CINOART PT2 User manual

PT2

PRODUCT MANUAL

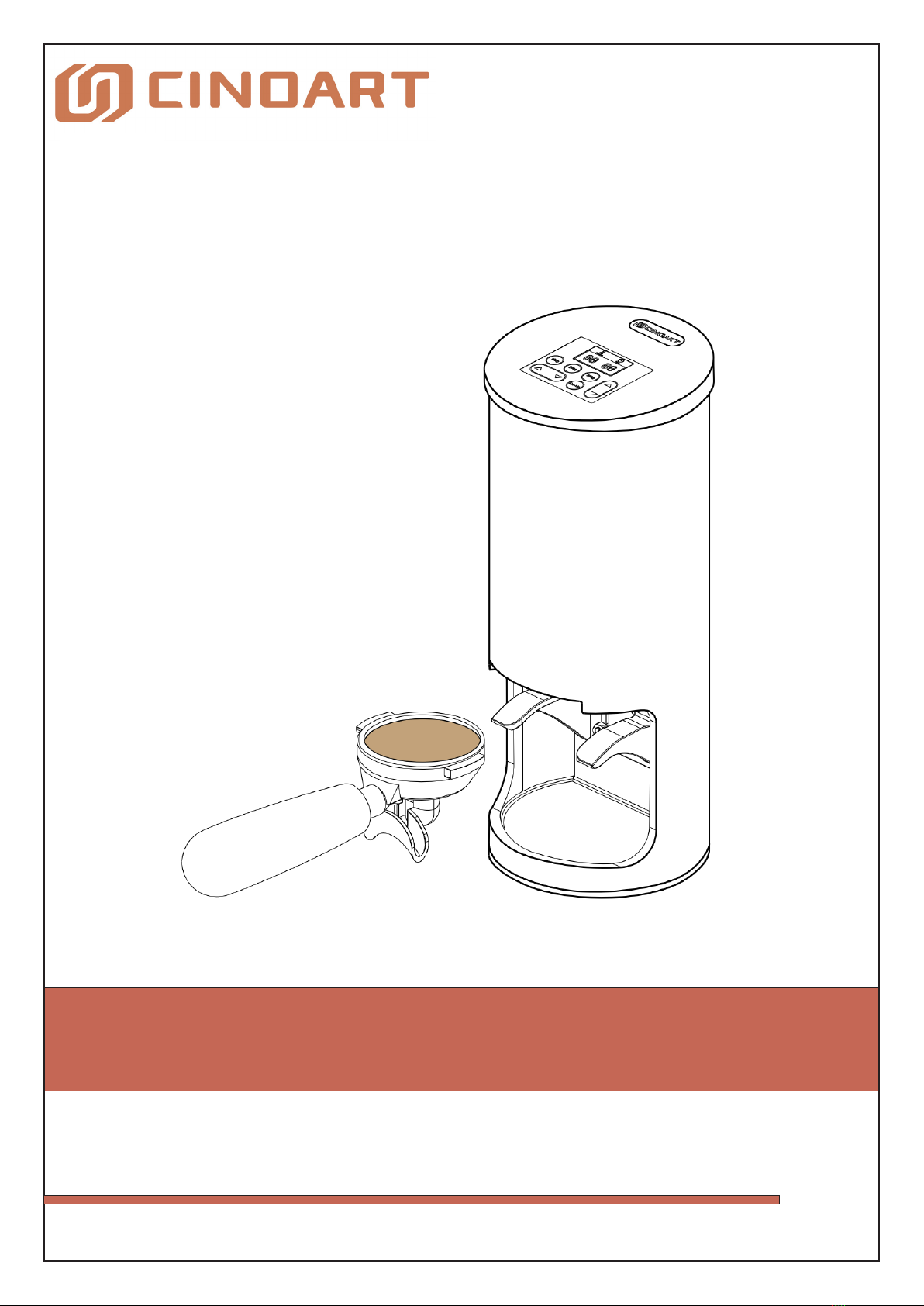

AUTOMATIC COFFEE TAMPER

-Precision Tamp 2

PT2 OVERVIEW

PT2 Precision Tamp

Thank you for choosing the CINOART PT2 (Precision Tamp 2).

Please read the following user guide and instructions carefully to ensure the correct use

and accurate setup of this machine.

The CINOART PT2 Automatic Coee Tamper will greatly assist the professional barista

with workow speeds while maintaining the consistency of espresso preparation.

Using the PT2 Precision Tamper greatly improves the avour yield, consistency, and

overall cup quality of each espresso.

The PT2 is simple and quick to operate. Clear display icons allow easy access into each

of the dierent modes for fast changes to the desired pressure.

If you require more information or have further questions not covered in these

instructions, please contact Shenzhen Meshining Technology Co. Ltd or your local

CINOART distributor.

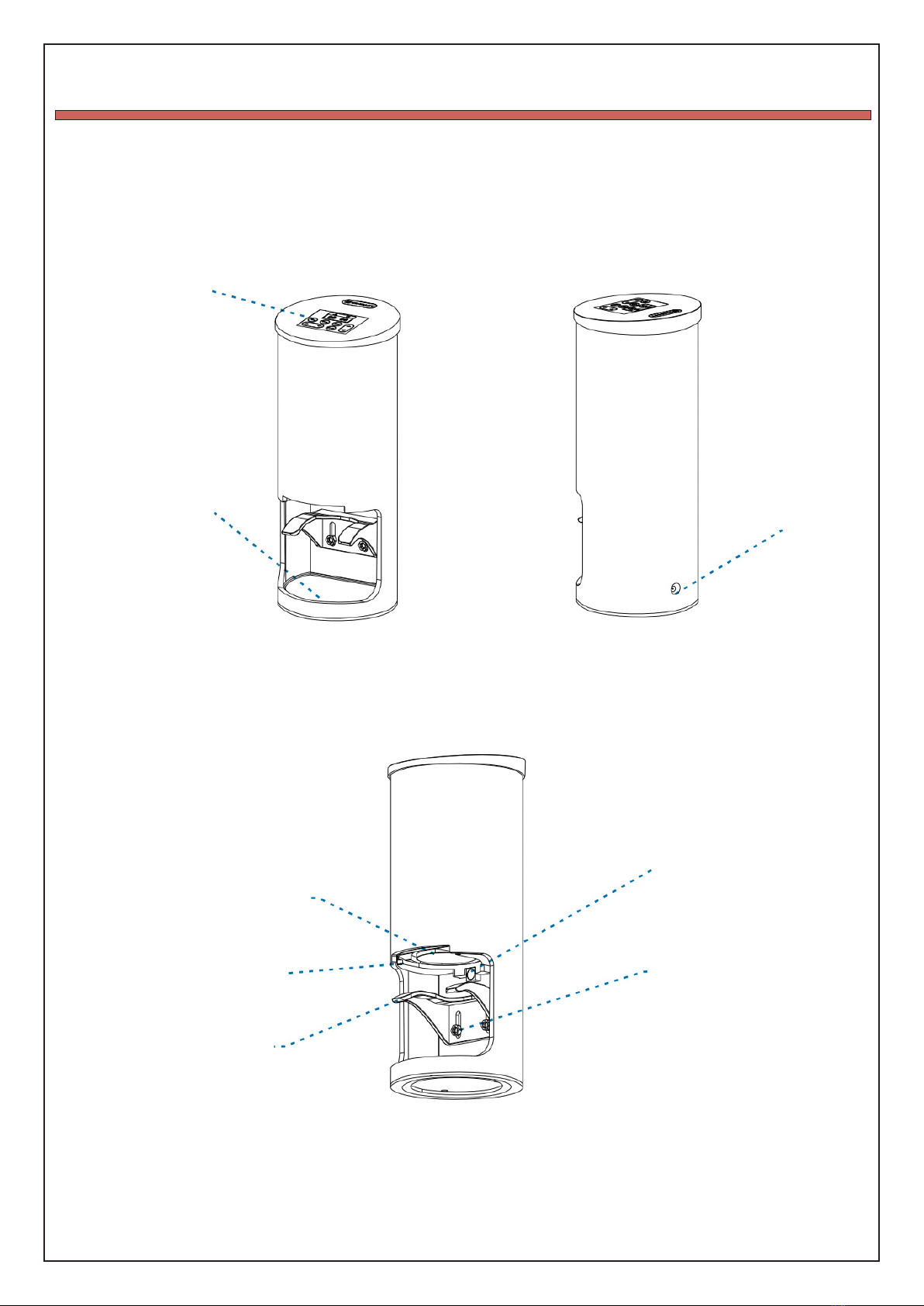

PT2 FEATURES

Touchpad Control Panel

Silicone Grinds Tray

Power Plug

Tamper Disk

Upper Guide

Portalter Support

Sensor

2 x Adjusting Hex

Screws

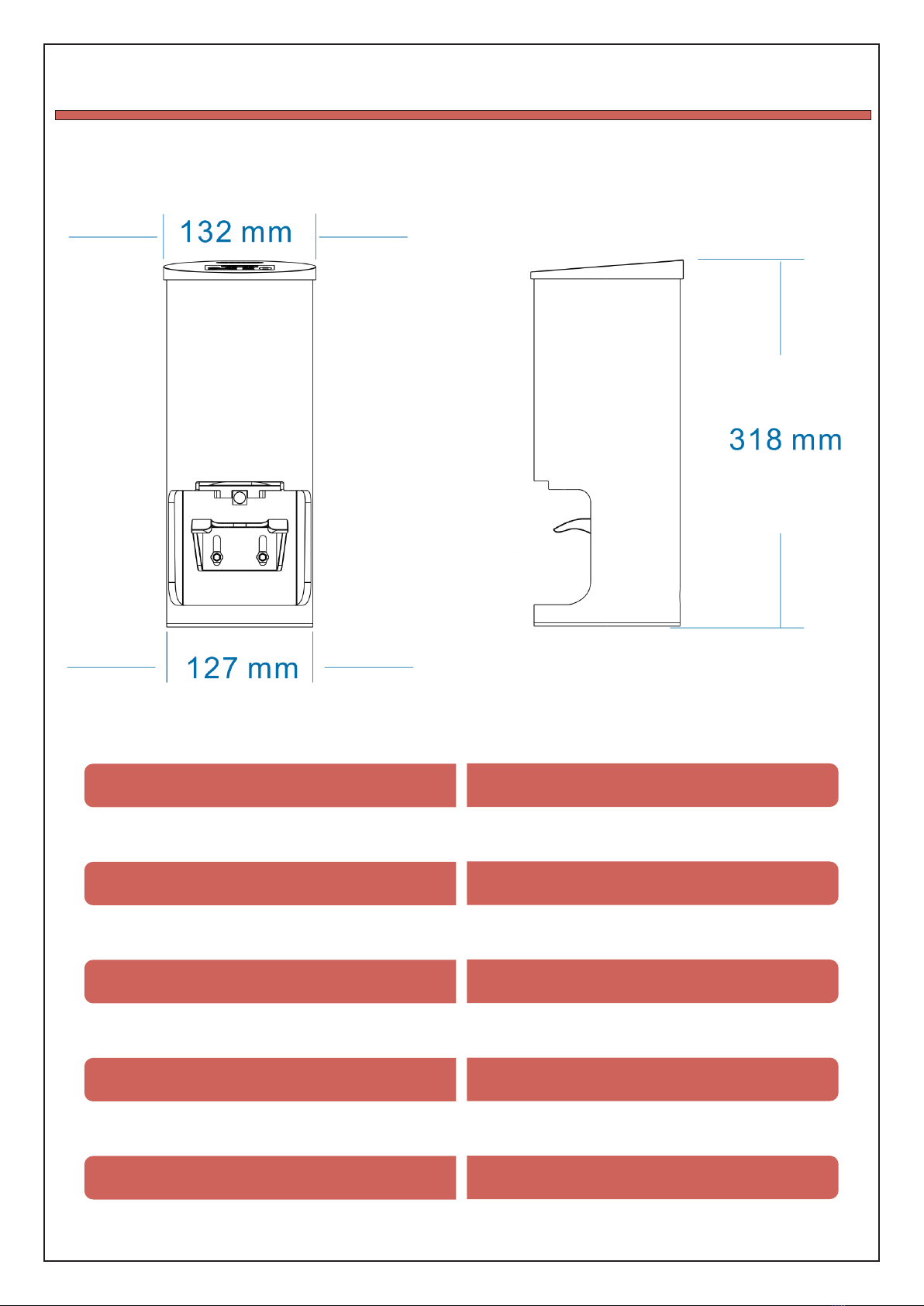

DIMENSIONS AND TECHNICAL SPECS

Product Name Automatic Coee Tamper

Model PT2 - Precision Tamp 2

Voltage In 110~240V 50/60Hz

Voltage Out 12V DC

Weight 3.7kg

Tamper Diameter 58.3mm / Flat Base

Pressure from 2kg to 38kg

Cycle Speed 1.2 Sec

Multi Segment Tamping 1, 2 or 3 times

1# SET UP AND PORTAFILTER ADJUSTMENT

The PT2 is designed for easy adjustment to the Portalter / Group Handle

1. Turn o the power by removing the power cord at the rear of the machine.

2. Turn the PT2 upside down on a smooth at nonslip surface.

3. Loosen the 2 Hex Screws with the supplied Allen Key.

4. Place the Portalter Levelling Guide tool on top of the Tamper Disk.

5. Place the Portalter handle upside-down on the Levelling Guide, then adjust the

Supporting fork down onto the underside of Portalter handle.

Portalter Levelling Guide Tool

Images - Step 5.

Images - Step 1, 2, 3, 4

Images - Step 6.

Re-tighten the 2 hex screws ensuring the supporting fork is level with the parallel

indicator markings.

Images - Step 7.

Remove the Levelling Guide Tool and return the PT2 to the upright position and

reconnect the power.

2# ENVIRONMENT

Place the PT2 Automatic Tamper on a at, solid and vibration-free surface.

Do not operate the machine in wet or extreme temperature environments.

3# PLEASE CHECK BEFORE USE

1. Inspect the power cord to ensure there are no signs of damage or poor connection

ttings.

2. Insert the power adaptor cord into the rear of the PT2 and then into the 10amp

PowerPoint.

4# OPERATION

1. Turn power on.

2. Ensure the digital display screen is illuminated and functional.

3. Set and program the desired tamp values via the touchpad.

4. The internal activation sensor will automatically detect the Portalter handle.

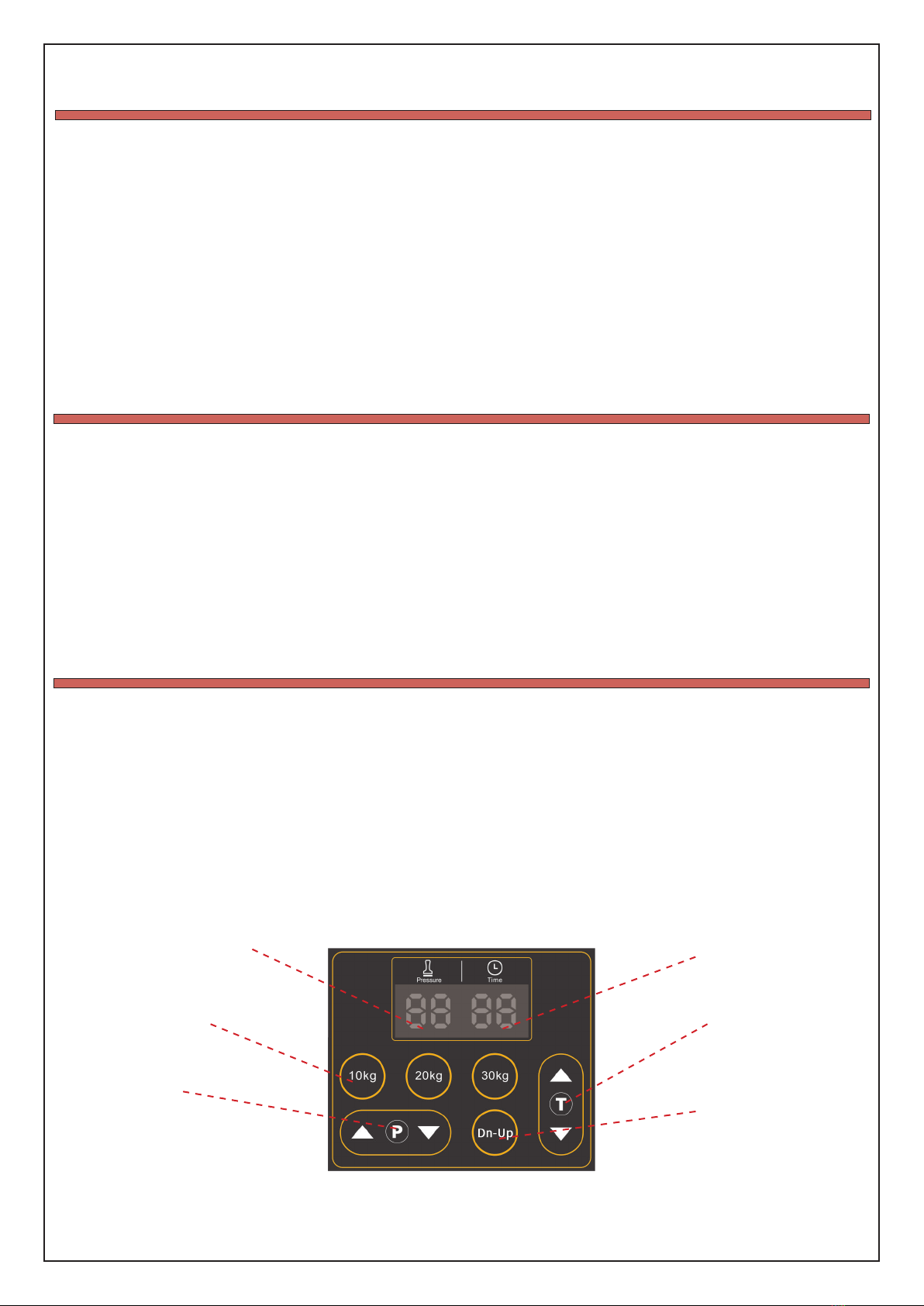

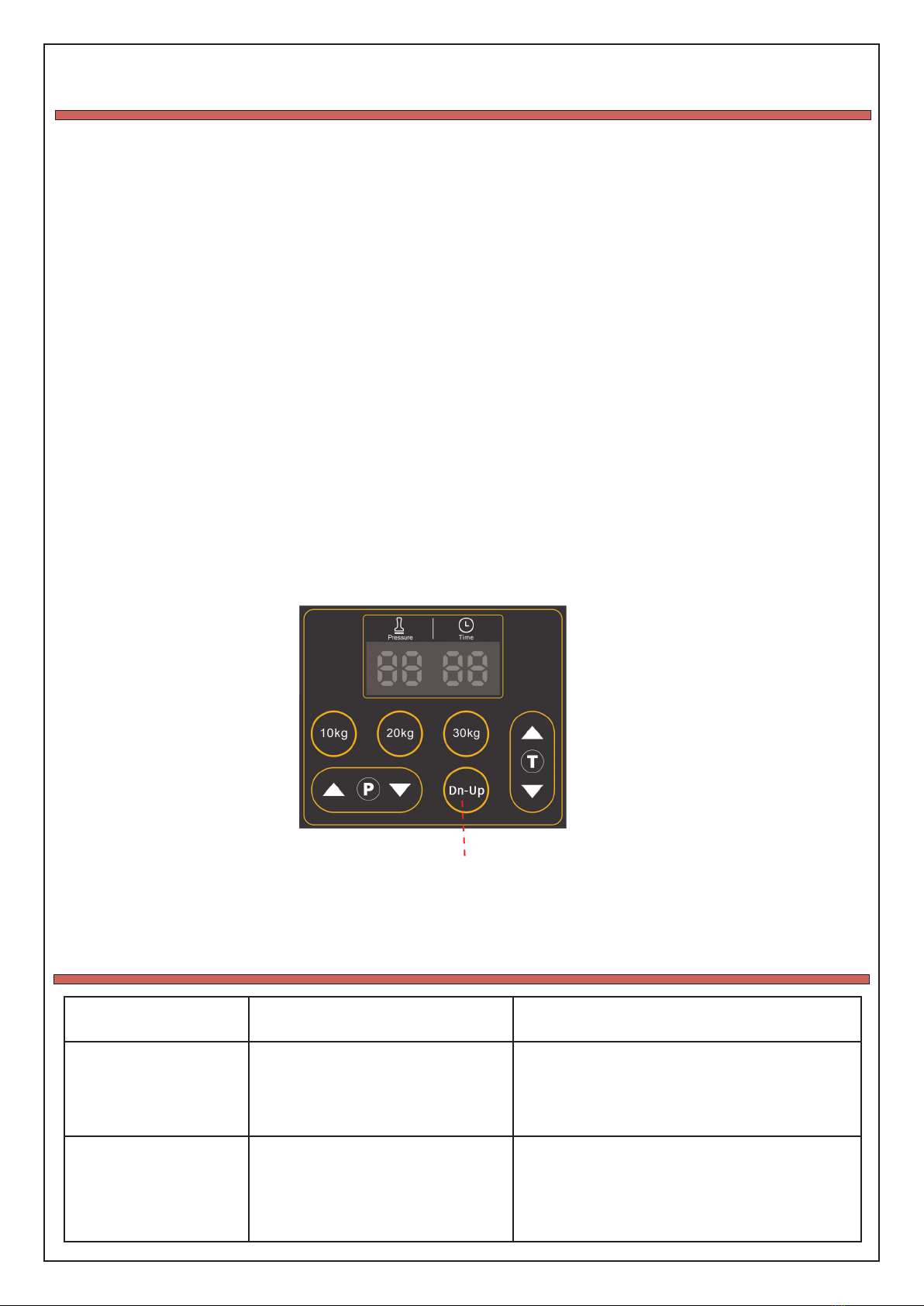

5# PRESSURE ADJUSTMENTS

1. Quick access to preset pressures (10kg, 20kg, 30kg)

2. Precise +/- 1kg Up or Down increments to achieve desired pressure.

3. Quick Press and Hold the DN-UP button to save the programmed values.

4. Multi Tamping Feature for 1, 2, 3 cycles

Multi Tamp Display

Multi Tamp Adjustment

Conrm / Save

Pressures & Times

Pressure(kg)

Preset Pressures

1kg +/- Adjustments

6# CLEAN MODE

Performing a clean of the Tamper Disk can be done anytime during service

and should be performed as a daily cleaning routine to brush o the residual

buildup of coee nes and oils to help ensure clean tamping for best avour

and espresso quality.

Follow these steps:

1. Press and hold the Dn-Up button for 5 seconds to access the Cleaning

Mode.

2. Clean the Tamper disk with a brush. Do not clean it with your ngers.

3. Press and hold the Dn-Up button for 5 seconds to return it up into its

original position.

Note *Cleaning Mode also allows the access needed to change the Tamper

Disk to a different diameter to suit other espresso machine brands. Your

local distributor will stock the dierent sizes.

Press and hold to entre Cleaning Mode.

COMMON ERRORS

Issues / Errors Potential Reasons Potential Solution

Coee nes and

oils sticking to the

tamper head

Tamper disk is wet, or has not

been cleaned regularly causing

further buildup

Perform the cleaning mode outlined in

Point 6. In this user guide

Machine not working

/ No illumination of

touchpad icons

Check power cord and power

adaptor

Check connection between wall

PowerPoint and Transformer Adaptor

and check connection from Transformer

Adaptor into the rear of the machine

Coee bed is uneven Portalter support fork is not

level

Perform Portalter Support alignment in

Point 1. In this user guide

Tamper Disk does not

fully extend

Cleaning Mode is on or the

Portalter support is not level

Cancel the Cleaning Mode or perform

Portalter realignment in Point 1. in this

user guide

Note * If issues persist please contact your supplier for after sales service and technical

support.

TECHNICAL SERVICE AND SUPPORT

WARRANTY

SPARE PARTS

• When or if you require after-sales service, please turn the power off, clean the

machine, and call your place of purchase.

• Any service or repair should be carried out by an authorized service dealer.

• Do not attempt to repair it yourself in case of electrical fault.

Please contact your CinoArt supplier / distributor if you require a different diameter

Tamper Disk for your espresso machine brand to the standard 58.3mm Portafilter

basket.

All Spare Parts in general can be ordered from your supplier / distributor.

Do not attempt to repair it yourself in case of electrical fault.

1. The warranty period is for one year from the date of purchase.

2. CinoArt warranties any defective or faulty components within the rst 12 months

from the date of purchase. Fair and reasonable use under normal wear and tear

environment conditions will always be considered.

3. The warranty conditions do not cover damages caused by incorrect installation

improper use, improper cleaning and maintenance.

4. Warranty does not cover damage caused from using non-genuine replacement parts.

5. Warranty does not cover general maintenance and or labor costs associated with

replacement spare parts.

Shenzhen Meshining Technology Co.Ltd

sales@cinoart.com

CN: www.cinoart.com

EN: www.beqsx.com

Room 302, Building 9, Xinwei Industrial Area, Xili, Nanshan, Shenzhen, China.

Table of contents