Cirs 769 User manual

USER GUIDE

Doppler Flow Pump

Model 769

900 Asbury Ave • Norfolk, Virginia 23513 • USA • Tel: 757-855-2765 • WWW.CIRSINC.COM

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Instructions for Use . . . . . . . . . . . . . . . . . . . . . . . 7

Program Pulsitile Flow . . . . . . . . . . . . . . . . . . . . . . 9

Contrast Injection Setup . . . . . . . . . . . . . . . . . . . . 10

Calibration and Resetting . . . . . . . . . . . . . . . . . . . . 10

Care and Handling . . . . . . . . . . . . . . . . . . . . . . . 11

Appendix 1: Pump Calibration . . . . . . . . . . . . . . . . . . 12

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Table of Contents

The Doppler Flow Pump is used to simulate blood ow when testing Doppler ultrasound devices. When used

in conjunction with a tissue mimicking phantom (sold separately; a list of compatible CIRS phantoms is on the

back), the ow pump supports routine Doppler quality assurance measurements of velocity accuracy, direc-

tional accuracy, sample volume accuracy and sensitivity. The congurable design also supports advanced

research and engineering tests. For instance, test circuit may be modied to support either constant veloc-

ity ow or pulsatile ow. When in pulsatile ow mode, the peristaltic pump may be programmed to produce

physiologic waveforms. In addition, the external tubing circuit ensures laminar ow rates over a wide range of

ow rates, and it allows users to easily inject contrast agents for testing contrast enhanced ultrasound (CEUS).

The pump comes in a plastic ABS housing that conveniently stores all accessories needed for setting up a

ow circuit, as described in the next section.

Overview

Included with Model 769

The CIRS Doppler Flow Pump consists of the following parts:

1. Peristaltic Pump. The pump provides ow rates of 0.5 to 12.5 ml/s, which translates to an average ow

velocity of 2-70 cm/s in a vessel with a 3/16” inside diameter. (Peak ow velocities will be 2-4 times greater

than the average ow velocity because of laminar and pulsatile ow). For more information on ow rates and

ow velocities, consult the Tables in Appendix 1.

2. CIRS Doppler uid and User Guide. The uid comes in a ½ gallon container that doubles as a uid reservoir.

More uid may be purchased separately at www.CIRSinc.com (CIRS model 769DF). See Doppler uid User

Guide for more information

3. Graduated Cylinder. Located next to the Doppler uid reservoir, the 500 ml graduated cylinder is used in

pump calibration and provides a handy transfer reservoir when purging phantoms of Doppler uid after each

use.

4. Pulse dampener. The pulse dampener evens out the pressure pulse from the peristaltic pump to deliver

constant velocity ow within the test circuit. Constant velocity ow is required for many quality assurance

test procedures for doppler ultrasound systems. Please note pulse dampener will always have a small

amount of Doppler uid remaining after each use. This is normal. The pulse dampener will not leak in stor-

age. Be sure to not get water in the dampener, as this will dilute the doppler uid, ruining its ability to mimic

blood under ultrasound.

5. Tubing Pack. The color-coded tubing comes with quick-disconnect ttings for easy setup.

6. Control Cables. Computer control of the peristaltic pump is possible through a pump-to-USB cable. See

Program Pulsatile Flow for instructions on downloading the control software and programing the pump.

3

QTY COMPONENT DESCRIPTION

1Blue 3/16” cassette with white rotor

2pump head tubing with quick disconnect ttings (two male each)

1container of pump head lubricant

QTY COMPONENT DESCRIPTION QUICK DISCONNECT FITTINGS

2red 3/8” outer diameter tubing one male, one female

1blue 3/8” outer diameter tubing two male

1reservoir cap with two uid ports two female

2ATS phantom adapters one male (each)

5

Specications

GENERAL SAFETY NOTICE

The pump provided is pre-set to operate with 3/16” inner diameter tubing. To achieve ow rates lower than the minimum rates those listed

below, the pump may be accommodated with 1/16” inner diameter tubing. Please contact CIRS to obtain a conversion kit to enable lower ow

rates with this pump.

PUMP SAFETY INFORMATION

Motor type: Step motor

Motor steps per revolution: 200

Microstepping: 1/8 to 1/1 depending on motor speed

DC connector: 2.1mm, center positive

Voltage at DC connector: 24V DC at full load

Amperage: 900mA at full load

Power supply type: Unregulated linear external wall adapter, country and

power source specic

Power supply output rating: 24V DC @ 1A

Dimensions: 7 ¾” x 5 1/4” x 5 3/4” High

(19.685 cm x 13.335 cm x 14.605 cm)

Weight: 4.51 lbs. (2.05 kg)

Maximum speed: 372 rpm

Minimum speed: 0.0168 rpm

Maximum pumping rate: 775.2 mL/min with 3/16 ID tubing

Minimum pumping rate: 0.035 mL/min with 3/16 ID tubing

This product is designed for use with CIRS Doppler Fluid and water (for cleaning purposes) only. Use of other uids (or non-liquids) may result in

damage to the pump.

Turn the pump off when re-conguring the system setup. Failure to do so may result in accidental spillage.

Review the enclosed Doppler uid User’s Guide for more information on the safe handling and disposal of Doppler uid.

WARNING: THE LIST BELOW PROVIDES INFORMATION THAT,

IF IGNORED OR APPLIED INCORRECTLY, CREATES THE POSSI-

BILITY OF DEATH OR SERIOUS INJURY. IE. FIRE, EXPLOSION.

!

• Read the user’s manual.

• This product is designed for liquid only.

• User is responsible to determine the suitability of the pump to its desired function.

• Verify that tubing is appropriate for liquid being pumped.

• Disconnect power from the pump when replacing tubing or connecting or disconnecting cables.

6

• Never leave any dangerous liquid inside of tubing when replacing tubing and disposing pump. Use of liquids other than CIRS Doppler

Fluid or water is not recommended.

• Never use in atmosphere with ammable gas.

• Never use in any location where there is a possibility of high humidity, high temperature, or extreme dust.

• Use only with the supplied power supply connected to a power source as specied on the power supply label.

• Never use a voltage that is different from voltage specied in this manual, unless authorized by CIRS.

• Do not operate with any foreign matter (water, dirt, metal or other materials) inside the Pump-head.

• Do not push objects of any kind into the chassis openings, except for appropriate cables and connectors.

• Never try to take the unit apart or modify it except as described in this manual or authorized by CIRS. No user serviceable parts inside.

• Do not immerse the pump in liquid. If spilling occurs unplug pump immediately.

• Install on a stable surface.

• The pump can automatically start when the Pumping Program is operating or when attached to an external control device.

• Prevent liquids from entering openings in the rear of the pump.

• If the pump becomes damaged, do not use unless certied safe by a qualied technician. Damage includes, but is not excluded

to ,frayed cords and deterioration in performance.

• Do not transport and store this product where the temperature and the humidity are high or uctuate greatly, or the product is subjected

to direct sunlight.

• Remove tubing from pump when not in use. Tubing will become deformed changing dispensed volume per rotation.

• Tubing wall may become permanently damaged if the roller compresses the same part of the tubing for a long time.

• During installation and use, be careful not to cut yourself on the edge of the Pump parts.

• Tubing life depends upon chemical and operating environment.

• Tubing Chemical compatibility list mentioned is only a guide. The user is responsible to determine the tubing compatibility to the chemi-

cal to be used.

• Keep delivery and suction lines as short as possible, use a minimum number of bends.

• Pump operates best at medium speeds. At very slow speeds pump will get hot. At high speeds pump and tubing life will decrease,

pump will lose force/ pressure and may stall.

• Run at slow speed and use larger diameter tubing when pumping viscous liquid.

• User is responsible to determine the maximum speed the pump can operate.

• Discharge static from control cables before connecting by touching the cable to ground.

• Before touching the pump, discharge static by touching ground.

CAUTION: THE LIST BELOW PROVIDES INFORMATION THAT, IF

IGNORED OR APPLIED INCORRECTLY, CREATES THE POS-

SIBILITY OF MINOR OR MODERATE PERSONAL INJURY OR

PROPERTY DAMAGE

!

7

Instructions for Use

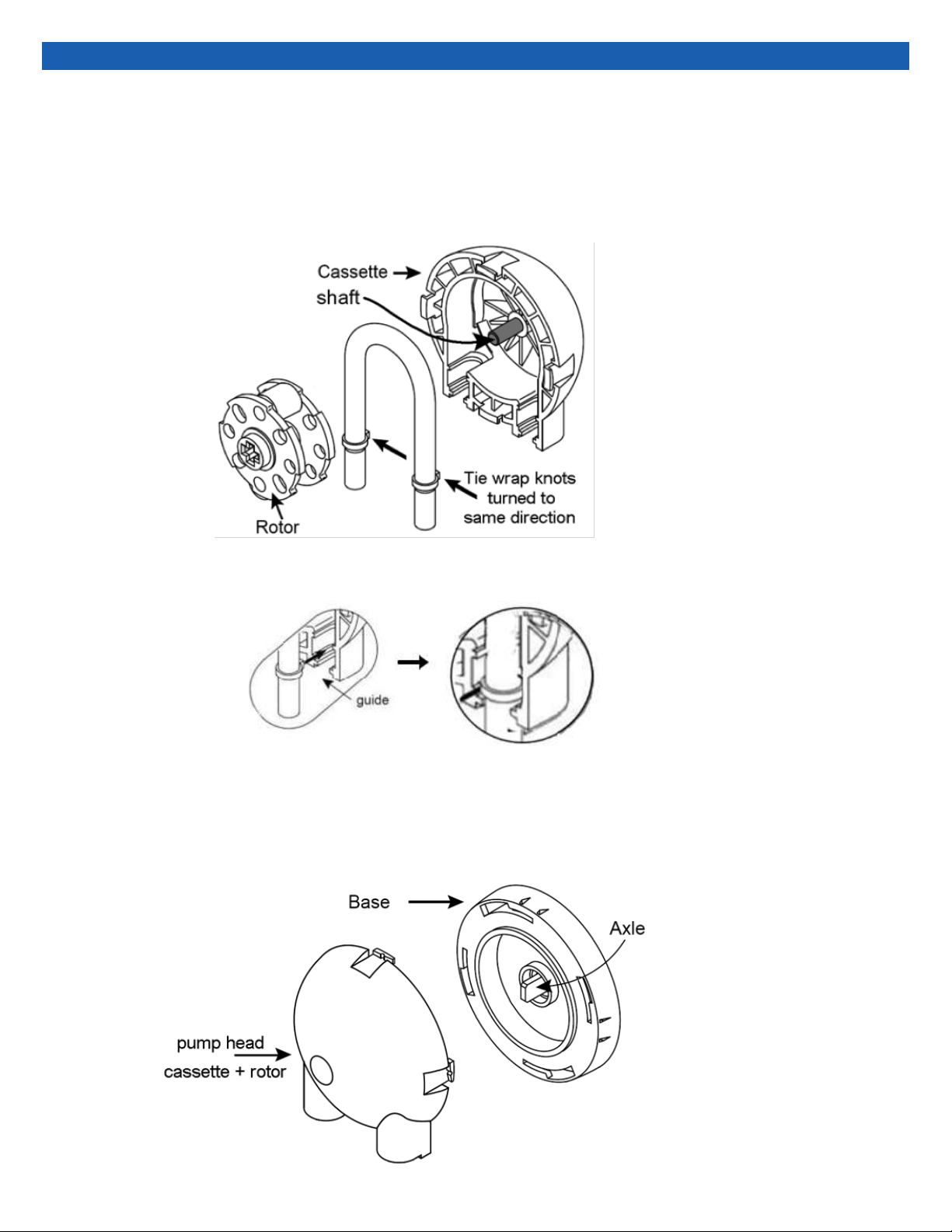

1. Assemble the pump head assembly

− Remove rotor from cassette (see gure below). Add grease to pump Shaft and pump Tubing.

(Tubing comes pre-cut with Quick-Disconnect ttings and tie-wraps spaced 5 3/8” apart.)

− Place tubing into the guide of the cassette, tie wrap knots facing cassette. This will be a tight t

and will NOT snap into place.

− Tuck the edge of the rotor under the center of tubbing, so the tubbing is resting between the yel

low wheels of the rotor.

− Push the rotor onto the shaft. Note that the rotor has two sides: one with a circle and one with a

cross. Only the circle side will t onto the shaft.

− Install the pump head onto base by rst lining up rotor and driving axle, then applying forward

pressure and rotating cassette clockwise until it enters its groove. Continue turning until it stops.

8

2. Prepare pump for operation

− Plug in the pump. Use appropriate power supply. (220V power supply is available. Please contact CIRS.)

− Press the power switch on the back of the pump to turn on power.

− Press any key to stop the display from blinking.

3. Setup Pump for Continuous Flow:

− Display the pumping rate by momentarily pressing the ‘Rate’ key.

− Momentarily press the ‘Rate’ key again. The display will show:

− Press any up arrow key to select the rate units until the “mL” and “min” indicators are lit.

− Press ‘rate’ key, or wait for the time out to set the rate units.

− Set the pumping rate using the arrow keys. If the pumping rate is out of range, the display will show:

− Display the volume by momentarily pressing the ‘Volume’ key. ‘Dispensed’ LED should be off. Press the up arrow

keys to change the display to 0; once entered the display will show which means the pump is set for con-

tinuous pumping.

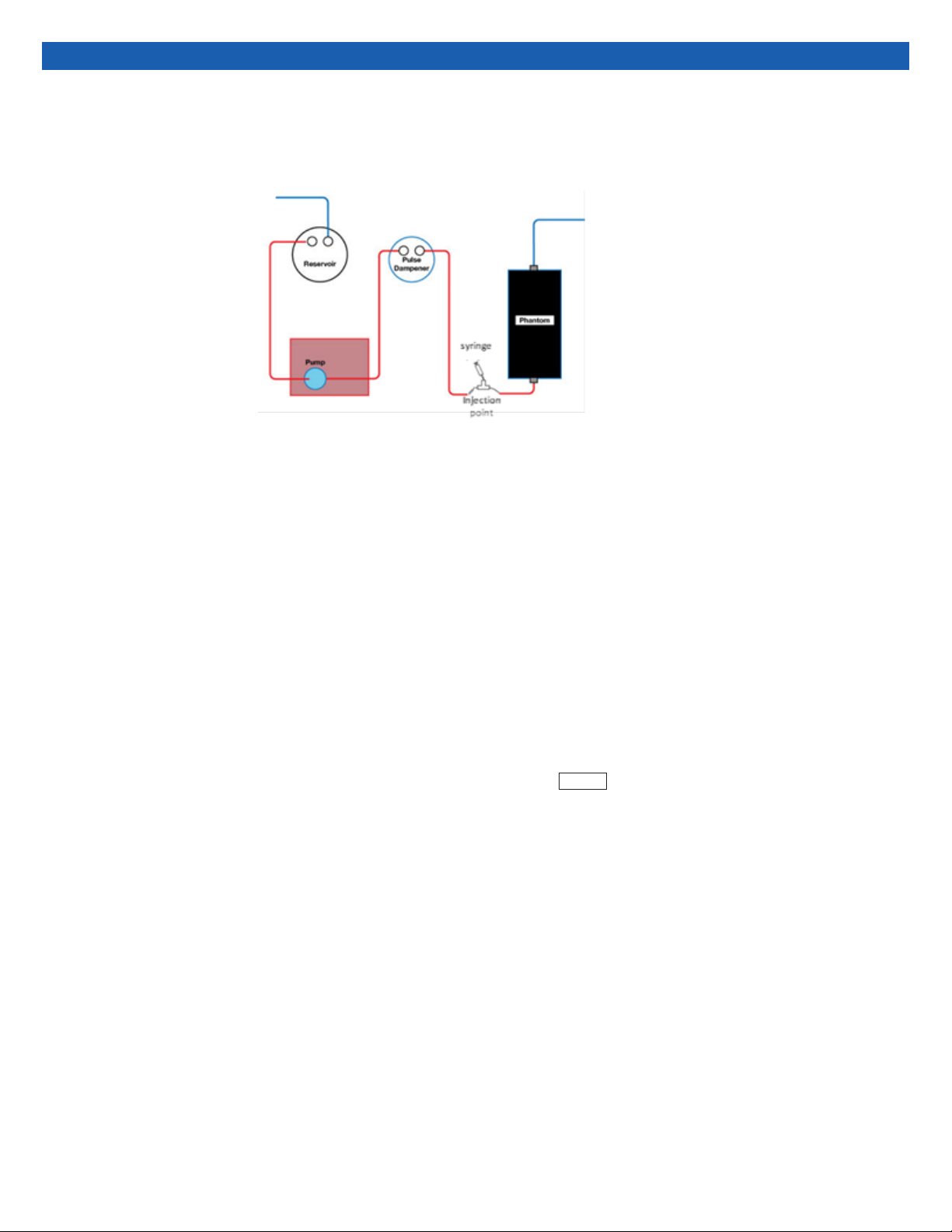

4. Construct the ow circuit

− Use the tubing pack and pulse dampener to construct a ow circuit with a Doppler phantom.

− For constant velocity ow, direct ow through the pulse dampener. (Setup 1)

− For pulsatile ow, remove the pulse dampener. (Setup 2)

5. Start the pump

− Momentarily press the ‘start/stop’ key to start the pump.

− The pumping rate can be changed by pressing the up-arrow keys, even while the pump is running. Note the pump

can make a loud noise at some ow settings. A small change in pump speed will eliminate this noise.

6. Stop the pump

− Momentarily press the ‘start/stop’ key to stop the pump.

Unt 5

or:01

OFF

9

1. Press the ‘diameter’/’setup’ key while turning on power to the pump. The display shows

2. Use the up-arrow keys to scroll through to

3. Press ‘rate’ or ‘volume’ or wait for the time out to select.

4. The display shows: where ‘n’ is the setting: ‘0’ = disabled, ‘1’ = enabled.

5. Use the up arrow to disable dispense mode. The display shows

6. Press ‘rate’ or ‘volume’ or wait for the time out to select.

The pump has a dispense mode that is useful for lling up bottles. But before programming the pump, the dispense mode must be disabled.

1. Go to http://www.syringepump.com

2. Under “Accessories”, click on “Pump Software.”

3. Scroll down to PumpTerm. Download for free.

4. Follow the installation instructions included in the download

Program Pulsitile Flow

To program pulsatile ow, you must rst download and install the PumpTerm program.

diA

disP

dis:n

dis:0

The pump is ready for programing.

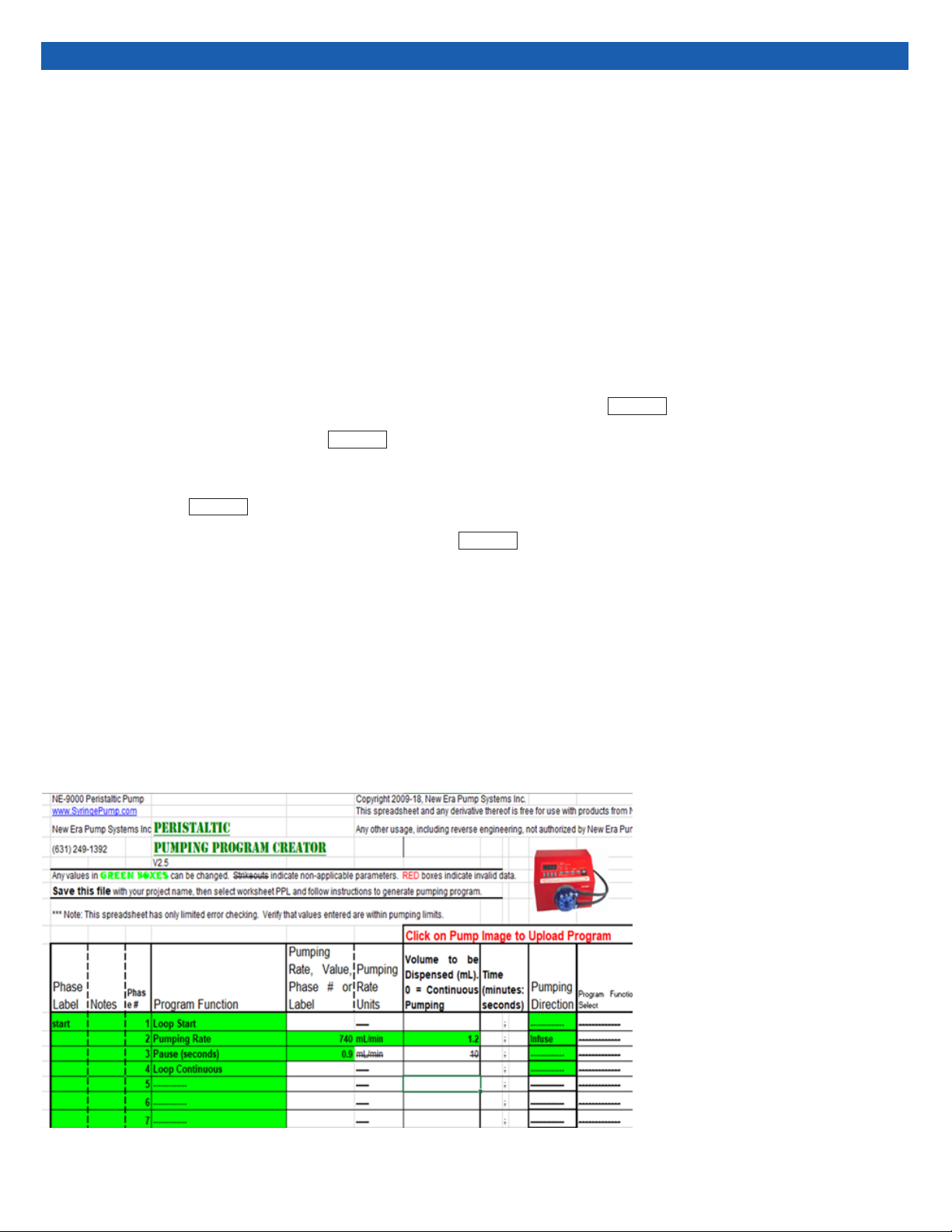

For a 60 beats-per-minute pulse, open the PPL Creator excel spreadsheet. Using the drop-down menu in each cell, set

− Phase 1 to Loop Start

− Phase 2 to Pumping Rate 740 ml/min for 1.2ml

− Phase 3 to Pause (seconds) 0.9

− Phase 4 to loop continuously.

− Leave other phases blank

The excel page will look like this:

Upload the program to the pump by

clicking on the pump picture in the Excel

le. The pump will beep twice to indicate

successful program upload.

10

Contrast Injection Setup

The model 769 can be used for contrast injection studies. See Setup 3 below. The outlet from the phantom is collected in a separate container.

The injection (not included with 769) is put between the pulse dampener and phantom.

The ow rate generated in a peristaltic pump depends on the inside diameter of the tubing used, the amount of occlusive force generated by

the pump head rollers and the pump head speed (revolutions per minute, or RPM). The control indicator for the pump is calibrated to the pump

RPM setting speed and converted to ow rate for a given tube diameter. However, the actual ow rate may vary from the value indicated if the

tubing stretches or deforms over time, causing the amount of occlusive force to change over time. Differing viscosities will also affect pumping

speed.

The pump has a built-in calibration setting, in which the pump operates in the dispense mode to deliver 250 mL of uid at a ow rate of 500 mL/

min. To calibrate the pump, you will need a graduated cylinder or similar calibrated measuring cup to verify the actual dispense volume.

NOTE: The graduated cylinder provided with the Model 769 is not calibrated & is provided for convenience. Users needing to perform calibra-

tion measurement as part of a quality process may want to obtain a calibrated cylinder.

cAlr

Calibration and Resetting

Pump calibration

1. Turn off power to the pump.

2. Press the ‘rate’ key while turning on power to the pump. The display will show:

3. Press the ‘start’ key to begin the dispense.

4. When the pump has dispensed 250 ml of uid it will stop, and the dispensed volume will be displayed with the volume units LED

blinking.

5. Use the up-arrow keys to enter the actual volume measured by the graduated cylinder.

6. Press the ‘rate’ key.

The pump uses the entered volume to recalibrate the pumping rate and dispense volume. Calibration may need to be repeated multiple times for

the best results.

Changing the tubing diameter or resetting the pump will cancel the entered calibration. The pump will use the tube diameter as the calibration

value.

11

Care and Handling

When the pump is not in use, remove the black tubing from the pump head. If the tubing is left in the pump head while the rotor is stationary, the

tubing will become stretched out. Failure to remove the tubing from the pump head will result in premature wear of the tubing, which

could aect pump calibration.

1. Disconnect the reservoir outlet from the pump and leave the tube in air.

2. Run the pump until all remaining uid is returned to the reservoir. Some uid will remain in the pulse dampener. This is by design. The

pulse dampener can be stored with uid inside. The uid will not leak out of the pulse dampener.

3. Turn off the pump. Remove the reservoir adaptor tubing from the Doppler uid. Replace the standard cap on the Doppler uid

4. Fill graduated cylinder with water and place the reservoir adapter in the cylinder. Remove the pulse dampener.

5. Re-attach reservoir outlet to the pump and circulate water through the phantom to clean any remaining Doppler uid from the circuit.

When complete, turn off the pump, disconnect the tubing from the phantom and return accessories to the pump storage drawer.

Storage conditions vary for each phantom. In general, urethane-based phantoms can be stored empty, while Zerdine-based phantoms

should remain lled with water to prevent the tube from collapsing. For more information, see the User Guide for the phantom.

4. Remove the black tubing from the circuit as described above. Place the pump head and black tubing in the pump storage drawer.

This pump is programable, so it can behave in unexpected ways if programmed incorrectly. If your pump is acting strange, resetting the pump

will clear the programs memory and return the pump to a continuous ow mode.

The pump has a built-in calibration setting, in which the pump operates in the dispense mode to deliver 250 mL of uid at a ow rate of 500 mL/

min. To calibrate the pump, you will need a graduated cylinder or similar calibrated measuring cup to verify the actual dispense volume.

Resetting the pump

Calibration and Resetting (Cont)

1. Press the right-most up arrow key while turning on power to the pump.

2. The display will show rEST

Pressing any key will clear the display.

After each use

1. Remove the pump head from the pump by turning the cassette counterclockwise

2. Remove the black tubing from between the cassette and rotor.

Doppler uid will not affect the tubes in the pumping system. However, particle agglomeration can occur if the Doppler uid remains stationary in

a tight space for too long. Particle agglomeration may cause the tubes to become clogged if the pump is not run for an extended period of time.

Purging the circuit of Doppler uid with water will ensure the tubes do not become clogged. To purge the circuit, follow the steps below:

Preparing for storage

12

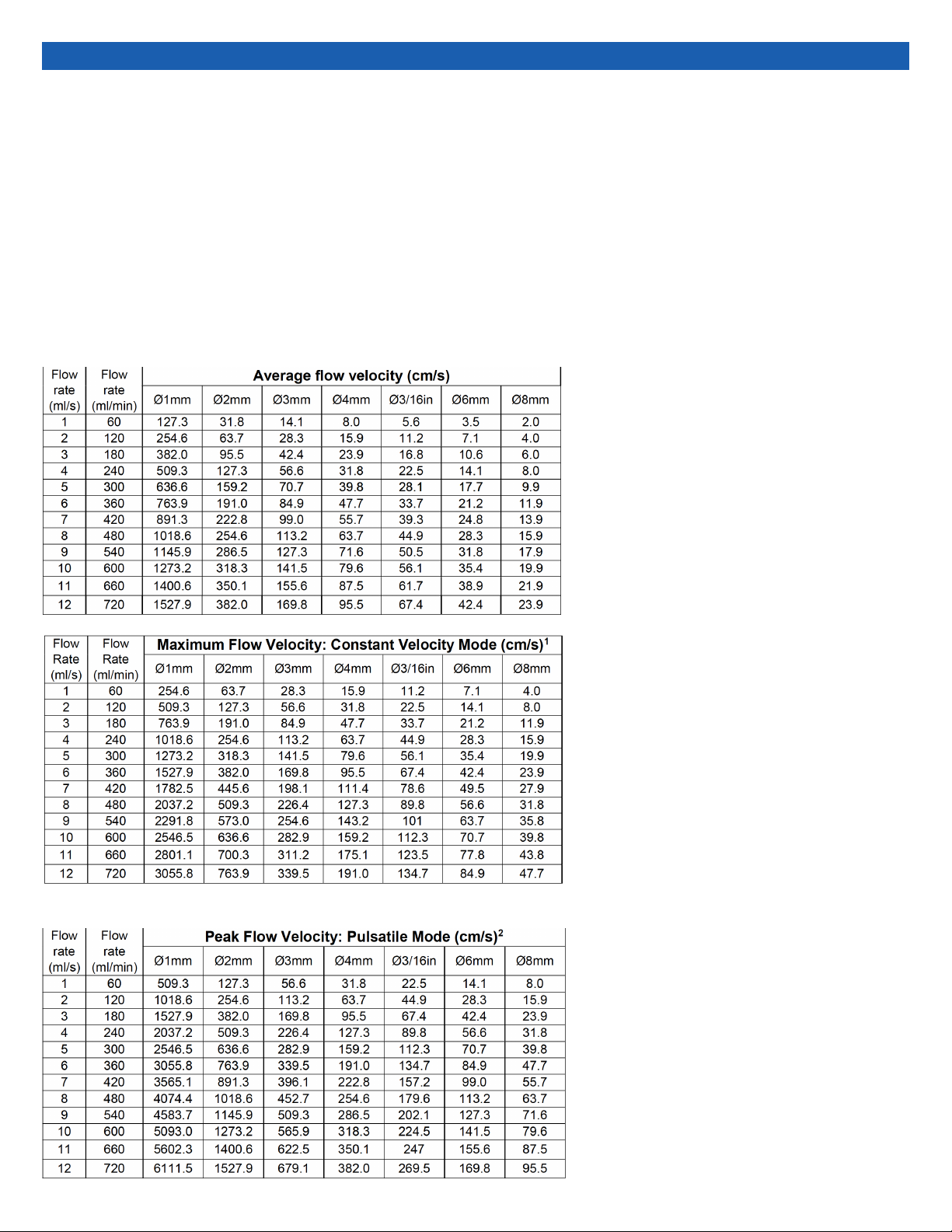

Appendix 1: Conversion of Flow

Rate to Flow Velocity

The conversion from ow rate to average ow velocity is made by dividing the ow rate by the cross-sectional area of the tubing.

For laminar ow, the ow velocity at the center of the tube is double the average ow velocity. In constant velocity mode, the maximum ow

velocity is double the average ow velocity. In pulsatile mode, the maximum ow velocity depends on the shape of the pulse prole. Assuming a

simple sine wave, the peak ow velocity will be double the maximum ow velocity in constant velocity mode.

CIRS doppler phantoms often have multiple ow tubing of different diameters by design. The following table have ow rates calculated using the

most common tubing diameters found in CIRS doppler phantoms.

Conversion Chart for Flow Velocities

1maximum ow velocity is given for laminar ow, in which the ow velocity at the center of the tube is

twice the average ow velocity.

2assumes simple sine wave pulse.

13

All standard CIRS products and accessories are warranted by CIRS

against defects in material and workmanship for a period as speci-

ed below. During the warranty period, the manufacturer will repair

or, at its option, replace, at no charge, a product containing such

defect provided it is returned, transportation prepaid, to the manu-

facturer. Products repaired in warranty will be returned transportation

prepaid.

There are no warranties, expressed or implied, including without

limitation any implied warranty of merchantability or tness, which

extend beyond the description on the face hereof. This expressed

warranty excludes coverage of, and does not provide relief for,

incidental or consequential damages of any kind or nature, includ-

ing but not limited to loss of use, loss of sales or inconvenience. The

exclusive remedy of the purchaser is limited to repair, recalibration,

or replacement of the product at manufacturer’s option.

This warranty does not apply if the product, as determined by the

manufacturer, is defective because of normal wear, accident, mis-

use, or modication.

NON-WARRANTY SERVICE

If repairs or replacement not covered by this warranty are required, a

repair estimate will be submitted for approval before proceeding with

said repair or replacement.

PRODUCT WARRANTY PERIOD

Model 769- Doppler Flow

Pump 24 Months

Warranty

RETURNS

If you are not satised with your purchase for any reason, please

contact Customer Service or your local distributor prior to returning

the product. Visit https://www.cirsinc.com/distributors/ to nd your

local distributor. Call 800-617-1177, email [email protected], or fax

an RMA request form to 757-857-0523. CIRS staff will attempt to

remedy the issue via phone or email as soon as possible. If unable

to correct the problem, a return material authorization (RMA) number

will be issued. Non-standard or “customized” products may not be

returned for refund or exchange unless such product is deemed by

CIRS not to comply with documented order specications. You must

return the product to CIRS within 30 calendar days of the issu-

ance of the RMA. All returns should be packed in the original cases

and or packaging and must include any accessories, manuals and

documentation that shipped with the product. The RMA number

must be clearly indicated on the outside of each returned pack-

age. CIRS recommends that you use a carrier that offers shipment

tracking for all returns and insure the full value of your package so

that you are completely protected if the shipment is lost or damaged

in transit. If you choose not to use a carrier that offers tracking or

insure the product, you will be responsible for any loss or damage

to the product during shipping. CIRS will not be responsible for lost

or damaged return shipments. Return freight and insurance is to be

pre-paid.

With RMA number, items may be returned to:

CIRS

Receiving

900 Asbury Ave,

Norfolk, Virginia, 23513 USA

14

16

©2016 Computerized Imaging Reference Systems, Inc. All rights

reserved.

All brand names, product names or trademarks belong to

their respective holders.

Specications subject to change without notice.

Publication: Doppler 769 UG 110920

Computerized Imaging Reference Systems, Inc. has

been certied by UL DQS Inc. to (ISO) 13485:2016.

Certicate Registration No.10000905-MP2016.

COMPUTERIZED IMAGING

REFERENCE SYSTEMS, INC.

900 Asbury Ave

Norfolk, Virginia 23513 USA

Toll Free: 800.617.1177

Tel: 757.855.2765

Fax: 757.857.0523

Email [email protected]

www.cirsinc.com

Technical Assistance

1.800.617.1177

Table of contents

Popular Water Pump manuals by other brands

WITA

WITA Delta Plus UE 65A Series TRANSLATION OF THE ORIGINAL INSTALLATION AND OPERATING INSTRUCTIONS

Anest Iwata

Anest Iwata ISP-1000 instruction manual

Rheem

Rheem Classic Plus Series manual

Aussie Pumps

Aussie Pumps Eco-Clean AB Scud Cadet Series Operator's instruction manual

North Ridge Pumps

North Ridge Pumps DM troubleshooting guide

Grundfos

Grundfos TPE 2 Series Installation and operating instructions

Edwards

Edwards STP-iXR1606 instruction manual

Bosch

Bosch Universal Pump 18V Original instructions

Grundfos

Grundfos MSS Series Installation and operating instructions

Liberty Pumps

Liberty Pumps 2LE Series installation manual

ABNOX

ABNOX Standard operating manual

Graco

Graco 210-208 Instructions and parts list