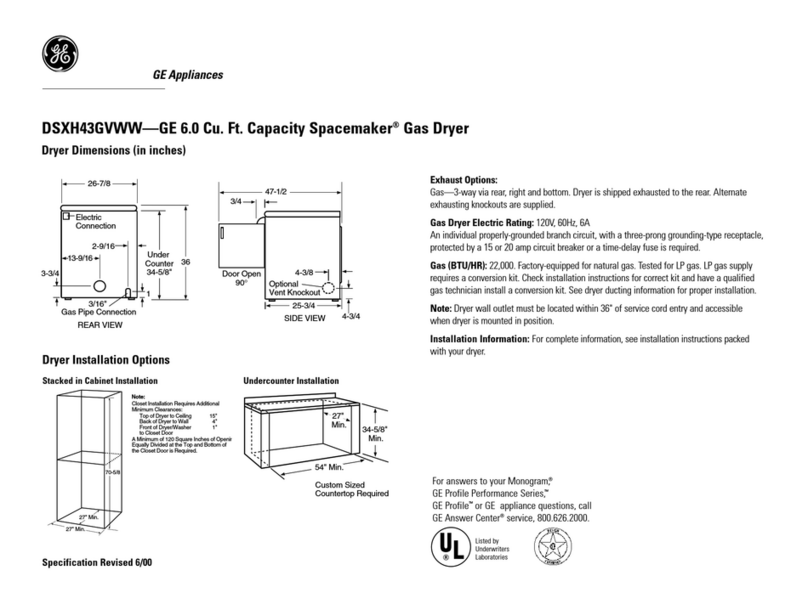

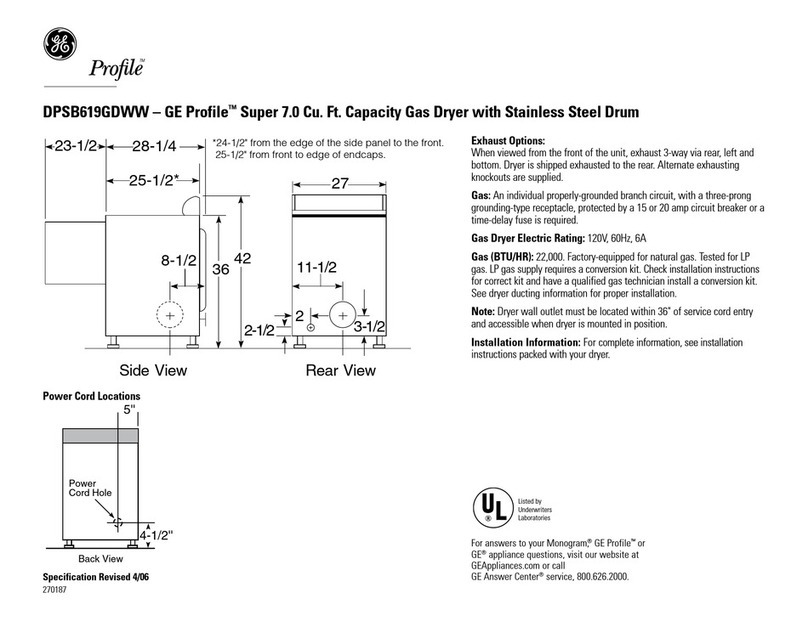

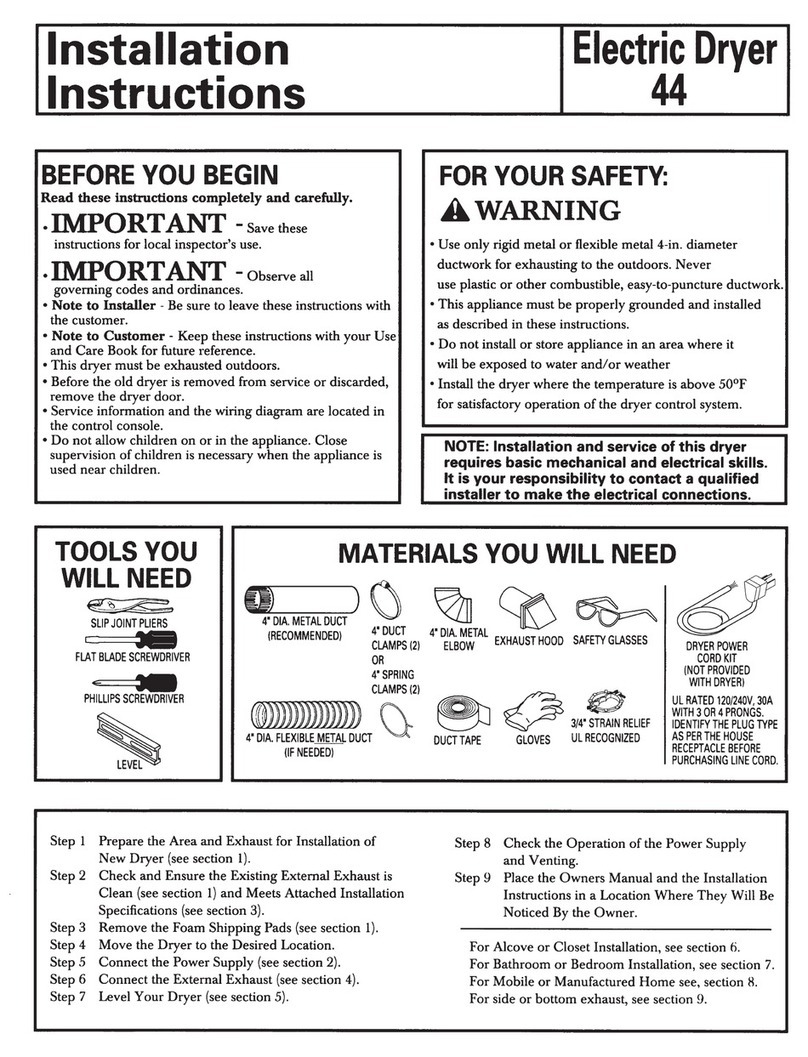

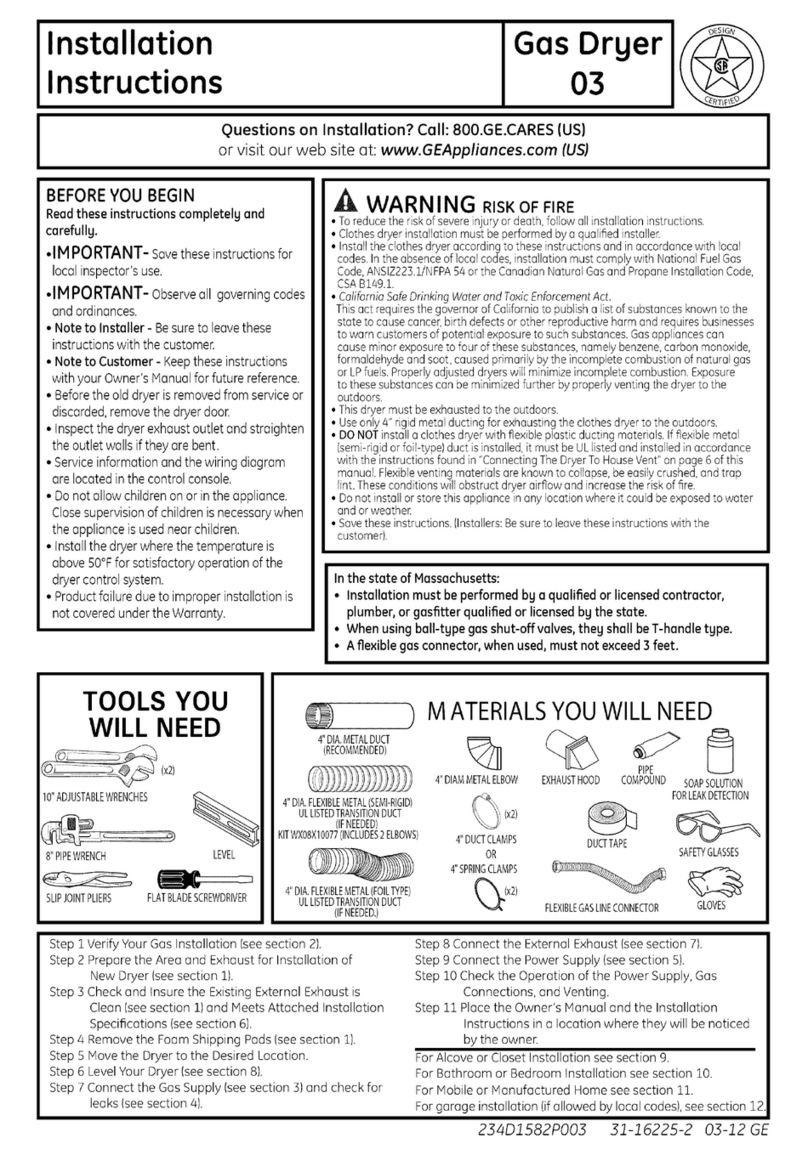

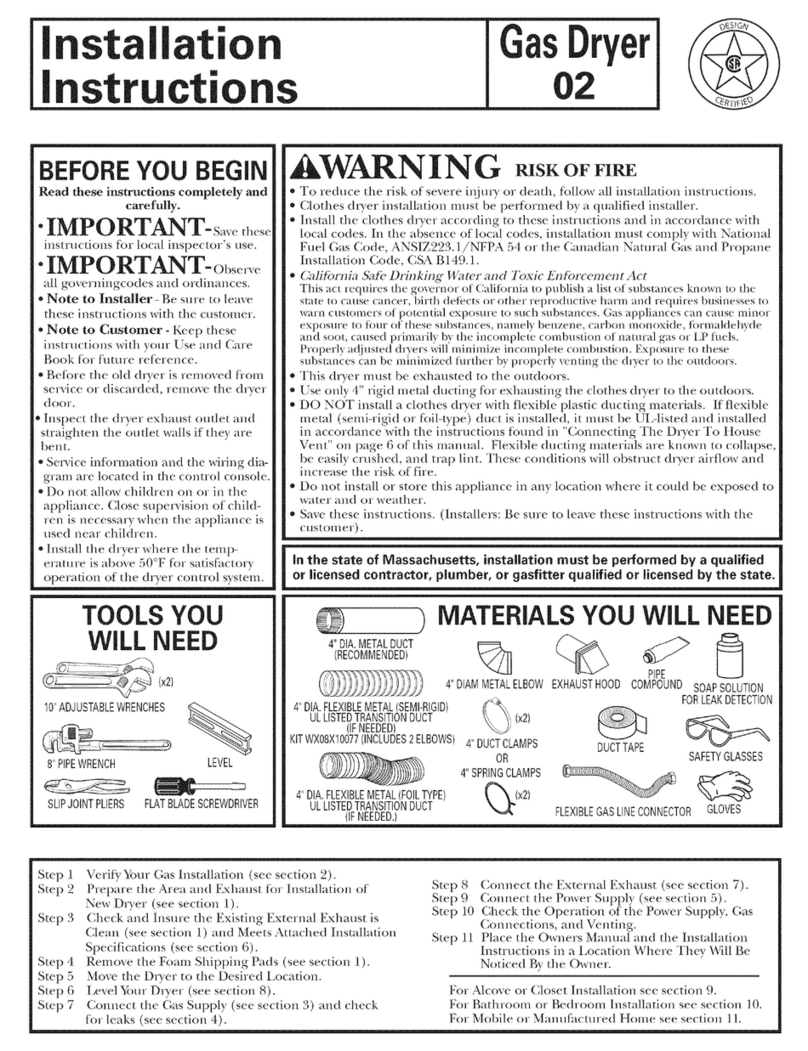

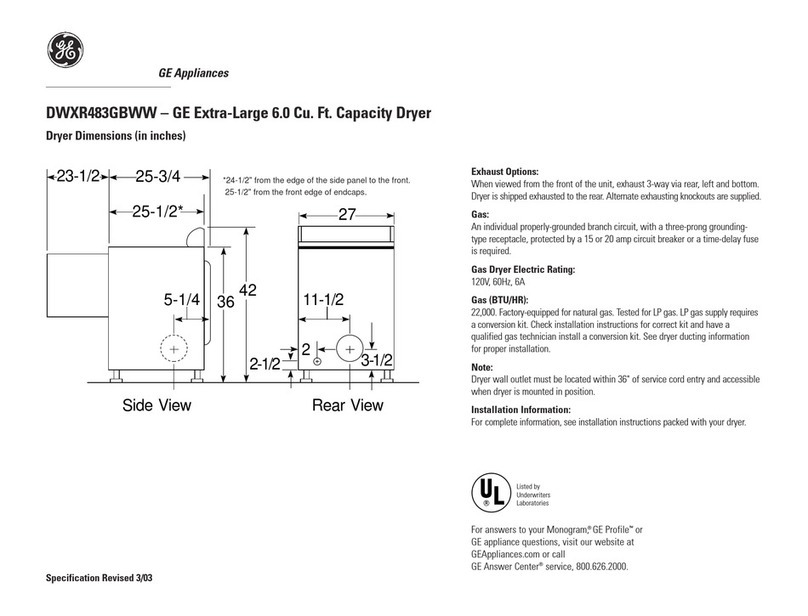

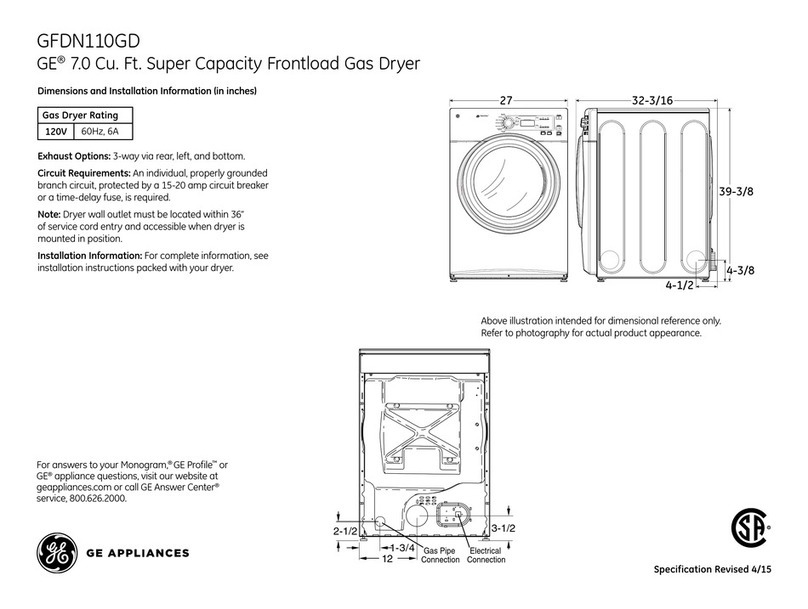

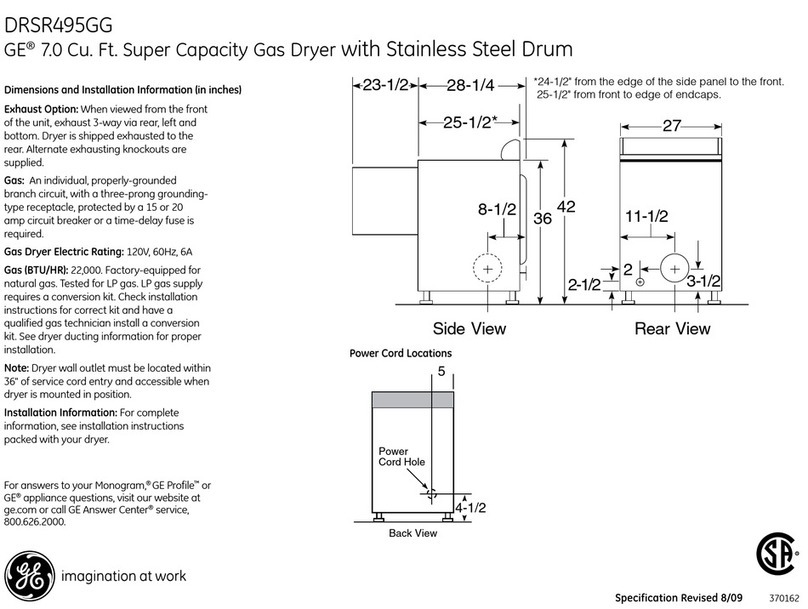

Installation Instructions

Minimum Clearance Other Than Alcove or Closet Installation

Minimum clearance to combustible surfaces and for air opening are: 0 in.clearance both sides and i in. rear.Consideration

must be given to provide adequate clearance for installation and service.

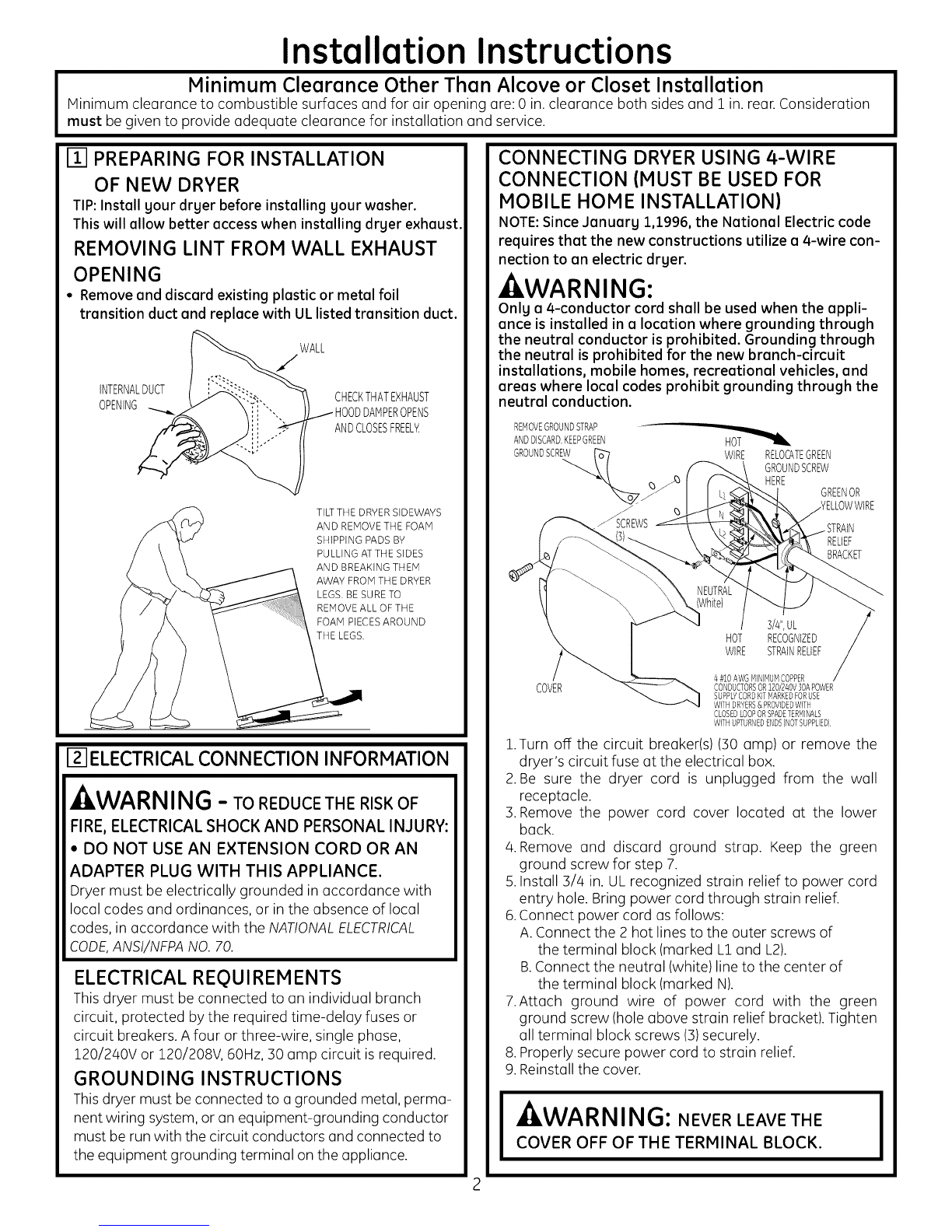

[] PREPARING FOR INSTALLATION

OF NEW DRYER

TIP:Install your dryer before installing your washer.

This will allow better access when installing dryer exhaust.

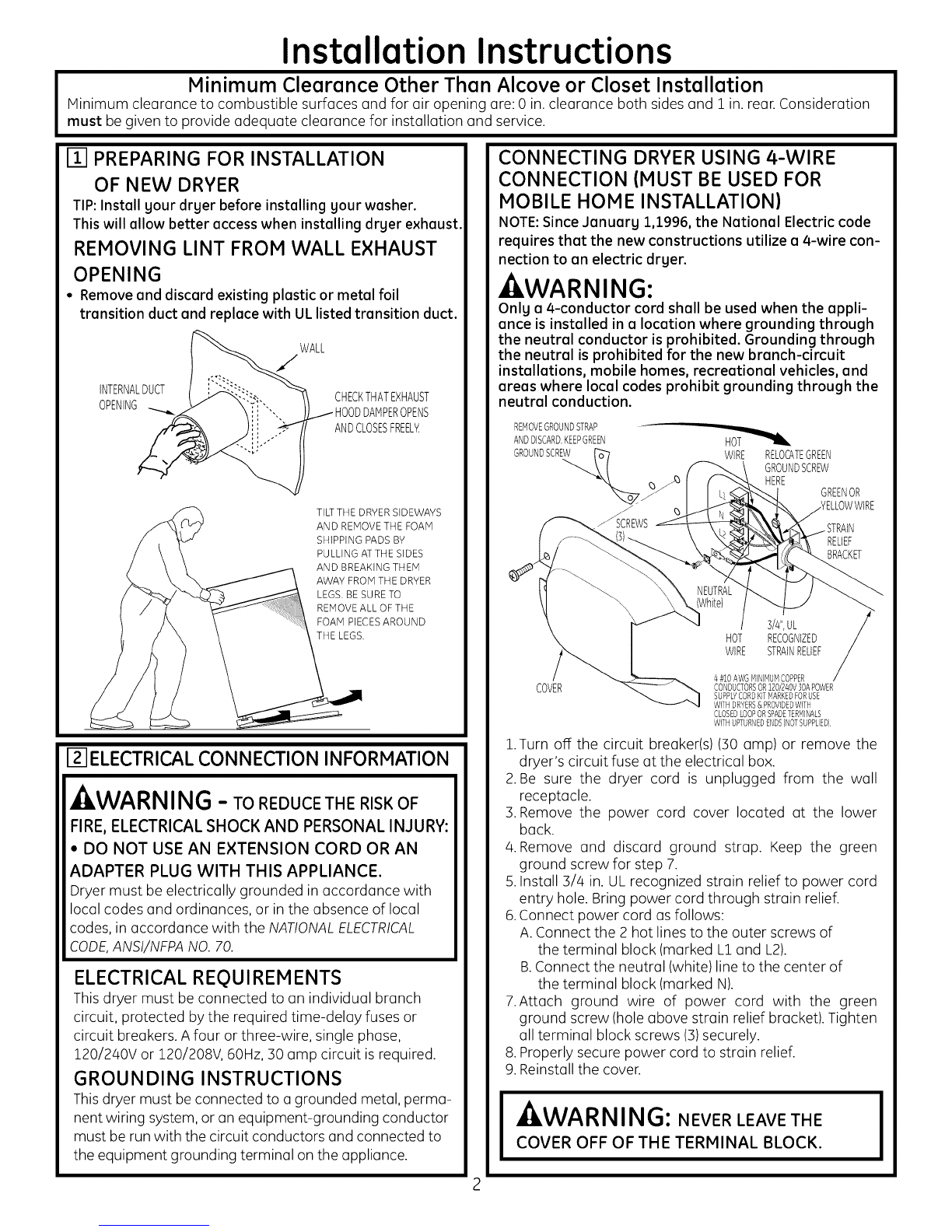

REMOVING LINT FROM WALL EXHAUST

OPENING

• Remove and discard existing plastic or metal foil

transition duct and replace with UL listed transition duct.

WALL

INTERNALDUCT CHECKTHATEXHAUST

OPENING OPENS

ANDCLOSESFREELY.

TILTTHE DRYER SIDEWAYS

AND REMOVE THE FOAM

SHIPPING PADS BY

PULLING ATTHE SIDES

AND BREAKING THEM

AWAY FROM THE DRYER

LEGS.BE SURE TO

REMOVE ALL OF THE

FOAM PIECES AROUND

THE LEGS.

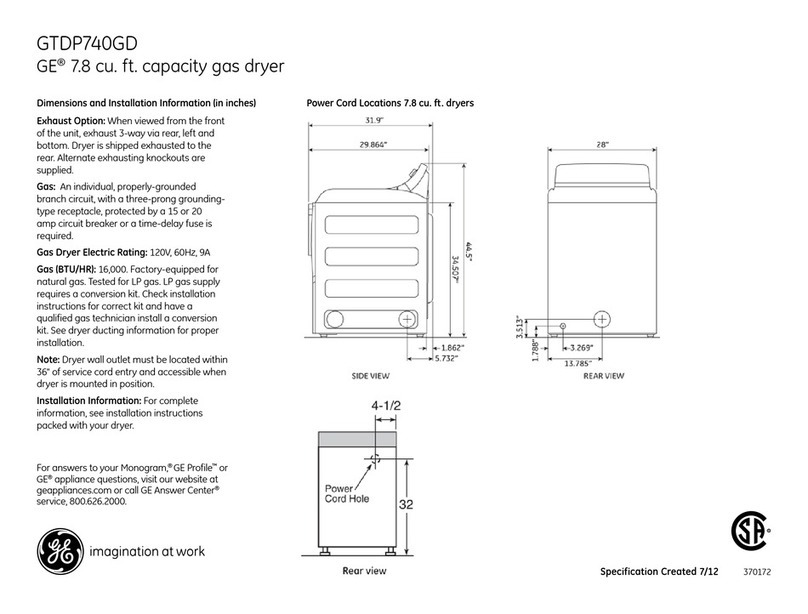

12-1ELECTRICALCONNECTION INFORMATION

- kWARNING - TO REDUCE THE RISK OF

FIRE, ELECTRICAL SHOCK AND PERSONAL INJURY:

• DO NOT USE AN EXTENSION CORD OR AN

ADAPTER PLUG WITH THIS APPLIANCE.

Dryer must be electrically grounded in accordance with

local codes and ordinances, or in the absence of local

codes, in accordance with the NATIONALELECTRICAL

CODE,ANSI/NFPANO. 70.

ELECTRICAL REQUIREMENTS

This dryer must be connected to an individual branch

circuit, protected by the required time-delay fuses or

circuit breakers. A four or three-wire, single phase,

Z20/240V or 120/208V, 60Hz, :30amp circuit is required.

GROUNDING INSTRUCTIONS

This dryer must be connected to a grounded metal, perma-

nent wiring system, or an equipment-grounding conductor

must be run with the circuit conductors and connected to

the equipment grounding terminal on the appliance.

CONNECTING DRYER USING 4-WIRE

CONNECTION (MUST BE USED FOR

MOBILE HOME INSTALLATION)

NOTE:Since January 1,1996, the National Electric code

requires that the new constructions utilize a 4-wire con-

nection to an electric dryer.

WARNING:

Onlg a 4-conductor cord shall be used when the appli-

ance is instolled in a location where grounding through

the neutral conductor is prohibited. Grounding through

the neutral is prohibited for the new branch-circuit

installations, mobile homes, recreational vehicles, and

areos where local codes prohibit grounding through the

neutrol conduction.

REMOVEGROUNDSTRAP

ANDDISCARD.KEEPGREEN

GROUNDSCREW

J

_SCREWS

HOT

WIRE RELOCATEGREEN

GROUNDSCREW

HERE GREENOR

RELIEF

BRACKET

3/4",UL

HOT RECOGNIZED

WIRE STRAINRELIEF

COVER /4#10AWGMINIMUMCOPPER

CONDUCTORSOR120/240V30APOWER

SUPPLYCORDKITMARKEDFORUSE

WITHDRYERS&PROVIDEDWITH

CLOSEDLOOPORSPADETERMINALS

WITHUPTURNEDENDS(NOTSUPPLIED}

1.Turn off the circuit breaker(s) (:30amp) or remove the

dryer's circuit fuse at the electrical box.

2.Be sure the dryer cord is unplugged from the wall

receptacle.

:3.Remove the power cord cover located at the lower

back.

4. Remove and discard ground strap. Keep the green

ground screw for step 7.

5.Install :3/4 in. UL recognized strain relief to power cord

entry hole. Bring power cord through strain relief.

6.Connect power cord as follows:

A.Connect the 2 hot lines to the outer screws of

the terminal block (marked L1 and L2).

B.Connect the neutral (white) line to the center of

the terminal block (marked N).

7.Attach ground wire of power cord with the green

ground screw (hole above strain relief bracket). Tighten

all terminal block screws (:3)securely.

8. Properly secure power cord to strain relief.

9. Reinstall the cover.

A, l ,^ ,-, ,, , , ,, , ,-

AEIiW/'AKI_III_I_: NEVER LEAVE THE

COVER OFF OF THE TERMINAL BLOCK.