Breaking capacity for each thermostat

- 15 A (2.5 A) at 250 V

- 10 A (2.5 A) at 400 V

•Only qualified personnel may carry out work on the thermostat.

•When replacing an old thermostat with a new model, remember to carry out the wiring

modifications and run an operating test.

VENTILATION UNITS

1. Fresh air only operation

If the temperature at the chamber outlet is lower than 25°C, the combustion chamber ventilation unit is 90% closed.

If the temperature at the chamber outlet is greater than 25°C, the combustion chamber ventilation unit is open.

The ventilation unit can be controlled by an On/Off servomotor without a zero return (zero return by phase inversion). This

servomotor may be controlled by the thermostat's 1st stage (to fine-tune the air outlet temperature setting, the servomotor may

be the modulating type controlled by a modulating regulator with a supply air sensor).

The servomotor will have a mechanical stop to allow the opening and closing percentages to be set (travel limit).

2. Adjusting the bypass flap

To obtain the ideal temperature at the combustion chamber outlet and reduce the risk of condensation, please set the

combustion chamber bypass according to the exhaust temperature (min. 160°C in the worst-case scenario).

Note: the settings are given for information only; they must be fine-tuned during operation at a low return temperature. A larger

bypass opening improves operation.

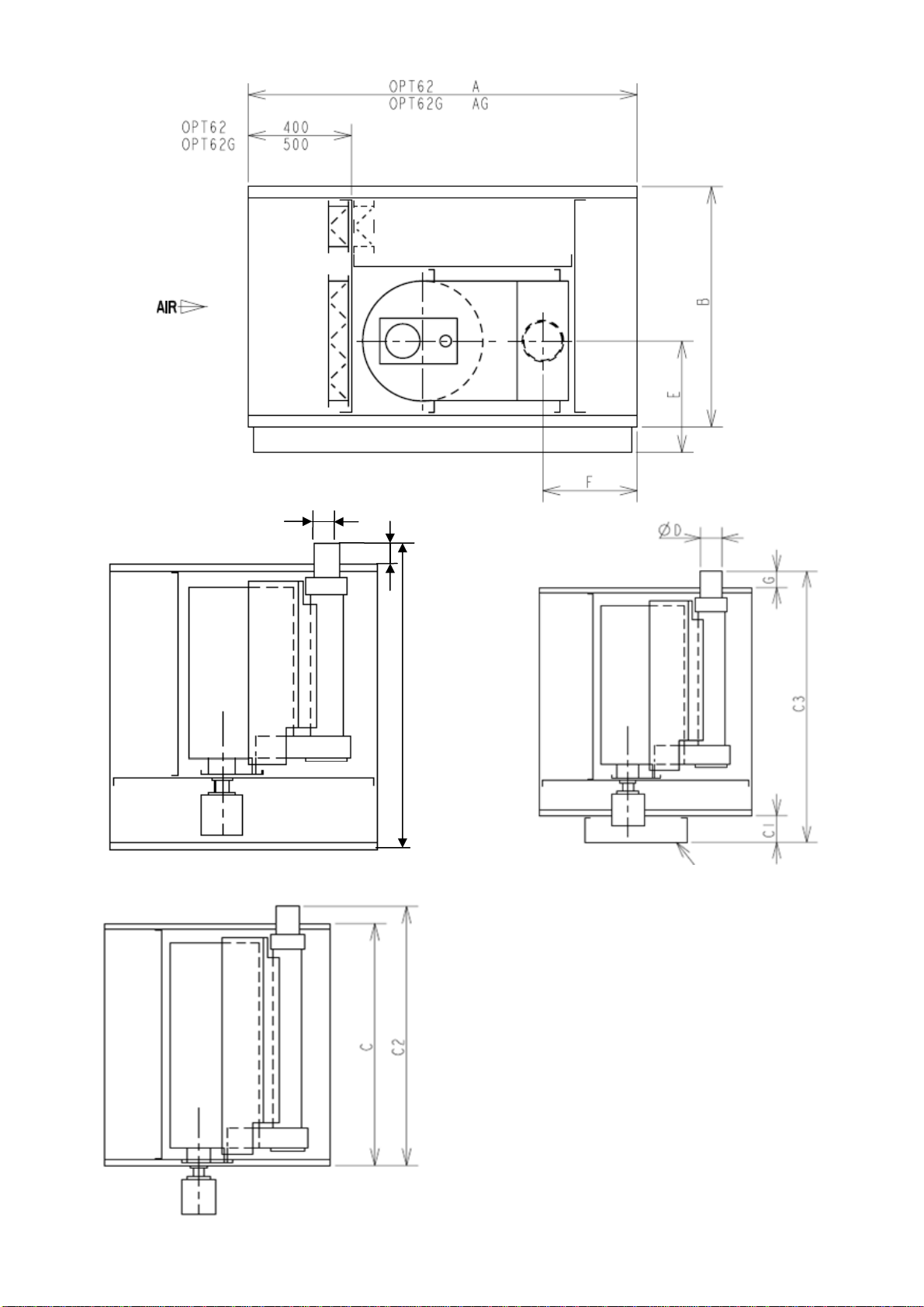

GENERATOR

For safety and maintenance reasons, please observe the clearances given below.

Access side

La distance between the GGS generator and the wall must be at least 900 mm (the desired distance is the depth of the GGS

generator).

Opposite side

The distance between the GGS and the wall must be determined on the basis of how the burnt gas duct is installed (see section

relating to its installation).

The unit must be installed in accordance with current regulations and standards in a well-ventilated area.

The unit must not be installed in an area with a risk of fire (fine flammable dust) or explosion, or in an area

containing aggressive products such as trichloroethylene, perchlorate, etc.

The fresh air flow required to supply combustion is at least 2 m3/h per kW of heat flow.

GAS PIPE AND ELECTRICAL ROUTING

Inside the GGS generator

•Observe the correct clearance for the smoke box access panel.

•Allow room to access the minimum gas pressure switch (adjustment).

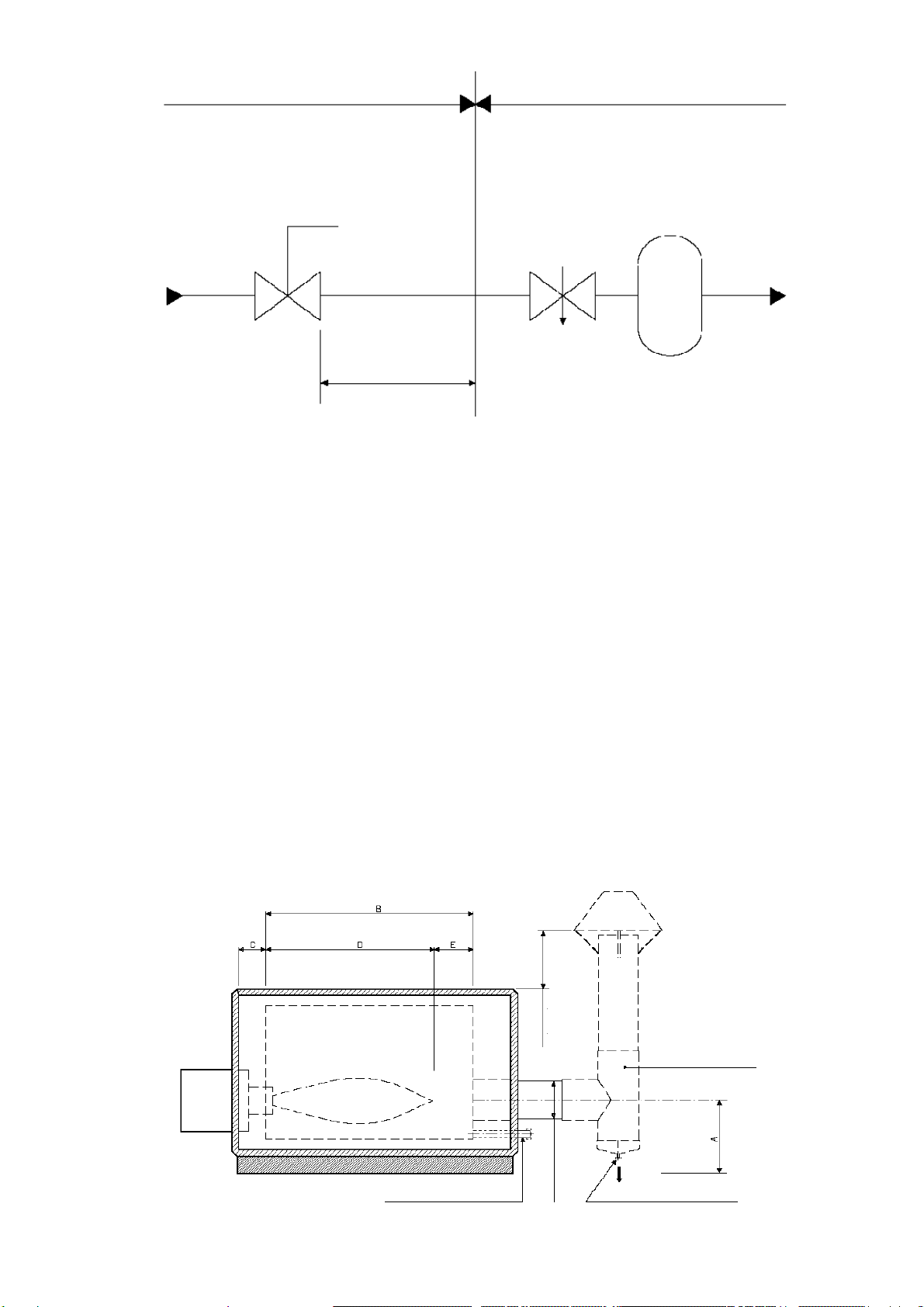

SELECTING THE BUFFER CAPACITY

The volume of the buffer tank + the volume of the pipework (expansion valve at the consumption point) must be based on the

maximum flow of the installation, at least: BP (16 to 21 mbar) 2 litres per Nm3

MP (0.06 to 4 bar) 1 litre per Nm3

NOTE: the buffer capacity does not compensate for undersized pipework.

Required buffer capacity in litres based on the max. flow in Nm3/h

Gas flow rate Nm

/h 6 10 16 25 40 65 100 160 250 400 650 1000

Buffer volume LP pressure 12 20 32 50 80 130 200 320 500 800 1300 2000

Buffer volume MP pressure 6 10 16 25 40 65 100 160 250 400 650 1000

8