CIECO PCI-100LS User manual

PCI-100LS

Programmable Limit

Switch

ProgrammingandInstallationManual

V2.6

•PH: 412-262-5581 •WEB: CIECOCONTROLS.COM •FX: 412-264-9272

TABLE OF CONTENTS

2 PROGRAMMABLE LIMIT SWITCH COMPONENTS

3 KEYPAD

4 MENUS and FUNCTIONS

6 INSTALLATION STEPS

7 CHAIN BRAKE DELAY

HIGH and LOW SPEED LIMITS

8 SPEED COMPENSATION

9 TROUBLE-SHOOTING

11 RESOLVER MOUNTING

12 PANEL CUTOUT (for loose package only)

13 POWER SUPPLY AND SOLENOID CONNECTIONS

14 RESETWIRING

15 RESOLVER WIRING

16 RELAYWIRING

17 QUICK PROGRAMMING REFERENCE

18 WARRANTY

LS1 F 1 0 0 - T 2 0 0

Interrupted Stroke

PCI-100

RESET

ENTER

MENU

Industrial Electronic Controls

Inc

PROGRAMMABLE LIMIT SWITCH COMPONENTS

22

Programmable Limit Switch control in a 8x6x6 enclosure

Industrial resolver

Resolver cable with connector

The PCI-100LS Programmable Limit Switch receives position and motion feedback from the resolver. The resolver

is attatched to the main shaft of the press. The PLS knows when the press is engaged, how fast it is running, the

position of the crank shaft, and when the clutch is disengaged.

Many safety features are included such as:

•Motion detect

•Resolver decouple/slippage detect

•Resolver cable brake detect

•Key and Coded security

•Rugged Quality design

•Clutch monitor

•Zero motion cable break detect

KEYPAD

MENUS:

There are 5 menus to choose from. Under each menu there may be

several different functions or screens.

POS/TACH displays the position and speed

INITIAL one time setup functions

LIMIT SWITCHES program limit switch functions

COUNTERS view/pgm counter functions

SUPERVISOR enable/disable programming

The MENU key will toggle to the next menu regardless of what function

you are currently viewing.

Resets faults or Saves (enter) data

>

Goes into a function, then once in a function will

move the cursor if applicable.

^

Selects functions within a Menu or increments

numbers if applicable.

^

Selects functions within a Menu

(in the opposite direction of

the up arrow)

or decrements numbers if applicable.

MENU

RESET

ENTER

Helpful display codes

>When this symbol is displayed the key enables that function to be programmed

^When this symbol is displayed the key causes the program to select the next function

(ENT) When (ENT) is displayed, pressing the ENTER key will perform the function shown.

When a blinking cursor is shown, use the arrow keys to change the data and the ENTER key to

save the data.

33

KEYPAD SUMMARY

44

MENUS and FUNCTIONS

There are 5 menus. Four of them have other functions.

1 POS/TACH shows the current real time position and speed of the press in strokes per minute.

There are no additional functions under this menu.

2 INITIAL contains 4 functions. These are only set when the control is initially installed.

• ^ZERO SET (ENT) zeroes the resolver to the mechanical position of the press. Press enter

to zero the resolver position.

• ^MDET >L000-H999 Motion DETect sets the low and high SPM limits. Press >, then use the

arrow keys to program the low and high SPM limits for the press.

Press ENTER to save. If during normal operation the press goes below

or above the limits a motion fault will occur and the fault output will

de-energize until reset.

• ^MDLY >D999 Motion DeLaY sets the delay before a low motion fault will occur so

that the press can get up to speed. Press >, then use the arrow keys to

adjust the setting in milliseconds. Press enter to save.

• ^TSTOP >A310 Top STOP sets the Angle that the Fault/Batch output will open when a

batch count is reached. Press >, then use the arrow keys to adjust the

setting in degrees. Press enter to save.

3 LIMIT SWITCHES contains 5 functions.

• ^LS1 >F000-T000 Limit Switch 1 programming output ON at (From degrees - To degrees)

Press > then use the arrow keys to program a From-To window. Press

enter to save.

• ^LS2 >F000-T000 Limit Switch 2 programming output ON at (From degrees - To degrees)

Press > then use the arrow keys to program a From-To window. Press

enter to save.

• ^LS3 >F000-T000 Limit Switch 3 programming output ON at (From degrees - To degrees)

Press > then use the arrow keys to program a From-To window. Press

enter to save.

• ^LS4 >F000-T000 Limit Switch 4 programming output ON at (From degrees - To degrees)

Press > then use the arrow keys to program a From-To window. Press

enter to save.

• ^SCOMP >S000-A000 Speed COMPensation adds the programmed angle A*(SPM/100) to

the limit switch settings. Compensation does not begin until the press

SPM (strokes per minute) is equal to or greater than the programmed

speed S. (See speed compensation, optional)

Menus and Functions continued

4 COUNTERS contains 5 counter functions

• ^STROKE S000000 keeps a running total of the strokes count. The strokes counter will

increment every stroke of the press. It can be used with the batch to

stop the press when the required number of parts have been made.

• ^BATCH> B000000 BATCH count programming. Press > then use the number keys to pro-

gram the number of parts/strokes. When the strokes count is equal to

the Batch, the counter output will de-energize and a Batch Count

message will be displayed.

• ^ZeroStrks (ENT) Zeros the Strokes count. Press enter to zero the strokes count

• ^THITS T00000000 keeps count of the Total HITS . Counts every stroke of the press. This

can be an excellent tool to schedule press mantainance.

• ^ZeroTOTAL(ENT) Zero the TOTAL hits counter. Press enter to zero the total hits count.

5 SUPERVISOR contains one function to enable or disable programming

• SETUP>DISABLED

OR displays whether programming is enabled or disable. Press>

SETUP>ENABLED then use the arrow keys to enable or to toggle to disable.

See programming quick reference guide.

55

INSTALLATION STEPS

1. Mount the controller in an area that can be easily viewed by the operator.

2. Install the resolver

3. Install the resolver cable

4. Make all the electrical connections and double check the connections to make sure they are correct

5. Apply power

6. Enable programming by entering the Supervisory Code

7. Zero the resolver at TDC.

8. Program the motion delay and motion detect.

9. Program the batch count as needed

10. Program the Programmable Limit Switch outputs as needed.

11. Program speed compensation (optional)

12. Disable programming to prevent unauthorized changes.

CAUTION: Do not use Programmable Limit Switch outputs for press con-

trol functions unless the press control checks for proper PLS operation

every stroke of the press.

66

CHAIN BREAK DELAY

The motion delay is used to compensate for starting delays caused by clutch slippage.

1. The motion delay is factory set at 999. Decrease the delay until motion fault occur.

2. Slowly increase the delay until motion faults are eliminated.

3. Add some delay to allow for clutch wear.

The motion delay is only used when the clutch is engaged. It delays before the low SPMs are checked to allow for

clutch slippage. The motion delay works in conjunction with the low speed limit. When the clutch is engaged the

press speed must reach the low speed limit before the motion delay times out.

SPM - Strokes Per Minute

^MDLY >D999

HIGH and LOW SPEED LIMITS

Monitors the press SPM during normal operation.

1. Program the Low speed for the minimum allowable speed of the press in SPM during normal operation.

2. Program the High speed for the maximum allowable speed of the press in SPM during normal operation.

Durring normal operation of the press if the speed should fall outside the programmed limits a Motion Fault mes-

sage will be displayed and the fault output will de-energize. The fault is cleared by pressing RESET. See MOTION

FAULT under fault messages for a complete explanation of possible motion fault problems.

^MDET >L000-H999

77

SPEED COMPENSATION

Speed compensation offset angle is the number of degrees of advance per 100 SPM increase in press speed over the

programmed starting speed.

Example 1: Top Stop

1. Program the speed compensation starting speed Sto the slowest operating speed of the press. eg. 50spm

2. Set the speed compensation offset angle Ato zero.

3. Run the press at its slowest operating speed and program the top stop output so the press stops at the top.

4. Set the press to its maximum operating speed. eg. 125 spm

5. Run the press at its maximum operating speed (keeping the top stop window the same) and note the number of

degrees over top that the press stops. eg. 23°

6. Divide the difference in stopping degrees (23°) by the difference in speed (75spm) and multiply by 100. This is

your speed compensation offset angle per 100 spm. Round off if necessary.

eg. (23 / 75) x 100 = 31° per 100spm

7. Program the angle Ato 31°

Example 2: Servo Feed Initiate

Follow steps 1 and 2 above

3. Run the press at the slowest operating speed and program the feed initiate PLS output to feed properly.

eg. F240-T270

4. Set the press to its maximum operating speed. eg. 125spm

5. Advance the feed initiate PLS output to feed properly at this speed. eg. F217-T253

6. Divide the difference in PLS output settings (F240 - F217 = 23°), by the difference in speed (125 - 50 = 75spm)

7. Program the angle Ato 31°.

8. Reprogram the feed initiate PLS output for the slowest press speed. eg. F240-T270

88

TROUBLESHOOTING

fault messages

MESSAGE

MOTION FAULT Resolver shaft speed equals or exceeds the boundaries of the programmed SPM limits while

the brake solenoid input is at 115VAC (brake off)

A broken resolver to machine shaft coupling or chain.

Excessive clutch slippage or the motion delay is set to short.

An attempt is made to run the machine with the brake solenoid input disconnected.

ANGLE FAULT The resolver cable becomes disconnected.

The line voltage momentarily drops below minimum.

Noise on the line voltage, the brake input, or the resolver input.

The resolver speed exceeds 999spm

BATCH COUNT Although not a fault the Fault relay will de-energize when the strokes count is equal to or

greater than the programmed batch and the programmed top stop angle is exceeded.

99

TROUBLE-SHOOTING

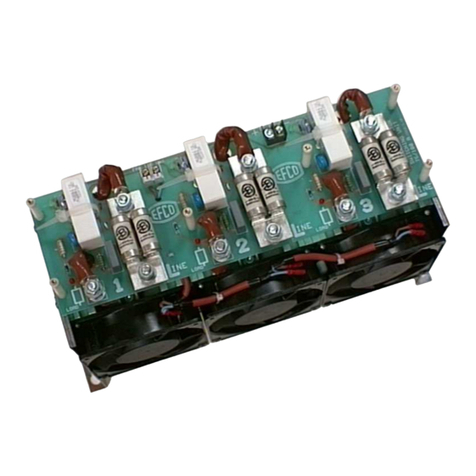

power supply and relay diagnostics

POWER SUPPLYBOARD

LEDs Color Indication

D1A Green FAULT/BATCHenergized

D2A Green Limit Switch 1 energized

D3 Green Limit Switch 2 energized

D4 Green Limit Switch 3 energized

D5 Green Limit Switch 4 energized

D6 Red Power on

10 10

1 2 3 4 5 6 7 8 9

Main Fuse

CIECO Inc

PWR

D3

D4

D5

D1A

D2A

13 14 15 16 17 18 19 20 21

22 23 24 25 26 27

Flt

relay

E-stop relay fuse

2.5amp

0.315A

To Stop circuit

Power Supply

and

Relay board

PLS1

PLS2

PLS3

PLS4

10 11 12

Fault relay 4A @110VAC

PLS 1 4A @ 110VAC NO

PLS 2 8A @ 110VAC NO

PLS 3 - 4

Option A 8A @ 110VAC NO standard

Option B 4A @ 110VAC NO-NC on request

Caution: Some relays on this board are NOT

interchangable. See description below.

120 140 160 180 200

.25

.50

.75

1.0

Inches from housing

Max radial load - LBS

0.625 .0625

1.032

1.032

1.31

2.75

1/4-20 threaded

holes

2.75

3.125

RESOLVER MOUNTING

11 11

The resolver shaft and stator should NEVER be rigidly coupled to the machine shaft and stator. Either the

shafts or the stators should have a flexible member which will allow freedom of movement in all planes except

rotation. (No two shafts ever have equal runout regardless of their precision. Even if individual shaft

assemblies have the same "amount" of runout, these assemblies will have different patterns which result

in different magnitudes at various rotational positions. This applies regardless of bearing types.)

If a pulley or sprocket is to be mounted to the resolver shaft, DO NOT hammer or force fit it onto or off the

shaft. If the resolver is belt or chain driven, DO NOT overtighten the drive belt or chain. To much side loading

can destroy the resolver bearings.

If these mounting rules are ignored, (warranty will be void) the machine shaft assembly will "fight" the resolver

shaft assembly and the final result will be failure of the weakest bearing.

4.65

GREY AREA

4 1/4" x 3 5/8"

CUTOUT

C

L

Drill holes

9/64"

4 places

1 13/16" 1 13/16"

2 1/8"

2 1/8"

1.65 1.65

2.325

2.325

PCI PANEL CUTOUT

12 12

13 13

WIRING

Power supply terminals 22-27

TERMINAL# DESCRIPTION

27 Must be earth grounded,

machine ground is not sufficient.

26 Internally connected to 27

25 Neutral

24 110VAC

23 Neutral

22 Brake Sol feedback input

NOTES:

GROUNDING: To avoid noise problems the earth ground input must be

connected directly to earth ground or to the earth ground of the electrical

panel.

Machine ground is not sufficient.

BRAKE SOLENOID INPUT: is used by the PCI-100LS to sense when

the clutch is engaged (110VAC) and when the brake is applied (0 VAC).

Incorrect wiring of this input will result in nuisance motion faults.

27 26 25 24 23 22

110VAC

One of the

solenoids from

the dual valve

110VAC NEUTRAL

NEUTRAL

NEUTRAL

26 AND 27 ARE INTERNALLY

CONNECTED

WIRING

PCI main terminal

RESET ENABLE/DISABLE:

Disable - will not allow any fault to be reset.

Enable - any fault can be reset from the keypad or the remote

reset button.

1 2 3 4 5 6 7 8 9

1 2 3 4 5 6 7 8 9 10

Disable Enable

Reset Remote

Reset not required

Connect input to

ground if not

needed. (Reset

always enabled).

15VDC

PCI MAIN TERMINAL

Connections 1 and 3 of the PCI main

terminal are to be connected in the

field as needed. All other main

terminal connections are factory

wired when ordered in a NEMA

enclosure.

14 14

POWER SUPPLY

LOW VOLTAGE I/O TERMINAL

FACTORYCONNECTED

PCI TERMINAL DESCRIPTION

1 reset supervisory input

2 clutch/brake status input

3 remote reset input

4 not connected

5 fault/batch output

6 limit switch 2 output

7 limit switch 3 output

8 limit switch 4 output

9 limit switch 1 output

10 +15VDC input

15 15

1 2 3 4 5 6 7

To terminal 27 of the power supply

and resolver cable shield.

PCI

7 pin Resolver terminal

1 - R1: BLUE/WHITE STRIPE

2 - R2: WHITE/BLUE STRIPE

3 - S3: WHITE/GREEN STRIPE

4 - S1: GREEN/WHITE STRIPE

5 - S4: WHITE/ORANGE STRIPE

6 - S2:ORANGE/WHITE STRIPE

7 - G: SHIELD

WIRING

PCI resolver terminal

CAUTION: To avoid noise problems, install the resolver cable away from any high power lines or motors.

Do not run the resolver cable in the same conduit with 110VAC or higher voltages.Any cables or wires that switch

noise producing loads such as solenoid coils and motors should kept away from the resolver cable.

•Install the resolver cable in its own grounded conduit.

•Keep noisy lines as far from the resolver cable as possible.

- 2” from 110VAC

- 12” from motors and motor wires

•Never install the resolver cable directly next to a high power line or motor.

Reversing S1 and S3 will change

the ascending count direction.

16 16

Fault/Batch relay

Is energized (closed) during normal operation and will open in a fault or batch condition

The fault/batch relay is rated for 8 amps @ 110VAC and is fused for 2.5 amps

PLS relays

•NO

•PLS 1, 4A @ 110VAC max

•PLS 2-4, 8A @ 110VAC max

WIRING

Relay outputs

1 2 3 4 5 6 7 8 9

Main Fuse

CIECO Inc

PWR

D3

D4

D5

D1A

D2A

13 14 15 16 17 18 19 20 21

22 23 24 25 26 27

Flt

relay

E-stop relay fuse

2.5amp

0.315A

To Stop circuit

Power Supply

and

Relay board

PLS1

PLS2

PLS3

PLS4

10 11 12

Fault relay 4A @110VAC

PLS 1 4A @ 110VAC NO

PLS 2 8A @ 110VAC NO

PLS 3 - 4

Option A 8A @ 110VAC NO standard

Option B 4A @ 110VAC NO-NC on request

Table of contents

Popular Switch manuals by other brands

Gembird

Gembird UHB-U3P7P-01 user manual

Aus Electronics Direct

Aus Electronics Direct AA6068 user manual

MicroNet

MicroNet SP212E Quick installation guide

ISON

ISON IS-DG306P Series Quick installation guide

steute

steute RF 96 SW868-NET Mounting and wiring instructions

Blue Sea Systems

Blue Sea Systems Dual Circuit 6010 user manual