Circul-Air C612 User manual

INSTALL & USE GUIDE 2023

CIRCUL-AIR CABINET DRYERS

208 & 240 V DRYERS, 1PH & 3PH North America

120 V DRYERS, 1PH North America

For models:

C612, C613, C633, C634

E612, E613, E633, E634

D612, D613, D633, D634

V511

REV 1, 2023

Email: circulair@circul-air-corp.com

Web: www.circul-air-corp.com

1-800-795-1150

SAFETY

WARNING

DISCONNECT POWER TO DRYING CABINET BEFORE SERVICING TO

PREVENT ELECTRICAL SHOCK OR BODILY INJURY

1. THIS MACHINE MUST HAVE A PROPER DUCT COVER OR VENTING IN PLACE BEFORE OPERATION.

FAILURE TO DO SO CAN RESULT IN INJURY OR PROPERTY DAMAGE.

2. THIS MACHINE MUST BE PROPERLY WIRED TO LOCAL, STATE / PROVINCE OR FEDERAL CODE BY A

COMPETENT ELECTRICIAN. A LOCAL, INDEPENDANT DISCONNECT PROPERLY SIZED FOR THE

EQUIPMENT IS RECOMMENDED FOR SAFE OPERATION. FAILURE TO FOLLOW THESE

INSTRUCTIONS MAY RESULT IN INJURY OR PROPERTY DAMAGE.

3. NEVER DRY EQUIPMENT WHICH HAS FLAMMABLE MATERIALS (OILS, FUEL ETC) IN THIS CABINET.

4. DO NOT OPERATE THE EQUIPMENT FOR PROLONGED PERIODS OF TIME WITH THE DOORS OPEN.

THIS WILL STALL THE AIRFLOW AND MAY RESULT IN DAMAGE OF THE HEATING ELEMENTS,

PERSONAL INJURY DUE TO BURNS OR PROPERTY DAMAGE.

MACHINE SPECIFICATIONS:

Model

PPE-2

PPE-4

PPE-6

PPE-6XL

Shipping Dimensions:

(Width x Depth x Height)

46” x 40” x 90”

46” x 56” x 90”

46” x 60” x 90”

60” x 64” x 90”

Shipping Weight:

615 lb

775 lb

875 lb

1175 lb

Cabinet Dimensions Closed: (Width x

Depth x Height) *

32.5” x 37” x 84”

47” x 33.9” x 81”

55” x 37.25” x 83”

48.5” x 55” x 81”

Door Depth @ 90: (Depth)

67”

60”

63”

80”

Width Clearance @ 120: (Width) **

39”

62”

73”

78”

Min Oset from rear wall

5

10

10

10

Min Oset from side wall

5

6

6

6

PERFORMANCE

Airow, Negave Pressure Axial:

600 CFM

900 CFM

900 CFM

900 CFM

Heang @ 240V, 1PH:

1500W

6000W

6000W

6000W

ELECTRICAL OPTIONS ***

240/1/60

NA

C612

E612

D612

208/1/60

NA

C613

E613

D613

240/3/60

NA

C633

E633

D633

208/3/60

NA

C634

E634

D634

120/1/60

V511

NA

NA

NA

CONSTRUCTION AND ACCESSORIES

Standard Finish:

Powder coat CAC

Grey, Galvanized

Powder coat CAC

RED, Galvanized

Powder coat CAC

Grey, Galvanized

Powder coat CAC

Grey, Galvanized

Grid Posions:

4

4

4

15

Standard Hose / Gear Grid:

3

2

3

10

Standard Boot / Gear Grid

1

2

1

0

Boot / Glove Hangers (CAC-BGH):

2

6

6

6

Gear Hangers (CAC-GH):

2

6

6

6

105F Max Temperature Control:

YES

YES

YES

YES

* This includes the door handle clearance

** This is the minimum opening required to remove the shelves from the unit.

*** Refer to electrical installaon for minimum amp service and wire requirements

ELECTRICAL CONNECTIONS:

Circul-Air cabinets are designed for simple electrical installaon. Follow this secon for preparing for and

connecng your cabinet to the building service.

PPE-2 Cabinet:

This cabinet comes equipped with an 8’ grounded power cord,

connected with a stain relief at the back of the cabinet. A 20A

standard recepcle is recommended for use, however a 15A outlet

will be sucient in most applicaons.

Ensure the strain relief is secure and that the cable is not under

tension when in use.

CAUTION

The prolonged use of an extension cord is not recommended.

PPE-4, PPE-6 and PPE-6XL Cabinets:

These larger cabinets come equipped with an electrical

connecon box at the top, rear le of the machine when

viewed from the rear of the equipment. A standard 1-

1/8” port suitable for a ¾” exible conduit ng is

provided to connect the equipment to the wall disconnect

(by customer).

Depending on the electrical conguraon chosen, the

customer will need to pull a sucient quanty and size of

wire to the equipment.

Connecon is at a marked locaon (L1/L2/L3/N/GND) and

is determined by the model chosen.

240 TYPICAL

208 TYPICAL

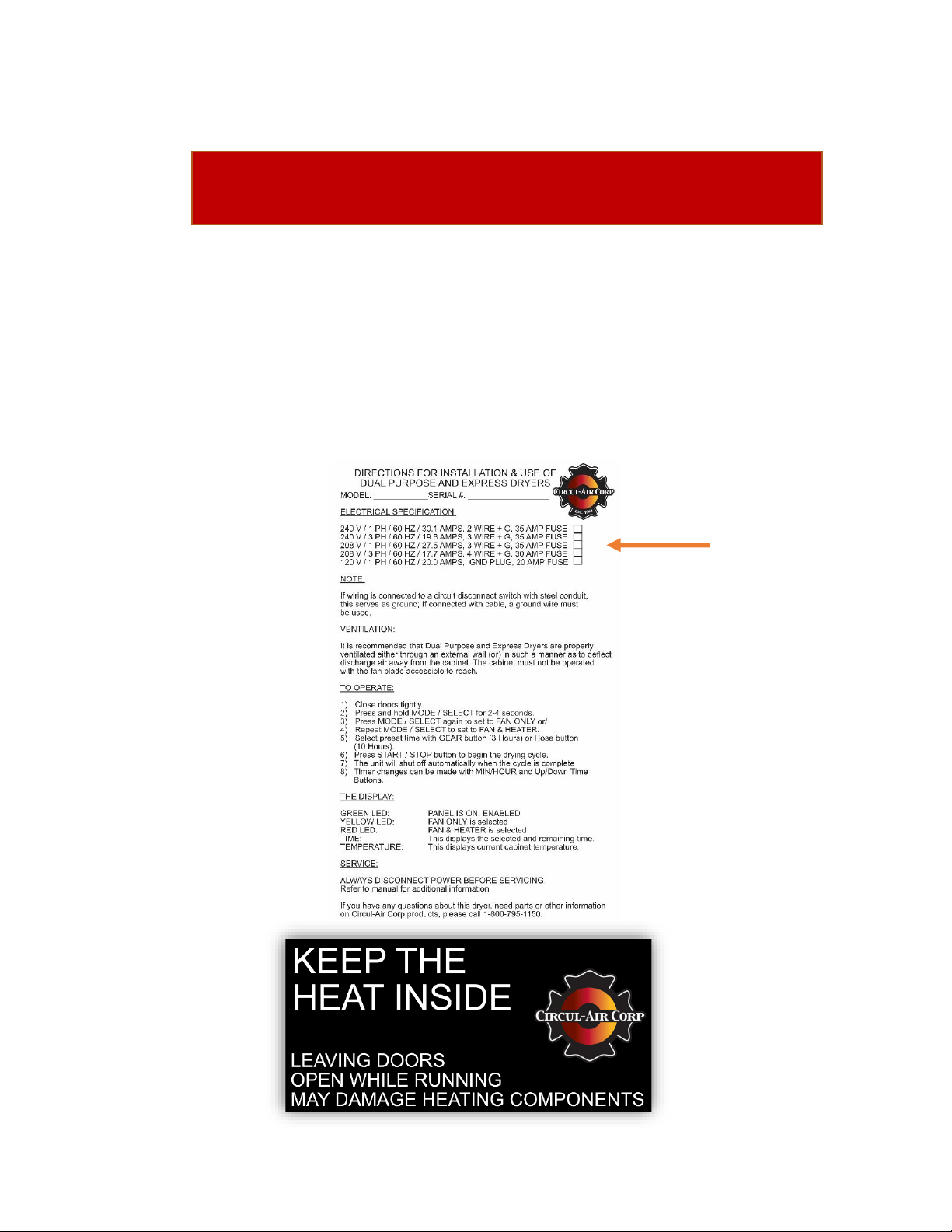

Machine Placard:

Each dryer has a placard inside the door which provides informaon on the machine

construcon as well as basic use. Key pieces of informaon to know are the model, serial # and

electrical conguraon. The fuse size noted is the wall disconnect sizing. Local electrical codes

take priority in sizing the disconnect.

ONLY CONNECT SUPPLY TO L1, L2, L3, N AND GND.

NEVER CONNECT TO THE INTERNAL TRANSFORMERS.

DUCTING & VENTILATION:

Circul-Air cabinets are negavely pressured, axial ow cabinets which means that the fan is connuously

evacuang high volumes of internal air from the cabinet. These cabinets require some backpressure to

work most eecvely, and for best drying the damp air should be removed from the area of the cabinet.

Recommended:

It is recommended that all cabinets are

ducted with a 10” or 12” diameter

duct, completely out of the room

where the unit is located to ensure

that the unit is not recycling the humid

air being removed form the cabinet.

Duct sizes smaller than 8” in diameter

are not recommended.

Oponal:

PPE-2 cabinets ship from the factory with a sloed guard which protects the operator and

establishes backpressure. It can be operated with this guard.

EVI-4, PPE-6 and PPE-6XL cabinets can be equipped with a deecon duct which steers the damp

air away from the cabinet. This soluon is best used in large spaces such as apparatus bays or

well-venlated rooms. These 10” or 12” ducts include a reducing collar, a short vercal duct, an

adjustable angle and a second straight secon. Fastened to the roof of the equipment this

establishes the necessary backpressure as well as protects the operator.

Some applicaons may also benet from an inline manual damper

which can be used to trim (or increase the backpressure) to account

for local condions such as proximity to sea level or cold humid

condions.

Complex installaons such as in high use hose drying may incorporate

2 or more cabinets and may incorporate building HVAC return ducts. In

this case interlocked dampers may be used to prevent backow of air

into cabinets not in use. A remote contactor is recommended and may

be ed to terminal “6” in the cabinet, 120V signal to me to the

operaon of the cabinet fan motor.

Other recommendaons:

•When passing through cold spaces the ducng must be insulated to prevent

condensaon.

•Use the maximum duct size available and reduce turns or angles when possible.

•Ensure external penetraons have a pest guard or rain hat to prevent ingress of pests,

water or debris.

•Limit duct runs to 15’-20’ or less. If duct runs need to exceed 15’-20’ an inline booster

may be required (by customer). These need to be at least 10” in diameter and supply at

least 700 cfm of airow. A remote contactor is recommended and may be ed to

terminal “6” in the cabinet, 120V signal to me to the operaon of the cabinet fan

motor.

Adjusng Back Pressure for Temperatures in Wet Climates

In some damp sea level condions, the cabinet may require addional backpressure to ‘trim’ the

performance of the heang system. The following process may be ulized.

1. Set adjustable damper or louver spring to open or no restricon.

2. Record ambient temperature on machine in fan only mode.

3. Turn on dryer and run for 15 minutes. Record temperature achieved empty. It should be

15 to 20 F over ambient.

4. Cool machine in fan mode 5-10 mins.

5. Adjust damper to 75% open.

6. Repeat test.

7. Adjust unl result is 15-20 F from ambient.

If more than 50% reducon is required, contact your Circul-Air Corp service department for

assistance.

LEVELING THE CABINET

Each drying cabinet has (4) leveling feet which can be accessed from inside the cabinet or from

underneath. Inside adjustment requires a large, sloed screwdriver, while adjustment from beneath may

require a larger adjustable wrench. Typically, these can be adjusted by hand.

Equipment is shipped with the feet fully retracted. If a foot pad is not touching, turn down unl just in

contact with the oor.

Adjusng Door Squareness for Single or Two Door Cabinets

1. Ensure the cabinet is level with the feet as retracted as possible.

2. Observe the alignment; if the le door is low, adjust the right foot and vice versa.

3. Open the doors rst.

4. While an assistant pushes up on the center of the door, adjust the appropriate front le

or front right foot. Have the assistant let the cabinet sele down, carefully close the

doors and check alignment.

Note: Use minimal adjustments to correct the leveling. 2-3 turns are more than sucient to adjust the

door squareness.

CABINET OPERATION

Each cabinet comes with a simple to operate NFPA 1851 compliant mer panel. The operator can select

the duraon of the drying desired and whether to opt for heated or ambient air to dry the equipment.

The mer displays the remaining drying me and the current temperature inside the cabinet.

The operator cannot increase the maximum temperature. Circul-Air cabinets are designed to heat the

incoming air above ambient to promote the release of water from the equipment (PPE & Hose). For PPE-

2 cabinets this is 10-15F and for the larger cabinets this is 15-25F depending on the local condions.

The cabinet will ensure that the heat is disabled once the airow reaches 105F to remain compliant.

Standard Circul-Air Cabinet Timer

Control Panel Buon

Acon

Result

HOLD 3-5s to turn on controls

Press 1x for FAN

Press 2x for FAN & HEATER

On Enable Green LED

Fan On Yellow LED

Fan & Heater Red LED

Press GEAR for 3:00 preset

Press HOSE for 10:00 preset

Sets Time to 3:00

Sets Time to 10:00

Press 1x to start cycle

Press 1x to stop cycle

Starts drying cycle

Stops drying cycle, sets me to 0:00

Hold to set custom me.

Press to switch between hr /

min

Tim e Blinks 0:__ or __:00

Press to increase or decrease

me

UP Arrow, increase value +1

Down Arrow, decrease value - 1

PREPARING EQUIPMENT (PPE, HOSE AND OTHER GEAR)

The proper decontaminaon of PPE equipment (aka bunker gear, turnout gear, re protecon gear)

requires the use of an NFPA 1851 compliant extractor which has been properly congured. This includes

disassembly of the gear, pre-treatment if required and a cleaning cycle with a spin speed of less than

100g, maximum 105F water and NPFA compliant cleaning chemicals.

Informaon on Circul-Air Corp’s complete line of Express and Heavy Duty extractors, recommended

Citro-Squeeze and SC-14 cleaning chemicals can be obtained at www.circul-air-corp.com, sales@circul-

air-corp.com or by contacng your local distributor of Circul-Air products.

Equipment that has been processed correctly should be disassembled into its base components, liners

and shells. Typical drying mes of shells components will be 1.25 – 2 hrs. Drying mes of lines can vary

between manufacturers, however this should take between 3-3.5 hrs for standard products and 3.5 – 4.5

hrs for heavier fabrics and quilng.

Each cabinet has a rigid aluminum bar to support the gear, ensuring

that the gear can be evenly distributed in the cabinet. Excessively

loading the cabinet will increase dry me.

Boots can also be dried in the small cabinets by inserng them tops

down in the supplied wire shelves. (Not applicable for 6XL cabinet).

Helmet holders are available for placing helmets on the grid.

Hoods, gloves and other loose equipment can also be spread on

the grids to aid in drying when the hangers are not appropriate.

Hose with diameters up to 5” can be dried in the cabinet. Ensure that the

water inside has been drained and then loosely spool the hose on the

provided shelves, allowing room for air to pass through the coils. Hose

will typically take between 10-12 hrs to dry in normal operang

condions. Informaon on Circul-Air Corp’s Roto-Jet hose washers is

available to aid in pre-cleaning hoses from 1-3/4 – 5” diameter can be

obtained at www.circul-air-corp.com, sales@circul-air-corp.com or by

contacng your local distributor of Circul-Air products.

PPE-2 Troubleshoong

No Heat / Low Heat

Does the temperature rise in 5-10

min when in heat mode, empty.

No rise - verify contactor is pulling

in, check the snap disc connuity.

Some rise - one or more element

may have failed. Compare ohm

reading with value on element.

No Control Panel Display

Will the panel come on with mode

buon held for 3-5 seconds?

No - remove front mer and check

le breaker for amperage trip.

Yes, but promptly turns o when

cycle started

Short in onboard component - call

service

No Fan

Does unit start and then stop?

Check for obstrucon in fan blades

Does the unit fail to start?

Remove front mer and check right

breaker for amperage trip.

Is the panel damaged or worn

Inspect for buon resistance, call

service

Long Dry Time

Conrm the clothing is properly

separated and extractor is

funconing correctly.

Ensure gear is separated, not

excessively loaded and hung

properly.

Is the operang condion close to

sea level or high humidity, low

temp?

Trim the outlet cover by restricng

25% of outlet and retesng.

Is the plenum (oor plate) installed

and unobstructed?

Verify to ensure proper airow

through boom of cabinet.

Is the outlet ducted or have a safety

cover?

Lack of back pressure can increase

dry me.

PPE-4, PPE-6, PPE-6XL

240V – Breaker 1 or 2 tripped

Is the trip instantaneous or

intermient?

Intermient - shared circuit drawing

down voltage, tripping amperage

on 240/120 transformer.

Instantaneous – 240 Leg to staon

dropped or failing.

Instantaneous – 208 supply to 240

panel. Check if leg 1 = 120V or

240V. Should be 240.

240V or 208V breaker 3 tripped

Is the breaker next to Terminal 6

tripped? No power to control panel.

Incorrect # of wires for 208 system

– call service for opons.

Intermient Overload – check for

other equipment on dedicated

circuit.

Shortage – check for loose wires in

panel.

Electrical surge - lightning strikes,

grid surges or drops can cause this

breaker to protect equipment.

Reset.

240V or 208 breaker 4 tripped

Is the breaker on the end of the rail

tripped?

Motor over amperage - check for

obstrucon.

Motor wire issue – check for loose

wire.

Failed motor – call service.

Secondary draw on terminal 6.

Check connected blowers or

dampers for short.

No Heat / Low Heat

Does the temperature rise in 15-25

min when in heat mode, empty.

No rise - verify contactor is pulling

in, check the snap disc connuity.

Some rise - one or more element

may have failed. Compare ohm

reading with value on element.

No Control Panel Display

Will the panel come on with mode

buon held for 3-5 seconds?

No - open top of control panel and

check breaker beside terminal 6

breaker for amperage trip.

Check breaker 1 and 2 beside

terminal 1 for amperage trip.

Yes, but promptly turns o when

cycle started

Short in onboard component - call

service

No Fan

Does unit start and then stop?

Check for obstrucon in fan blades

Does the unit fail to start?

Remove top of control panel and

check right breaker for amperage

trip.

Is the panel damaged or worn

Inspect for buon resistance, call

service

Long Dry Time

Conrm the clothing is properly

separated and extractor is

funconing correctly.

Ensure gear is separated, not

excessively loaded and hung

properly.

Is the operang condion close to

sea level or high humidity, low

temp?

Trim the outlet cover by restricng

25% of outlet and retesng.

Is the plenum (oor plate) installed

and unobstructed?

Verify to ensure proper airow

through boom of cabinet.

Is the outlet ducted or have a safety

cover?

Lack of back pressure can increase

dry me.

CIRCUL-AIR CORP. WARRANTY CLAIMS

The Circul-Air Corporaon (hereaer referred to

as CAC) warrants THIS product to be free of

defects in material and workmanship for Ten

(10) years from the date of shipment from the

factory. CAC shall only be liable under this

warranty if the product is installed properly and

used according to the direcons furnished by the

CAC.

The Basic Product Warranty is a “PARTS ONLY”

warranty and CAC’s obligaon shall be limited

to the replacement of new parts of the products

for those returned to CAC undamaged at the

purchaser’s expense and found to be defecve

by CAC. CAC will then repair or replace, at its

opon any such part determined to be defecve

during this warranty period. Replacement parts

will be shipped F.O.B. CAC’s facility. CAC is not

responsible for damages during transport of any

product to or from CAC. Replacement of parts

shall not extend the original warranty period of

the original total product, including any

replacement parts supplied.

This Standard warranty does not cover

corrosion; normal deterioraon; misapplicaon;

improper installaon; labor charges paid for

parts replacement, adjustments, repairs or other

work supplied by others; defects in parts

resulng from neglect, negligence, accident,

re, explosion, high or low voltage, jumpering or

jamming controls, shorng out of components;

improper voltage; or any acts of nature.

This warranty does not cover failure of the

purchaser to provide normal recommended

maintenance, adjustments, cleaning or service

on the CAC equipment; improper repairs or

alteraons; or misapplicaon of the equipment.

It is expressly understood that this warranty is

made IN LIEU OF ALL OTHER WARRANTIES,

EXPRESSED OR IMPLIED, WHETHER ARISING

FROM STATUTE, COMMON LAW, CUSTOM, OR

OTHERWISE, INCLUDING WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR ANY

PARTICULAR PURPOSE, QUALITY, DESIGN,

CONDITION, DURABILITY OR SUITABILITY, and in

consideraon of the express warranty herein

contained, BUYER EXPRESSLY WAIVES ANY

RIGHT TO CLAIM OTHER WARRANTIES,

EXPRESSED OR IMPLIED.

It is further understood that CAC’s liability for

breach of warranty shall be limited to terms of

this warranty and buyer agrees that CAC SHALL

NOT, IN ANY EVENT, BE LIABLE FOR SPECIAL,

INDIRECT, OR CONSEQUENTIAL DAMAGES, OR

DELAY. The buyer’s remedies are exclusive, and

shall be limited to those provided herein.

CAC neither assumes and does not authorize any

person to assume any obligaon or warranty

other than those stated herein.

Any suggeson to the contrary notwithstanding,

CAC shall not, in any event, have any liability

under this warranty unless and unl it has been

paid in full for the products. The warranty

period shall begin as described above, whether

or not payment has been made.

Defecve material may be repaired or replaced

at our opon. If replaced, full credit will be

issued in the amount of the original purchase

price if returned undamaged within 30 Days of

shipment, for the returned material; in the

event the material is found to be not defecve,

or to be damaged or abused, we reserve the

right to return the material “as is” to the sender

and at his freight cost. If CAC agrees to keep

such material, credit will be issued minus the

cost of repair and recondioning, the return and

less restocking charges.

Otherwise only cost of the part will be covered

by our warranty. But if the part(s) CAC has sent

are not the problem please reinstall the old part

and return within 30 Days of shipment the new

unused part back to CAC, we will then aer

inspecng the part to insure it is sll in good

working order will return the new unused

part(s) to inventory and issue credit. Old parts

returned to us that are in good working

condion or aer the 30 Day period will be

charged to you and not covered by warranty. It

is important to remember that in order for our

warranty to cover the cost of the new part you

must return the faulty part to us within 30 days

to receive credit. Then aer CAC receives the

part we must conrm that the returned part is

actually faulty before issuing credit. When

returning the faulty part, please reference the

Return Merchandise Authorizaon number

(Known as the RMA number). Be sure to

adequately package the part to be shipped back

to CAC to prevent it from being damaged during

shipment. You will not receive credit for parts

received at CAC that are damaged and cannot

be returned to the part manufacturer for credit.

Also please provide a small descripon as to

what is wrong with the part that is being

returned under warranty:

Reminder: Our warranty only covers the cost of

the faulty part and MUST be returned within 30

days from the me of shipment from the factory

to receive credit. You are responsible for any

other expenses you incur, including freight

charges, miscellaneous parts and the labor to

install the part(s).

Warranty DOES NOT cover the following Items:

1. A maintenance items. 2. Normal wear,

adjustments, and periodic service. 3. Damage

caused by accidents, improper installaon or

handling, or faulty repairs. 4. Damage caused by

operaon of the unit at improper voltage loads,

condions, modicaons, or installaon

contrary to published specicaons or

recommendaons. 5. Damage caused by

negligent maintenance such as: a. Breakage due

to mishandling or misuse of the product or part.

b. Failure to follow and perform scheduled

maintenance as prescribed in supplied manuals.

6. Parts purchased from sources other than CAC,

Replacement of a failed CAC part with a non-

CAC part voids warranty on that part. (Unless

prior wrien authorizaon has been given by

CAC for you to do so.) 7. Warranty Labor.

REPLACEMENT PARTS

When wring or calling to Circul-Air Corporaon

for service parts, provide the model number

and serial number of the unit as stamped on the

unit plate aached to the unit. If replacement

parts are required, include the date of

installaon, the date of failure, an explanaon

of the malfuncon, and a descripon or part

number of the replacement parts required.

This manual suits for next models

11

Table of contents

Popular Dryer manuals by other brands

Maytag

Maytag YMEDB755DW1 Use & care guide

Air Wolf

Air Wolf A Series manual

Siemens

Siemens WQ55A2D80W User manual and installation instructions

Fisher & Paykel

Fisher & Paykel AeroSmart Series Installation instructions and user guide

Zanussi

Zanussi TDS333E Instruction booklet

Maytag

Maytag MED6000X installation instructions

Hotpoint

Hotpoint HTDP120EDWW use and care manual

LG

LG TD-H803CSW owner's manual

GE

GE GTDL200EM1WW installation instructions

Fisher & Paykel

Fisher & Paykel AeroSmart DG27C Installation instructions and user guide

Alliance Laundry Systems

Alliance Laundry Systems continuity Installation and operation

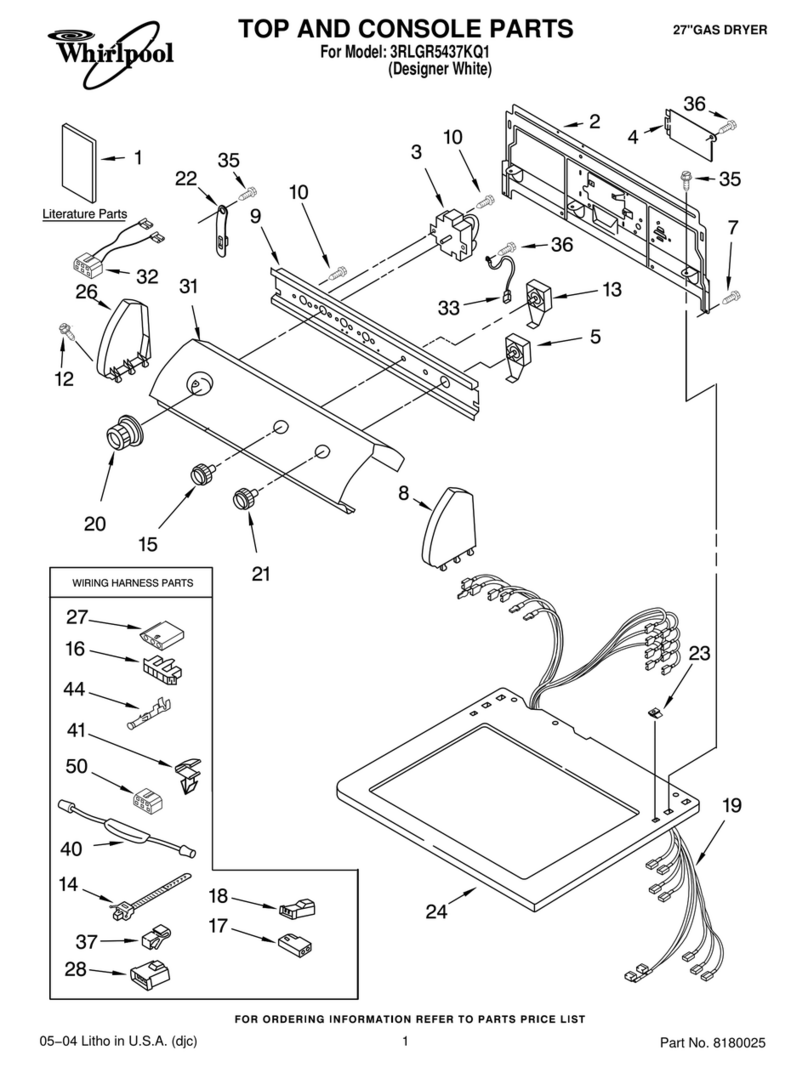

Whirlpool

Whirlpool 3RLGR5437KQ1 parts list