NovaTec NovaWheel NWB- DC+ Series User manual

USER GUIDE

MODELS:

NWB- DC+ Series, With NovaTouch™

7” Color Touch Panel PLC

> MODELS NWB-25-DC+ through

NWB-300-DC+

NWB-DC Series, With NovaTouch™

4” Color Touch Panel PLC

> MODELS NWB-25-DC through

NWB-200-DC

NovaWheel™Portable

Dry-Convey Dryers

NWB-DC & DC+ UG 18 JULY 2019

©2019 NOVATEC, Inc. All Rights Reserved

In the space provided below you should record the model and serial

number(s) of your equipment and the date the equipment was received.

In the event you would need aermarket assistance our parts and ser-

vice department uses this informaon, along with the manual number, to

provide help for the specic equipment installed.

Please keep this instrucon manual, any relevant addendums, engineer-

ing prints and parts lists together for accurate documentaon of your

equipment.

NOTES

User Manual: NWB-DC & DC+ UG 18 JULY 2019

Serial Number(s):

Model Numbers:

DISCLAIMER: NOVATEC, Inc., shall not be liable for errors in this instrucon

manual. Informaon can change without noce. Novatec makes no warranty of

any kind concerning the informaon contained herein, including, but not limited

to the implied warranes of merchantability and tness for a parcular purpose.

©2019 NOVATEC, Inc. All Rights Reserved.

Table of Contents

1.0 SALES AND SERVICE 6

2.0 SHIPPING AND INSPECTION 6

3.0 UNPACKING for NovaWheel™

NWB-DC & DC+ DRY/CONVEY MODELS 6

3.1 Unpacking 6

3.1.1 Tools You Will Need for Unpacking: 6

3.1.2UnpackingInstrucons: 6

3.1.3 List of UNPACKED CONTENTS: 6

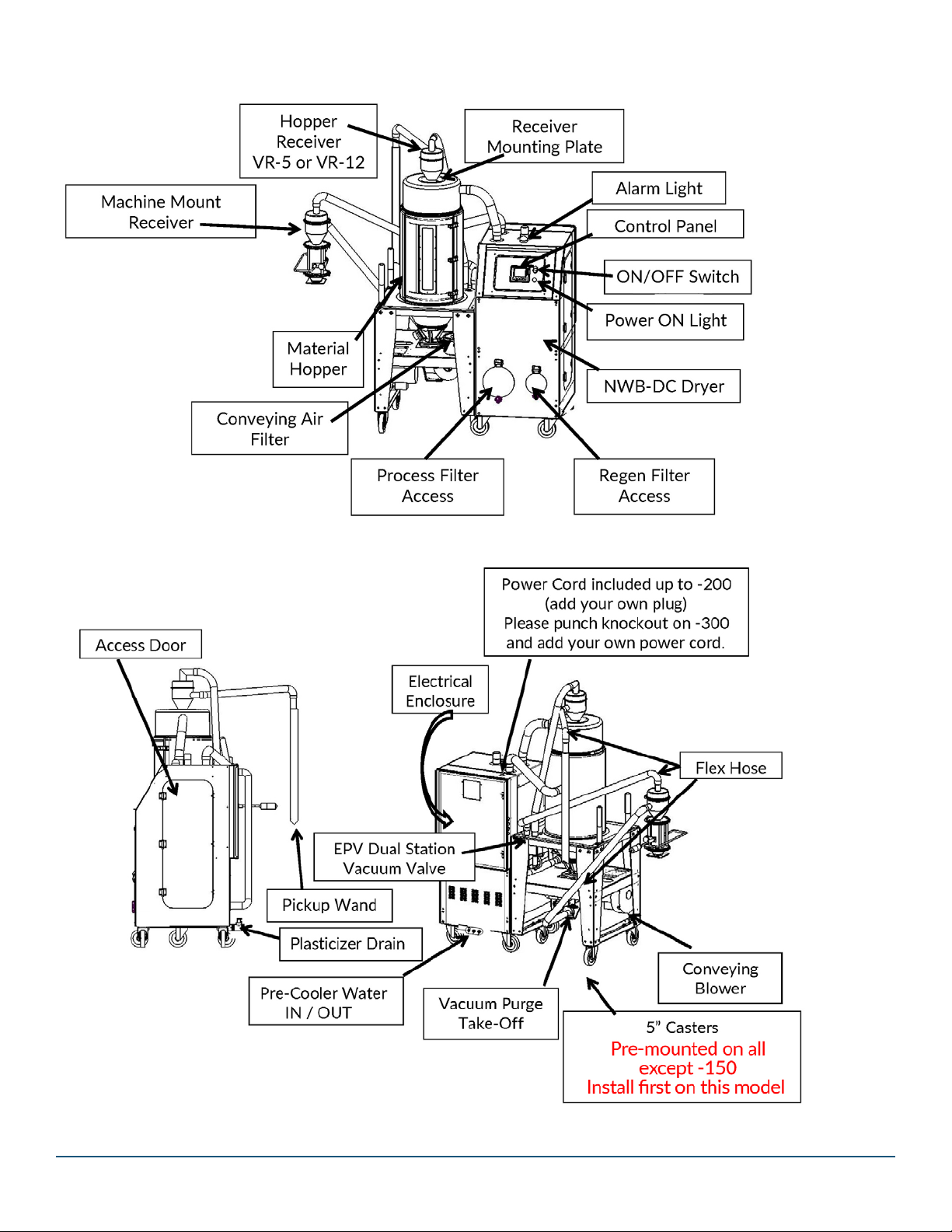

4.0 BASIC COMPONENTS OF NOVATEC

NWB-DC DRYER ASSEMBLY 7

4.1DierencesinLayoutfor-300model 8

5.0ASSEMBLYINSTRUCTIONS 8

5.1Prepare/AssembleMachineMountReceiver 8

5.2 Mount Hopper Receiver & Connect

FlexHoseandPickupWand 8

5.3PosioningtheNWB-DC 9

5.4 Install Machine Mount Receiver and

ConnectFlexHose 9

6.0 ELECTRICAL CONNECTIONS 10

7.0 PRE-COOLER WATER CONNECTIONS 11

8.0COMPRESSEDAIRCONNECTION 11

9.0HOPPEREXTENSIONS 11

10.0 ADJUSTABLE DIFFUSER CONE POSITIONING 11

11.0 PRINCIPLE OF OPERATION 11

11.1ResinDrying 11

11.2ResinConveying 12

11.3SystemFlowDiagram 12

12.0 SPECIFICATIONS – NWB-DC+ DRY CONVEY SERIES 12

13.0 FUNCTION CONTROLS 13

4

13.1ProcessTemperatureControl

(DryingTemperature) 13

13.2RegeneraonTemperatureControl 13

13.3Process&RegeneraonAirFilter

PressureSwitches(PS) 13

13.4ProcessAirDewPointMonitor 13

13.5IntelligentRegeneraon 13

13.6ConveyingControl 13

14.0 PRE-OPERATING SYSTEM CHECK 13

14.1StarngTheDryer 13

14.2 Checking Electrical Phase 13

14.3ChangingFromF°toC° 13

15.0 NovaTouch™ CONTROL 14

15.1SystemConvenons: 14

15.2 Screen Map 15

16.0 INITIAL DRYER STARTUP 15

16.1DryerPre-Check 15

16.2ExplanaonofPasswordLevels 15

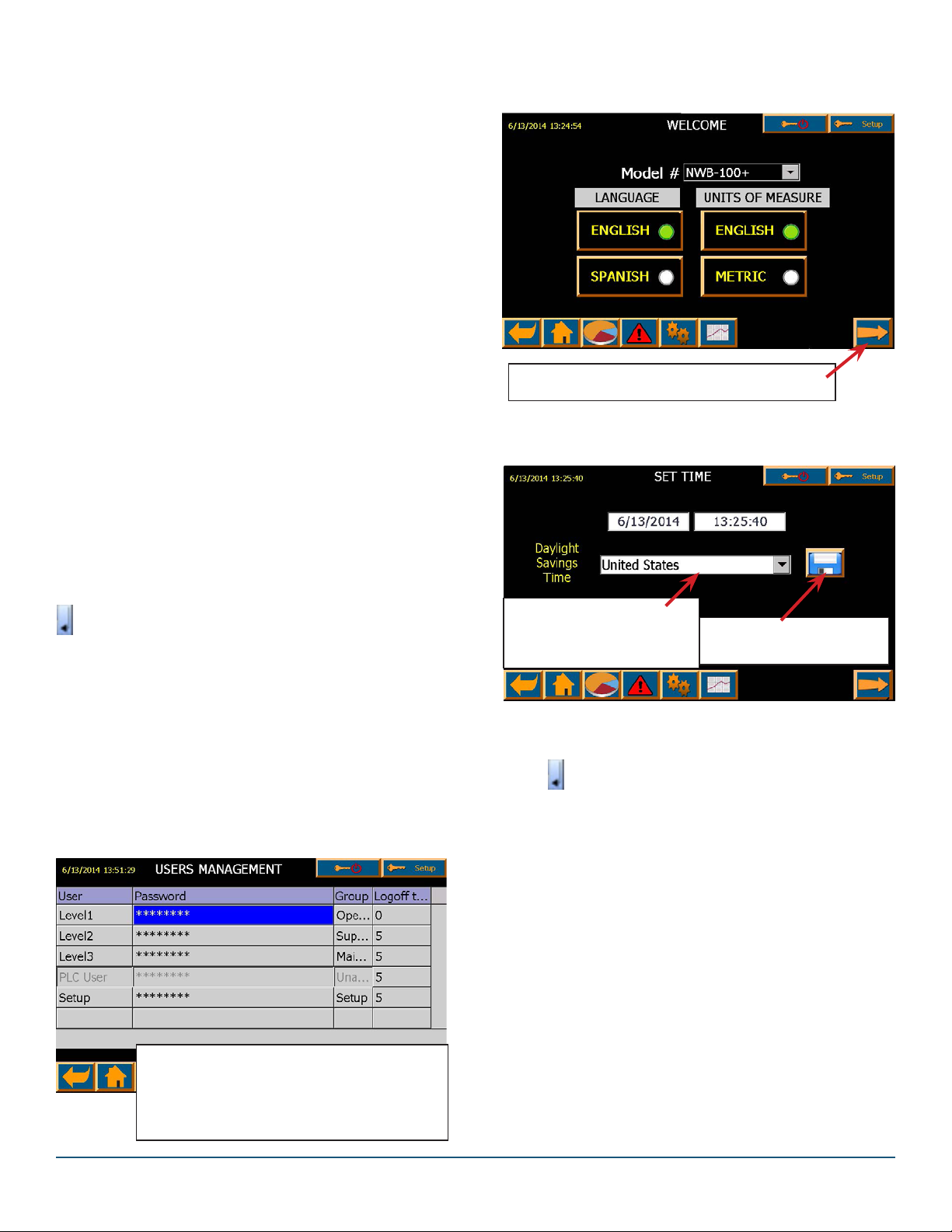

16.3 WELCOME Screen 16

PressingMETRICwillchange°Fto°C. 16

16.4Verify/SetTime&Date 16

16.5AutoStart/Stop(Level2) 16

16.6MaintenanceSchedule(setup) 17

16.7InstallaonChecklist(setup) 17

17.0SETTINGSSCREEN(Anylevelcanview) 18

17.1DryerAlarmSengs(level2) 18

17.2UsersManagement 19

17.3AdvancedOpons(level2&up) 19

17.4TouchScreenSengs 20

5

18.0DRYINGMATERIAL 20

18.1QuickOpScreen 20

18.2HopperLoaderSetup 21

18.3MachineLoaderSetup 22

18.4ResinMenu 22

18.5DryerStatusScreen 23

18.6MessageScreen–Alarms 23

19.0INSTRUCTIONALTROUBLESHOOTINGSCREENS 23

20.0 MAINTENANCE INSTRUCTIONS 25

20.1 Suggested Maintenance Schedule* 25

20.2 Filters 25

20.3ProcessandRegeneraonFilters 26

20.4ConveyingAirFilter 26

20.5DrainingPlascizer 26

20.6 Chain and Sprockets 26

20.7 Desiccant Rotor 26

20.8MotorRotaonSignal 26

20.9RotorReplacement 27

20.10SealReplacement 27

20.11DriveMotorReplacement 27

21.0TROUBLESHOOTINGandERRORMESSAGES 28

22.0WARRANTY 29

FOREWORD

Thismanualisdedicatedtotheprinciplethatanyengineeredsystemwillhave

manyelementscontribungtothesmoothoperaonofthesystem,andthat

thesemustbeunderstoodinorderthatinstallaonandoperaoncanproceed

successfully.

TheelectricalandmechanicalcomponentsintheNWB-DCSeriesdryershave

beenmanufactured,selectedandassembledwithcaretogiveyouexcellent

service.AwiderangeofNWB-DCseriesdryershavebeenintroducedtoenable

ourvaluedcustomerstoselecttherightmodelfortheirapplicaon.TheseNWB-

DC(NovaWheel™Dry/Convey)seriesdryershavebeendesignedforbeside-the-

pressdryingapplicaons.AllcomponentsofyourNWB-DCseriesdryershave

beencarefullyengineeredandmanufacturedandhavebeenthoroughlyinspect-

edforquality,funconandperformance.

Beforeinstallingthissystem,pleasereadthismanual,reviewthediagramsand

thesafetyinformaon.Thisshouldsavevaluableinstallaonandoperaonme

laterandwillhelpensuresafeoperaonandlonglife.

6

Figure 2

1.0 SALES AND SERVICE

NOVATECmaintainsqualiedsales,engineering,and

servicepersonneltoassistinanywaypossible.Ifyou

haveanycommentsconcerningthetypesofequipment

whichNOVATECmanufacturesthatmightimproveyour

process,oranyquesonsconcerningservice,weurge

youtocontactus.PleasehaveyouModelandSerial

Numberhandy.

Sales:1-800-BEST-DRY●1-800-237-8379

Fax:410-789-4638●[email protected]om

TechnicalServiceDepartment:1-800-938-6682

Service@novatec.com

2.0 SHIPPING AND INSPECTION

Although NOVATEC uses reputed carriers to deliver

products,ithasnocontrolovertheproductsonceit

leavesthemanufacturingfacility.Uponreceivingthe

products,thoroughlyinspectallequipmentinsideandout

fordamagethatmayhaveoccurredduringshipment.If

anydamageisfound,aclaimshouldbeledimmediately

withyourcarrier.

NOVATECthoroughlytestsandinspectsallproducts

beforeshipment.Youaretomakethepiping,andelectri-

calconneconsfornalinstallaonandcommissioning.

Ifthereanyproblems,shutdowntheequipmentand

contacttheNOVATECTechnicalServiceDepartment.

3.0 UNPACKING for NovaWheel™ NWB-DC &

DC+ DRY/CONVEY MODELS

3.1 Unpacking

3.1.1 Tools You Will Need for Unpacking:

•BoxCuer

•Malletorhammer

• Tin Snips

•½”socketwrenchfor-150through-300modelonly

1–Pleaselookforanysignsofdamageandreportto

yourcarrierimmediately.

2–UnpacktheDryer/Hopper

3–Removeshrinkwrap,andanywoodframing

aachedtotheskid.

4–CutthemetalstrappingthatsecurestheDryer/

Hopper to the skid.

5–LitheDryer/Hopperothepalletandsetitina

low-tracarea.

NOTE:Allmodelsareshippedwithcastersinstalledex-

ceptthe-150&-200,sowhiletheyarebeingsupported

bytheforkli,aachoneofthesuppliedcastersunder

eachcorneroftheframeusinga½”socketwrench.

–Unpackthecomponentstobeassembledfromseparate

cartons.

–Removetheshrinkwrapfromthecarton(s)andtakeout

the contents.

NOTE:TheHopperReceivershouldbesetontheoor

withtheboominsidetheroundbertube(supplied)so

theboomapperisprotectedbythetube.

3.1.3 List of UNPACKED CONTENTS:

•Dryer/HopperAssembly

•MachineMountReceiver(withsightglass)

•HopperReceiveronFiberTube(withappervalve

underneath)

• 5’ Long Pickup Wand

•PhotoEyeLevelSensor

• 50’ of 1.5”of Flex Hose*

•8HoseClamps

•Casters,Bolts&Washers(packedseparatelyfor

-150 & -200

7

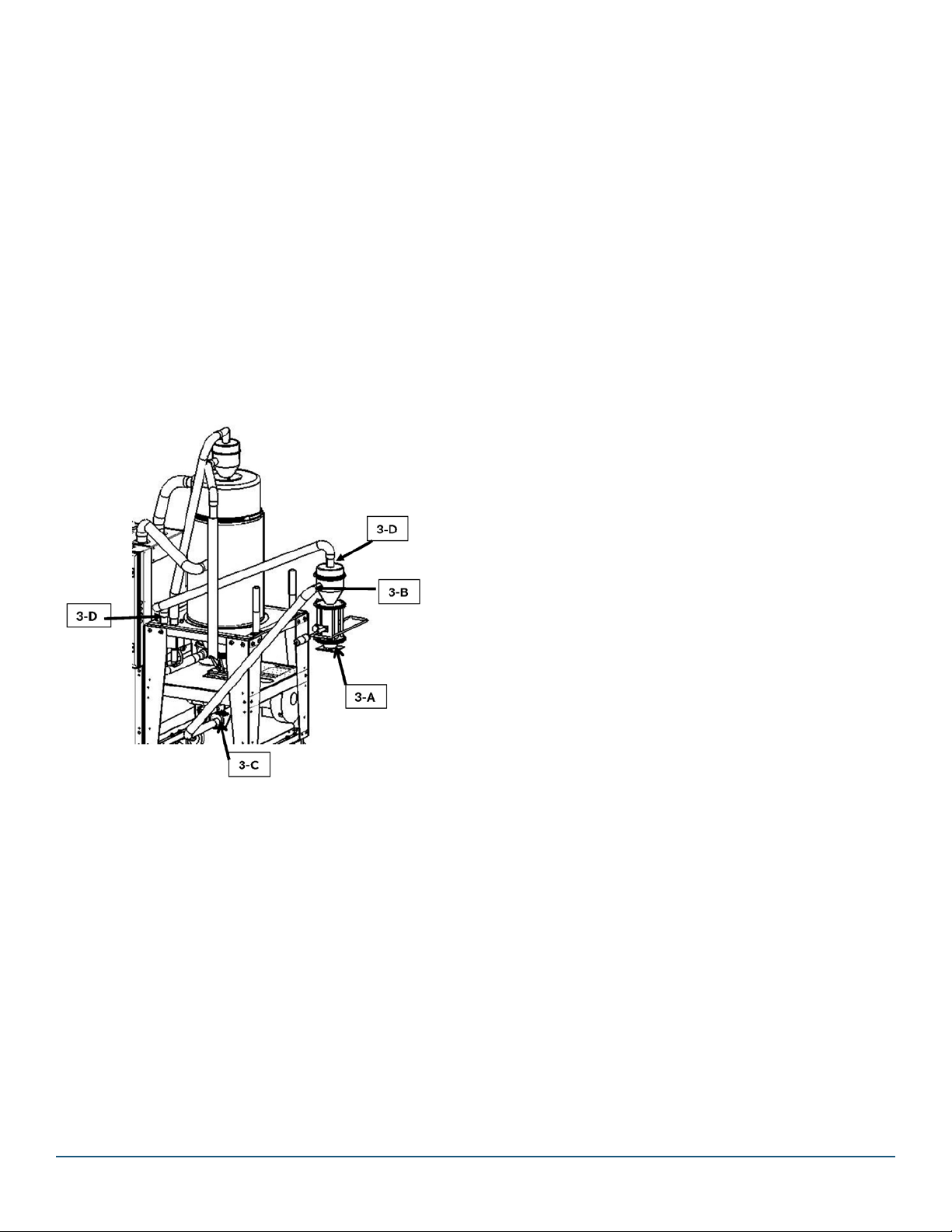

4.0 BASIC COMPONENTS OF NOVATEC

NWB-DC DRYER ASSEMBLY

8

5.0 ASSEMBLY INSTRUCTIONS

ToolsYouWillNeedforAssembly:

•HacksawtocutPVCexhose

•FlatBladeScrewdriverand/or5/16”socketforhose

clamps

•5/32”AllenwrenchtomountReceivers

•Drillpressanddrillbitsizedtomatchmounngholes

onmachinethroatsoholescanbedrilledinbaseof

MachineMountReceiver.(Unlessbaseispre-drilled)

•6’-8’Ladder

•Tapemeasure

NOTE:Asyouproceedwithassembly,makesurethatall

boltsandhoseclampsaresecurelyfastenedtoensure

thattherearenoairormaterialleaksinthesystem.Do

notuseexcessiveexhosebutavoidsharpturnsasthis

willhurttheeciencyofthesystemoperaon.

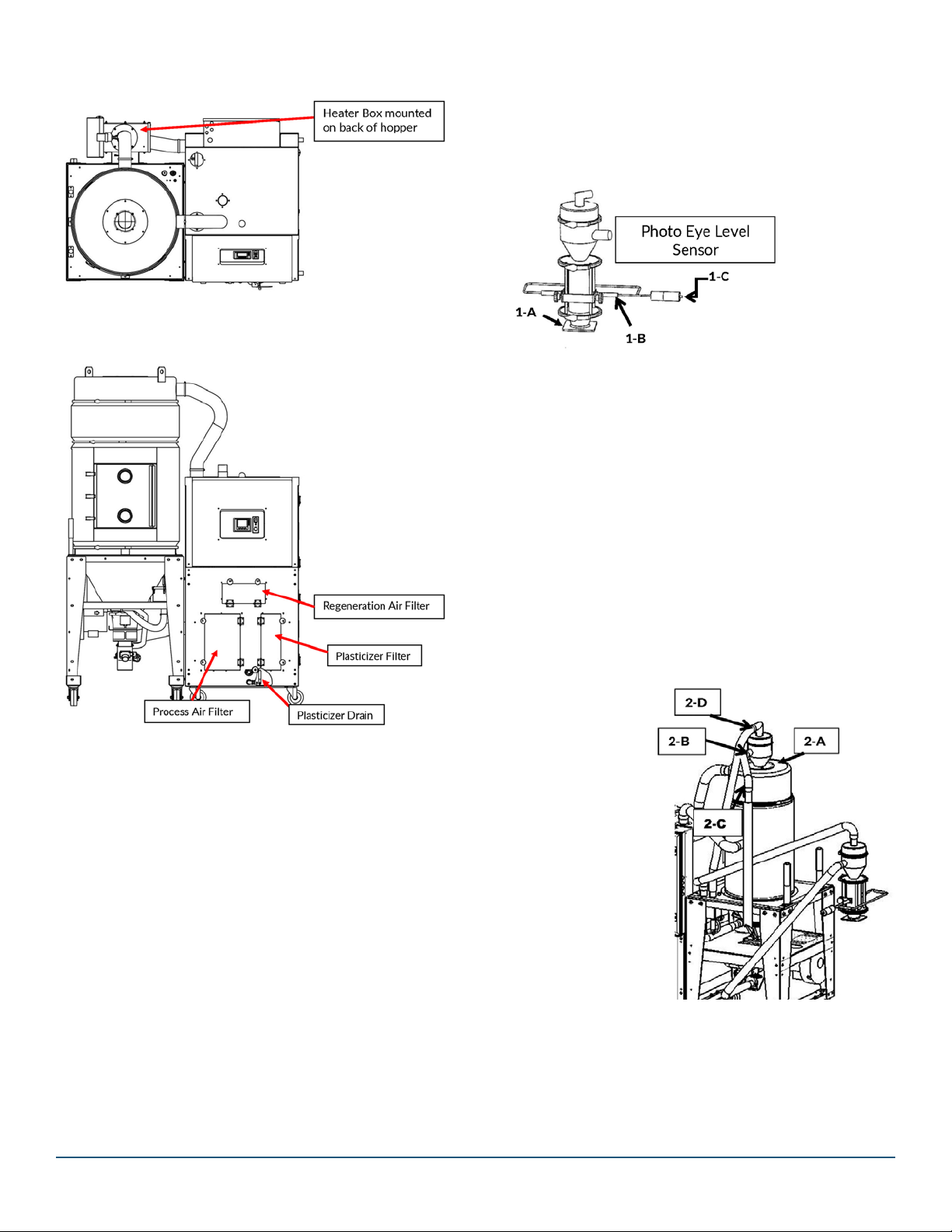

5.2 Mount Hopper Receiver & Connect Flex Hose and

Pickup Wand

2-A: RemovecoverplatefromtopofMaterialHopper

(saveboltsandwashers)then,aerremovingmask-

ingtapefromapper,placeHopperReceiverin

hole.Aligninletstubtofacedireconfromwhere

materialwillbepulled.FastentheReceivertothe

Hopperusingthesaved¼”x20boltsandwashers.

2-B: Placehoseclampoveroneendofexhoseand

pushendofthehoseontothematerialinletstub

onthesideofthereceiver.Fastenhoseclamp

securely.

2-C: Cuttheexhosetoalengththatwillallowthe5’

longpickupwandtoreachallcornersofthebulk

container

supplyingthe

materialtothe

dryerhopper.

Push the cut

end of the

exhoseover

the end of the

pickupwand

and secure

withhose

clamp.

2-D: Followsame

instrucons

toaachex

hose running

fromthevacu-

umstubontopoftheHopperReceiverto the near-

(Seeillustraon)

9

Hopper Receivers with Blowbackaresuppliedwitha

male/femaletwistlockplugtowhich115/1/50-60VAC

shouldbewired.Acleansourceof80-120psicom-

pressedairshouldbeconnectedtothesuppliedFNPT

ng.(3/8”ontheVR-5and¼”ontheVR-12)

RolltheNWB-DCintoposionnexttotheprocessma-

chineitwillbeserving.

NOTE: LOCATION

PosionyourNWB-DCSeriesdryerinalocaonwhere

materialandvacuumhoseswillnotbedisturbed.Allow

sucientdistance(atleast2feet)fromthesurround-

ingequipment,sotheaccessdoorsmaybeopenedto

performrounemaintenanceonthedryerandforsafe

operaon.

5.4 Install Machine Mount Receiver and

Connect Flex Hose

5.4 Install Machine Mount Receiver and Connect

Flex Hose

3-A Bolt the Machine Mount Receiver to the process

machinethroatwithuser-suppliedbolts.

3-B Pushoneendoftheexhoseallthewayontothe

materialinletstubonthesideofthereceiverand

fastenitsecurelywithahoseclamp(supplied).

3-C Stringexhosetothevacuumpurgetake-o(at-

tachedtotheboomofthehopper)cutittolength

andfastensecurelywithahoseclamp.

3-D Aachoneendofexhosetothevacuuminletstub

on top of the Machine Mount receiver and fasten it

securelywithahoseclamp.Stringtheexhoseto

thefarthestEPVDualStaonVacuumValveStub

extendingfromthetopofthedryer.Cutexhoseto

lengthandaachitsecurelytothestubwithahose

clamp.

10

6.0 ELECTRICAL CONNECTIONS

TheNWB-DC+Seriesdryerscomefromthefactory

withallcontrolcircuitswiredanda10’powercord.

Aquick-connectplugshouldbeinstalledifmoving

theNWB-DC+tootherprocessmachinesisanci-

pated.

CAUTION

•Allelectricalconneconsmustbemadebyqualied

electricians,pernaonalandlocalelectricalcodes.

•Disconnectandlockoutthemainpowersourcebefore

makingtheelectricalconnecon.

Turn the Main Disconnect on the electrical panel door to

the“OFF”posion,lockoutthemainpowersourceand

opentheelectricalenclosure.Pertheelectricaldiagram,

installthemainpowerwiretothemaindisconnectswitch

holderandinstallthegroundwire.

Full size electrical drawings are included with this

ordered

NOTE: 3 Phase detecon is included on this model. If

the connecon is not correct, a pop-up alarm will appear

on the touch screen upon startup. You should immediate-

ly correct this condion.

NOTE: Please make sure all electrical connecons are

ght. It is not common but a loose connecon is possible

aer a long truck ride.

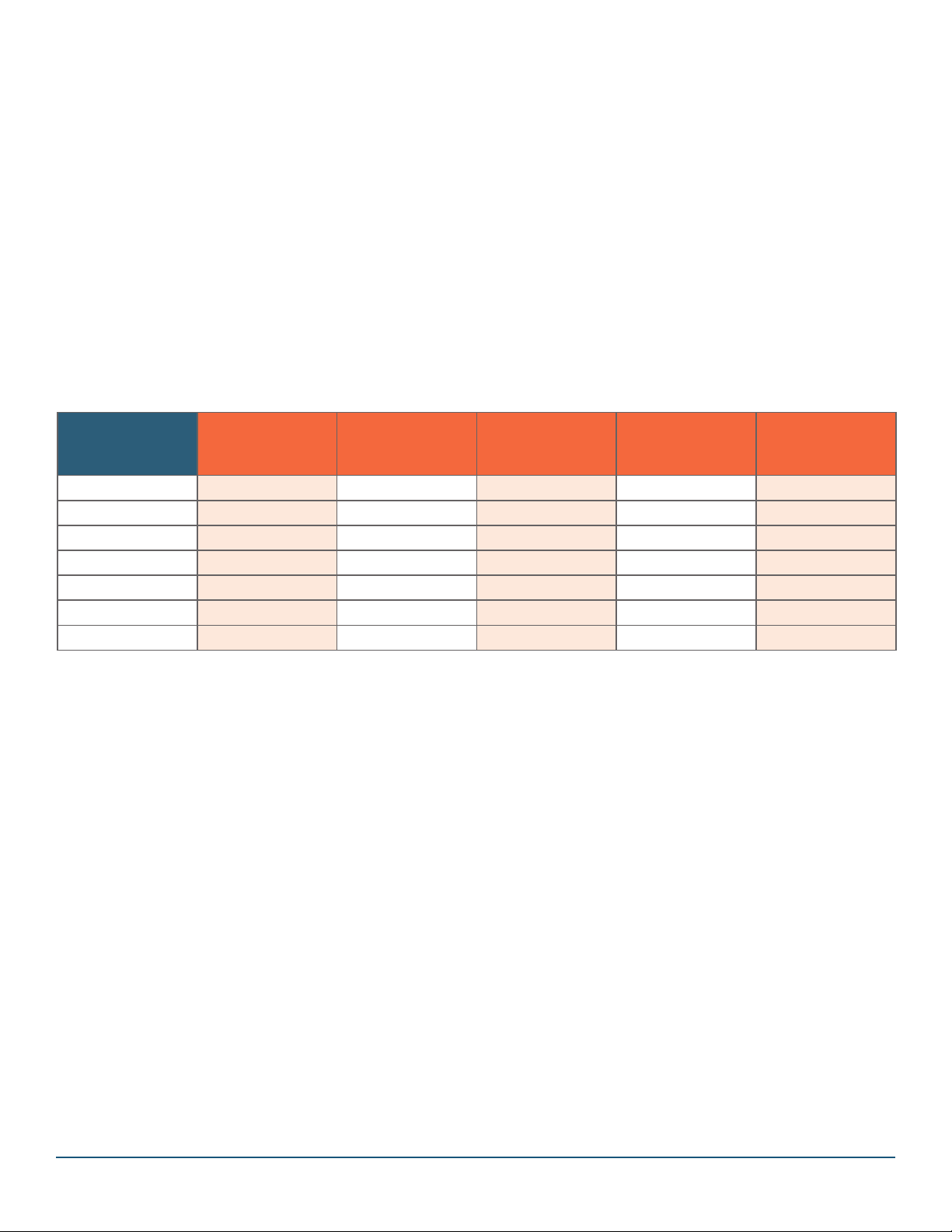

Model Total connected

power KVA/AMPS

Pro Motor

Hp/AMPS

Regular Motor

Hp/AMPS

Regular Heater

Kw/AMPS

Pro Heater

Kw/AMPS

-25 9.0/10.8 .025/0.4 .025/0.4 3.0/3.8 3.0/3.8

-50 11.9/14.7 0.67/1.2 .025/0.4 3.0/3.8 5.5/6.9

-75 14.2/17.8 1.1/1.8 .025/0.4 3.0/3.8 7.5/9.4

-100 16.7/20.9 1.1/1.8 .025/0.4 5.5/6.9 7.5/9.4

-150 16.7/20.9 1.1/1.8 .025/0.4 5.5/6.9 7.5/9.4

-200 24.0/30.1 2.5/3.5 0.67/1.3 5.5/6.9 13.0/16.3

-300 38.3/48.0 3.5/5.4 0.67/1.3 10.0/12.6 22.5/28.2

11

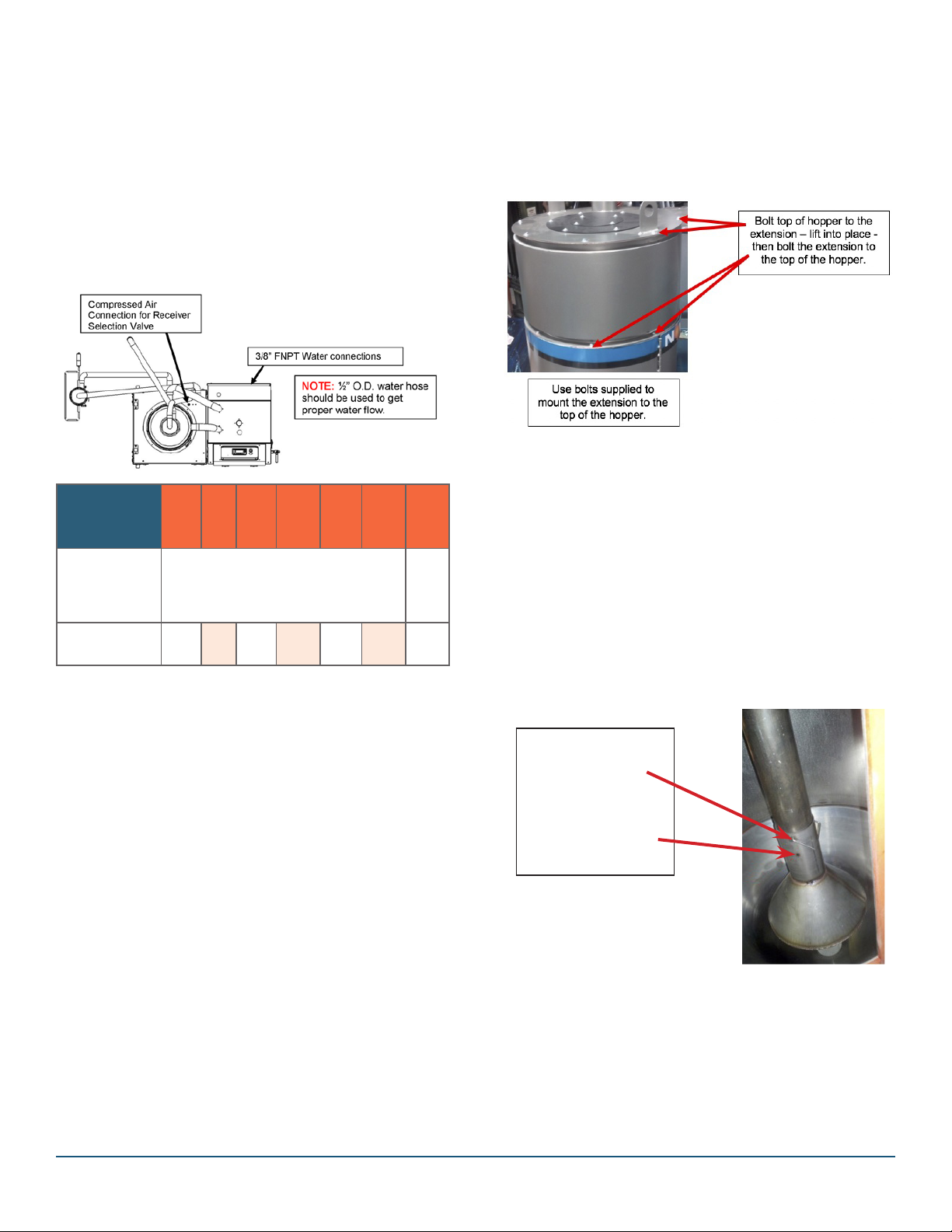

7.0 PRE-COOLER WATER CONNECTIONS

ACoolingCoilisinstalledinNWB-DC+seriesdryersand

isrequiredtolowerthehopperreturntemperatureand

thisincreasestheeciencyofdryerIF THE DRYING

TEMPERATURE IS ABOVE 225°F .

Tower,cityorchilledwaterisrequiredatbetween40to

85°F.Connectthecoolingwatersupplyandreturnusing

exiblehosethatisatleast2feetlong,toallowforeasy

removalofthecoolingcoilforcleaning.Thewaterow

ratesandtherequiredcustomerconneconsizesfor

dierentmodelsareshowninthechartbelow.

NOTE: Processor must use ½” ID water hose to get

properow.

NOTE: Cooling water is required if drying temperature is

over 225°F.

Theprocessairstreammustbeconnectedtoanexternal

coolingcoilifthedryingtemperatureisbelow170°F.

ContactFactoryforOpons.

8.0 COMPRESSED AIR CONNECTION

Thetouchscreencontroloperatesadualstaonvacuum

valveinsidethedryertoacvatevacuumtoeitherthe

hopperreceiverorthemachinemountreceiver.Aclean

compressedairsupply(60-90psi)shouldbeconnectedto

the1/8”NPTinlet.

9.0 HOPPER EXTENSIONS

Ifyouorderedahopperextension,itwillbeabolt-on

type.Theextensionwillbeinstalledatthefactoryifthe

overallheightoftheunittsintoastandardheighttruck

forshipping.Iftheunitistootallfortheextensiontobe

factory-mounted,itwillbeshippedinaseparatecontain-

erandmustbeinstalledattheprocessor’splant.

10.0 ADJUSTABLE DIFFUSER CONE

POSITIONING IMPORTANT FOR

PROPER DRYING

Wehavefoundthatprocessorscanimprovetheecien-

cyoftheirdryingprocessbyadjusngtheposionofthe

diuserconeasdescribedbelow.

Thediuserconeshouldbeplacedinthelowerposion

z(shown)whendryingvirginresinorresinwithalow

percentage of regrind.

Whendryingresinwithahighpercentageofregrind,

spreadtheclip,raisetheconeandplacetheclipthrough

thelowersetofholes.

Clip through upper

setofholesforlow

percentage of regrind.

Clip through upper

set of holes for higher

percentage of regrind

To raise level of cone.

YouarenowreadytoproceedtoDryerSetup.

SeeQuickCardaachedtodryer.

Models

NWB-XX-DC

NWB-XX-DC+

.25 -50 -75 -100 -150 -200 -300

Water

Inlet/Oulet

(inches)

3/8 1/2

Flow Rate-

0.25 0.5 0.75 1.0 1.5 3.0 3.0

12

11.0 PRINCIPLE OF OPERATION

TheNWB-DC+Seriesisdesignedtoconveymoisture

ladenresinfromasourcecontainer,dryit,anddeliverit

tothethroatofaprocessmachine.

TheNWB-DCandDC+NovaWheelSeriesdryerswas

engineeredanddesignedtoeecvelyremovemoisture

(inthevaporstate)fromhygroscopicplascresins.This

processisaccomplishedbytheconnuouslyrotang

desiccantwheelandthethreeairstreams(Process,Purge

andRegeneraon).TheProcessreturnairisexposed

toanadsorbingmedia(desiccantwheel)inasealedair

stream,wherethedesiccantadsorbsthemoisturefrom

processair.Aerthedesiccanthasadsorbedthemois-

ture,itisexposedtoaRegeneraonairstreamwhich

hasbeenpre-heatedtoatemperatureofabout380°F.

(190°C).Thiscausesthemoisturetobedrivenoutfrom

thedesiccantandpreparesitformoremoistureadsorp-

on.Nowthedesiccantmediapassesthroughthirdair

streamcalledpurgeairstream.Herethedesiccantmedia

iscooleddownbysomeoftheprocessairbeforeen-

teringbackintotheprocesstoprovideforbeerper-

formance.Thethreeairstreams(process,regeneraon

andpurge)areseparatedbyspecialTeonfabriccoated

siliconseals.Theprocessairandregeneraonairiscom-

pressedbyusingregeneraveblowers.

Thedryairfromthedryeristhenheatedtothedesired

dryingtemperaturebyanelectricheaterlocatedinthe

dryercabinet.Thehotdryairentersthehopperatthe

boomandremovesmoisturevaporfromtheresininthe

hopper.Theairfromthetopofthehopperisreturned

tothedryer,whereitisltered,passedthroughthe

desiccantwheeltoremovemoisturefromtheairstream

andcooledbeforetheprocessblowersendstheairback

throughtheheaterandintotheboomofthehopper

againinaconnuousprocess.

Aregeneraveblowerpullsresinfromabulkcontainer

throughapickupwandandexiblehosetoanappro-

priately-sizedvacuumreceiverwherethematerialisfed

intothedryinghopper,asneeded.Asthematerialpasses

throughthedryinghopperitismeteredthroughavac-

uumtakeovalvetoamachinemountvacuumreceiver

mountedontheprocessmachine,therebymaintaininga

constantowofdrymaterialtothefeedthroat.

12.0 SPECIFICATIONS – NWB-DC+ DRY

CONVEY SERIES

ProcessAirdewPoint(nominal):-40ºF(-40°C)

DryingTemperature:150-350°F(66-177°C)

AirandMaterialHoseDiameter:1.5”ID(40mm)

CompressedAirFingsforHopperReceivers

withBlowback:

VR-5-B:3/8”FNPT,VR-12-B:¼”FNPT

CompressedAirrequirementsforBlowback:

80-120psi(5.5-8.3Bar)

*Basedonmaterialbulkdensityof38lb./.3

Model NWB-DC & DC+ -25 -50 -75 -100 -150 -200 -300

25/11.4 50/22.7 75/34 100/45.4 150/68.2 200/92 300/136

Voltage—Phase -Hz 460-3-60

Hopper Receiver VR-5 VR-5 VR-12 VR-12 VR-12 VR-12 VR-12

Machine Mount Receiver VR-5MM VR-5MM VR-5MM VR-5MM VR-5MM VR-5MM VR-5MM

hr.) 10 10 10 10 10 10 10

3/8” 3/8” 3/8” 3/8” 3/8” 3/8” 1/2”

0.25 0.5 0.75 1.0 1.5 3.0 3.0

13

13.0 FUNCTION CONTROLS

TheNWB-DC+Seriesdryerscomecompletewiththe

followingcontrols:

TheTemperatureControlisapartoftheNovaWheel

NovaTouch PLC controller and controls the process outlet

temperatureasperthesetvalue.Inaddion,thereisa

processhightemperaturelimitthermostatthatisprovid-

edforextrasafety.(Refertothecontrollersecon).

TheregeneraontemperatureiscontrolledbytheNova-

TouchPLCcontroller.Inaddion,thereisaregeneraon

hightemperaturelimitthermostat,whichprovidesextra

safety.Theregeneraontemperatureissetatabout

380°F.(190°C)andshouldnotbechanged.

Switches (PS)

Theairpressuredierenalacrosstheprocesslterand

theregeneraonlterismonitoredandtheNovaTouch

displaywillalarmandshowwhenalterneedstobe

cleanedorreplaced.Thesearefactorysetbutoenneed

tobeadjustedintheeldoncethecustomerloadsresin

in the hopper.

Accesspressureswitchesaeropeningthesidepanelof

thedryer.RemovePhillipsscrewthatholdsclearcoverin

place(Fig.1).Turnknobclockwiseorcounter-clockwise

to either increase or decrease.

13.4 Process Air Dew Point Monitor

Itmeasurestheprocessairdewpointfromthedryer.

IntelligentRegenconstantlymonitorstheregeneraon

inletandoutlettemperaturesandcontrolsthemtoop-

mizetheenergyanddewpointperformanceofthedryer.

Providesentryofload/dumpmesandnumberof

aemptedloadsbeforeNo-LoadAlarmisacvatedplus

BlowBackcontrol,ifspecied.

14.0 PRE-OPERATING SYSTEM CHECK

Oncematerial,vacuumhose,waterandelectricalcon-

neconsaremade,theNWB-DC+Seriesdryershouldbe

givenanalcheckout.

Turnthemaindisconnectswitchto“ON”

p o s i o n t o p o w e r t h e d r y e r.

DepresstheGREENSTARTswitchonthe

frontpaneltostartthedryer.

Theblowersandheatersarenowenergizedandthedes-

iccantwheelwillbeginturningandstarttodrythereturn

air.Itwilltakeseveralminutesandacouplerevoluons

ofthewheel,forthedewpointtogetdowntothe-40°

dewpoint.

WARNING: AlwaysusetheGreen/RedswitchtoSTART

orSTOPthedryer.ThePowerDisconnectswitchshould

onlybeusedinTrueEmergencycondions.Repeated

useofPowerDisconnectcancausedryercomponent

failure.

14.2 Checking Electrical Phase

YourNOVATECNWB-DC+DryerincludesPhaseDe-

tecon.Thisisparcularlyimportantfordryersthatmay

bemovedaroundtheplant.WhenyouturntheMAIN

DisconnectswitchtotheONposion,aPop-UpAlarm

willappearonthescreeniftheconneconisnotcorrect.

Youshouldimmediatelycorrectthiscondion.

WARNING: Anywiringprocedureshouldonlybedoneby

aqualiedelectricianfamiliarwiththreephaseelectrical

wiring.

ThefactorysengifFbutdegreescanbesettoCorF

ontheopeningWELCOMEscreen.(Seepage21)

NOTE:Alldryersaresettodisplaytemperaturesinde-

greesFwhenshipped.

ProcessFilterPressureSwitch

RegenFilterPressureSwitch

14

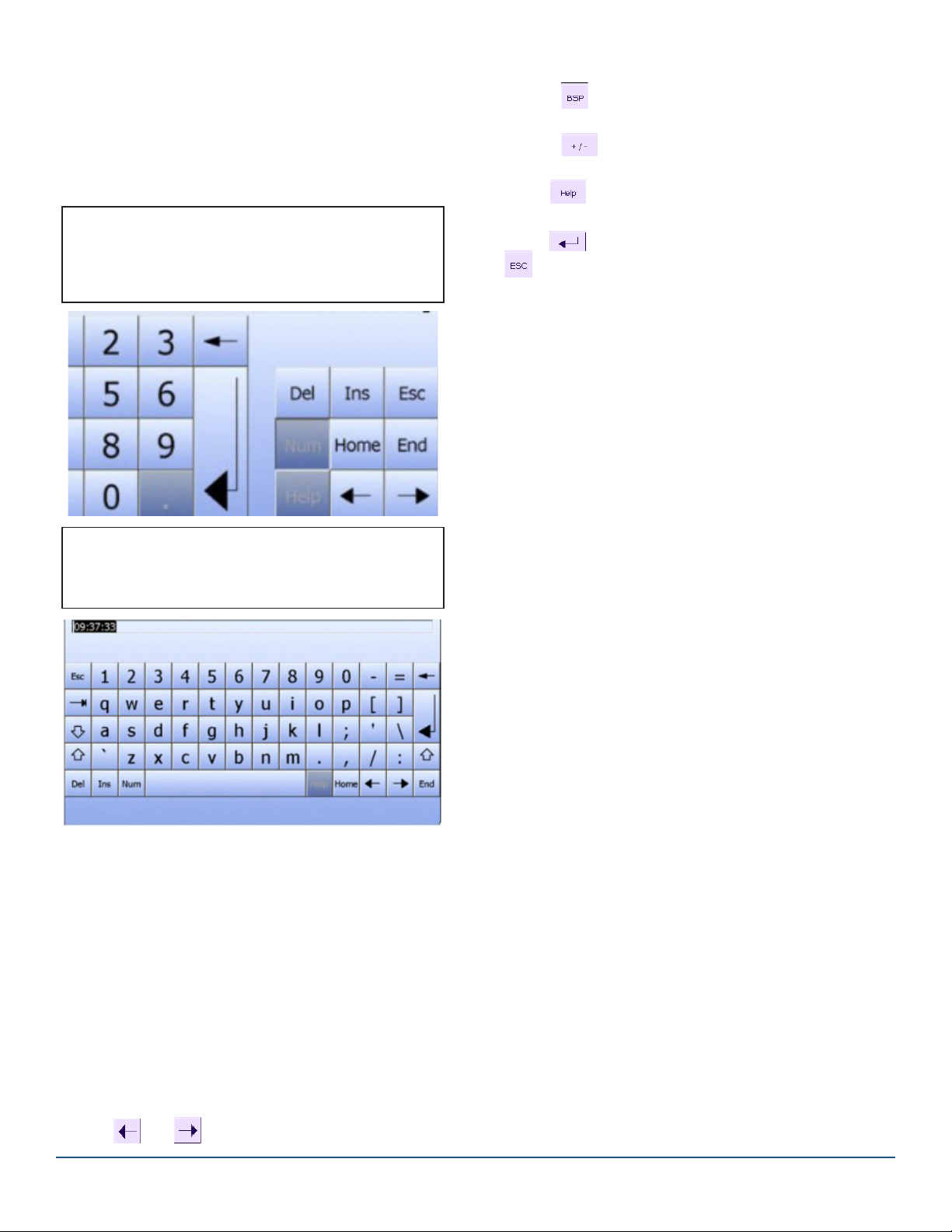

15.0 NovaTouch™ CONTROL

Allinformaonanddatadisplayswillappeartwodimen-

sionalinconguraonandat.Alldataentrypointsor

operaonalfeatureswillappearthreedimensionalin

conguraonandraisedordepressedinappearance

dependingontheiroperaonalposion.

Numerical Entries: WhenyoutouchanIOeldon

theHMIdevicetouchscreenthatrequiresonlya

numericalentry(Password,Temperature,numberof

secondsetc.)thefollowingkeyboardwillappear.

Alpha/Numeric Entries:Whenyouarepromptedto

enteralphabecalandnumericaldata(ResinNames/

Numbers)thisscreenwillappear:

Proceed as follows:

1.TouchtherelevantIOeldonthescreen.

Thenumericalscreenkeyboardopensanddisplaysthe

current value.

2. Set the value.

Youcanonlyoperatekeyswhicharevisualizedin3Dfor-

mat.Thetypeofvaluetobeentereddetermineswhether

akeyisenabledordisabled.

Thefollowingoponsforenteringvaluesareavailable:

Thecurrentvalueisdeletedwhenyouentertherst

character. Enter the value again.

Use the and keystomovethecursorwithinthe

currentvalue.Youcannoweditthecharactersofthe

current value or add characters.

Use the keytodeletethecharactertotheleofthe

cursor.

Use the keytochangethesignofthevalue.

Select toviewtheinfotextoftheIOeld.

Select toconrmyourentriesorcancelthemwith

.

Bothaconsclosethescreenkeyboard.

15

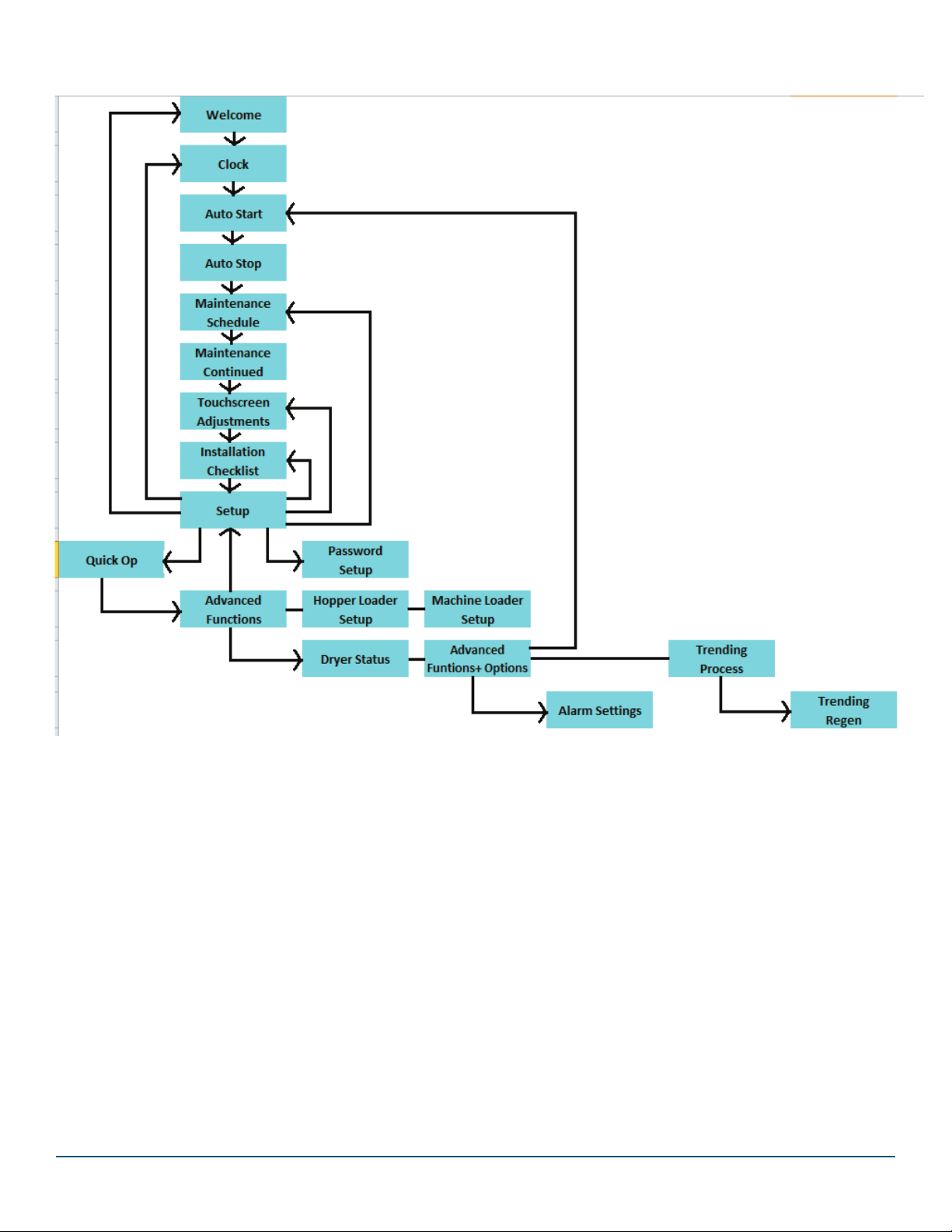

15.2 Screen Map

Forallprocessoroperaons.

16

PressingMETRICwillchange°Fto°C.

Ifcorreconsarerequired,pressdateormebox.

16.0 INITIAL DRYER STARTUP

NOTE:Assurevoltage,conneconandphasingarecor-

rect,coolingwaterissupplied(fordryingover225°F)and

thermocoupleisinsertedinhopper.

ConnectmaterialsourcetoHopperLoader

TurnMainDisconnectSwitchto“ON”posion.

OnrststartyoushouldenterInformaonrequestedon

WELCOME screen.

NOTE: Usernamesetupandpassword4444isrequired

forinialsetup.Iftheproperlevelofpasswordprotec-

onhasnotbeenenteredpriortoaempngchanges,

thealpha/numericpasswordentrykeypadwillappear,

prompngtheusertoinputtheproperpasswordbefore

changescanbemade.

passwords.

UsernameandPasswordfactorydefaults(below)should

beupdatedtoensureproperaccess.

Todothat,double-tapthe********aereachLeveland

enterthenewpasswordonthealpha/numericscreen

thatwillappear.

Youwillbepromptedtoenterthepasswordtwice.Press

to return to USERS MANAGEMENT screen.

should be updated to ensure proper access.

Level1:1111(Operator)–Canchoosepre-setrecipeand

run it.

Level2:2222(ProduconSupervisor)

–level1pluscanchangerecipes,setclock&Auto

START/STOP

Level3:3333(Maintenance)Sameaslevel2

Setup: 4444RequiredforInialsetup

Setup: can change passwords for all levels

Level 3 can change Level 3 passwords

Level 2 can change Level 2 passwords

Level 1 can change Level 1 passwords

Press the Forward Arrow to TIME and DATE

Press the SAVE icon to save

themeanddate.

SelectNONEondrop-downif

DaylightSavingsTimedoes

notapply.

Analpha-numericscreenwillappear.Enterdateasxx/

xx/xxandmeasxx:xx:xxAMorPM.

Press aereachentryiscomplete.

TohavemefollowDaylightSavingsTimeinyour

geographicarea,chooseareafromdropdownandpress

SAVE.

Sengdateandmeassuresthatalarms

willhavecorrectdate&mestamp.

17

16.5 Auto Start/Stop (Level 2)

Press andtheAUTOSTARTscreenwillappear.

Choosedaysandentermesonnumericentryscreen

thatwillappear.Press aereachentryand to

enterAUTOSTOPdaysandmes.Entriesareoponal.

IfyoudonotwanttosetAutoStart/Stop,simplypress

IGNORE.

16.6 Maintenance Schedule (setup)

Press topageforwardtosetupmaintenance

schedule.

Itisimportantthateachofthesethingsarechecked

beforestarngthedryer

Choosethematerialcondionthatwillberunandthen

theappropriatemaintenancescheduleforeachtask.

NOTE:Performingmaintenanceonregularintervalswill

enhancedryerperformanceandlifeandminimizedown-

me.

PressingtheFORWARDbuononemoreme

willopentheSengsscreen(nextpage).

18

17.0 SETTINGS SCREEN (Anylevelcanview)

Thisscreenallowschangestobemadetopreviousscreensandalsoallowsadjustmentstobemadeto…

Alarm Setpoints User Passwords Advanced Opons

Screen Sengs

NOTE: You will go directly to

Quick Op screen (page 25) on all

future starts.

NOTE: From here on, these icons

will appear at the boom of every

screen.

To TRENDING Screen

To SETTINGS Screen Screen

To ALARMS Screen

To DRYER STATUS Screen

To QUICK OPS Screen

To Previous Screen Shown

(Anylevelcanview)

AsetupFuncon

Youmaywanttosetpasswordsforvariouspersonnelso

theyonlyhaveaccesstocertainfuncons.

Todothat,double-tapthe********aereachLeveland

enterthenewpasswordonthealpha/numericscreen

thatwillappear.

Youwillbepromptedtoenterthepasswordtwice.Press

to return to USERS MANAGEMENT screen.

Thesevariablesarepre-setatthefactorybutcanbe

changedbytheprocessor.Sengthevaluestooghtly

cancausenuisancealarms.

19

OverDryProteconisStandardonDC+modelsandcan

beacvatedformoisturesensiveresinslikenylon.

WaterSavercanbeacvatedwhenanexternalCooling

oilisemployed.

MoistureManagerisanoponthatmustbeorderedin

advance.

AlarmSengsarepre-setatNOVATECbutLevel3

personnelcanadjustthesengs.

NosecuritytoviewthesepagesbutLevel2andup

requiredtomakechanges

Youcancalibrate“Touch”,BrightnessandturnSoundON

orOFF.Ifthescreenisdirty,abuonallowsyoutoclean

itwithoutdisturbingthesengs.

Press toaccessQuickOpScreen.

20

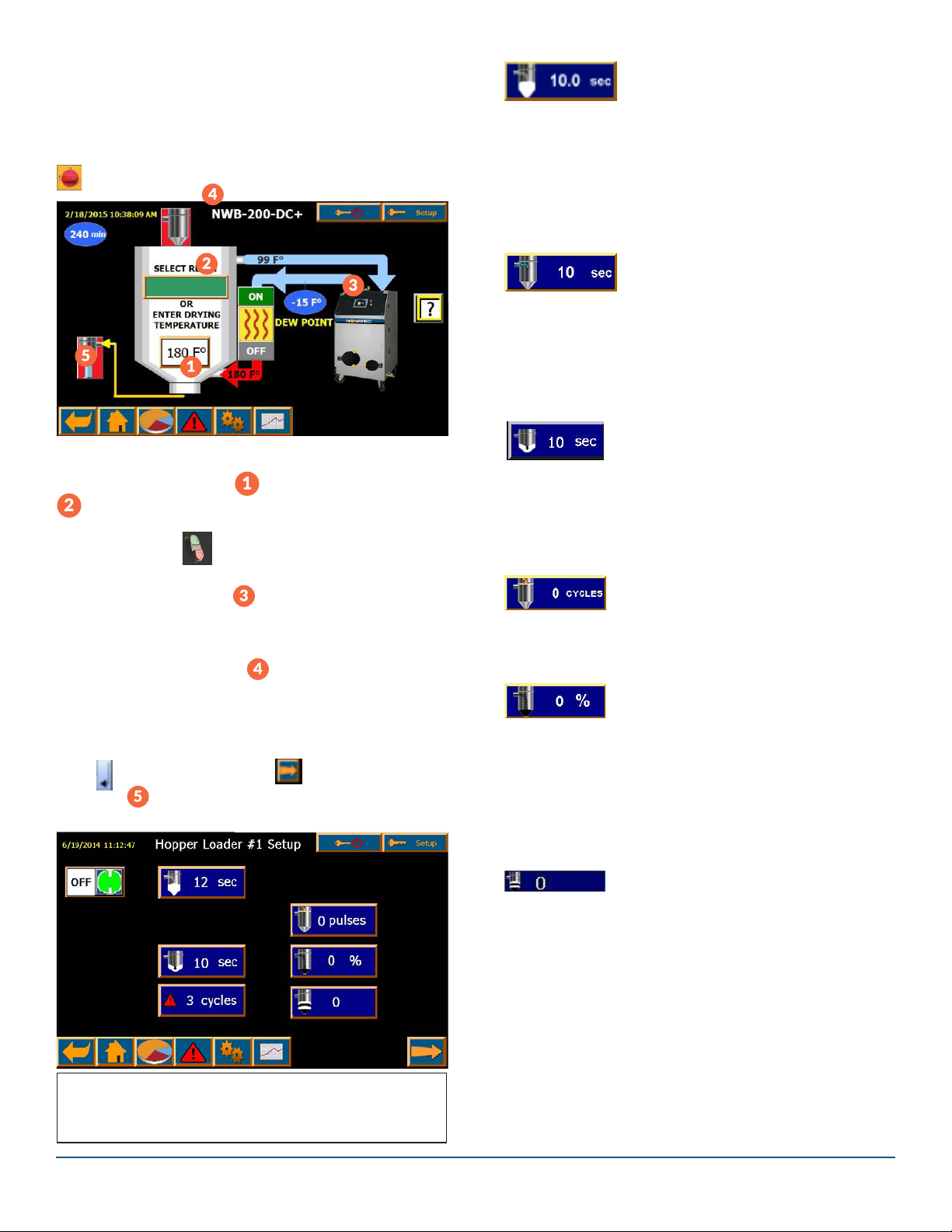

18.0 DRYING MATERIAL

18.1 Quick Op Screen

NOTE:Assurevoltage,conneconandphasingare

correct,coolingwaterissupplied(fordryingover225°F)

andthermocoupleisinsertedinhopper.Connectmaterial

sourcetoHopperReceiver.TurnMainDisconnectSwitch

to“ON”posion.

ProcessTemperatureisfactorysetat160°F.

Presstemperaturebuon tochangetemperatureor

to access RESIN MENU and choose one of the

pre-set resins.

Press Green “ON” switchtostarttheProcessHeater

andBlowers.NotethatProcessHeatercanbeturned

OFForONusingbuons ontheQuickOpscreen.

NOTE: Do not turn the process heater and blowers

Press Hopper Receiver icon to access Hopper Loading

screenshownbelow.

18.2 Hopper Loader Setup

Presseachfunconandentervalueonnumericscreen.

Press aereachentry.Press on Hopper Loader

screen or onQuickOpscreentoaccessMachine

MountReceiverscreen(below).

NOTE: Values in Hopper and Machine Receiver screens

shouldbeadjustedtoopmalvaluesaerprocessingbegins.

Blowbackmustbespeciedwhenorderplaced.

theoverallme,inseconds,

thatmaterialenterstheconveyair

stream.ItisthemethestaonTvacuumvalve,andif

equipped,thematerialpurgevalve,areopen,allowing

materialow.Thissengisrelavetothesizeofthe

receiverandtheowcharacteriscsofthematerial.

Defaultmeis10seconds.Notethatonreceivers

equippedwithaproporoningvalvethisistheoverall

virginandregrindloadingme.

(ifequipped)isthemein

secondsthatthestaonTvalveremains

openwhilethematerialpurgevalveisclosedtomaterial

ow.Itallowsforthepurgingofmaterialfromthe

conveyinglineaertheLoadTimehasexpired.Thisme

isrelavetothedistancefromthematerialpurgevalve

tothereceiverandhowsmoothlythematerialows.

Defaultmeis10sec.

thisisthemethatthe

materialtakestofallfromthereceiver

intothedryinghopper,binormachineaerloadingis

completed.Thismeisdeterminedbyhowsmoothlyor

slowlythematerialowsbygravityfromthereceiver.

Defaultis10seconds.NOTE:DumpTimeshouldbeset

for10secondsormore.

Pulses –Forreceiversequippedwith

ltercleaningblowbackcapability,this

sengdeneshowmanyburstsofcompressedairare

releasedintothereceiverduringthedumpcycle,toclean

thelter.Requirespasswordlevel3tomakechanges.

Regrind Pct (Regrind Percent) –denes

whatproporonofvacuummewill

dedicated to loading regrind into the hopper. This value

isapercentageoftheFILLme.Forexample,iftheFILL

mewas10secondsandtheRegrindPercentwas40%,

thentheproporoningvalvewilldedicate4secondsto

llingregrindmaterial.Theproporoningvalvewillthen

allowvirginmaterialtobeloadedfortheremaining6

seconds.

worksinconjunconwith

the Regrind Percent. It tells the propor-

oningvalvehowmanymestoswitchbetweenloading

regrindmaterialandvirginmaterialwithinasinglell

cycle.Alayerconsistsofbotharegrindmaterialpartand

avirginmaterialpart.CAUTION:Thecalculatedload

meperlayershouldbe2secondsorgreatertomove

materialconsistently.Proporoningrepeatabilityim-

provesaseachlayer’sloadmeincreases.

This manual suits for next models

8

Table of contents

Other NovaTec Dryer manuals

Popular Dryer manuals by other brands

Kenmore

Kenmore 6972 - 700 7.5 cu. Ft. Capacity Electric... installation instructions

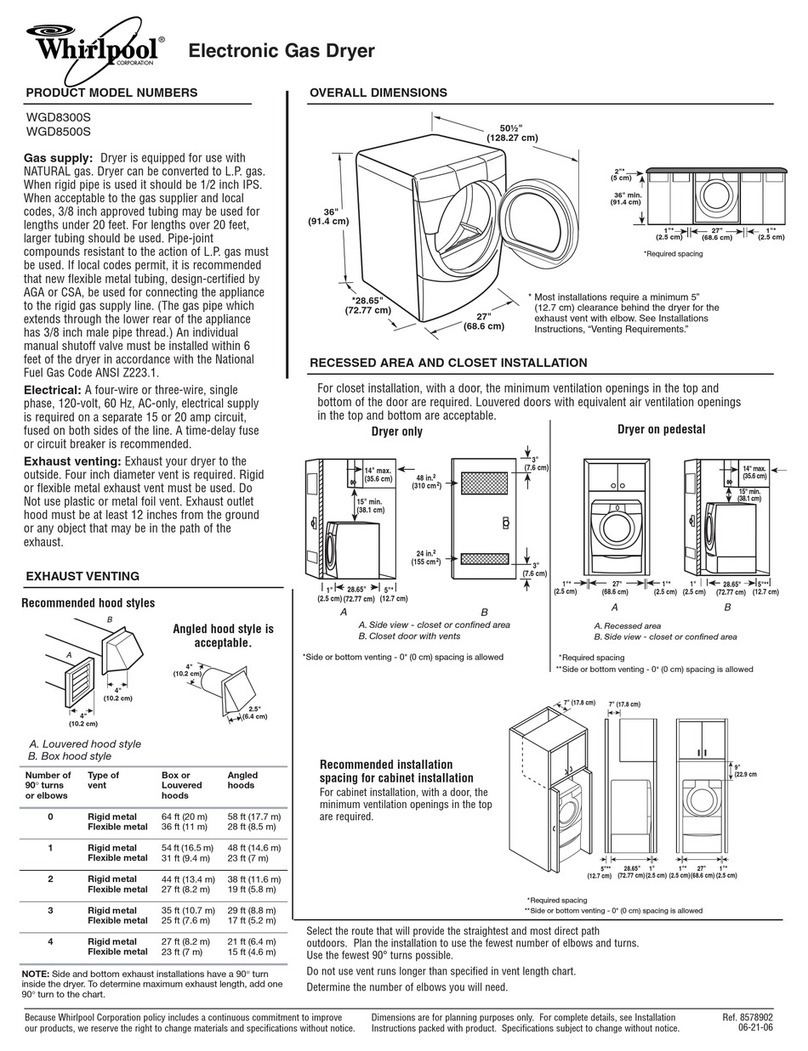

Whirlpool

Whirlpool WGD8300S Dimensions and installation information

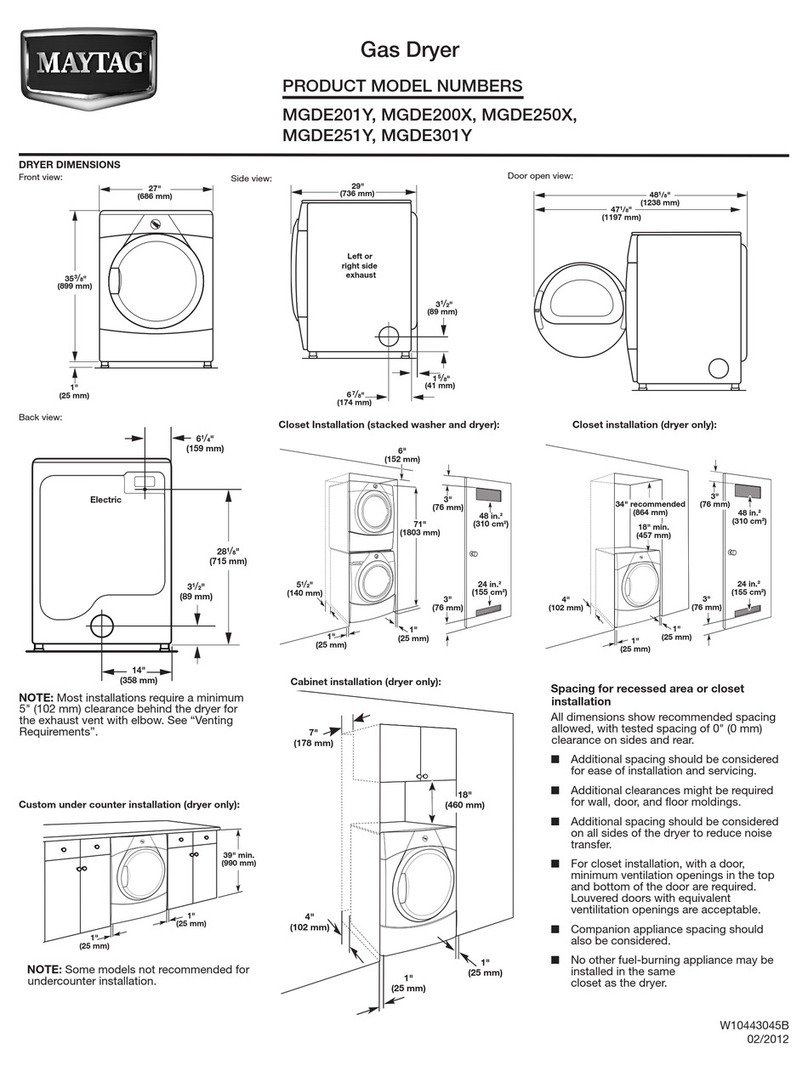

Maytag

Maytag MGDE301Y user manual

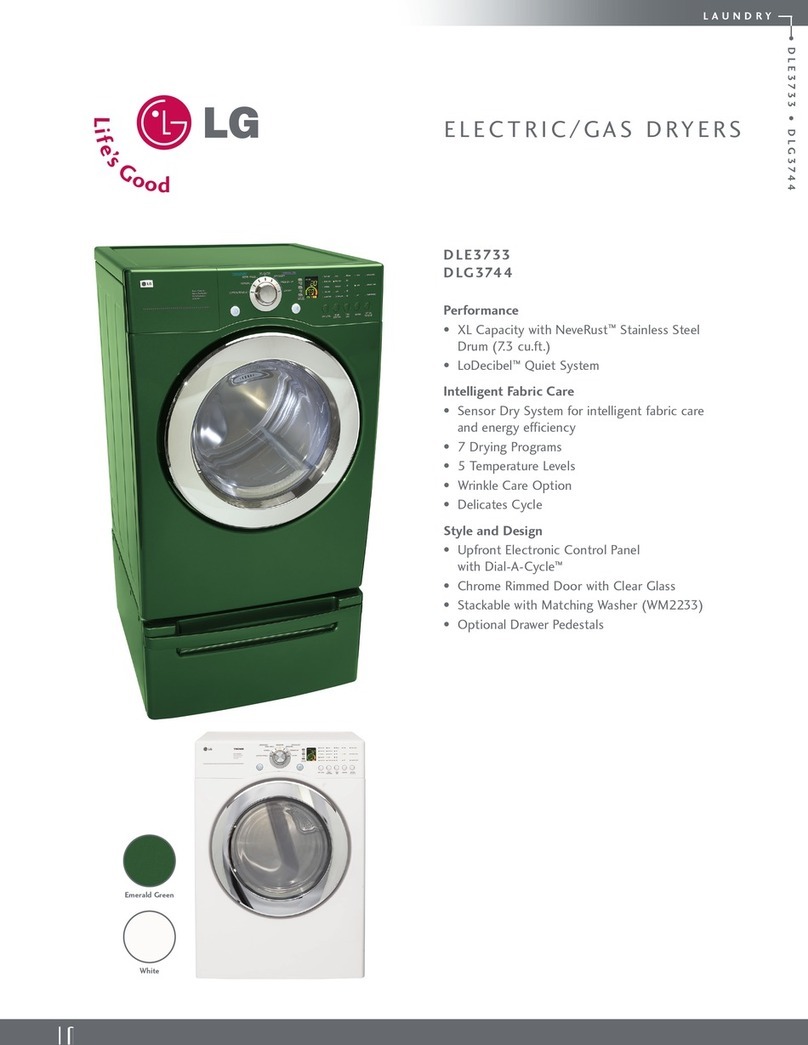

LG

LG DLE3733 Specifications

Sharp

Sharp KD-NCB8S7PB9-EN user manual

World Dryer

World Dryer smartdri K4 series user manual