CIAC CK43BV028-CYJ1H User manual

Version: Mar.6th,2018

2

CONTENTS

1. General Information ................................................................................................................ 1

1.1 Indoor units ..........................................................................................................................1

1.2 Features...............................................................................................................................3

2. Specification ........................................................................................................................... 5

3. Refrigerant Circuit................................................................................................................. 11

4. Dimension............................................................................................................................. 14

5. Wiring Diagram ..................................................................................................................... 16

6. Performance Curves............................................................................................................. 19

7. Operation Range .................................................................................................................. 21

8. Noise Level ........................................................................................................................... 23

9. Outdoor Installation............................................................................................................... 24

9.1 Safety.................................................................................................................................24

9.2 Installation instruction.........................................................................................................26

10. Electric Installation.............................................................................................................. 34

11. Trial Operation .................................................................................................................... 36

12. PCB Photo .......................................................................................................................... 38

13. Dip Switch Setting............................................................................................................... 39

14. Digital Tube Display ............................................................................................................ 41

15. Outdoor Unit Control........................................................................................................... 43

16. Failure Code ....................................................................................................................... 46

17. Troubleshooting .................................................................................................................. 49

1

1. General Information

1.1 Indoor units

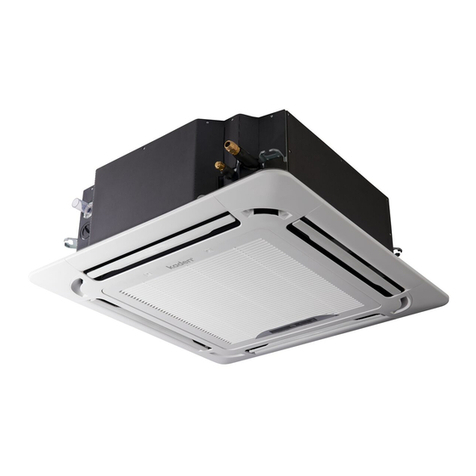

4-WAY CASSETTE

CK43BV028-CYJ1H

CK43BV036-CYJ1H

CK43BV045-CYJ1H

CK43BV056-4YJ1H

CK43BV071-4YJ1H

CK43BV080-4YJ1H

CK43BV090-4YJ1H

CK43BV112-4YJ1H

CK43BV140-4YJ1H

ROUND-WAY CASSETTE

CK43BV022-6YJ1H

CK43BV028-6YJ1H

CK43BV036-6YJ1H

CK43BV045-6YJ1H

CK43BV056-6YJ1H

CK43BV071-6YJ1H

CK43BV090-6YJ1H

CK43BV112-6YJ1H

CK43BV126-6YJ1H

CK43BV140-6YJ1H

2-WAY CASSETTE

CK43BV022-2YJ1H

CK43BV028-2YJ1H

CK43BV036-2YJ1H

CK43BV045-2YJ1H

CK43BV056-2YJ1H

1-WAY CASSETTE

CK43BV016-1YJ1H

CK43BV022-1YJ1H

CK43BV028-1YJ1H

CK43BV036-1YJ1H

SLIM DUCT (0/30Pa)

CC43BV022LLYJ1H

CC43BV028LLYJ1H

CC43BV036LLYJ1H

CC43BV045LLYJ1H

CC43BV056LLYJ1H

CC43BV071LLYJ1H

MEDIUM ESP DUCT (50/96Pa)

CC43BV056MHYJ1H

CC43BV071MHYJ1H

CC43BV080MHYJ1H

MEDIUM ESP DUCT (80/120Pa)

CC43BV090MHYJ1H

CC43BV112MHYJ1H

CC43BV140MHYJ1H

2

HlGH ESP DUCT (100/196Pa)

CC43BV056HHYJ1H

CC43BV071HHYJ1H

CC43BV080HHYJ1H

CC43BV090HHYJ1H

CC43BV112HHYJ1H

CC43BV140HHYJ1H

CC43BV224HHYJ1H

CC43BV280HHYJ1H

CEILING / FLOOR

CF43BV028-MYJ1H

CF43BV036-MYJ1H

CF43BV045-MYJ1H

CF43BV056-MYJ1H

CF43BV071-MYJ1H

CF43BV080-MYJ1H

CF43BV090-MYJ1H

CF43BV112-MYJ1H

CF43BV140-MYJ1H

CONSOLE

CJ43BV022-MYJ1H

CJ43BV028-MYJ1H

CJ43BV036-MYJ1H

CJ43BV050-MYJ1H

HI WALL

CH43BV022-HYJ1H

CH43BV028-HYJ1H

CH43BV036-HYJ1H

CH43BV045-HYJ1H

CH43BV056-HYJ1H

CH43BV071-HYJ1H

3

1.2 Features

DC Inverter Twin Rotary Compressor

1) Realize high efficiency and compact designed compressor

by joint wrap & earths metal magnet motor.

2) Wide range inverter compressors would satisfy the

customer's innovative requirement and design.

DC Inverter Motor

DC fan motor speed can be adjusted from 0~1000 r/min, it

can improve the unit efficiency, at the same time, the unit can

realize low ambient cooling operation.

High efficiency

Low vibration, low noise

High reliability

Precise Control

PID control adjusts the output of compressor and the open degree of EEV, balances the indoor refrigerant flow,

realizes the linear output, creates a comfortable environment. The temperature could be controlled precisely.

Imprecise common control

PID precise control

Refrigerant �ow speed

Refrigerant �ow speed

P : Proportion adjustment

I : Integral adjustment

D :Differential adjustment

MRVIII (PID control)

Conventional control

Time

Indoor temperature

Cooling

Temp

Setting

temp

Begin

Too cool

Constant

speed system

MR V inverter

system

Notcool

enough

Comfort

Cooling the room

quickly

Temp. di�erence

Cooling running

Timer

180° Vector Control Technology

IMFV using power resistance to detect the rotor position of compressor, results in the consistency of

the compressor working current and current sine waves, improve power efficiency about 17%.

240 300 0

60 120 180

240 300

0

90-degree

120 18060

4

1

Parts Instroduction (CM43BV140-HEJ1H CM43BV160-HEJ1H)

1. Control the compressor running frequency by temp. Sensor, more precise and prompt than conventional

control system;

Protections: Pressure, temp., compressor, fan motor, refrigerant, oil quantity etc. Realize perfect performance;

Malfunction self-diagnose.

2. DC fan motor (CM43BV140-HEJ1H CM43BV160-HEJ1H).

3. DC inverter compressor, high efficiency.

4. Single set valve, easy to installation and save installation time.

2

3

4

5

2. Specication

Model CM43BV110-HYJ1H CM43BV140-HYJ1H

Power supply Ph/V/Hz 1/220~230/50 1/220~230/50/60

Cooling

Rated capacity kW 8 15

Rated capacity kBtu/h 27.3 51.2

Rated power input kW 2.08 3.98

Max. power input kW 4 7.1

EER 3.85 3.77

Rated current A 10 19.1

Max. current A 19.2 34.1

Heating

Rated capacity kW 9.5 17.0

Rated capacity kBtu/h 32.4 58.0

Rated power input kW 2.1 3.9

Max. power input kW 3.84 6.9

COP 4.52 4.35

Rated current A 10.1 18.8

Max. current A 18.5 33.2

Compressor

Brand MITSUBISHI ELECTRIC MITSUBISHI ELECTRIC

Model TNB220FLHMC MNB42FFAMC-L

Type Rotary Rotary

Compressor quantity 1 INV 1 INV

Capacity W 7130 13780

Power input W 2200 4310

Rated current (RLA) A 9.7 15.8

Speed rps 60 60

Crankcase heater W 25 28

Refrigerant oil brand Itochu.,LTD.,Shanghai Itochu.,LTD.,Shanghai

Refrigerant oil type FV50S FV50S

Refrigerant oil charge ml 670 1400

Outdoor fan motor

Brand BROAD OCEAN BROAD OCEAN/NIDEC

Model Y6S643C831 ZWK511B51006

Voltage 220-230 310

IP class IP44 IP42

Type AC DC

Insulation class B E

Safe class I I

Power input W 192 225*2

Output W 100 180*2

Rated current A 0.88 0.6

Capacitor μF 5 /

Speed rpm 870 850

Outdoor fan

Brand SHUNWEI LANGDI

Model / /

Material Plastic Plastic

Type Axial Axial

Diameter mm 482 450

Height mm 150 150

6

Model CM43BV110-HYJ1H CM43BV140-HYJ1H

Outdoor coil

Number of rows 2 2

Tube pitch (a)×row pitch (b) mm 21*18.186 21*18.186

Fin spacing mm 1.4 1.40

Fin type (code) Corrugated Corrugated

Fin coating type Optional Hydrophilic aluminum Hydrophilic aluminum

Salt spray test duration Hour 500 500

Tube outside dia. and type Internal thread copper tube Internal thread copper

tube

mm Ф7 Ф7

Coil length×height mm 955×792 970×1197

Number of circuits 6 7

Cabinet coating

Coating type Powder Coating Powder Coating

Salt spray test duration Hour 500 500

Sheet metal material Hot zinc plate Hot zinc plate

Sheet metal thickness mm 0.8 0.8

Control panel enclosure IP class Standard IP24 IP24

Outdoor air flow m3/h 3500 6500

Outdoor sound level (sound pressure level ) dB (A) 54 58

Outdoor sound level (sound power level ) dB (A) 65 69

Outdoor unit

Dimension (W*H*D) mm 960/340/830 960/340/1250

Packing (W*H*D) mm 1095×410×945 1095×410×1400

Net weight kg 70 99

Gross weight kg 76 107

Refrigerant Type R410A R410A

Charged volume kg 2.4 3.8

Throttle type EXV EXV

Design pressure MPa 4.15 4.15

Refrigerant piping

Liquid pipe mm 9.52 9.52

Gas pipe mm 15.88 19.05

Total pipe length m 100 150

Max. pipe length m 50 70

Max. Di. indoor/outdoor unit m30(Outdoor higher than indoor)

20(Indoor higher than outdoor)

Max. Di. indoor/indoor unit m 10 10

Connectable indoor unit ratio % 50%~130% 50%~130%

Maximum indoor units Piece 5 8

Connection wiring Power wiring mm26 16

Signal wiring mm2Shield wire:(0.75-2)*2 Shield wire:(0.75-2)*2

Operation range °C Cooling: 10~48

Heating: -15~21

Cooling: -5~48

Heating: -15~21

Nominal condition:

Indoor temperature (cooling): 27 DB(°C)/19 WB(°C), indoor temperature (heating): 20 DB(°C)/14.5 WB(°C).

Outdoor temperature (cooling): 35 DB(°C)/24 WB(°C), outdoor temperature (heating): 7 DB(°C)/6 WB(°C).

The data is measured with 7.5m equivalent pipe and 0m height dierence.

The noise level will be measured in the third octave band limited values in the semi-anechoic chamber, using a

real time analyser calibrated sound intensity meter. It is a sound pressure noise level.

7

Model CM43BV155-HYJ1H

Power supply Ph/V/Hz 1/220~230/50/60

Cooling

Rated capacity kW 18

Rated capacity kBtu/h 61.4

Rated power input kW 4.75

Max. power input kW 8.10

EER 3.79

Rated current A 22.7

Max. current A 38.8

Heating

Rated capacity kW 20.0

Rated capacity kBtu/h 68.2

Rated power input kW 4.56

Max. power input kW 7.90

COP 4.39

Rated current A 21.8

Max. current A 37.8

Compressor

Brand MITSUBISHI ELECTRIC

Model MNB42FFAMC-L

Type Rotary

Compressor quantity 1 INV

Capacity W 13780

Power input W 4310

Rated current (RLA) A 15.8

Speed rps 60

Crankcase heater W 28

Refrigerant oil brand Itochu.,LTD.,Shanghai

Refrigerant oil type FV50S

Refrigerant oil charge ml 1400

Outdoor fan motor

Brand BROAD OCEAN/NIDEC

Model ZWK511B51006

Voltage 310

IP class IP42

Type DC

Insulation class E

Safe class I

Power input W 225*2

Output W 180*2

Rated current A 0.6

Capacitor μF /

Speed rpm 850

Outdoor fan

Brand LANGDI

Model /

Material Plastic

Type Axial

Diameter mm 482

Height mm 150

8

Model CM43BV155-HYJ1H

Outdoor coil

Number of rows 2

Tube pitch (a)×row pitch (b) mm 19.05×22

Fin spacing mm 1.40

Fin type (code) Fracture

Fin coating type Optional Hydrophilic aluminum

Salt spray test duration Hour 500

Tube outside dia. and type Internal thread copper tube

mm Ф8

Coil length×height mm 970×1210

Number of circuits 14

Cabinet coating

Coating type Powder Coating

Salt spray test duration Hour 500

Sheet metal material Hot zinc plate

Sheet metal thickness mm 1.0

Control panel enclosure IP class Standard IP24

Outdoor air flow m3/h 6500

Outdoor sound level (sound pressure level ) dB (A) 58

Outdoor sound level (sound power level ) dB (A) 69

Outdoor unit

Dimension (W*H*D) mm 960/340/1250

Packing (W*H*D) mm 1095×410×1400

Net weight kg 99

Gross weight kg 107

Refrigerant Type R410A

Charged volume kg 3.8

Throttle type EXV

Design pressure MPa 4.15

Refrigerant piping

Liquid pipe mm 9.52

Gas pipe mm 19.05

Total pipe length m 150

Max. pipe length m 70

Max. Di. indoor/outdoor unit m"30

20"

Max. Di. indoor/indoor unit m 10

Connectable indoor unit ratio % 50%~130%

Maximum indoor units Piece 8

Connection wiring Power wiring mm210

Signal wiring mm2Shield wire:(0.75-2)*2

Operation range °C Cooling: 10~48

Heating: -15~21

Nominal condition:

Indoor temperature (cooling): 27 DB(°C)/19 WB(°C), indoor temperature (heating): 20 DB(°C)/14.5

WB(°C).

Outdoor temperature (cooling): 35 DB(°C)/24 WB(°C), outdoor temperature (heating): 7 DB(°C)/6

WB(°C).

The data is measured with 7.5m equivalent pipe and 0m height dierence.

The noise level will be measured in the third octave band limited values in the semi-anechoic chamber,

using a real time analyser calibrated sound intensity meter. It is a sound pressure noise level.

9

Model CM43BV140-HEJ1H CM43BV160-HEJ1H

Power supply Ph/V/Hz 3/380~400/50/60 3/380~400/50/60

Cooling

Rated capacity kW 15 18

Rated capacity kBtu/h 51.2 61.4

Rated power input kW 3.98 5.19

Max. power input kW 7.1 7.3

EER 3.77 3.47

Rated current A 6.3 8.2

Max. current A 11.2 11.6

Heating

Rated capacity kW 17.0 20.0

Rated capacity kBtu/h 58.0 68.2

Rated power input kW 3.9 5.1

Max. power input kW 6.9 7.1

COP 4.35 3.90

Rated current A 6.2 8.1

Max. current A 10.9 11.2

Compressor

Brand MITSUBISHI ELECTRIC MITSUBISHI ELECTRIC

Model MNB42FFDMC-L MNB42FFDMC-L

Type Rotary Rotary

Compressor quantity 1 INV 1 INV

Capacity W 13780 13780

Power input W 4060 4060

Rated current (RLA) A 12.3 12.3

Speed rps 60 60

Crankcase heater W 28 28

Refrigerant oil brand Itochu.,LTD.,Shanghai Itochu.,LTD.,Shanghai

Refrigerant oil type FV50S FV50S

Refrigerant oil charge ml 1400 1400

Outdoor fan motor

Brand BROAD OCEAN/NIDEC BROAD OCEAN/NIDEC

Model ZWK511B51006 ZWK511B51006

Voltage 310 310

IP class IP44 IP44

Type DC DC

Insulation class E E

Safe class I I

Power input W 225*2 225*2

Output W 180*2 180*2

Rated current A 0.6 0.6

Capacitor μF / /

Speed rpm 850 850

Outdoor fan

Brand LANGDI LANGDI

Model / /

Material Plastic Plastic

Type Axial Axial

Diameter mm 450 450

Height mm 150 150

10

Model CM43BV140-HEJ1H CM43BV160-HEJ1H

Outdoor coil

Number of rows 2 2

Tube pitch (a)×row pitch (b) mm 21*18.186 21*18.186

Fin spacing mm 1.40 1.40

Fin type (code) Corrugated Corrugated

Fin coating type Optional Hydrophilic aluminum Hydrophilic aluminum

Salt spray test duration Hour 500 500

Tube outside dia. and type Internal thread copper tube Internal thread copper tube

mm Ф7 Ф7

Coil length×height mm 970×1197 970×1197

Number of circuits 7 7

Cabinet coating

Coating type Powder Coating Powder Coating

Salt spray test duration Hour 500 500

Sheet metal material Hot zinc plate Hot zinc plate

Sheet metal thickness mm 0.8 0.8

Control panel enclosure IP class Standard IP24 IP24

Outdoor air flow m3/h 6500 6500

Outdoor sound level (sound pressure level ) dB (A) 58 59

Outdoor sound level (sound power level ) dB (A) 69 70

Outdoor unit

Dimension (W*H*D) mm 960/340/1250 960/340/1250

Packing (W*H*D) mm 1095×410×1400 1095×410×1400

Net weight kg 99 99

Gross weight kg 107 107

Refrigerant Type R410A R410A

Charged volume kg 3.8 3.8

Throttle type EXV EXV

Design pressure MPa 4.15 4.15

Refrigerant piping

Liquid pipe mm 9.52 9.52

Gas pipe mm 19.05 19.05

Total pipe length m 150 150

Max. pipe length m 70 70

Max. Di. indoor/outdoor unit m30(Outdoor higher than indoor)

20(Indoor higher than outdoor)

Max. Di. indoor/indoor unit m 10 10

Connectable indoor unit ratio % 50%~130% 50%~130%

Maximum indoor units Piece 8 9

Connection wiring Power wiring mm24 4

Signal wiring mm2Shield wire:(0.75-2)*2 Shield wire:(0.75-2)*2

Operation range °C Cooling: -5~48

Heating: -15~21

Cooling: -5~48

Heating: -15~21

Nominal condition:

Indoor temperature (cooling): 27 DB(°C)/19 WB(°C), indoor temperature (heating): 20 DB(°C)/14.5 WB(°C).

Outdoor temperature (cooling): 35 DB(°C)/24 WB(°C), outdoor temperature (heating): 7 DB(°C)/6 WB(°C).

The data is measured with 7.5m equivalent pipe and 0m height dierence.

The noise level will be measured in the third octave band limited values in the semi-anechoic chamber, using a

real time analyser calibrated sound intensity meter. It is a sound pressure noise level.

11

Te

Td

Inverter

compressor

d

s

c

e

4wv

Gas pipe

stop valve Condensor

HP Tc

Ts PMV

SV1

Liquidpipe

stopvalve

LP

Ta

Gas-liquid

separator

3. Refrigerant Circuit

CM43BV110-HYJ1H

12

CM43BV140-HYJ1H

CM43BV155-HYJ1H

CM43BV140-HEJ1H

CM43BV160-HEJ1H

Td

d

s

c

e

4wv

Ts PMV

SV2

SV1

Gas pipe

stop valve

Liquidpipe

stopvalve

HP LP

Inverter

compressor

Gas-liquid

separator

Condensor

Ta

Tc Te

13

Part name Model Sign Function Date

Compressor

CM43BV110-HYJ1H

Capacity control, meet indoor load

request by adjusting the frequency

Motor resistance

(at 20°C): 0.88Ω

CM43BV140-HYJ1H

CM43BV155-HYJ1H

Motor resistance

(at 20°C): 0.29Ω

CM43BV140-HEJ1H

CM43BV160-HEJ1H

Motor resistance

(at 20°C): 0.53Ω

Pressure

switch ALL

HP High pressure protection 4.15Mpa, OFF

LP Low pressure protection 0.05Mpa, OFF

Electronic

expansion

valve

ALL PMV In heating, refrigerant flow control ¢

2.4

Solenoid

valve ALL

SV1 Keep balance of high/low pressure

when compressor starts up or stops

AC220V

SV2 Refrigerant jet protection when

discharging temp. is too high

4-way valve ALL 4WV Change over between cooling and

heating

AC220V, electried in heat;

not electried in cooling or

defrosting

Temp.

sensor ALL

Te Check frost condition of outdoor

heat exchanger

R (25°C)=10K

B(25/50°C)=3700K

Ts Detect the suction temp. of

compressor

Tc

Check the temp. of main pipe of

condenser gas pipe control PMV in

heating

Ta

Detect ambient temp. set primary

setting for fan speed target

pressure and PMV open angle

Td Detect the discharging temp. of

compressor

R (80°C)=50K B

(25/80°C)=4450K

Heater

CM43BV110-HYJ1H

HEATER Used to heat oil in compressor

25W, 220V

CM43BV140-HYJ1H

CM43BV155-HYJ1H

CM43BV140-HEJ1H

CM43BV160-HEJ1H

28W, 220V

14

4. Dimension

CM43BV110-HYJ1H

960

830

580

184 184

340

380

67

21

Drain hole

15

CM43BV140-HYJ1H

CM43BV155-HYJ1H

CM43BV140-HEJ1H

CM43BV160-HEJ1H

960

1250

23

340

380

580

184 184 67

Drain hole

Fixinghole4-φ15

16

5. Wiring Diagram

L N

PQ

Control

Board

Display

Board

P

ACL

ACL

ACN

HEATER

SV1

SV2

4WV

CA

ACFAN1

LED1-4

SW1-4

HPS

P

LPS TD TE

(1)

TC TS TA

ACN

BM1BM2

CN1

CN19

PTC

CN2 CN3 CN4CN5 CN6 CN7

LED4

LED3

LED1

LED2

PC

Symbol Signification

Live Wire

Neutral Wire

electric heating tape

unloading valve

spray valve

4 way valve

motor capacitor

ac fan

lights

button

BM1,2

DIP switch

CN29 CN28

CN21

CN32 CN31

CN30

SW01

LD1 LD2 LD3

SW02

CN24

CN10

CN9

CN8

EEV

CN30

6.3A 250VAC

FUSE1

CN18

CN17

CN16

CN25

CN15

CN12

SW1SW3

SW4 SW2

HEATER

4WV

SV1

SV2

NO

12345678

NO

12345678

CA

M

【WARING】

【Symbol Signification】

【NOTES】

·Please check the power firstly before test , and make

sure the crankcase heater powering on for 12 hours

at least to protecting compressor.

·Forbid connecting the power wire to the “P” and “Q”,

otherwise the control board will be damaged.

HPS

TD

TE(1)

TS

TA

EEV

LD1-3

SW01,02

high pressure switch

LPS

low pressure switch

compressor vent sensor

defrost temp sensor

compressor inhale sensor

TC

coil temperature sensor

ambient temp sensor

electronic expend valve

digital display tubes

PC

Monitor

Tfin

IPM temperature sensor

BL

R

BL

CN20

CN11

~

CN14

ACFAN1

M

CN13

U

P

V

W

N

AC-N

AC-L

LI

LO

CN11

REACTOR

DC-

DC+

COMP

R

B

W

Tfin

CN19

CN1

P1 P2

E

P7

RL1 4

3

P4 P3 Noise Filter

R

B

W W

R

R

BL

BL

Please power off firstly for about 10

minutes before checking control box,

and make sure the voltage between

P and N below 20V.

[1] [2] [3] [4] [5] [6] [7] [8]

-0 0 0 0 0 0

0 0 0

CM43BV110-HYJ1H

0 0 0 0 0

BM1

BM2

BM Cap. O:OFF

1:ON

-:FIELD

SET

【BM Indication】

1

R

·The switch BM1-1 is used for locking the indoor units

number, the initial situation is “ OFF”. After power on,

the display board will display 【U**】, “**” indicates

the number of Indoor units that the outdoor unit can

communicate with. If it can match the actual number

of indoor units, please change “OFF” to “ON”, or else

fix the communication problem firstly.

Symbol Signification

thumbwheels

B:Black

Y:Yellow

W:White

BL:Blue

Wire Colour:

Def. display indication

U**

220

6.0P

7.0P

380

Indoor units

quantity

power

type

Out door

unit

capability

3.0P capability:AU28

capability:AU48

capability:AU60

**:NUM of the connected indoor units

single phase power type

three phase power type

ACFAN2

CM43BV110-HYJ1H

17

ACL-IN ACN-IN PE

ACL-OUT PE

ACN-OUT

L N

PQ

Control

Board

Display

Board

Noise Filter

P

ACL

HPS

P

LPS TD TE

(1)

TC TS TA

ACN

BM1BM2

CN1CN2 CN3 CN4CN5 CN6 CN7

LED4

LED3

LED1

LED2

PC

CN29 CN28

CN21

CN32 CN31

CN30

SW01

LD1 LD2 LD3

SW02

CN24

CN10

CN9

CN8

EEV

CN30

6.3A 250VAC

FUSE1

CN18

CN17

CN16

CN25

CN15

CN12

SW1SW3

SW4

DCFAN1

SW2

HEATER

4WV

SV1

SV2

NO

12345678

NO

12345678

M

R BL

R

BL

CN20

CN11

CN14

CN13

DCFAN2

DCP

U

V

W

DCN

DCL2 CN1

Tfin

CN11

COMP

R

R BL

R

B

B

W

白

白

ACN

ACL

DCL1

DC-

DC+

Reactor

M

M

ACL

ACN

HEATER

SV1

SV2

4WV

CA

DCFAN1

DCFAN2

LED1-4

SW1-4

Symbol

Signification

Live Wire

Neutral Wire

electric heating tape

unloading valve

spray valve

4 way valve

motor capacitor

up fan

low fan

lights

button

BM1,2

DIP switch

HPS

TD

TE(1)

TS

TA

EEV

LD1-3

SW01,02

high pressure switch

LPS

low pressure switch

compressor vent sensor

defrost temp sensor

compressor inhale sensor

TC

coil temperature sensor

ambient temp sensor

electronic expend valve

digital display tubes

PC

Monitor

Tfin

IPM temperature sensor

Symbol

Signification

thumbwheels

【WARING】

【NOTES】

·Please check the power firstly before test , and make

sure the crankcase heater powering on for 12 hours

at least to protecting compressor.

·Forbid connecting the power wire to the “P” and “Q”,

otherwise the control board will be damaged.

Def. display indication

U**

220

6.0P

7.0P

380

Indoor units

quantity

power

type

Out door

unit

capability

3.0P capability:AU28

capability:AU48

capability:AU60

**:NUM of the connected indoor units

single phase power type

three phase power type

Please power off firstly for about 10

minutes before checking control box,

and make sure the voltage between

P and N below 20V.

·The switch BM1-1 is used for locking the indoor units

number, the initial situation is “ OFF”. After power on,

the display board will display 【U**】, “**” indicates

the number of Indoor units that the outdoor unit can

communicate with. If it can match the actual number

of indoor units, please change “OFF” to “ON”, or else

fix the communication problem firstly.

[1] [2] [3] [4] [5] [6] [7] [8]

-0 1 0 0 0 0

1 0 1

CM43BV140-HYJ1H

01 1 0

CM43BV155-HYJ1H

0 0 0 0

BM1

BM2

BM

Capability.

【BM Indication】

1

B:Black

Y:Yellow

W:White

BL:Blue

Wire Colour:

O:OFF

1:ON

-:FIELD

SET

CM43BV140-HYJ1H

CM43BV155-HYJ1H

18

L1 L2 L3 N E

L1 L2 L3 N E

R S T N

PQ

Control

Board

Display

Board

Noise Filter

P

ACL

HPS

P

LPS TD TE

(1)

TC TS TA

ACN

BM1BM2

CN1CN2 CN3 CN4CN5 CN6 CN7

LED4

LED3

LED1

LED2

PC

CN29 CN28

CN21

CN32 CN31

CN30

SW01

LD1 LD2 LD3

SW02

CN24

CN10

CN9

CN8

EEV

CN30

6.3A 250VAC

FUSE1

CN18

CN17

CN16

CN25

CN15

CN12

SW1SW3

SW4

DCFAN1

SW2

HEATER

4WV

SV1

SV2

NO

12345678

NO

12345678

M

【BM Indication】

R W B BL

R

BL

CN20

CN11

CN14

CN13

DCFAN2

RDC-

P

L

S

T

U

V

W

Reactor

DC-

DC+

COMP

R

B W

CN1

CON6

CON5

CT

R

W

B

W

W

R

B

M

M

【WARING】

【NOTES】

·Please check the power firstly before test , and make

sure the crankcase heater powering on for 12 hours

at least to protecting compressor.

·Forbid connecting the power wire to the “P” and “Q”,

otherwise the control board will be damaged.

Please power off firstly for about 10

minutes before checking control box,

and make sure the voltage between

P and N below 20V.

·The switch BM1-1 is used for locking the indoor units

number, the initial situation is “ OFF”. After power on,

the display board will display 【U**】, “**” indicates

the number of Indoor units that the outdoor unit can

communicate with. If it can match the actual number

of indoor units, please change “OFF” to “ON”, or else

fix the communication problem firstly.

ACL

ACN

HEATER

SV1

SV2

4WV

CA

DCFAN1

DCFAN2

LED1-4

SW1-4

Symbol

Signification

Live Wire

Neutral Wire

electric heating tape

unloading valve

spray valve

4 way valve

motor capacitor

up fan

low fan

lights

button

BM1,2

DIP switch

HPS

TD

TE(1)

TS

TA

EEV

LD1-3

SW01,02

high pressure switch

LPS

low pressure switch

compressor vent sensor

defrost temp sensor

compressor inhale sensor

TC

coil temperature sensor

ambient temp sensor

electronic expend valve

digital display tubes

PC

Monitor

Tfin

IPM temperature sensor

Symbol

Signification

thumbwheels

B:Black

Y:Yellow

W:White

BL:Blue

Wire Colour:

Def. display indication

U**

220

6.0P

7.0P

380

Indoor units

quantity

power

type

Out door

unit

capability

3.0P capability:AU28

capability:AU48

capability:AU60

**:NUM of the connected indoor units

single phase power type

three phase power type

[1] [2] [3] [4] [5] [6] [7] [8]

-0 1 0 0 0 0

1 0 1

CM43BV140-HEJ1H

01 1 0

CM43BV160-HEJ1H

1 0 0 0

BM1

BM2

BM

Capability.

1

O:OFF

1:ON

-:FIELD

SET

CM43BV140-HEJ1H

CM43BV160-HEJ1H

This manual suits for next models

66

Table of contents

Other CIAC Air Conditioner manuals