4

T-Series™

1. Getting Started

Delivery Inspection

Each unit is tested prior to packaging to ensure that the unit is operational and in good working

order.

Upon receipt of goods, be sure to check the shipment for any signs of damage, and if any

damage has occurred, notify both the carrier and the shipper in writing within 72 hours of the

damage and retain the parts and packaging for inspection.

Check that all working parts of the unit have been received.

For a UVG T Series unit this will include:-

a. Tank Connection with Sealing Nuts

b. Power Supply Box with 4 Pin lamp connector

c. Quartz Thimble

d. UV lamp

e. O ring x 2 (normally included in tank connection)

Spares:-

Item UVG T20 UVG T30 UVG T30

UV lamp (ozone free) 11020 11030 11040

UV lamp (ozone producing) -11031 11041

Quartz thimble 20280 20290 20310

O ring seal 31000 31000 31000

2. SETTING UP

Disinfection Unit Mounting

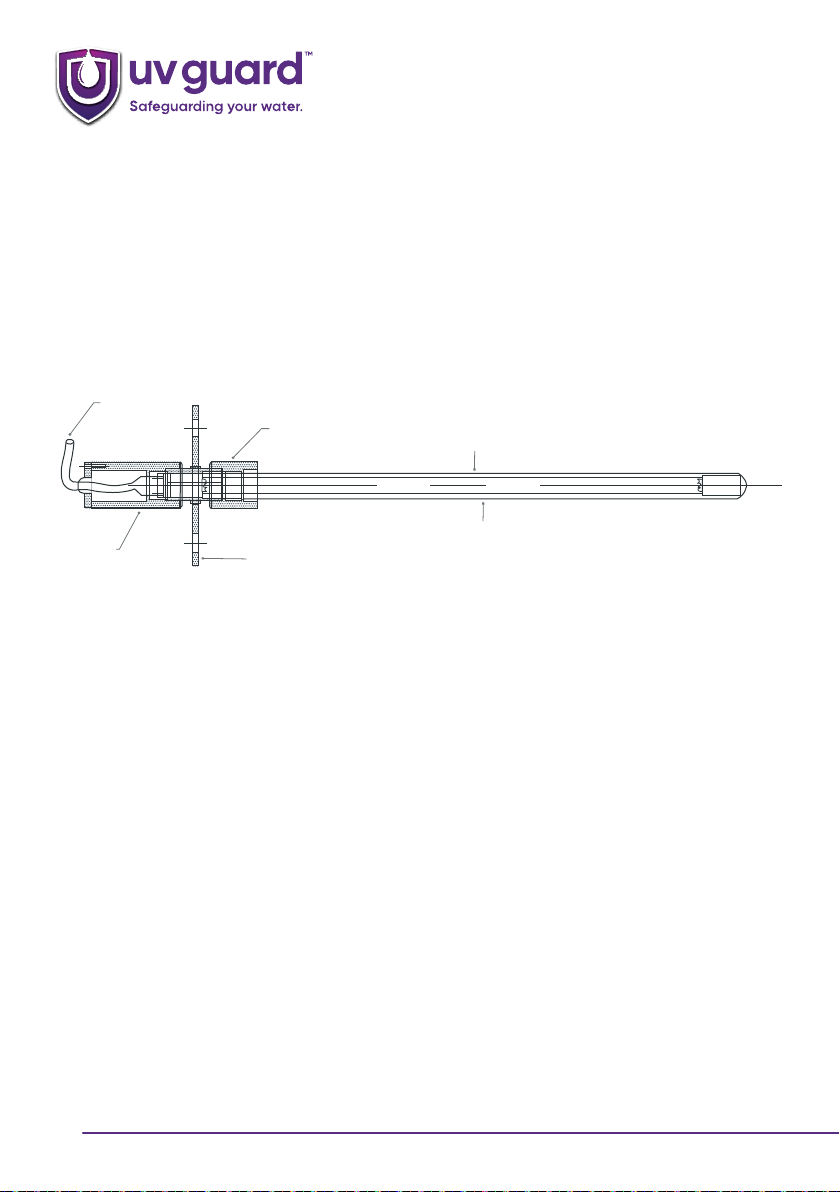

The UVG T Series disinfection unit comes complete with its own flange mount. The standard flange will

be 2” table D. Other options such as, BSM, BSP, Triclover, Table E flange etc… are available on request.

The unit can be mounted in the vertical or horizontal position

Up to one metre space is required on the outside of the tank at the power head for servicing purposes.

(T40 requires 1000mm, T30 requires 600mm, T20 requires 400mm)

Ensure there is sucient space inside the tank to accommodate the glassware without interfering with

any mechanical components such as mixers.