Cirs Beam Profile & Slice Thickness Phantom ATS... User manual

USER GUIDE

U

L

T

R

A

S

O

U

N

D

Q

U

A

L

I

T

Y

A

S

S

U

R

A

N

C

E

Beam Profile & Slice

Thickness Phantom

Model ATS 538NH

900 Asbury Ave • Norfolk, Virginia 23513 • USA • Tel: 757-855-2765 • WWW.CIRSINC.COM

2

TABLE OF CONTENTS

1 OVERVIEW

1

2 INSTRUCTIONS FOR USE

1

HANDLING AND CARE

��������������������������������������������������������������� 1

GENERAL GUIDELINES FOR PERFORMING MEASUREMENTS

������������������������� 2

ESTABLISHING A BASELINE

��������������������������������������������������������� 3

3 TESTING PROCEDURES

4

BEAM PROFILE/FOCAL ZONE/LATERAL RESPONSE WIDTH

��������������������������� 4

ELEVATIONAL RESOLUTION

���������������������������������������������������������� 6

4 SPECIFICATIONS

10

5 WARRANTY

11

1

OVERVIEW

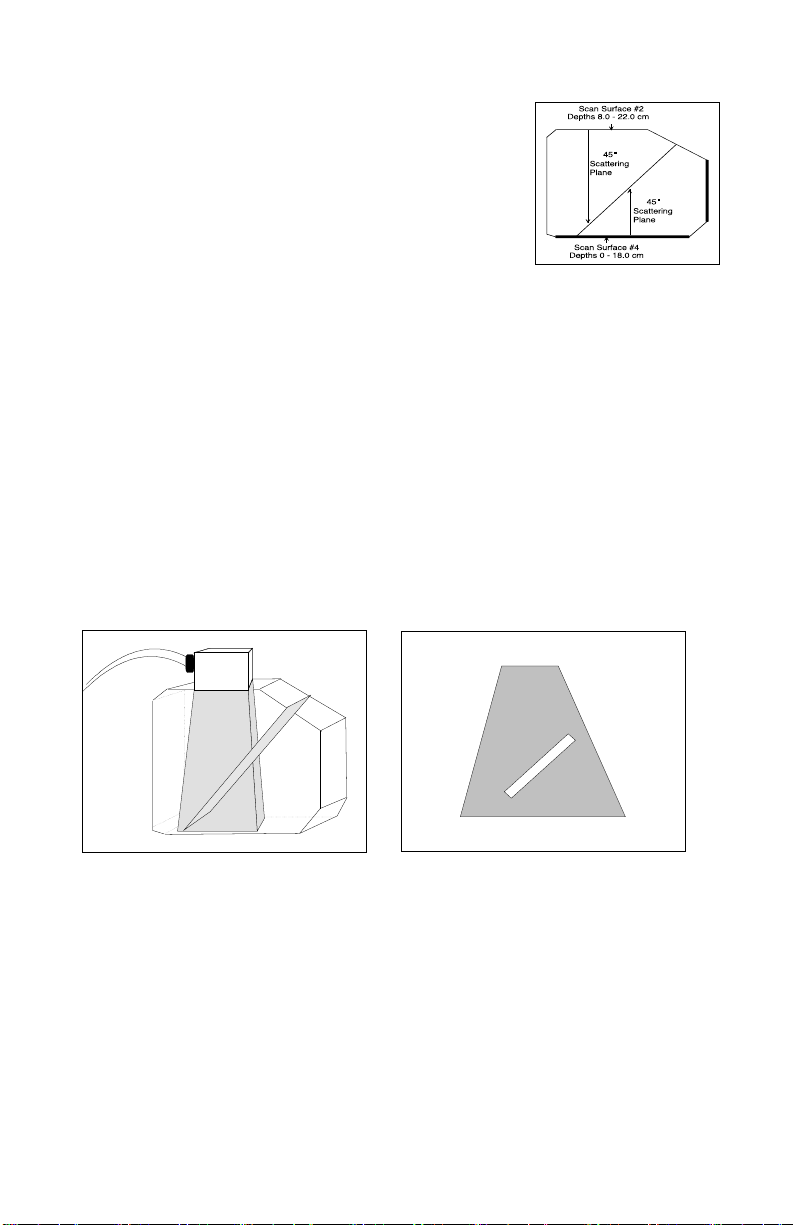

The Model 538NH can measure

the beam prole and slice thickness

of ultrasound imaging systems by

evaluating the appearance of a thin

plane of echogenic material against

an anechoic background.

Scanning the scattering plane from

one surface, perpendicular to the

thin plane, obtains an image of the

beam prole at varying depths of the

538NH. This image contains a great

deal of information about the sound

beam as it propagates through the

tissue-mimicking media such as the focal length, focal zone, beam width, side and

grating lobes, and far-eld beam divergence. In addition, the near eld region of the

beam can be easily distinguished from the far eld as varying degrees of brightness

close to the scan surface versus the homogeneous amplitude further down.

Scanning the scattering plane from a second surface, 45 degrees from the scat-

tering plane, allows users to evaluate the slice thickness of an imaging system at

varying depths. Slice thickness or elevational resolution, the third component of

spatial resolution, displays reections produced by structures in front of or behind

the beam’s main axis. The effect of changes in the slice thickness is identical to

those seen with axial and lateral resolution. The thinner the slice thickness, the

better the resolution: as the slice thickness increases, the degree of spatial resolu-

tion decreases. All ATS urethane phantoms are guaranteed for the useful life of the

phantom, dened as 10 years.

Key Tests with Model

ATS 538NH

• Tissue Harmonic Imaging

Compatibility

• Beam Prole/ Focal Zone/

Lateral Response Width

For more information on these tests, see

"Testing Procedures" starting on page 4

INSTRUCTIONS FOR USE

HANDLING AND CARE

For best results the phantom should be kept clean at all times. In particular a build-

up of dried coupling gel on the scan surface should be avoided. The phantom may

be cleaned with warm water using a lint free cloth. Particularly stubborn stains and

dirt may be removed with a mild household cleaner. The use of petroleum solvents

should be avoided since they may adversely react with the rubber-based material.

2

GENERAL GUIDELINES FOR PERFORMING MEASUREMENTS

It is recommended that all measurements be performed at the most frequently used

imaging arrangements. The importance of these tests is to make sure that system

performance remains constant over an extended period of time. Measurements

may also be used to compare the performance of various setups of the same

machine or to compare different machines in a quantitative manner.

The following are general steps for imaging all targets:

• If a convex probe is used, center the target within the scan plane in order to

minimize degradation and distortion introduced on the outer edges of the

probe.

• Always be sure the phantom is scanned while at room temperature. A

phantom just received may be colder or hotter than room temperature de-

pending on where it was stored during shipping. Temperature affects the

speed of sound and, ultimately, the perceived measurements. The phantom

should be stored at room temperature for at least 24 hours before use to

ensure its core temperature is correct.

• Most diagnostic imaging systems and tissue-mimicking phantoms are

calibrated at room temperature, commonly referred to as 23°C. To ensure

measurement accuracy, a thermometer strip is afxed to the outside surface

of the phantom housing.

• The sound velocity of most diagnostic imaging systems is calibrated to

1,540 meters per second (mps), the assumed average velocity of sound

through human soft tissue. The rubber-based tissue-mimicking material has

a sound velocity of 1450 at 0.5db/cm/MHz at room temperature (23°C).

The differences in the speed of sound between the assumed calibrated value

of the imaging system of 1540 mps and the rubber-based phantoms as

given above, if gone un-corrected will cause distortion of the measurements

obtained. A simple measurement conversion calculation has been provided,

and should be used when indicated in the test procedure.

3

ESTABLISHING A BASELINE

Before performing routine quality assurance measurements, establish:

1. System settings for each measurement:

System setup can have a dramatic impact on the results obtained from quality as-

surance measurements. You must establish and record what system settings

should be used for each of the quality assurance tests. These same settings

should be used each time the test is performed. If not, then the conclusions

drawn may not be valid. CIRS recommends that you use the most commonly

used settings for the type of probe tested ( i.e. the liver preset values for an abdominal

probe) which are called a "normal" technique in the sections that follow.

2. Baseline measurements:

The rst set of measurements taken will be the baseline measurements for the

combination of system settings and phantom. Record the system settings and

phantom serial number used to acquire each measurement along with

your measurement results. On subsequent scans, refer to the baseline results

to determine if the ultrasound system has drifted to an unacceptable level. It is

each facility's responsibility to establish the magnitude of drift allowed

before corrective action is warranted.

3. Allowable deviation from baseline measurements:

The difference between the original baseline measurements and subsequent

measurement should be calculated and recorded. At some point the difference

will be large enough that some action is required (call service, replace system,

etc.). Each facility needs to determine the action level for each test. You should

refer to the user’s manual of your ultrasound scanner and note the stated

accuracies of the system’s general imaging measurements. These stated ac-

curacies may greatly inuence the conclusion made when evaluating the ultra-

sound system. For example, if the measurement accuracy for your system

is 10% for distances up to 2 cm, the scanner may detect 2.0 cm as being any

where from 1.8 cm to 2.2 cm and still be functioning properly. The user is

responsible for establishing action levels.

4. Frequency of system assessment:

How often each system is evaluated is also up to each facility to determine.

CIRS recommends at least annually.

Reference the accreditation programs established by the ACR and AIUM at

www.acr.org or www.aium.org for further guidance on establishing a QA program.

4

TESTING PROCEDURES

The following sections outline procedures for routine quality control tests with the

Model ATS538NH. It may be useful to refer to the target map, shown in the Speci-

cations section of page 10, when reviewing these procedures.

BEAM PROFILE, FOCAL ZONE AND LATERAL RESPONSE WIDTH

The beam prole or cross-sectional display of the sound beam (termed Lateral

Response Width) contains a great deal of information regarding the conguration of

the sound beam as it propagates through the tissue-mimicking media. The beam

prole clearly displays the near eld, focal length, focal zone, beam width, side and

grating lobes, and beam divergence in the far eld. In addition, amplitude varia-

tions in the near eld, are displayed as varying degrees of brightness versus the

almost homogeniticity of the amplitude in the far eld. The beam prole is affected

by the performance of the transducer and the pulser/receiver section of the imaging

system.

1. Place the phantom on a clean, at surface with #1 scanning surface positioned

for use.

2. Apply a liberal amount of acoustic coupling gel to the scanning surface. It is

suggested, when evaluating array systems a low viscosity coupling agent be

used to minimize a "snowplowing" affect on the surface of the phantom. When

testing, transducer faces with a high degree of curvature, the use of a high

viscosity gel is recommended to maintain good coupling.

3. Adjust the instrument settings (TGC, output, etc.) to establish baseline values

for "normal" liver scanning. If the penetration is such that the bottom of the

phantom is seen, the gain settings are reduced such that the image fades

and goes entirely black. These settings should be noted on the quality

assurance record and used for subsequent testing.

5

BEAM PROFILE, FOCAL ZONE AND LATERAL RESPONSE WIDTH (CONTINUED)

4. The phantom is constructed with a scattering plane located in the center of

and at 90° to the scanning surface. Place the transducer on scan surface #1.

Adjust the position until the prole of the beam is clearly displayed.

Note: For sector imaging systems, the beam will sweep back and forth as it

passes through the scattering plane, imaging the cross-section of the

beam. In a multitransducer sector scan head, the image will be the integrated

sum of all the beam proles. To examine the beam prole of the individual

transducer, the frame rate must be decreased, until the individual beam prole

is displayed. Depending upon the system, it may be necessary to reduce

the frame rate to zero.

5. Freeze the image and obtain a hard copy.

6. Examine the display. The image should be "hour-glass" in shape. Note the

presence or absence of any grating lobes, which will be displayed as

two "horns" on either side of the main beam, usually in the near

eld. Using the electronic calipers, measure the focal length and beam width at

the focal point. If you desire, measurements of the near and far elds can also

be obtained.

NOTE: A correction factor of 0.94 adjusts for the speed of sound in ATS

urethane (1450 m/s).

7. Document all measurements and observations on the quality assurance record.

6

BEAM PROFILE, FOCAL ZONE AND LATERAL RESPONSE WIDTH (CONTINUED)

Results

The beam prole should remain consistent from week to week, when using the

same instrument settings, transducer and the Model #538NH phantom. Compare

the test results obtained with a baseline or previous test. If the current image dem-

onstrates changes in the system, investigation should be made to determine the

cause.

ELEVATIONAL TESTING

A third component of spatial resolution,

the slice thickness, is often referred to as

the elevation resolution. A sound beam

travels through a medium along the beam

axis until it reaches an interface which is

perpendicular to the axis of the

sound beam, creating a two-dimensional

image. The image resolution is depedent

upon the degree of axial and lateral resolu-

tion of the diagnostic system. Elevational resolution displays reections produced by

structures in front of or behind the beam's main axis. The effect of changes in the

slice thickness measurements are identical to those seen with axial and lateral reso-

lution. The smaller the slice thickness measurement the better the resolution, as the

slice thickness increases, the degree of spatial resolution decreases. In diagnostic

ultrasound, this factor becomes critical in determining an imaging system's ability

to detect and display small isolated lesions or structures of low contrast, which may

appear to be lled-in and go undetected.

ELEVATIONAL TESTING (CONTINUED)

7

ELEVATIONAL TESTING (CONTINUED)

1. Two scan surfaces are provided for obtaining slice

thickness measurements. For depths ranging from 8.0

to 22.0 cm scan surface #2 should be used. Scan

surface #4 is used when the scanning depths required

range from 0 to 18.0 cm. Place the phantom on a

clean, at surface with the proper scan surface

positioned for use.

2. Apply a liberal amount of acoustic coupling gel to the

scanning surface. It is suggested, when evaluating array systems a low

viscosity coupling agent be used to minimize a "snowplowing" affect on the

surface of the phantom. However, transducer faces with a high degree of

curvature, the use of a high viscosity gel is recommended to maintain good

coupling.

3. Adjust the instrument settings (TGC, output, etc.) to establish baseline values

for "normal" liver scanning. If the penetration is such that the bottom of the

phantom is seen, the gain settings should be reduced such that the image

fades and goes entirely black. These setting should be noted on the quality

assurance record and used for subsequent testing.

4. Position the transducer on the scan surface providing the proper depth range.

The image displayed will appear as a band or thick line positioned at a given

depth in an angular plane.

8

5. Rotate the transducer until the image displayed is positioned in the horizontal

plane. This is the slice thickness of the sound beam at a given depth.

Note: For sector imaging systems, the beam will sweep back and forth as it passes

through the scattering plane, imaging the cross-section of the beam. In a multi-

transducer sector scan head the image will be the integrated sum of all the slice

thickness. To examine the slice thickness of the individual transducers, the frame

rate must be decreased permitting a single slice thickness to be displayed. De-

pending upon the system, it may be necessary to reduce the frame rate to zero.

6. Freeze image.

7. Using the electronic calipers, measure the distance from the scan surface to

the center of the displayed slice thickness image.

8. Again using the electronic calipers, measure the thickness of the image. This is

the slice thickness of the sound beam at a given depth.

9. Obtain a hard copy and document all measurements on the quality assurance

record

10. To obtain a series of slice thickness measurements at various depths, slide the

transducer along the scan surface. Repeat steps 4 through 9.

9

ELEVATIONAL TESTING

11. Using graph paper, plot the slice thickness

measurements obtained at each given

depth. Draw a connecting line on each

side of the results plotted. The resulting

drawing will be a graphical representa-

tion of the slice thickness beam prole.

Document the smallest measurement of

the slice thickness and depth at which it

occurred; this area is the focal zone.

NOTE: A correction factor of 0.94 adjusts for

the speed of sound in ATS urethane (1450

m/s).

Results

The slice thickness of the beam should remain consistent from week to week,

when using the same instrument settings, transducer and the Model #538NH

phantom. Compare the test results obtained with a baseline or previous test. If the

current image demonstrates changes in the system, investigation should be made

to determine the cause.

10

SPECIFICATIONS

TARGET LAYOUT

PHANTOM

Housing PVC

Overall Dimensions 25 x 22 x 7 cm (10" x 9" x 3”)

Weight 5.1 kg

Scanning Surface Dimensions 15.0 x 7.0 cm, 12.0 x 7.0 cm, 12.0 x 7.0 cm,

22.0 x 7.0 cm, 19.0 x 7.0 cm

URETHANE PROPERTIES

Freezing point: < -40°C

Melting point: Above 100° C

Speed of Sound: 1450 m/s at 23°

Attenuation Coefcient: 0.5 dB/cm/MHz (measured at 3.5 MHz)

TARGETS

Scattering plane oriented at 45° to the scan planes used to measure slice

thickness, and 90° to the beam prole scan plane

Size: 26 x 7 cm

Depth: 0 to 22 cm

11

WARRANTY

All standard CIRS products and accessories are warranted by CIRS against defects

in material and workmanship for a period as specied below. During the warranty

period, the manufacturer will repair or, at its option, replace, at no charge, a product

containing such defect provided it is returned, transportation prepaid, to the manu-

facturer. Products repaired in warranty will be returned transportation prepaid.

There are no warranties, expressed or implied, including without limitation any im-

plied warranty of merchantability or tness, which extend beyond the description on

the face hereof. This expressed warranty excludes coverage of, and does not pro-

vide relief for, incidental or consequential damages of any kind or nature, including

but not limited to loss of use, loss of sales or inconvenience. The exclusive remedy

of the purchaser is limited to repair, recalibration, or replacement of the product at

manufacturer’s option.

This warranty does not apply if the product, as determined by the manufacturer,

is defective because of normal wear, accident, misuse, or modication.

NON-WARRANTY SERVICE

If repairs or replacement not covered by this warranty are required, a repair estimate

will be submitted for approval before proceeding with said repair or replacement.

RETURNS

If you are not satised with your purchase for any reason, please contact your local

distributor prior to returning the product. Visit https://www.cirsinc.com/distributors/

to nd your local distributor. If you purchased your product direct through CIRS, call

Customer Service at 800-617-1177, email [email protected], or fax an RMA request

form to 757-857-0523. CIRS staff will attempt to remedy the issue via phone or

email as soon as possible. If unable to correct the problem, a return material autho-

rization (RMA) number will be issued. Non-standard or “customized” products may

not be returned for refund or exchange unless such product is deemed by CIRS

not to comply with documented order specications. You must return the product

to CIRS within 30 calendar days of the issuance of the RMA. All returns should be

packed in the original cases and or packaging and must include any accessories,

manuals and documentation that shipped with the product. The RMA number must

be clearly indicated on the outside of each returned package. CIRS recommends

that you use a carrier that offers shipment tracking for all returns and insure the full

value of your package so that you are completely protected if the shipment is lost or

damaged in transit. If you choose not to use a carrier that offers tracking or insure

the product, you will be responsible for any loss or damage to the product during

shipping. CIRS will not be responsible for lost or damaged return shipments. Return

freight and insurance is to be pre-paid.

WITH RMA NUMBER, ITEMS MAY BE RETURNED TO:

CIRS

Receiving

900 Asbury Ave,

Norfolk, Virginia, 23513 USA

PRODUCT WARRANTY PERIOD

Model ATS538NH - Beam Prole & Slice thickness

Phantom 120 Months

12

©2020 Computerized Imaging Reference Systems, Inc. All rights reserved.

Specications subject to change without notice.

Publication: ATS538NH UG 073120

Computerized Imaging Reference Systems, Inc. has been

certied by UL DQS Inc. to (ISO) 13485:2016. Certicate

Registration No.10000905-MP2016.

COMPUTERIZED IMAGING

REFERENCE SYSTEMS, INC.

900 Asbury Ave

Norfolk, Virginia 23513 • USA

TOLL FREE 800.617.1177

TEL: 757.855.2765

FAX: 757.857.0523

EMAIL: [email protected]

www.cirsinc.com

Technical Assistance

1.800.617.1177

Table of contents

Popular Laboratory Equipment manuals by other brands

BANDELIN

BANDELIN SONOPULS HD 4200-SB operating instructions

3M

3M 9900 Series instructions

LW Scientific

LW Scientific MX5 Centrifuge instruction manual

Apex Instruments

Apex Instruments XC-5000 Operator's manual

Four E's Scientific

Four E's Scientific Overstar60 quick start guide

uv guard

uv guard T Series Installation and operation manual

Gilson

Gilson macroman user guide

Holland Green Science

Holland Green Science Antidrastiras CG05 user manual

Braun

Braun SpaceControl Instructions for use

CPS

CPS CPS-UVC-19-S-1000 quick guide

Stanford Research Systems

Stanford Research Systems SIM985 Operation and service manual

VERDER

VERDER Carbolite Gero HTMA 4/95 Installation, operation and maintenance instructions