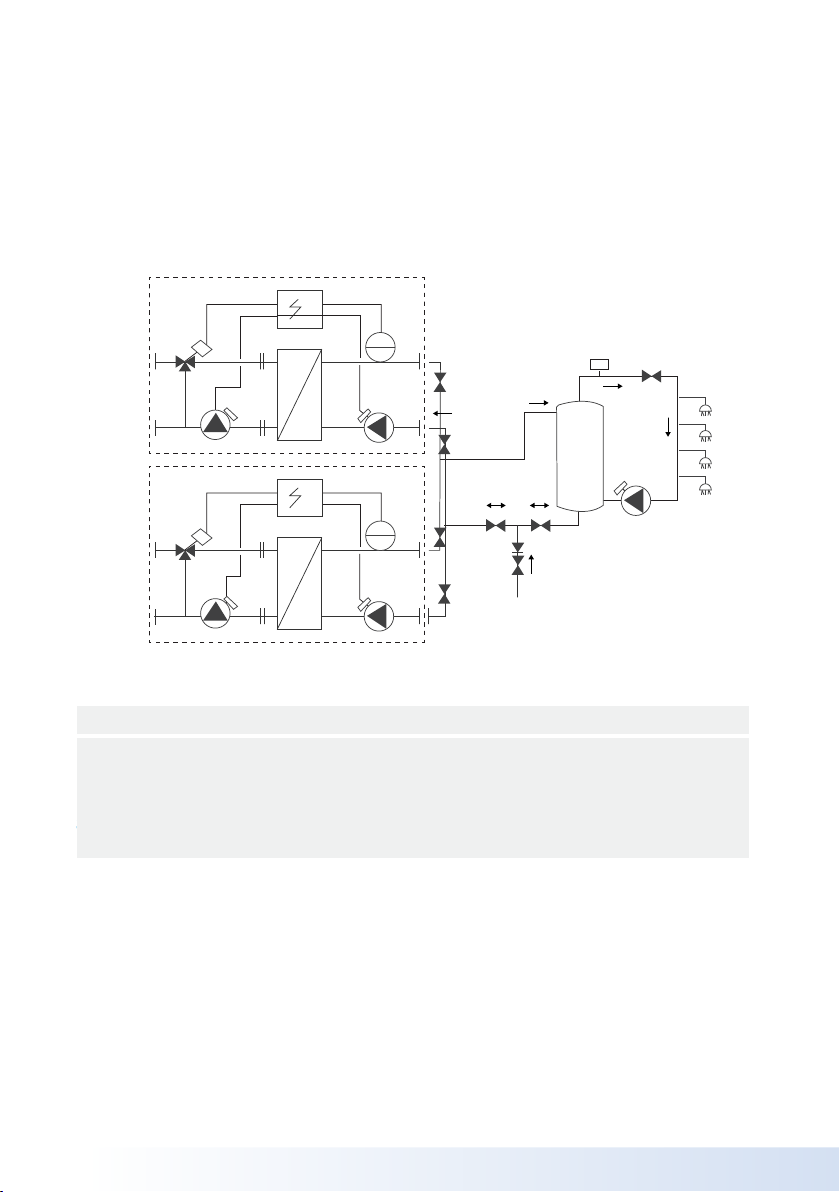

Semi-Instantaneous Applications Duty-Duty

1

2

C

E

4

G

4

J

H

J

5

G

B

TT

1

A

D

AAV

1

2

C

E

G

G

3

B

TT

1

A

F

G

D

G

G

K

4

5

G

5

F

The Propak & Propak Plus come fully

assembled and are ready to operate. All

ancilliaries are mounted on the unit using

stainless steel piping. All Propak & Propak

Plus units are tested hydraulically and

electrically at the factory.

Semi-Instantaneous Applications

Primary ow

Primary return

Cold mains feed

Building service ow

Building service return

Key

1

2

3

4

5

Isolation valve

Buer vessel

Secondary return pump

Non-return valve

Automatic air vent

G

H

J

K

AAV

Heat exchanger

Primary pump

Control valve

Control panel

Temperature sensor

Secondary shunt pump

A

B

C

D

E

F

5

OPERATION & MAINTENANCE MANUAL |

Installation

All installation work must be undertaken by a

qualied and competent person.

The heat exchangers must be installed in

accordance with the following requirements:

The current Building Regulation

The Water Supply (Water Fittings)

Regulations 1999

Additionally, installation should be

performed in accordance with all relevant

requirements of the Local Authority and

recommendations of the British Standards

and Codes of Practice:

BS EN 806 Parts 1-5: 2000 – 2012

Specication for design, installation, testing

and maintenance of services supplying

water for domestic use within buildings and

their curtilages. This standard supersedes

the following British Standards and Codes

of Practice: CP99, CP310, CP324, CP202,

CP342 Part 2, Centralised Hot Water Supply.

BS 7206:1990 Specication for unvented

hot water storage units and packages.

•

•

6| OPERATION & MAINTENANCE MANUAL

Unloading

The Propak unit comes assembled on a

mild steel skid which should be mounted

on prepared foundations that are level and

suitable for the size and weight of the unit.

The unloading of the equipment is the

responsibility of the recipient and should be

carried out with care to avoid damage to the

unit.

Use web slings (no metal chains). Insert

them in the designated notches on the

head and follower.

When moving and handling the heat

exchanger, make sure that it is properly

supported and secured as its high

centre of gravity may cause it to tip over.

Never lift the unit by its guide rails,

compression bolts or pipework.

Shield the plates, pumps, valves &

controller from impacts as they could

cause irreparable damage.

Pipework

Make sure that the pipework connections

are aligned and correctly spaced before

connecting. See that the weight of the

pipework is taken by external supports and

not by the Propak. Allowances should be

made for expansion of the pipes either by

suitable bends or exible joints. Threaded

connections may be sealed with PTFE tape.

Flanged connections should be sealed with

a suitable gasket and sealing agent.

Venting Vent valves must be tted at the

highest point in the connecting pipework to

enable purging air for initial operation.

Purge all pump bodies, see the pump

manufacturers instructions supplied. Flush

out the system pipework before installing

to remove any foreign matter which may

impact on the valve and pump operation.

Filling

Before lling the system check that the

drain valve is closed and all air vents are

open. Slowly ll both sides of the system

with water. Caution:- Do not ll the system

too quickly otherwise pockets of air may

become trapped. Once lled purge air at

high points and purge all the pump bodies.

Switch the power on to the unit and check

the controller settings and enable the

required functions.

(see further set up instructions)

The heat exchanger and its components

must never be used for purposes other than

those for which they were initially designed.

Electrical connection

Connect a single phase 230V 50Hz supply

to the Mains Input terminals. (See electrical

wiring diagrams section). If the unit is to

be controlled remotely connect the remote

control switch or contacts to the Remote

enable terminals.

•

•

•

•

7

OPERATION & MAINTENANCE MANUAL |

Commissioning

Before installation this manual must be read.

The controller has been set at the factory

with default parameters. If any function

needs tuning, values can be changed

with reference to the instruction manual

for parameter setting. Initially, the

commissioning process should be carried

out with the factory settings.

Contact us to arrange a commissioning

engineer’s visit.

Maintenance and repairs

The frequency of the inspections depends

on the water hardness, temperature and

ow rate. CHWS can oer a low cost annual

service contract. Please contact us for more

information.

We recommend the following periodical

checks:

Weekly inspection to check for leaks

from pipes or components.

Weekly inspection to make sure that

the operation control systems is stable

and that the temperature does not

uctuate. Temperature hunting causes

unnecessary wear of valves, actuators.

The control box does not require any

specic maintenance; annually check

the electrical connections tightening.

Annually check the control valve that

no leaks are detected. Lime scaling on

the connected devices. Scaling of the

secondary side will be evidenced by:

a high pressure drop on the secondary

side of the exchanger, improper

temperature range on the secondary

side of the exchanger, low temperature

dierence between inlet and outlet on the

primary side of the exchanger when the

control valve is fully open.

Only replace any defective parts with the

original spare parts. Please contact CHWS

for spare parts. Maintenance work must be

carried out by a qualied and authorized

technician.

Hazard of electrical shock or scalding.

Before carrying out any works

disconnect power supplies.

With high primary and secondary

temperatures there is a risk of scalding.

All pipework must be cool before

carrying out work.

•

•

•

•

•

•

•

•

8| OPERATION & MAINTENANCE MANUAL

Warranty

Our equipment comes with a 24-month

warranty from the date of shipment and

is subject to commissioning by CHWS.

The manufacturer’s liability is limited to

the replacement of any damaged parts

that are not repairable. No other nancial

reimbursement may be claimed in any case

under the warranty. The fault and probable

cause must be advised to CHWS before

any remedial works is undertaken. The

defective part should then be returned to

our Head Oce for assessment unless prior

arrangement to proceed otherwise has been

supplied from CHWS. Assessment of the

defective part will conclude whether or not

the terms of the warranty apply.

Exclusions:

Non-compliance with the guidelines for

installation, conguration and maintenance:

Over pressures, water-hammer, scaling,

noncompliant water quality.

Also excluded from the warranty:

Fitting costs, retting costs, packaging,

transport, and any accessories or

equipment not supplied

by CHWS, which will only be covered by

any warranties issued by said third-party

manufacturers.

Any damage caused by connection

errors, insucient protection,

misapplication or faulty or careless

operations.

Equipment disassembled or repaired by

any other party than CHWS or TPS.

Non-payment for goods will lead to all

operational warranties covering the delivered

equipment being terminated.

•

•

•

9

OPERATION & MAINTENANCE MANUAL |

Operation & Maintenance

Manual

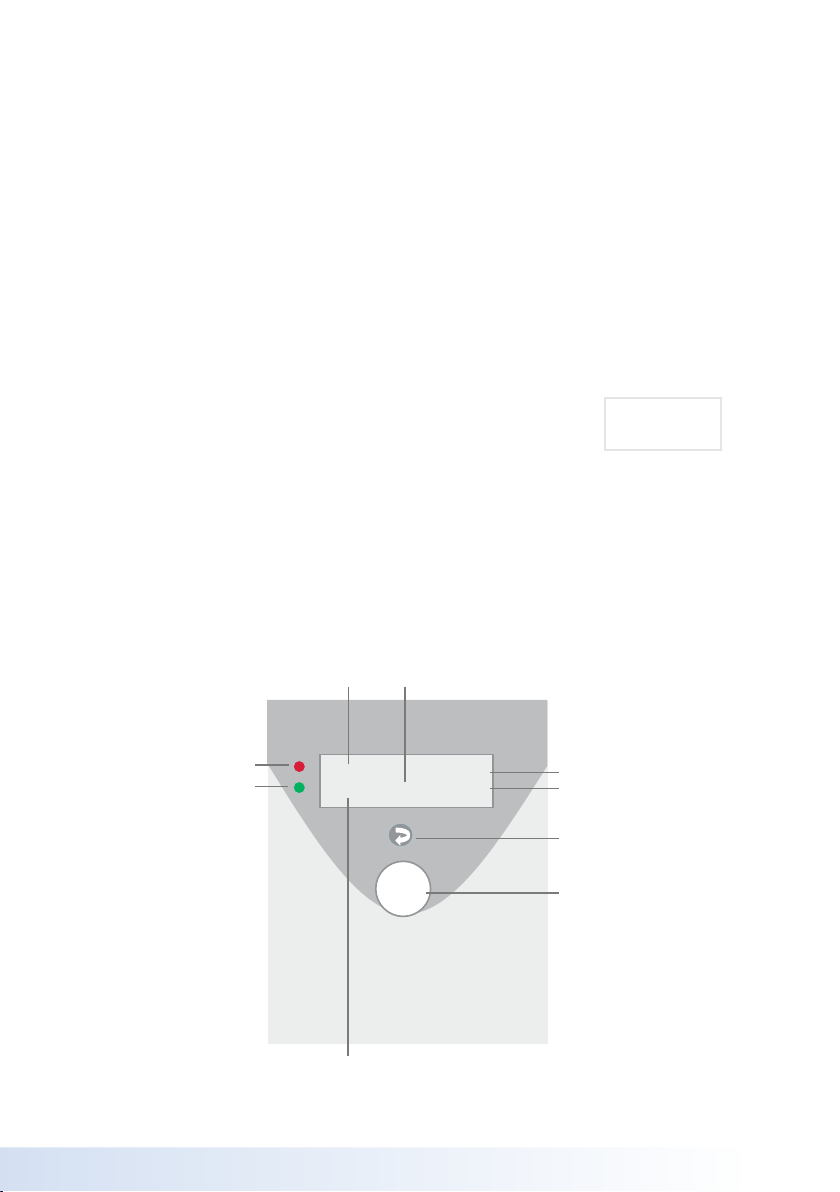

Control box

Display

The control unit allows the display of

operating conditions: factory settings or

programmed settings and indication of

errors – it also enables users to respond to

changes in basic and advanced settings.

The Propak Thermal comes with a range

of factory pre set parameters, these can

be changed by adjustments in the basic

parameter setting mode or the advanced

programming mode.

2

Time

Control Dial

Percentage open position

of 3 port control valve

Date

Measured temperature

Red LED (Defect)

Green LED (Operational)

Return Button

Temperature setpoint

10H15 02/03/2014

65.0ºC Tc: 65 100%

Navigation

To enter the programming menu, press the

and hold the control Dial for 5 seconds and

then release.

The screen displays:

All consolidation and modication of

program settings are achieved using the

Control Dial.

To enter a program or to consent a

parameter, press the Control Dial.

To exit a program step, press the return

button.

MENU ECS

Selection PROG

•

•

•

10 | OPERATION & MAINTENANCE MANUAL

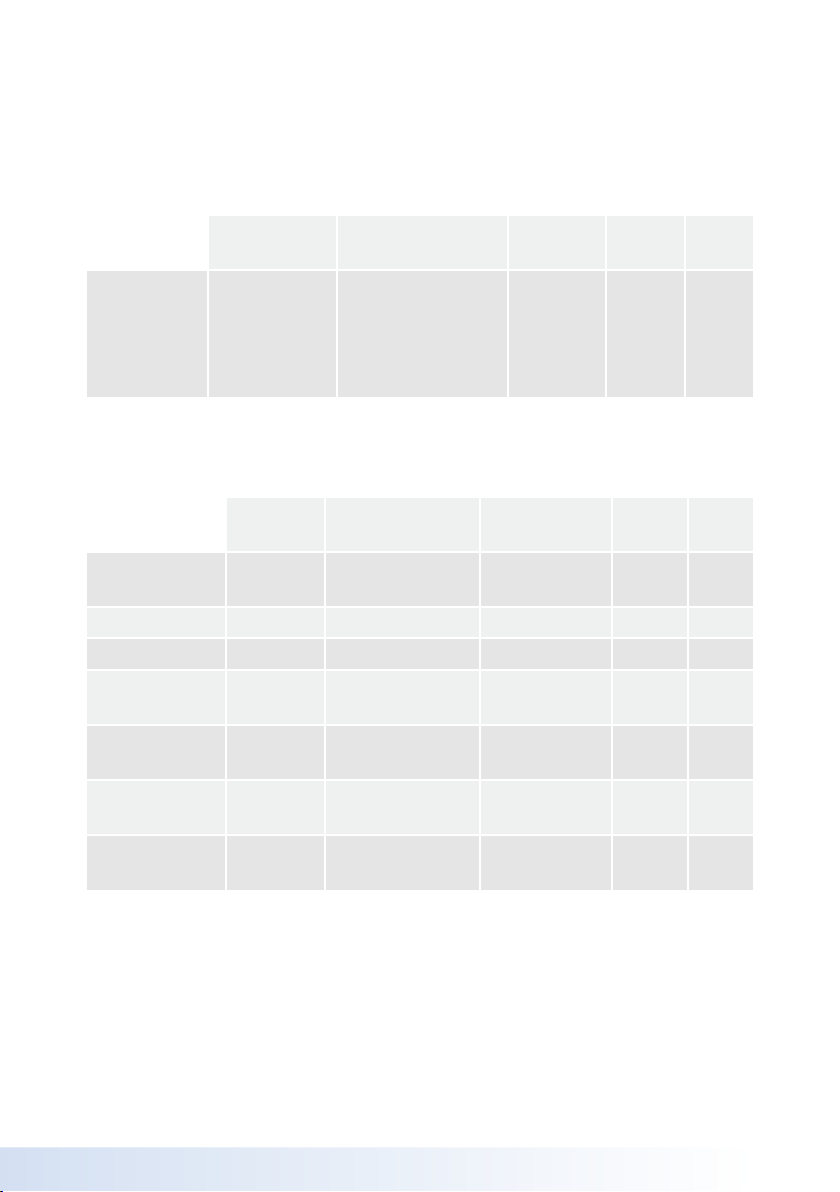

Simple and advanced settings

The factory settings can be modied in basic

and advanced settings.

List of simple settings

Menu Factory settings Setting mode

Day setting

• DHW temperature setting

• Adjustment Single or Daily

Temperature setpoint

Starting time

Basic and

Advanced

conguration

mode

Night setpoint

• DHW temperature setting

• Adjustment Single or Daily

Temperature setpoint

Starting time

Basic and

Advanced

conguration

mode

Setting the time

• Setting the time

• Setting the date

• Setting the day of the week

Basic and

Advanced

conguration

mode

11

OPERATION & MAINTENANCE MANUAL |

Details of basic and advanced settings

DAY

SETPOINT

Factory

settings

Basic and Advanced

conguration mode

Settings

on site Index

Temp: ºC 58ºC 0ºC - 99ºC DHW temperature

setting -100

Daily No Yes - No Daily setting - 101

Monday: ºC 58ºC 0ºC - 99ºC

DHW

temperature

setting and daily

starting time

-102

Monday: hrs 6:00 0:00 - 23:00 - 103

Tuesday: ºC 58ºC 0ºC - 99ºC - 104

Tuesday: hrs 6:00 0:00 - 23:00 - 105

Wednesday: ºC 58ºC 0ºC - 99ºC - 106

Wednesday: hrs 6:00 0:00 - 23:00 - 107

Thursday: ºC 58ºC 0ºC - 99ºC - 108

Thursday: hrs 6:00 0:00 - 23:00 - 109

Friday: ºC 58ºC 0ºC - 99ºC - 110

Friday: hrs 6:00 0:00 - 23:00 - 111

Saturday: ºC 58ºC 0ºC - 99ºC - 112

Saturday: hrs 6:00 0:00 - 23:00 - 113

Sunday: ºC 58ºC 0ºC - 99ºC - 114

Sunday: hrs 6:00 0:00 - 23:00 - 115

Administrator mode can be accessed from

Operator mode via the last sub-menu of the

setting menu.

12 | OPERATION & MAINTENANCE MANUAL

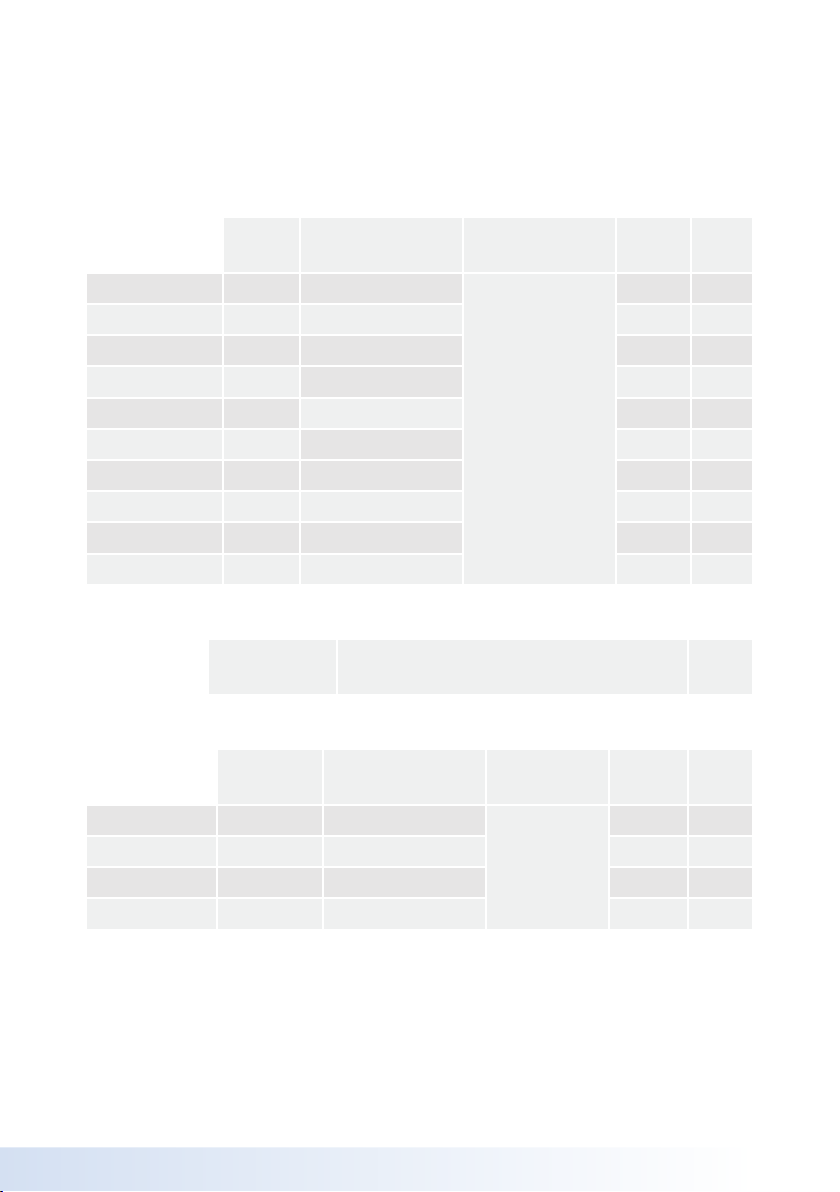

Details of basic and advanced settings

NIGHT

SETPOINT

Factory

settings

Basic and Advanced

conguration mode

Settings

on site Index

Temp: ºC 58ºC 0ºC - 99ºC DHW temperature

setting - 130

Daily No Yes - No Daily setting - 131

Monday: ºC 58ºC 0ºC - 99ºC

DHW

temperature

setting and daily

starting time

- 132

Monday: hrs 22:00 1:00 - 23:00 - 133

Tuesday: ºC 58ºC 0ºC - 99ºC - 134

Tuesday: hrs 22:00 1:00 - 23:00 - 135

Wednesday: ºC 58ºC 0ºC - 99ºC - 136

Wednesday: hrs 22:00 1:00 - 23:00 - 137

Thursday: ºC 58ºC 0ºC - 99ºC - 138

Thursday: hrs 22:00 1:00 - 23:00 - 139

Friday: ºC 58ºC 0ºC - 99ºC - 140

Friday: hrs 22:00 1:00 - 23:00 - 141

Saturday: ºC 58ºC 0ºC - 99ºC - 142

Saturday: hrs 22:00 1:00 - 23:00 - 143

Sunday: ºC 58ºC 0ºC - 99ºC - 144

Sunday: hrs 22:00 1:00 - 23:00 - 145

13

OPERATION & MAINTENANCE MANUAL |

INSTAL. TYPE Factory

settings

Advanced

conguration mode

Settings

on site Index

(following

product

conguration)

Simple Inst.

Double Inst.

Semi - Inst. S-S

Semi - Inst. D-S

Semi - Inst. D-D

Installation

type -200

LEGIONELLA Factory

settings

Advanced

conguration mode

Settings

on site Index

Active: No Yes - No Activating

treatment -240

Day: Wednesday - Date - 241

Starting hour: hrs 3h 0h - 23h Time -242

Duration cycle:

min 20 min 1 min - 99 min Duration - 243

Second sensor: No Yes - No Second sensor

option -244

Temp. Settings:

ºC 80 ºC 0ºC - 99ºC Treatment

temperature -245

Neut. Legio AL:

min 3 min 0 min - 9 min Alarm delay

after completion -246

In compliance with the regulations

(preventing risk of burn), all safety measures

should be taken to ensure that during the

water treatment, water temperature does not

exceed 60ºC at the taps.

14 | OPERATION & MAINTENANCE MANUAL

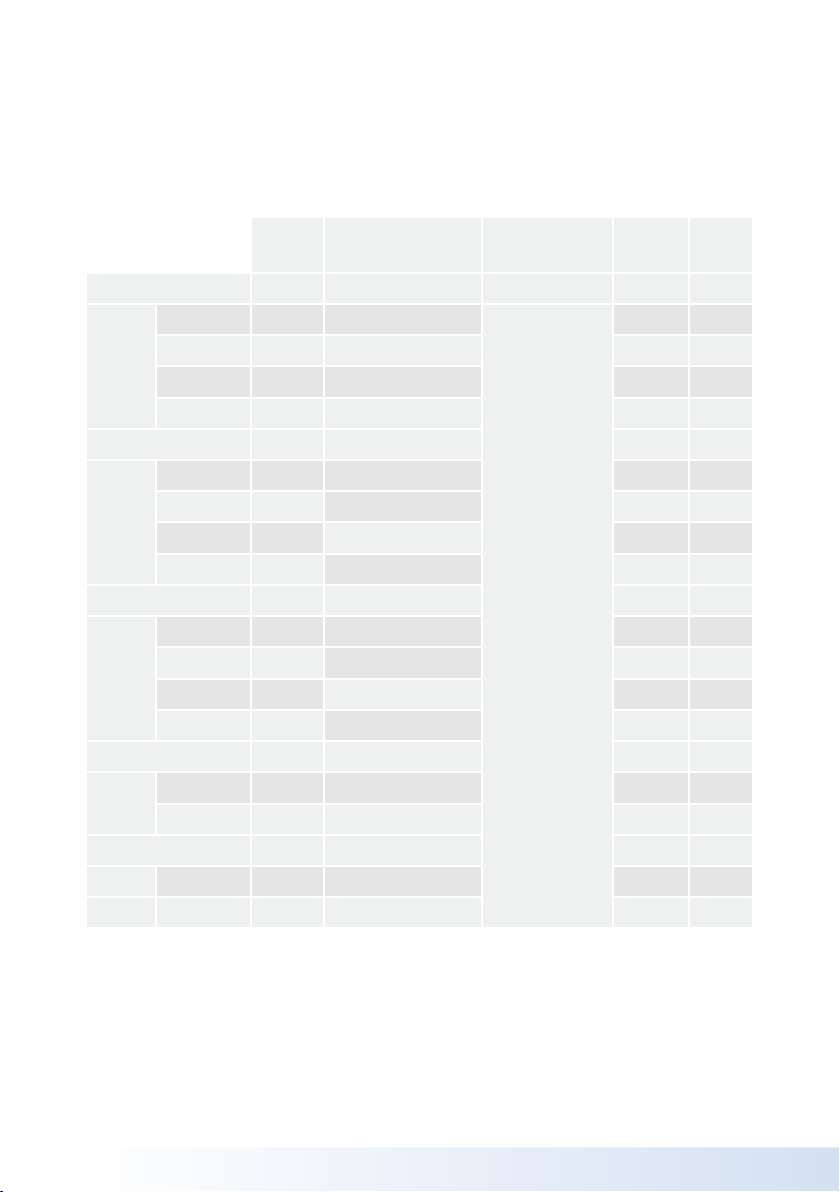

ALARM AND

STEP

Factory

settings

Advanced

conguration mode

Settings

on site Index

Turbo: Tc- ºC 10ºC 0ºC - 99ºC T to set o turbo -260

Al High: Tc+ ºC 15ºC 0ºC - 99ºC T to set o alarm -261

Al low: Tc- ºC 15ºC 0ºC - 99ºC High or low - 262

High abs AL: ºC 80ºC 0ºC - 99ºC Absolute alarm - 263

Low abs AL: ºC 40ºC 0ºC - 99ºC High or low - 264

Temp2Max Out: No Yes - No Activate the

limitation and -268

Temp2Max: ºC 80ºC 10ºC - 99ºC Max output

temperature - 269

Hysteresis: 0.2 0.1 - 9.9 Hysteresis defects -270

Check mes: No Yes - No Return signal of the

opening of the 3WV -271

Di mes: % 10% 1% - 99% Measure dierence

at opening -272

Open Valve: % 10% 0% - 99% Opening 3WV - 273

Auto reset: Ye s Yes - No Automatic reset - 299

15

OPERATION & MAINTENANCE MANUAL |

OPERATING

COUNTER

Factory

settings

Advanced

conguration mode

Settings

on site Index

Pump 1: hrs Oh Oh - 99999h Time duration

of each pump

operation in

hours

- 350

Pump 2: hrs Oh Oh - 99999h - 351

Pump 3: hrs Oh Oh - 99999h - 352

Pump 4: hrs Oh Oh - 99999h - 353

DISPLAY

DEFECT RELAY

Factory

settings

Advanced

conguration mode

Settings

on site Index

AL high Temp: 10 - 2

Relay / defects

assignment

- 300

AL low Temp: 10 - 2 - 301

AL pump 1: 20 - 2 - 302

AL pump 2: 20 - 2 - 303

AL pump 3: 20 - 2 - 304

AL pump 4: 20 - 2 - 305

AL Input Ana 1: 20 - 2 - 306

AL Input Ana 2: 20 - 2 - 307

AL Input Ana 3: 20 - 2 - 308

AL sensor: 20 - 2 - 313

HISTORY OF

DEFECTS List of defect history (max 20) Index

340

16 | OPERATION & MAINTENANCE MANUAL

INPUTS /

OUTPUTS

Factory

settings

Advanced

conguration mode

Settings

on site Index

Analog Input 1

Type: Pt100

PT100

0-10v / 4-20mA

and

shift of input

signal

0-10v / 4-20mA

Output signal

- 370

Oset: 0-10 to 100 - 371

Low scale: 0-9.9 to 9.9 - 372

High scale: 100 -10 to 100 - 373

Analog Input 2

Type: Pt100 - 380

Oset: 0-10 to 100 - 381

Low scale: 0-9.9 to 9.9 - 382

High scale: 100 -10 to 100 - 383

Analog Input 3

Type: 0-10V - 390

Oset: 0-10 to 10 - 391

Low scale: 0-9.9 to 9.9 - 392

High scale: 100 -10 to 100 - 393

Analog Input 1

Type: 4-20mA - 400

Oset: 0.0 -100 to 100 - 401

Analog Input 2

Type: 4-20mA - 405

Oset: 0.0 -100 to 100 - 406

17

OPERATION & MAINTENANCE MANUAL |

PID

CONTROLLER

Factory

settings

Advanced

conguration mode

Settings

on site Index

Prop band: 8.0 0 - 100 Proportional

band -420

Derivated: % 40.0% 0.0% - 100% Derivative time - 421

Integral: 0.2 0 - 100 Integral time - 422

Dead band: 0.0 0 - 20 Dead band - 423

3WW opening

time: secs 35s 0s - 255s

Time duration

of the 3 way

valve

-424

Output max: % 100% 25% - 100% Opening limite

of the valve -425

Cold: No Yes - No Cold option -426

PP/3WV: % 40.0% 0.0% - 99%

Shift of

pump/3WV

signal

-427

Taking into account the parameters of PID

occurs after a reboot of the box.

PROG.

SELECTION

Factory

settings Advanced conguration mode Index

DHW DHW / GMP*/ aquaAirless* Application type 439

* unavailable

18 | OPERATION & MAINTENANCE MANUAL

FORCED START Factory

settings

Advanced

conguration mode

Settings

on site Index

Pump 1: No Yes - No

Forced start

for

each pump

440

Pump 2: No Yes - No - 441

Pump 3: No Yes - No - 442

Pump 4: No Yes - No - 443

Three-way-valve 3P

Forced: No Yes - No Forced start - 445

No change: +/-% 5% 0% - 50% No settings -446

Analog Output 1

Forced: No Yes - No Forced start - 450

Value: % 50% 0% - 100% No settings -451

Analog Output 2

Forced: No Yes - No Forced start - 455

Value: % 50% 0% - 100% % of cancelling - 456

Cancel: No Yes - No value 459

19

OPERATION & MAINTENANCE MANUAL |

SET THE TIME Factory

settings

Advanced

conguration mode

Settings

on site Index

Hour: hrs 0h00 - 23h59 Hour - 480

Date: - - / - - / - - Date - 481

Day: - - - - - - day Day of the week - 482

FACTORY

SETTINGS

Factory

settings

Advanced

conguration mode

Settings

on site Index

Reset: No Yes - No Reset to factory

settings - 479

MODBUS

RTU / RS485

Factory

settings

Advanced

conguration mode

Settings

on site Index

Address: 11 - 128 Modbus

address -460

Bauds: 9600 4800 - 9600 - 19200 Communication

speed -461

Parity: None None / Even / Odd Parity - 463

Num Stop Bit: 11 - 2 output RS 485 - 464

20 | OPERATION & MAINTENANCE MANUAL

ADMINISTRATOR

MODE

Factory

settings

Basic and Advanced

conguration mode

Settings

on site Index

Administrator

mode: No Yes - No Access admin.

mode - 899

Index Modbus Variables

1Measure

2 Set point

3 Output

4Current defects

5 Word State 1

6In Ana1

7In Ana2

8In Ana3

9 Out An1

10 Out An2

11 In Digital

12 In Ipso

13 Out Relay

14 Current step

15 Bit Defect 1

16 Bit Defect 2

This manual suits for next models

12

Table of contents

Other CHWS Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

ROBOD

ROBOD MULTICHRON PRO VIS Usage and maintenance manual

Halma

Halma Crowcon Xgard S011843 Installation, operating and maintenance instructions

Siemens

Siemens SIWAREX R operating instructions

Schmalz

Schmalz SCPSi-L operating instructions

X-Rite

X-Rite PANTONE Judge QC Operation manual

Phuel

Phuel 145-2884-HV0 user manual

Pasco Scientific

Pasco Scientific WA-9401 Instruction manual and experiment guide

ATS

ATS Pressure Aging Vessel 4 instruction manual

Schmalz

Schmalz FMP-SVK Series operating instructions

Rohloff

Rohloff SPEEDHUB 500/14 Mounting

MBO

MBO SAP 46 L operating manual

Buhler

Buhler GAS 222.10 Assembly, installation and operation instructions