Effective 6/98

I.B. 48017

Cutler-Hammer

Instructions for Converting AMPGARD™Type LFM

Isolation Switch With Type 25LFR2 Design

This kit was specifically designed to replace old type LFM

isolation switches supplied prior to July, 1975, with new

type 25 LFR2 isolation switches. The shutter assembly

has been moved from the isolation switch to the starter

cell. This provides an insulating barrier over the line stabs

when the isolation switch is removed from the enclosure.

This industrial type control is designed to be installed,

operated,andmaintainedbyadequatelytrainedworkmen.

These instructions do not cover all details, variations, or

combinations of the equipment, its storage, delivery,

installation,checkout, safe operation, or maintenance.

Care must be exercised to comply with local, state, and

national regulations, as well as safety practices, for this

class of equipment.

Make certain that the incoming line breaker is locked open

and the connections to the line stabs have been de-

energized before any work is started on removal of old

parts.

Also check all auxiliary power circuits into the enclosure.

REMOVAL OF OLD PARTS

1. Rotatetheisolating switch handle counter-clockwise

90°tothe open-door position.

2. Loosendoorfastenersand open doors.

3. Remove the main power fuses and the contactor

phasebarriers.

4. Remove the contactor from the enclosure per instruc-

tionsinI.L.11-202-14under“Maintenanceand

Repair”.

5. Remove two .312 inch-18 x 1.00 inch Allen head cap

screws holding the isolation switch in place. Save

hardware.

6. Disconnect the auxiliary switch connections from the

terminal block if an auxiliary switch was originally

supplied.

7. Slide the old isolation switch out of the enclosure.

8. If any mechanical interlock linkage was supplied as

part of the original isolation switch, this linkage should

be transferred to the new switch using the holes

provided. Special care must be taken to properly

adjust the linkage so the complete mechanical

interlock system functions as originally intended.

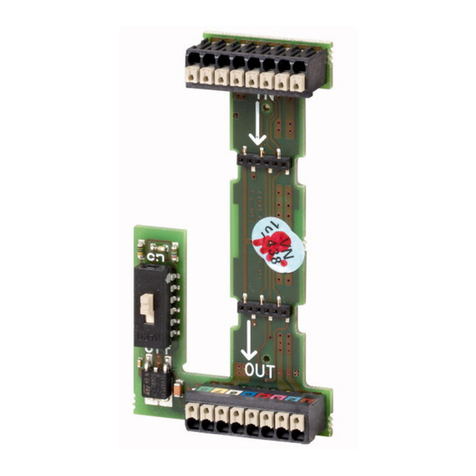

9. See Fig. 1. Remove the 16-inch long glass polyester

line stab finger barrier that is held in place with two

.312inch-18 hex bolts. Dispose of the hardware and

thefingerbarrier.

Fig. 1 Existing Line Stab Finger Barrier