CIT Superior VAS-4 User manual

VAS-4

VACUUM MONITORING

SYSTEM

INSTALLATION

AND USER’S GUIDE

VAS-4 O&M Manual, Revision 0, 01 July 2020

Chemical Injection Technologies, Inc.

835 Edwards Road, Fort Pierce, FL 34982

Tel: 772-461-0666 Fax: 772-460-1847

Bulletin 4018

Pub. No. 0720-1 Copyright © 2020, Chemical Injection Technologies,Inc. Printed in U.S.A.

Table of Contents

Section 1 Introduction ................................................................. 1

Section 2 Inventory ...................................................................... 1

Section 3 Specifications .............................................................. 2

Section 4 Operation Basics ......................................................... 3

Digital Display .............................................................. 3

LED Indicators ............................................................. 3

Alarm Outputs ............................................................. 4

Section 5 Installation ................................................................... 4

Opening Unit ................................................................ 5

Enclosure Mounting .................................................... 5

Installing Vacuum Hose .............................................. 6

Installing Power/Alarms .............................................. 6

Section 6 Set Up and Calibration ................................................ 6

Delay Timer Adjustment ............................................. 6

Low Level Adjustment ................................................ 7

High Level Adjustment ............................................... 7

Alternate Method for Adjustment .............................. 7

Analog Output ............................................................. 8

Maintenance and Calibration ..................................... 8

Warranty Information .................................................. 9

Figure 1 Installation Diagram .................................................. 10

Figure 2 Enclosure Mounting .................................................. 11

VAS-4 O&M Manual, Revision 0, 01 July 2020

1

Section 1 Introduction

The VAS - 4 is a full-featured vacuum monitoring system. The system uses

the latest in integrated circuit technology, which allows a compact design,

accuracy and reliability. The VAS - 4 features both high and low vacuum

detection, separate high, low and latch alarm relays, three digit display of

vacuum in inches of Hg., LED status indicators and an analog output. The

high and low alarm levels are user adjustable along with a variable delay

timer. The enclosure has a NEMA 4X rating; therefore it can be mounted

outside. Applications include loss of chlorinating in water and wastewater

treatment, pool pump monitoring, automotive test equipment and many

others.

Section 2 Inventory

The following items are included with the VAS - 4:

1.

VAS - 4. Contains the electronics housed in a NEMA 4X enclosure.

2.

Sensor enclosure with oil based protection device.

3.

Two watertight fittings used for running the power and alarm

wires from the control box to the alarms.

4.

¼” tube fitting attached to the oil based protection device.

5.

Power cord.

6.

Instruction manual.

7.

Warning label attached to the oil based protection device.

2

Section 3 Specifications

Input Voltage: 90-265 VAC 50/60 Hz

Alarm Relays: NO\NC Type

240V AC @ 5A Resistive Load

115V AC @ 5A General Use

30V DC @ 5A General Use

Gas\Fluid compatibility: System includes a protection device that uses a

chemically inert synthetic oil compatible with chlorine, sulfur dioxide, and

ammonia gas.

Enclosure: .............................................................................NEMA 4X Rated

Vacuum Measurement Range: ................................................ 0 to 30 inHg

Low Alarm Range: ................................................................... 0 to 15 inHg

High Alarm Range: ................................................................ 15 to 30 inHg

Over Pressure: ................................................................................... 50 PSI.

Delay Timer: .............................................................................. 1 to 100 sec.

Analog output:

Voltage: ............................................................................. 0 to 3 VDC.

Current: ......................................................................... 0 to 3 ma DC.

Reset Switch:........................................................................ IP 65 protection

External Connectors: ............................................................ IP 68 protection

Indicators:

Vacuum: ....................................................... 3-Digit Digital LED Display

Alarms: ..................................... 3 LED Indicators/High, Low and Latch

Polarity: .................................................... 1 LED indicator for pressure

Temperature Range (System):

Storage: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -30 C to 70 C

Operating: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -20 C to 50 C

Vacuum Temperature Range: . . . . . . . . . . . . . . . . . . . . . -40 C to 50C

Humidity ................................................... Relative 0 to 90% Noncondensing

(Specifications are subject to change without notice.)

3

Section 4 Operation Basics

Digital Display

The three-digit display represents the real time vacuum pressure in inches of

mercury (inHg). Minimum vacuum equals 00.0 and the maximum vacuum

reading, depending on altitude, is approximately 30.9 inHg.

LED Indicators

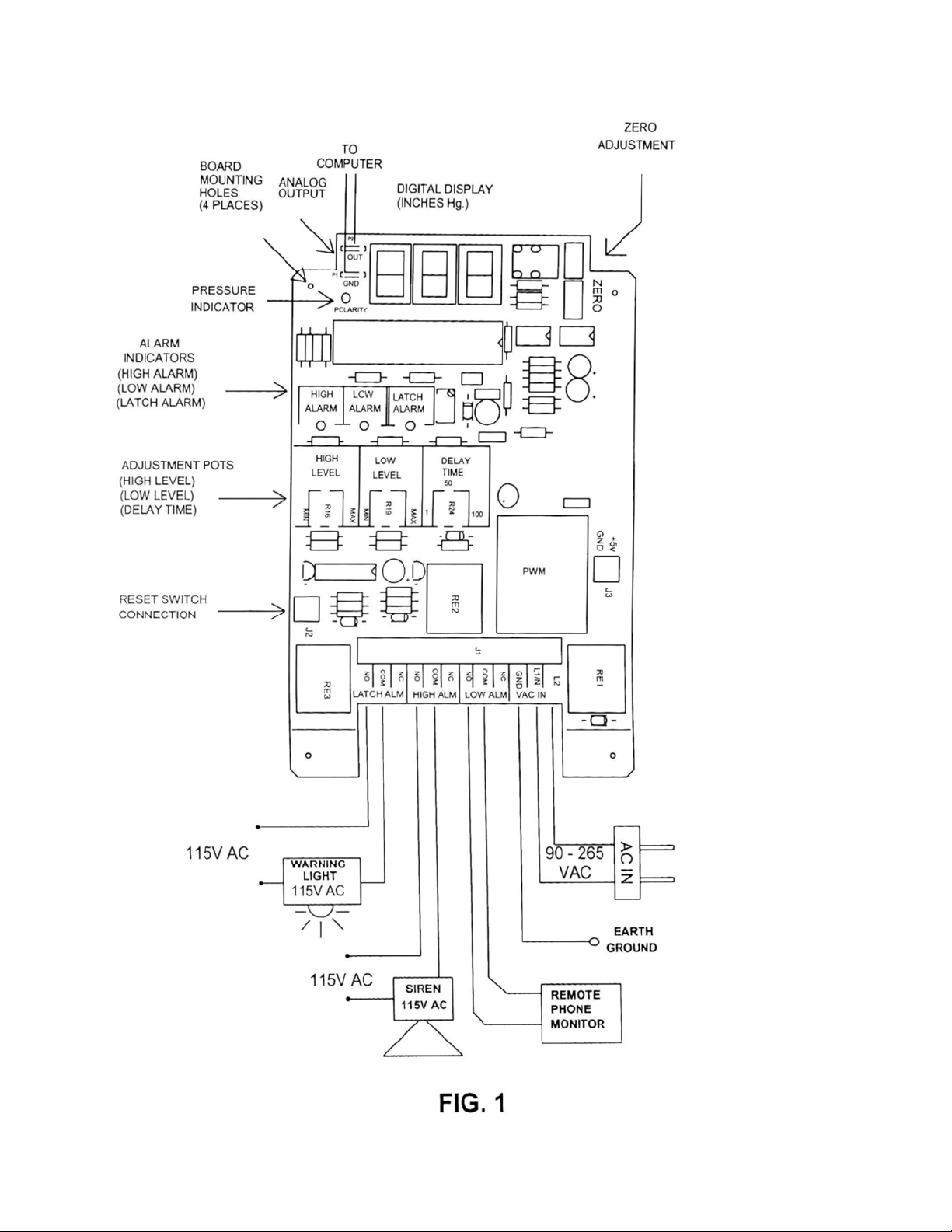

The VAS - 4 has four LED indicators; High, Low, Latch and Polarity. See

Fig. 1 for their locations.

High LED Indicator

This LED indicates that the vacuum pressure exceeds the preset High Alarm

set point.

NOTE: This indicator is real time, i.e., it does not wait for the delay timer to

time out.

Low LED Indicator

This LED indicates that the vacuum pressure is below the preset Low Alarm

set point. This LED indicator is also real time.

Latch LED Indicator

When either the high or low indicators are active, this starts the delay timer.

If the alarm is active longer than the preset delay time, then the latch LED

indicator will become active. This indicator stays active until the manual reset

button (see Fig. 2) is pushed. This indicator implies that either an alarm has

occurred or is still active. If the latch indicator is on and the High/Low

indicators are off, then an alarm condition has occurred, but is not active now.

If either the High or Low indicators are active, then this represents that the

alarm condition is still active.

NOTE: The High or Low alarm relays do not become active until the latch

alarm indicator is on.

Polarity LED Indicator

When this LED is on this indicates that the VAS - 4 is measuring

pressure. The digital display shows this pressure measurement in inches

of mercury (inHg). (1 inHg = 0.49 psi)

4

Alarm Relays

The VAS - 4 has three alarm relay outputs. The alarm relays do not

become active until the delay timer times out, which causes the latch alarm

indicator to become active. The three alarm relays are general purpose

and can be used for exterior alarms, load switching or phone monitoring.

Note: Do not exceed relay specifications.

High Alarm Relay

The High Alarm relay becomes active from a high alarm condition after the

delay timer times out. This relay stays active as long as the alarm condition

exists. Once the alarm condition goes away, this relay becomes inactive.

Low Alarm Relay

The Low Alarm relay becomes active from a low alarm condition after the

delay timer times out. This relay stays active as long as the alarm condition

exists. Once the alarm condition goes away, this relay becomes inactive.

Latch Alarm Relay

When either the High or Low Alarm relays become active and the delay time

is over the latch alarm relay also becomes active. This is indicated by the

Latch Alarm indicator. This relay stays active until the manual reset button is

pushed (see Fig. 2).

NOTE: In some applications, like gas chlorination in water and wastewater

treatment, special attention needs to be given to the electrical hookup. If your

vacuum source under normal operation is cycled on and off, as is the case

when the vacuum is created only when a well pump is operating, then the

AC power to the VAS - 4 should be switched on and off with the well pump.

This will prevent a low alarm condition when the pump is off.

Section 5 Installation

Installation should only be performed by a licensed electrician. Follow any

local, state or other applicable codes that apply when installing this unit.

THIS UNIT SHOULD BE WIRED TO A GROUND FAULT RECEPTACLE.

CAUTION: HIGH VOLTAGE COULD EXIST INSIDE THIS UNIT.

DISCONNECT ALL POWER BEFORE INSTALLATION.

5

Opening Unit

Remove the four plastic screws to open the unit. The printed circuit board

contains static sensitive parts, so the installer should wear a grounding strap

when handling the board.

Enclosure Mounting

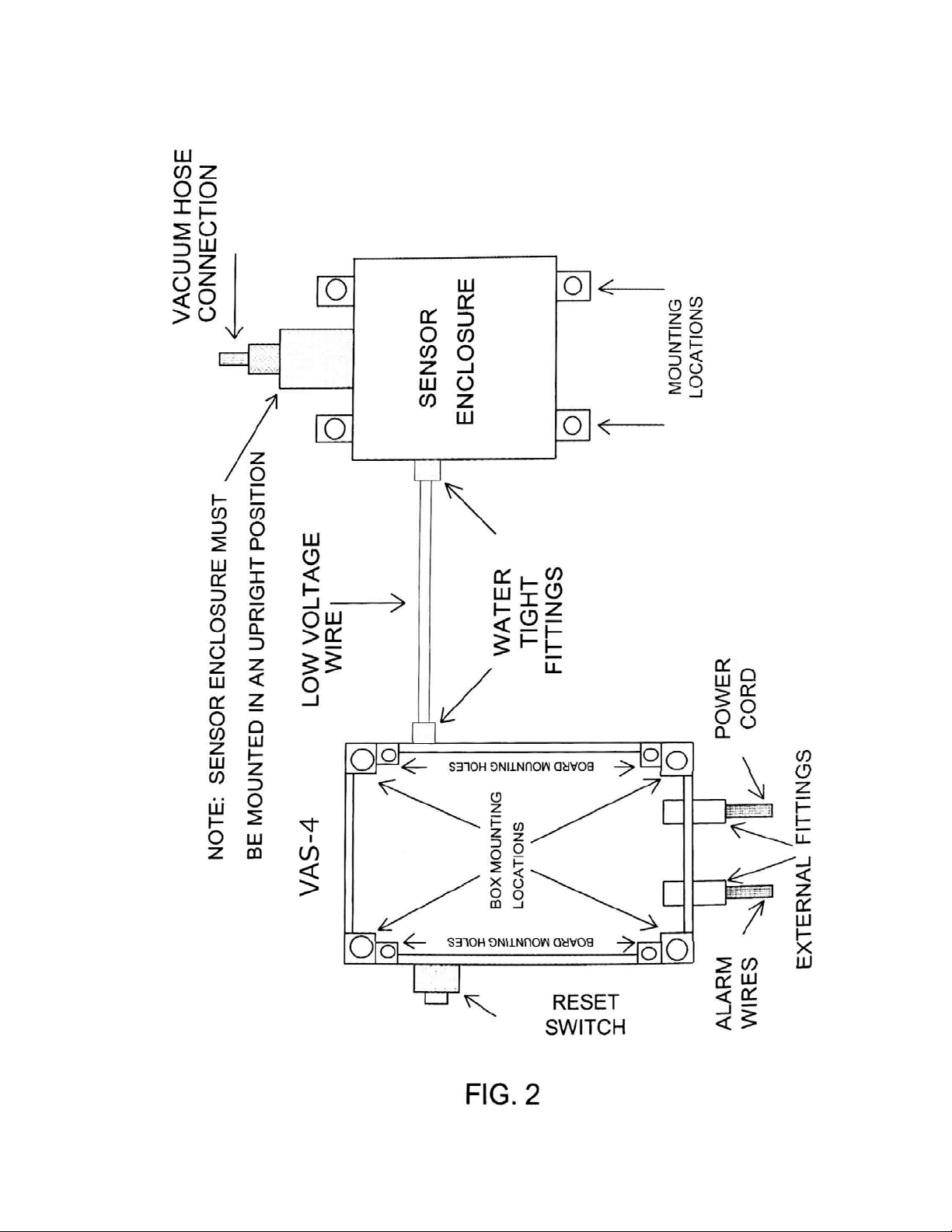

IMPORTANT: This unit contains two enclosures. The larger one contains the

electronics (VAS - 4) and the smaller one contains the sensor. The two

enclosures are permanently connected together by a low voltage wire. The

sensor enclosure contains an oil based protection device that is filled with a

special fluid. The protection device has a cap over the ¼" fitting to prevent the

oil from leaking out during shipping and installation. THE SENSOR

ENCLOSURE MUST BE MOUNTED IN AN UPRIGHT POSITION TO

PREVENT THE FLUID FROM LEAKING OUT. Once the unit is securely

mounted in an upright position, the cap over the ¼" fitting can be removed.

The recommended mounting method for the VAS - 4 is to use four mounting

holes located where the 4 plastic screws are that hold down the lid. Use the

box as a template for mounting (see Fig. 2).

NOTE: THE VAS - 4 SHOULD NOT BE MOUNTED WHERE SUNLIGHT

CAN DIRECTLY ENTER THE TRANSPARENT COVER.

The printed circuit board is designed to have power come ln from the bottom

of the box. Remove the knockouts that are needed for power entry. Two

watertight fittings are provided for the power and alarm line. If the board must

be removed to install a watertight fitting, care must be taken in handling the

board.

NOTE: IF YOU RUN CONDUIT INTO THE BOX AND DO NOT USE THE

WATERTIGHT FITTINGS, YOU MUST USE A SEALANT TO SEAL

AROUND THE CONDUIT CONNECTION.

Install the printed circuit board after the connectors have been installed. Use

the four #6 screws provided to mount the board in the box and tighten only to

a snug fit. DO NOT OVER TIGHTEN (see Fig. 2)

6

Vacuum Line and Reset Switch

Connect your ¼” vacuum hose to the ¼" barb fitting attached to the protection

device. The reset switch is prewired to the board reset terminals.

Power and Alarm Wiring

CAUTION: BE SURE POWER IS DISCONNECTED BEFORE HANDLING

ANY WIRES.

WARNING: IMPROPER WIRING TO THIS UNIT CAN DAMAGE UNIT AND

COULD CAUSE SERIOUS BODILY INJURIES. OVER PRESSURE ON THIS

UNIT IS RATED AT 50 PSI. EXCEEDING THIS PRESSURE CAN CAUSE A

RUPTURE OF THE SENSOR. See Fig. 1 for typical electrical wiring. Connect

input AC power to the connector location labeled L2, L1/N and GND.

NOTE: A surge arrestor is recommended on the AC power line to prevent

damage from lightning strikes or other power surges. The alarms can be

hooked up in many ways. Be sure the relay specifications are not exceeded.

The relay outputs are labeled HIGH ALARM, LOW ALARM and LATCH

ALARM. Remember the latch alarm will stay active until the reset button is

pushed.

Note: NO = Normally Open Contact

NC = Normally Closed Contact

COM = Relay Common

Section 6 Set up and Calibration

The VAS - 4 comes preset at the following default levels:

Delay: 50 sec.

Low Alarm: 5 in. Hg.

High Alarm: 25 in. Hg.

The following Is a procedure for changing these values. See Fig. 1 for the

location of the adjustment pots.

CAUTION: HIGH VOLTAGE EXISTS INSIDE THE UNIT.

Delay Adjustments

The delay time is adjustable from approximately 1 second to 100 seconds.

To adjust the delay, insert a small screwdriver into pot R24 rotate until the

desired delay is achieved. The delay value is printed on the board.

7

Low level Alarm

The Low Level alarm is adjustable from approximately 0.0 to 15 inches of Hg.

To adjust the low level, insert a screwdriver into pot R19 and rotate it to the

desired level. MIN = 0 and MAX = 15 inches of Hg.

NOTE: If you want to disable the low alarm, turn the pot counter clockwise

until it stops.

High Level Alarm

The High Level alarm is adjustable from approximately 15 to 30 inches of Hg.

To adjust the high level, insert a screwdriver into pot R16 and rotate it to the

desired level. MIN = 15 inches of Hg. and MAX = 30 inches of Hg.

NOTE: If you want to disable the high alarm, turn the pot clockwise until it

stops.

Alternate Method for Accurate

High/Low Level Adjustment

If a high degree of accuracy is required, then use the procedure in the

following example:

Example: If you desire a high level alarm at 26.3 inches of Hg.

1.

Adjust your vacuum level until the digital readout

reaches 26.3.

2.

Rotate the high level alarm pot full R16 counter-clockwise.

3.

Then, rotate the high level alarm pot R16 clockwise slowly until

the high level LED comes on. This represents

the correct adjustment for 26.3 inches of Hg.

This method can be used for low level adjustment, except the rotation of the

low level alarm pot R19 is reversed.

8

Analog Output

The VAS - 4 has an analog output, which will allow the vacuum to be

remotely monitored. The connection for this is located in the upper left

section of the printed circuit board (see Fig. 1). Two spade lugs are

provided for the connection. They are labeled GND for ground and OUT for

the output. The output is capable of sourcing 0 to 3 VDC or 0 to 3 ma. If a 4

to 20 ma loop is required, a signal conditioner can be used to convert the

output. These are available from many sources.

Maintenance and Calibration

Once the VAS - 4 has been in operation for approximately one week, the

unit should be checked for the correct zero reading. This is the reading

when no vacuum is present. Ideally, the zero reading would be 00.0.

However, due to the ambient temperature, some variation is normal. If the

zero reading is over 00.7 then an adjustment is needed. The zero

adjustment pots are located in the upper right hand comer of the board. One

of the pots, if looked at from, the middle of the board, is rotated all the way

to the right and the other pot is rotated to approximately the 12:00 position.

The pot that is close to the 12:00 position is the pot to adjust. Slowly turn

this pot to get the zero reading as close to 00.0 as you can. This will end

the zero calibration. If the reading still does not read 00.0 then slowly adjust

the other pot until a reading of 00.0 is set.

NOTE: AT LEAST ONE OF THE POTS MUST ALWAYS BE ROTATED ALL

THE WAY TO THE RIGHT.

Once a month the system should be functionally tested. This testing should

include all relays, LED indicators, delay timer and vacuum level accuracy. To

perform this test adjust your vacuum level up and down to cause the high and

low alarms to engage. The delay timer and reset can also be tested in the

same manner. At this time, inspect the board for any corrosion or loose wires.

If corrosion is present check all fittings for a snug fit.

DO NOT ATTEMPT TO CLEAN ANY CORROSION FROM THE BOARD.

HIGH VOLTAGE EXISTS ON THE BOARD.

Corrosion can only be removed by a trained technician. The outside of the

enclosure can be cleaned with warm water and a damp cloth.

9

LIMITED WARRANTY

THE MANUFACTURER. warrants this product to be free from defects in

material and workmanship for a period of one (1) year from the date of the first

consumer purchase.

Except as specified below, this warranty covers all defects in materials or

workmanship in this product. The following are NOT covered by the warranty:

1.

Any product on which the serial number has been defaced, modified or

removed.

2.

Damage, deterioration or malfunction resulting from:

a.

Accident, misuse, abuse, neglect, fire, water, lightning or any o t h e r

acts of Nature.

b.

Any unauthorized product modification or failure to follow

instructions supplied with the product.

c.

Repair or attempted repair by anyone not authorized by THE

MANUFACTURER.

d.

Any shipment of the product.

e.

Any other causes which do not relate to a product defect.

LIMITATION OF IMPLIED WARRANTIES

ALL IMPLIED WARRANTIES, INCLUDING WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, ARE

LIMITED IN DURATION TO THE LENGTH OF THIS WARRANTY.

EXCLUSION OF DAMAGES

THE MANUFACTURER’S LlABiLITY FOR ANY DEFECTIVE PRODUCT IS

LIMITED ONLY TO THE REPAIR OR REPLACEMENT OF THE PRODUCT

AT OUR OPTION. THE MANUFACTURER SHALL NOT BE LIABLE FOR:

1.

DAMAGE TO OTHER PROPERTY CAUSED BY ANY DEFECTS IN

THIS PRODUCT, DAMAGES BASED UPON INCONVENIENCE,

LOSS OF USE OF THE PRODUCT. LOSS OF TIME, OR

2.

ANY OTHER DAMAGES, WHETHER INCIDENTAL,

CONSEQUENTIAL OR OTHERWISE.

10

11

VAS-4

VACUUM MONITORING

SYSTEM

Chemical Injection Technologies, Inc.

835 Edwards Road, Fort Pierce, FL 34982

Tel: 772-461-0666 Fax: 772-460-1847

Table of contents