- 3 -

Copyright ©2014 LG Electronics. Inc. All right reserved.

Only for training and service purposes LGE Internal Use Only

Notes:-

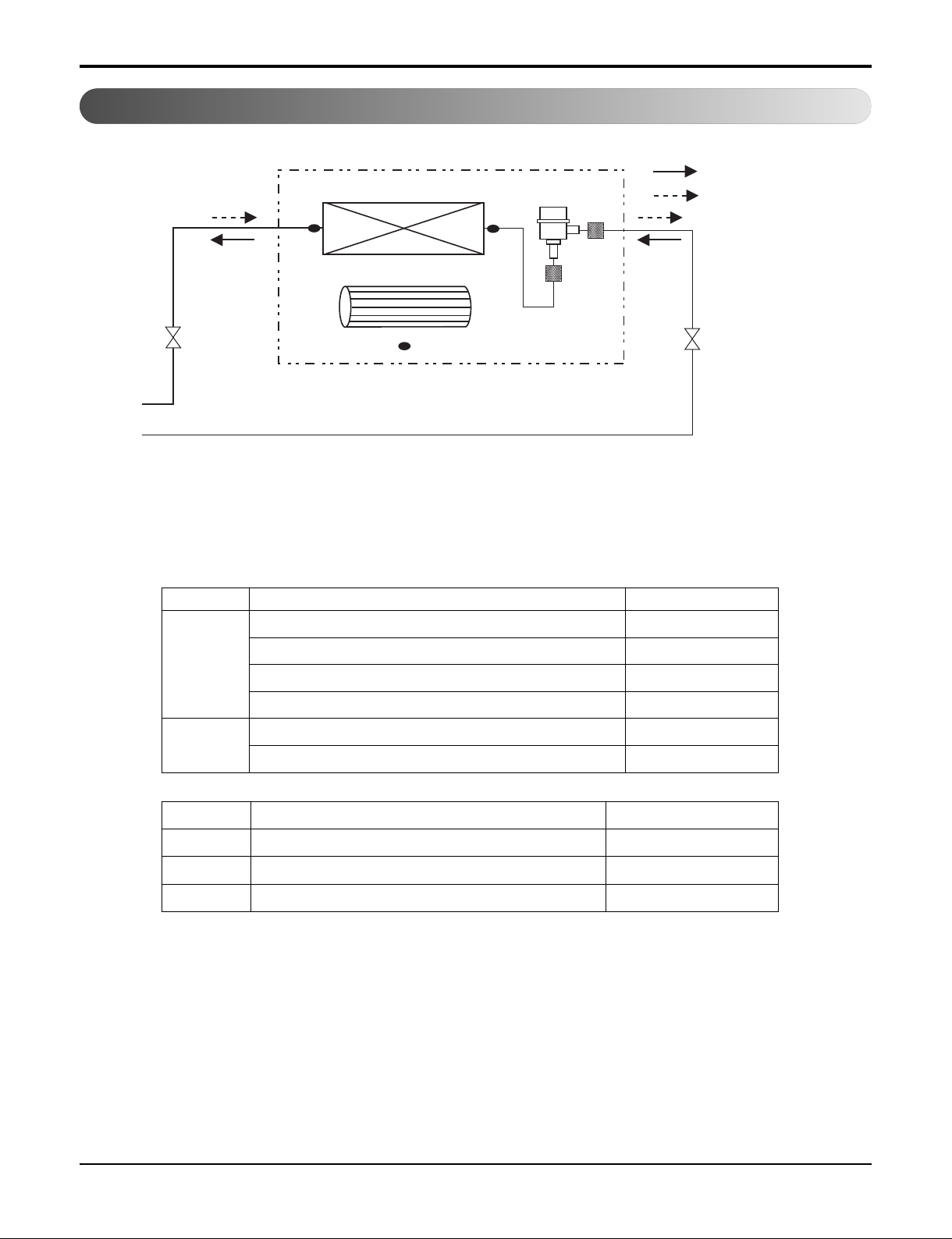

1. Capacities are based on the following conditions:

Cooling • Indoor temp. 27°C[80.6°F]DB/ 19°C[66.2°F]WB

• Outdoor temp. 35°C[95°F]DB/ 24°C[75.2°F]WB

• Interconnecting Piping Length 7.5m(24.6ft)

• Level Difference of Zero

Heating • Indoor temp. 20°C[68°F]DB/ 15°C[59°F]WB

• Outdoor temp. 7°C[44.6°F]DB/ 6°C[42.8°F]WB

• Interconnecting Piping Length 7.5m(24.6ft)

• Level Difference of Zero

2. Capacities are net capacities

3. Due to our policy of innovation some specifications may be changed without notification

4. EEV: Electronic Expansion Valve

5. To be added for more available Models

Conversion Formula

kcal/h= kW x 860

Btu/h = kW x 3412

cfm = m3/min x 35.3

l/s = CMM x 1000/60

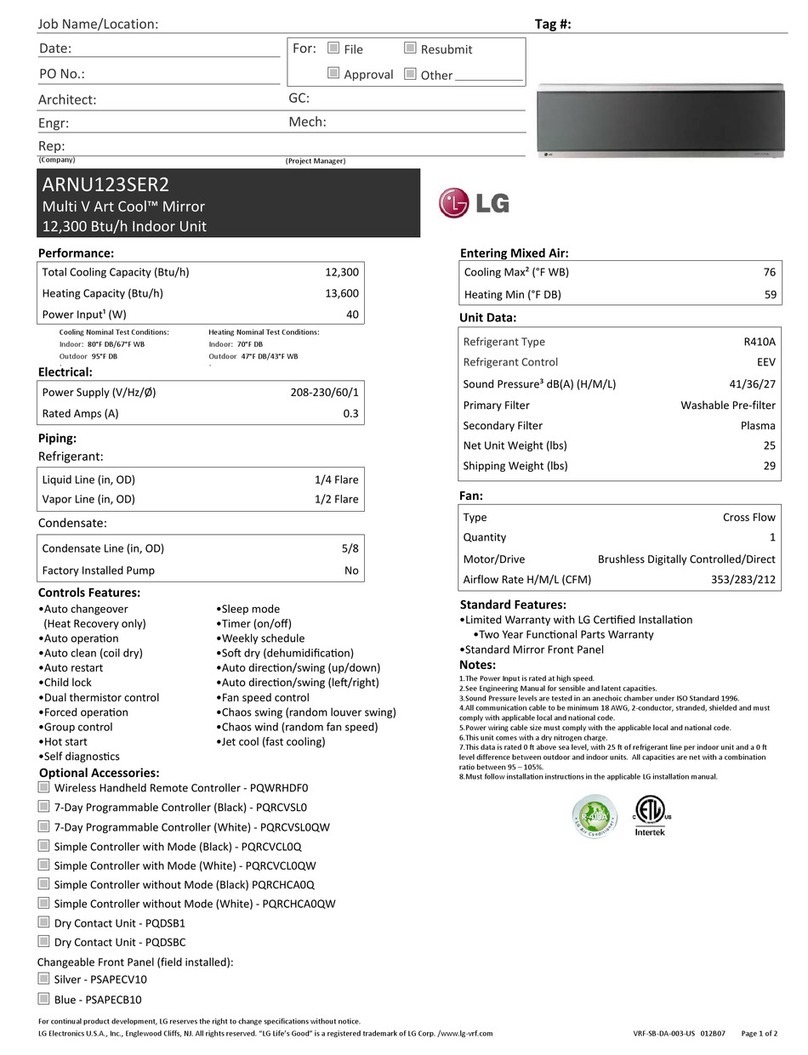

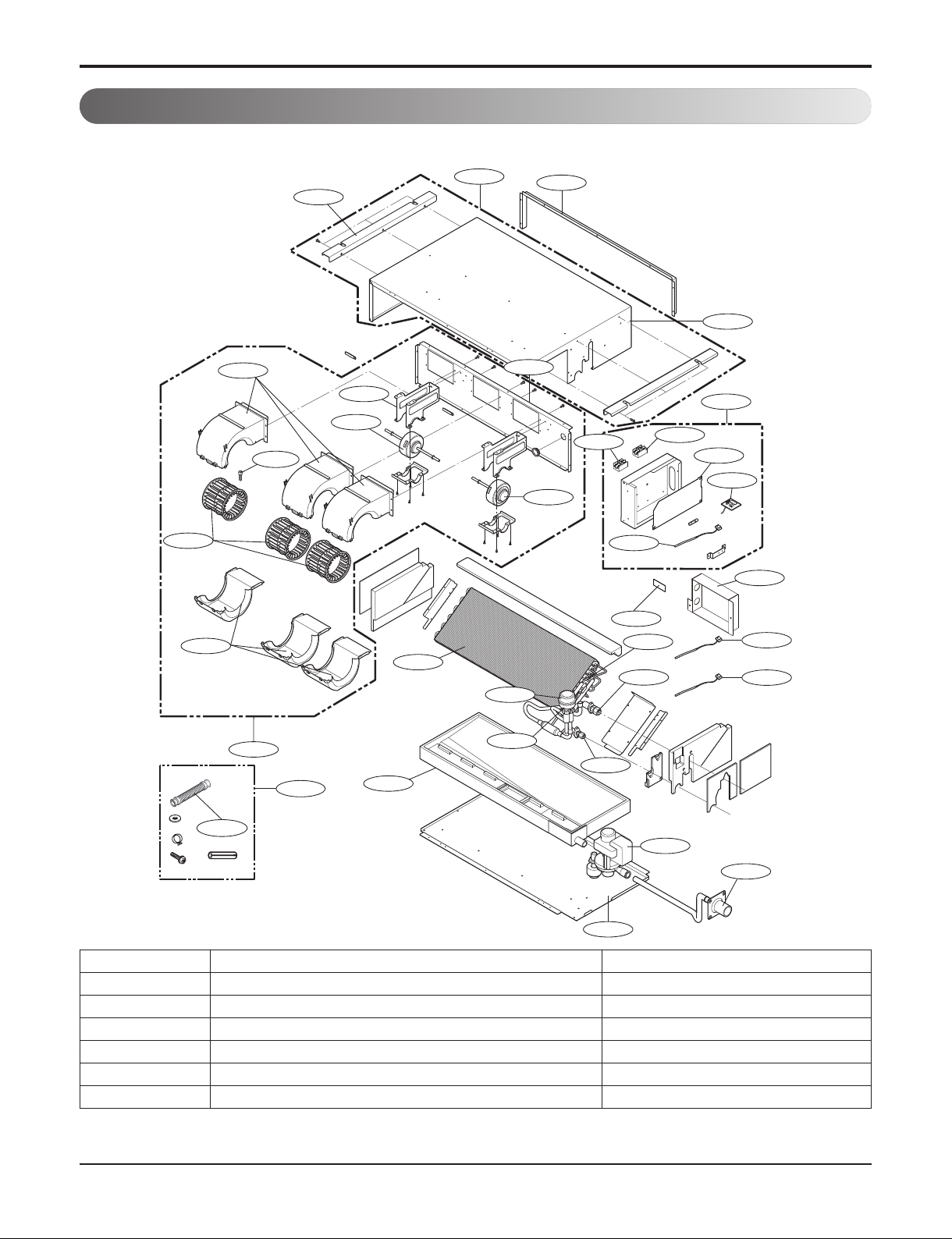

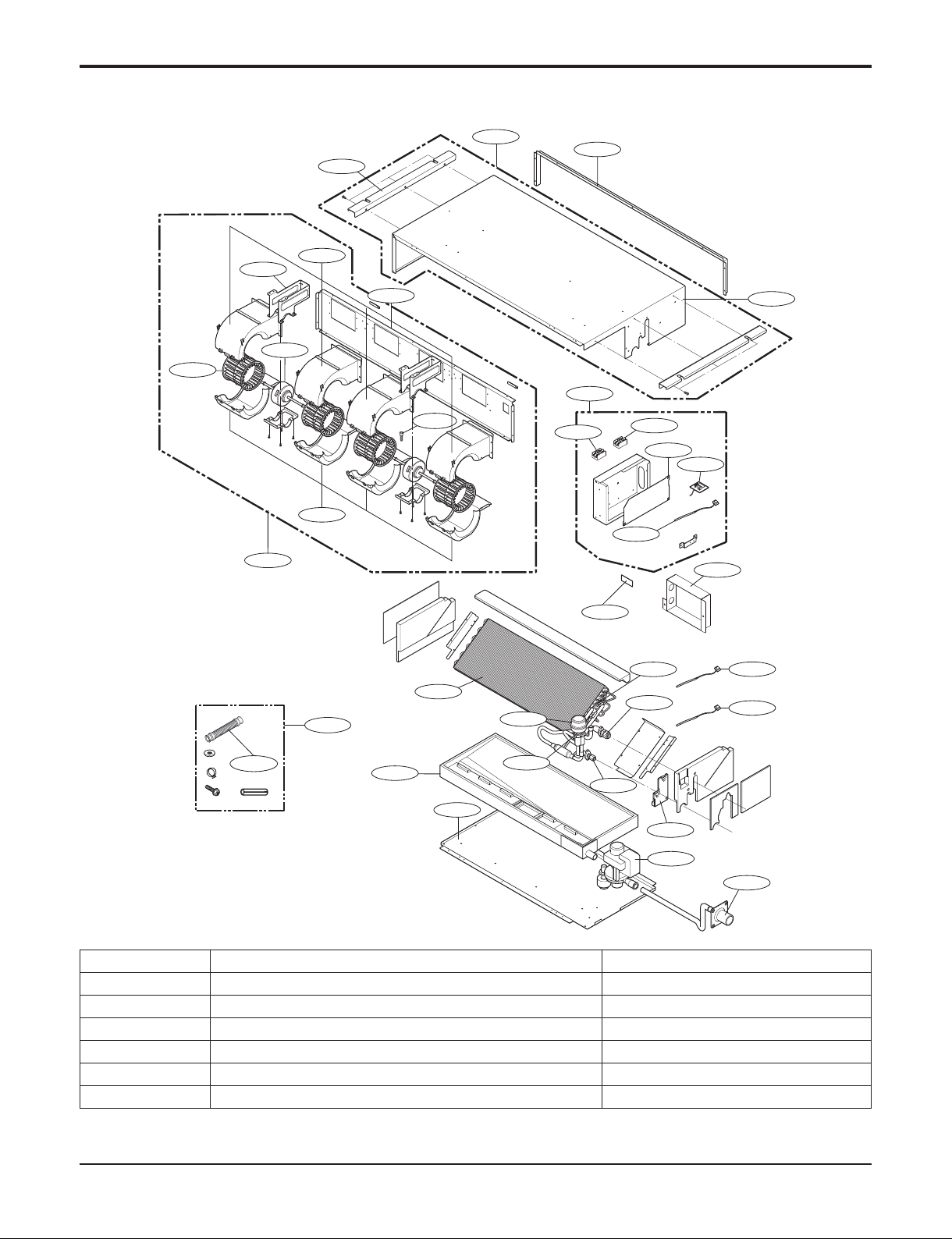

Type Ceiling Concealed Duct (Built-in)

Accessory PBSGB30/PBSC30 PBSGB40/PBSC40 PBSGB40/PBSC40

Model Unit ARNU15GB3G4 ARNU18GB4G4 ARNU24GB4G4

Cooling Capacity

kW 4.5 5.6 7.1

kcal/h 3,900 4,800 6,100

Btu/h 15,400 19,100 24,200

Heating Capacity

kW 5 6.3 8

kcal/h 4,300 5,400 6,900

Btu/h 17,100 21,500 27,300

Casing Galvanized Steel Plate Galvanized Steel Plate Galvanized Steel Plate

Dimensions

(WxHxD) Body mm 820 x 190 x 575 1,100 x 190 x 575 1,100 x 190 x 575

inch

32-9/32 x 7-15/32 x 22-5/8 43-5/16 x 7-15/32 x 22-5/8 43-5/16 x 7-15/32 x 22-5/8

Coil Rows x Columns x FPI 2 x 11 x 21 3 x 10 x 18 3 x 10 x 18

Face Area m30.16 0.23 0.23

Fan

Type Sirocco Fan Sirocco Fan Sirocco Fan

Motor Output x Number

W 19 x 1, 5 x 1 19 x 2 19 x 2

Running Current A 0.76 0.97 0.97

Air Flow Rate(H / M / L)

(High Mode-factor set)

External Static Pressure

CMM 11.0 / 10.0 / 8.0 14.0 / 12.0 / 10.0 17.0 / 15.0 / 10.0

cfm 388 / 353 / 283 494 / 424 / 353 600 / 530 / 353

mmAq(Pa) 2(20) 2(20) 2(20)

Air Flow Rate(H / M / L)

(Standard Mode)

External Static Pressure

CMM 11.0 / 10.0 / 8.0 14.0 / 12.0 / 10.0 17.0 / 15.0 / 10.0

cfm 388 / 353 / 283 494 / 424 / 353 600 / 530 / 353

mmAq(Pa) 0(0) 0(0) 0(0)

Drive Direct Direct Direct

Motor type BLDC BLDC BLDC

Temperature Control

Microprocessor, Thermostat

for cooling and heating

Microprocessor, Thermostat

for cooling and heating

Microprocessor, Thermostat

for cooling and heating

Sound Absorbing Thermal Insulation Material Foamed polystrene Foamed polystrene Foamed polystrene

Air Filter - - -

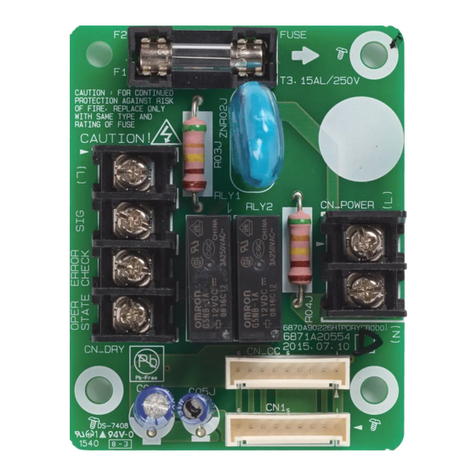

Safety Device

Fuse, Thermal Fuse for Fan Motor Fuse, Thermal Fuse for Fan Motor Fuse, Thermal Fuse for Fan Motor

Pipe Connections

Liquid Side mm(inch) Ø6.35(1/4) Ø6.35(1/4) Ø9.52(3/8)

Gas Side mm(inch) Ø12.7(1/2) Ø12.7(1/2) Ø15.88(5/8)

Drain Pipe(Internal Dia.)

mm(inch) 25.4(1) 25.4(1) 25.4(1)

Net Weight kg(lbs) 21(46.3) 26(57.3) 26(57.3)

Noise Level(Sound Press, 1m, H / M / L) dB(A) 41 / 40 / 37 43 / 40 / 37 46 / 43 / 37

Power Supply Ø, V, Hz 1, 220-240, 50 1, 220-240, 50 1, 220-240, 50

1, 220, 60 1, 220, 60 1, 220, 60

Refrigerant Control EEV EEV EEV

Power cable mm2CV1.5 x 3C CV1.5 x 3C CV1.5 x 3C

Transmission cable mm2CVV-SB 1.0~1.5 x 2C CVV-SB 1.0~1.5 x 2C CVV-SB 1.0~1.5 x 2C