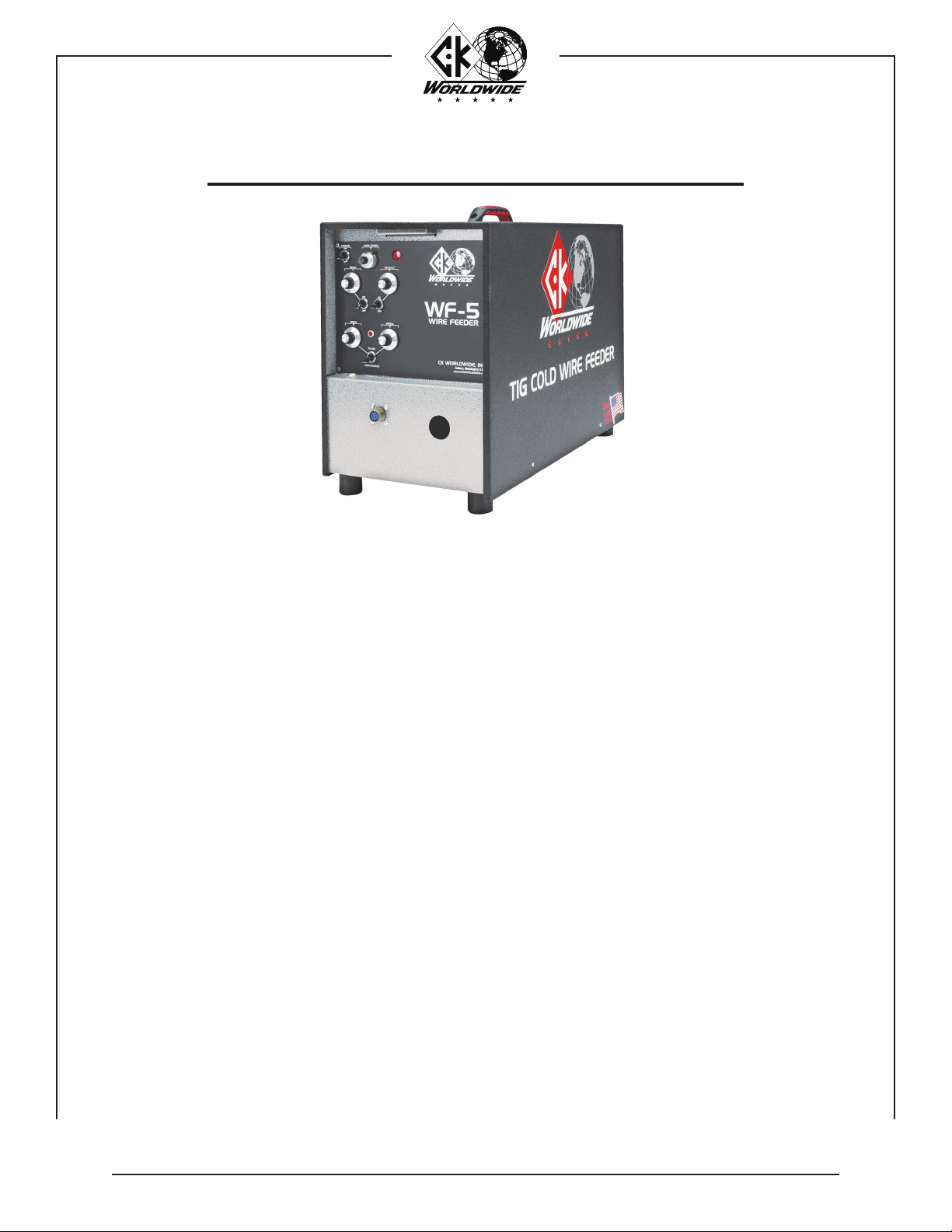

CK WORLDWIDE WF5 User manual

1

Cold Wire Feeder Manual

September 2015

CK Worldwide, Inc.

3501 C St. N.E. Auburn, WA 98002

tel: (253) 854-5820

tel: (800) 426-0877

fax: (253) 939-1746

The important safeguards and instructions appearing in

this pamphlet should be read and understood prior to

operating your equipment.

NOTE:

Safety Warning ................................................................

Warranty ..........................................................................

Introduction .....................................................................

Description ......................................................................

TIG Welding Process ........................................................

Specifications ..................................................................

Check List ........................................................................

Optional Items .................................................................

Installation .......................................................................

Operation .........................................................................

Welding............................................................................

Maintenance....................................................................

Troubleshoot Chart ...........................................................

Cables and Guides ............................................................

Feeding Difficult Wires / Bracket Extensions ....................

Electrical Diagram ...........................................................

FunctionsofControls........................................................

Parts Lists: WF5 Feed Unit Left Side ....................

WF5 Feed Unit Right Side .................

CWH1812 Hand Torch .......................

CWH2312 Hand Torch .......................

CWHTL312 Hand Torch .....................

Parts Lists: CWH3512 Hand Torch.........................

CWM2312 Machine Torch .................

CWM3512 Machine Torch .................

CWMT412 Machine Torch .................

CWMT512 Machine Torch .................

CWH Wire Feed Hand Unit .................

CWMES Remote Switch ....................

Drive Rolls .......................................................................

Spare Parts .....................................................................

CWH1812HeadAccessories .............................................

CWH2312HeadAccessories .............................................

CWHTL312 Head Accessories .........................................

CWH3512 ........................................................................

CWM2312 HeadAccessories ............................................

CWM3512 HeadAccessories ............................................

CWMT412 Head Accessories ..........................................

CWMT512 Head Accessories ..........................................

Tungsten Electrode Information ......................................

Tungsten Preparation ......................................................

Welding Parameters .......................................................

2-3

4

4

4-5

5

6

7

7

7-9

10

10

10

11

12

12

13

14

15

16

17

17

18

18

19

19

20

20

21

21

21

21

22

22

23

23

24

25

26

27

28

29

30-31

2

WARNING:

UNSAFE PROCEDURES OR PRACTICES CAN CAUSE SERIOUS PERSONAL INJURY OR DEATH.

All end users of this equipment, the operators and helpers, must read and understand these safety instructions.

This product, when used for welding or cutting, produces fumes or gases which contain chemicals known to the

State of California to cause birth defects and, in some cases, cancer.

California Health & Safe Code 25249.5 et seq.

PREVENT ELECTRICAL SHOCK:

Touching live electrical parts can cause severe burns or fatal shock.

1. Do not touch live electrical parts.

2. Do not work in wet or damp areas.

3. Wear dry insulating gloves and body protection.

4. Disconnect all power before installing or servicing this equipment.

5. Turn off all equipment when not in use.

6. Properly install and ground the welding power source according to its Owner’s Manual and all applicable

codes.

7. Do not use worn or damaged cables or cables that are too small or poorly spliced.

8. Do not wrap cables around your body.

9. Do not touch electrode and any grounded object or circuit at the same time.

10. Use only well-maintained equipment. Repair or replace damaged parts at once.

PROVIDE PROTECTION FROM FUMES AND GASES:

Breathing welding fumes and gases can be hazardous to your health.

1. Keep your head out of welding fumes.

2. Use adequate ventilation in the work area to keep fumes and gases from your breathing zone and the

general work area.

3. If ventilation is inadequate, use an approved breathing device.

4. Read and understand the Material Safety Data Sheets (MSDS) and the manufacturer’s instructions for any

materials used.

Gas cylinders are normally used when welding, treat them with care.

1. Protect compressed gas cylinders from excessive heat, mechanical shocks and arcs.

2. Install and secure cylinders so that they cannot fall or tip over by fastening them to a mounting bracket,

wall or other stationary support.

3. Keep cylinders away from any welding or other electrical circuits.

4. Never allow a welding electrode to touch any cylinder.

PROTECT COMPRESSED GAS CYLINDERS:

PROTECT EYES AND SKIN FROM ARC RAYS, PROTECT EARS FROM NOISE:

Welding arc rays produce intense heat and ultraviolet rays that can burn eyes and skin. Noise from some

processes can also damage hearing.

1. Wear a welding helmet fitted with a proper filter lens (see ANSI Z49.1 for detailed information).

2. Use protective screens or barriers to protect others from welding flash and glare.

3. Wear protective clothing and foot protection.

NOTE: The important safeguards and instructions

appearing on this pamphlet should be read and

understood prior to operating your equipment.

3

The hot workpiece, hot equipment, spatter, and arc sparks can cause fires and burns.

PREVENT FIRES AND BURNS:

1. Wear correct eye, face, and body protection in the work area.

2. Allow work and equipment to cool before handling.

3. Do not weld near flammable materials.

4. Watch for fire, and keep a fire extinguisher nearby.

5. For additional information, refer to NFPA Standard 51B, “Fire Prevention in Use of Cutting and Welding

Processes”, available from the National Fire Protection Association, Batterymarch Park, Quincy MA 02269.

PROVIDE PROTECTION FOR SPECIAL SITUATIONS:

1. Do not weld or cut containers or materials which have held or been in contact with hazardous substances

unless they are properly cleaned and inspected.

2. Do not weld or cut painted or plated parts unless special ventilation is provided to remove highly toxic

fumes or gases.

3. Since welding can affect pacemakers, keep all pacemaker wearers out of the work area. Have them

consult a doctor before coming near a welding operation.

PROVIDE PROPER EQUIPMENT MAINTENANCE:

Improperly maintained equipment can result in poor work, but most importantly it can cause physical injury or

death through fires or electrical shock.

1. Always have qualified personnel perform the installation, troubleshooting, and maintenance work. Do not

perform any electrical work unless you are fully qualified.

2. Before performing any maintenance work inside a power supply, disconnect the power supply from the

electrical power source.

3. Maintain cables, grounding wire, connections, power cord, and power supply in a safe working order. Do

not operate any equipment in questionable condition.

4. Do not abuse any equipment or accessories. Keep equipment away from heat sources such as furnaces,

wet conditions such as water puddles, oil or grease, corrosive atmospheres, and inclement weather.

5. Keep all safety devices, guards, panels, and covers in position and in good repair.

6. Use equipment for its intended purpose. Do not modify it in any manner.

For more information on safe practices for setting up and operating electric welding and cutting equipment and

on good working habits, ask your welding equipment supplier. For your protection, read and comply with the

latest editions of the following standards:

1. ANSI Standard Z49.1

Available from the American Welding Society, 550 N.W.

LeJeune Rd., Miami FL 33126.

2. ANSI Standard Z87.1

“Safe Practices for Occupation and Educational Eye and

Face Protection”, available from the American National

Standards Institute, 1430 Broadway, New York, NY 10018.

3. AWS Standard A6.1

“Recommended Safe Practices for Shielded Arc Welding”,

available from the American Welding Society 550 N.W.

LeJeune Rd., Miami FL 33126.

4. AWS Standard F4.1

“Recommended Safe Practices for the Preparation for

Welding and Cutting of Containers and Piping that have

Held Hazardous Substances”, available from the American

Welding Society 550 N.W. LeJeune Rd., Miami FL 33126.

ADDITIONAL SAFETY INFORMATION:

5. CSA Standard W117.2

“Code for Safety in Welding and Cutting”, available from

the Canadian Standards Association, 178 Rexdale Blvd.,

Rexdale, Ontario, Canada M9W 1R3.

6. NFPA Standard 51B

“Fire Prevention in Use of Cutting and Welding Processes”,

available from the National Fire Protection Association,

Batterymarch Park, Quincy MA 02269.

7. NFPA Standard 70

“National Electrical Code”, available from the National

Fire Protection Association, Batterymarch Park, Quincy MA

02269.

8. OSHA Standard 29 CFR, Part 1910, Subpart Q

“Welding, Cutting, and Brazing”, available from the

Superintendant of Documents, U.S. Government Printing

Office, Washington D.C. 20402.

4

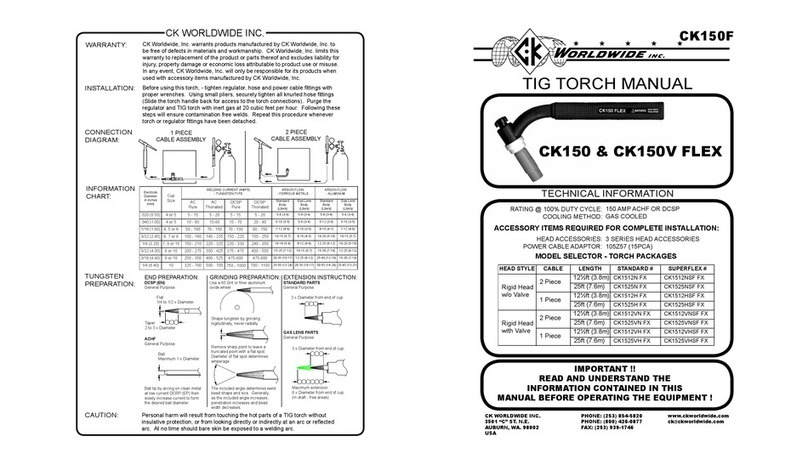

CK Worldwide, Inc. warrants the cold wire feed unit (WF-5) against defects in materials and

workmanship for a period of one year from the date of purchase. Should it become defective for such

reason, the Manufacturer will repair it without charge, if it is returned to the Manufacturer’s factory,

freight prepaid. Prior to returning the equipment, written authorization, in the form of an RGA number

must be obtained prior to any returns for any reason. This warranty does not cover: (1) failure due

to normal wear and tear; (2) consumable parts, such as, but not limited to, feed cables, wire guides,

torch and torch parts; (3) damage by accident, force majeure, improper use, neglect, unauthorized

repair or alteration; (4) any one other than the original purchaser. In any event, CK Worldwide, Inc. will

only be responsible for its products when used with accessory items manufactured by CK Worldwide,

Inc.

This limited warranty is in lieu of all other warranties, express or implied. The manufacturer shall

not be liable for any injury to persons, including death; or loss or damage to any property, direct or

consequential, including, but not limited to loss of use, arising out of the use, or the inability to use, the

product. The user assumes all risk and liability whatsoever in connection with the use of the product,

and before doing so shall determine its suitability for his intended use, and shall ascertain the proper

method of using it. This warranty gives you specific legal rights, and you may have other rights,

which may vary from state to state.

The CK Cold Wire TIG System consists of (1) The Cold Wire TIG Wire Feed Unit and (2) The Cold Wire

TIG Torch Outfit. The Wire Feed Unit is a model WF-5. The TIG Torch Outfit includes the feed cable and

wire guide. The application and features of each is described below. See pages 17 through 21 for the

model numbers of standard CK Cold Wire TIG Torch Outfits

WF5:

The WF5 Wire Feed Unit can be used with hand held CK torches for semiautomatic operation or with

machine mounted CK torches for fully automatic operation. The WF5 Feed Unit houses the drive

motor, feed roll mechanism, solid state control circuitry, and spool of filler wire. It has a ten turn

potentiometer for wire feed speed adjustment and a toggle switch for continuous or pulsed wire feed

operation. For automatic operation, it has controls for delay start and wire retract capabilities. The

WF5 is supplied with one dual grooved drive roll for two sizes of wires and one pressure roll of the

size and type best suited for the filler wire being used (as specified at time of order). See page 21 for

a range of available drive rolls.

The patented CK Cold Wire TIG System is used in the Gas Tungsten Arc Welding (GTAW) / Tungsten Inert

Gas (TIG) process to provide automatic or semiautomatic feeding of the filler metal. Depending on

the configuration of the system, it can be used to feed .025” (.65m) through 1/16” (1.6mm) diameter

stainless steel / alloy steel wire or .035” (.9mm) through 1/16” (1.6mm) aluminum wire from standard

12” (30.5mm) spools.

WARRANTY:

INTRODUCTION:

DESCRIPTION:

5

TORCH OUTFIT:

The CK Cold Wire TIG Torch Outfit is a hand held or machine mounted CK TIG torch with the built

in added capacity of delivering a filler wire directly to the weld puddle.The torch outfit includes

torch, power cable, feed cable, wire guide and wire guide bracket. The feed cable is fitted with

a replaceable, low-friction cable liner. Various torch configurations are available. All models use

standard CK collets, collet bodies and gas cups. See pages 22 through 27 for parts and order

numbers.

DIRECT CURRENT STRAIGHT POLARITY (DCSP):

DC straight polarity produces the deepest penetration because the heat of the weld is concentrated

at the work or joint. Straight polarity provides no cleaning action (removal of surface oxides). This

polarity is generally used to weld most materials except aluminum and magnesium. May be used

with or without high frequency starting.

DIRECT CURRENT REVERSE POLARITY (DCRP):

DC reverse polarity provides good cleaning action. The combining force of the shielding gas ions

striking the work surface and the flow of electrons from the work, cause thesurface oxides to be

broken away. Penetration is shallow because the heat of the weld is concentrated at the electrode.

The use of DCRP is limited to special applications. Maybe used with or without high frequency

starting.

ALTERNATING CURRENT HIGH FREQUENCY (ACHF):

AC combines the good penetration of straight polarity (electrode negative half cycle) and the good

cleaning action of reverse polarity (electrode positive half cycle). Continuous high frequency is

necessary to reestablish the arc which breaks between each half cycle. ACHF current is generally

used to weld aluminum and magnesium.

The TIG welding process uses a nonconsumable tungsten electrode secured in the TIG torch. The

welding arc is produced between the tungsten electrode and the work. The weld is shielded by a

stream of Argon gas, Helium gas, or a mixture of the two, which is fed through the torch, around the

electrode and to the molten weld puddle. Filler metal is added to the weld puddle as required. The

Cold Wire TIG System mechanizes the addition of the filler metal to ensure consistent, high quality

welds.The TIG welding process is the first choice for welding thin sections, welding thin-wall tubing,

making pipe joint root passes, and other similar critical welding applications.

NOTE: Cold Wire TIG welding of tubing under 2-1/2” (6.4cm) diameter requires

CWH pendant style feed unit and separate TIG torch. Unless being used with

turn table or pipe roller.

The TIG welding process requires a constant current welding power source. Power sources designed

specifically for TIG welding may include a built in high frequency arc stabilizer, shielding gas control

solenoid, cooling water control solenoid and other special equipment. They may be AC or DC or a

combination of AC/DC units. The proper current for TIG welding depends on the material being welded,

speed of application and on the desired weld characteristics.

DESCRIPTION:

TIG WELDING

PROCESS:

6

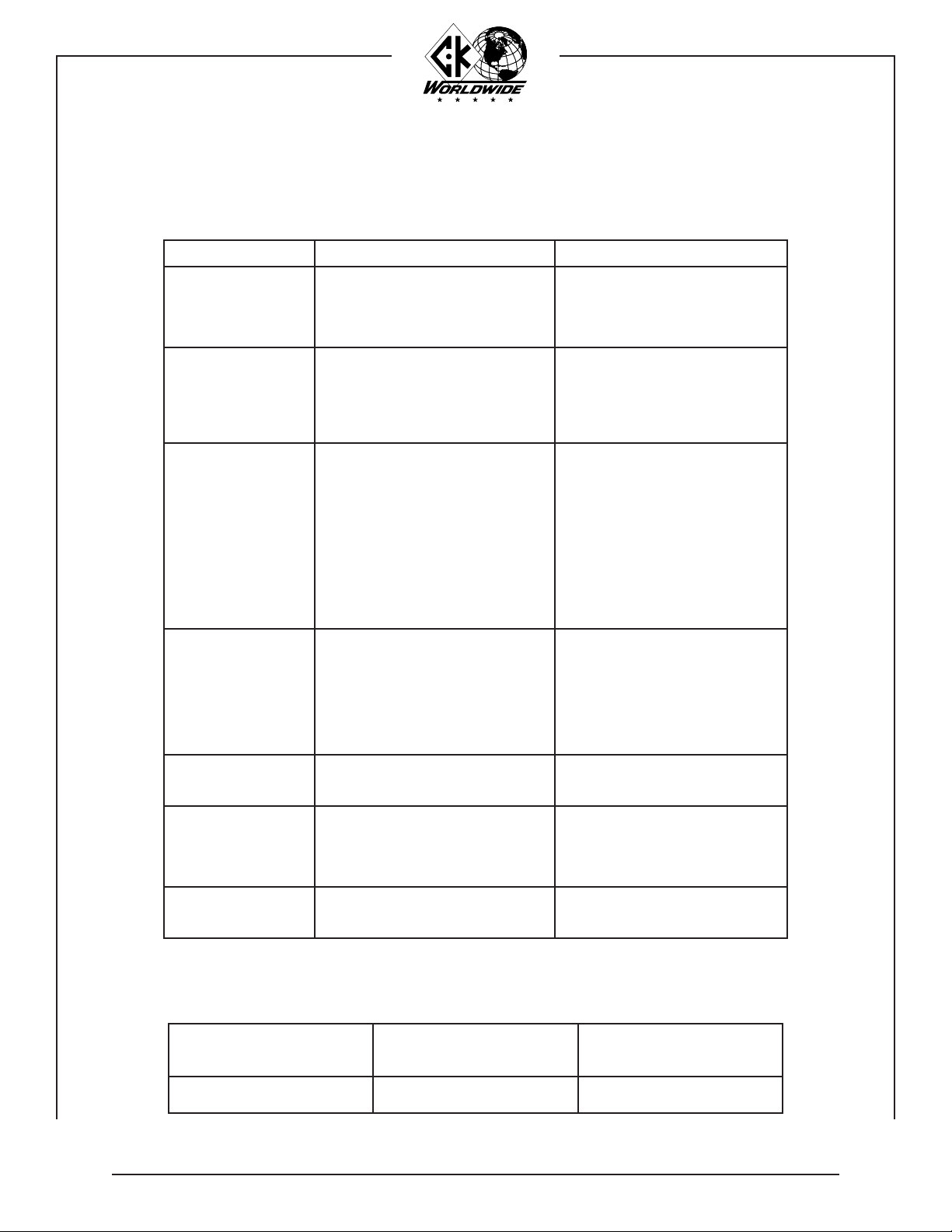

SPECIFICATIONS: WF5 WIRE FEED UNIT:

HAND TORCHES:

MACHINE TORCHES*:

*REMOTE SWITCH REQUIRED:

PART NUMBER: CWMES

See Page 21

Voltage:

Phase:

Frequency:

Height:

Width:

Length:

Weight:

Filler Wire Spool Size:

Filler Wire Sizes:

Wire Feed Speed Range:

Feed Time (pulsed mode):

Dwell Time (pulsed mode):

Delay Start Time (continuous mode):

Wire Retract Time (continuous mode):

115V AC (220V AC 50hz - special item)

Single Phase

50 / 60 hz.

15 in. (38.1cm)

10 in. (25.4cm)

21 in. (53.3cm)

54 lbs. (24.5 kg. )

12 in. (30.5cm)

.023” (.58mm), .030” (.76mm), .035”

(.9mm), .045” (1.1mm), 1/16” (1.6mm)

0-700 in/min (0-1,775cm/min)

continuously variable

continuously variable

continuously variable

continuously variable

180 amp ACHF or DCSP

300 amp ACHF or DCSP

350 amp ACHF or DCSP

400 amp ACHF or DCSP

Water

12-1/2 ft (3.81m)

8 ft. (2.44m)

10 ft. (3.05m)

300 amp ACHF or DCSP

400 amp ACHF or DCSP

400 amp ACHF or DCSP

500 amp ACHF or DCSP

Water

12-1/2 ft (3.81m)

8 ft. (2.4m)

10 ft. (3m)

CWH1812 Rating at 100% Duty Cycle:

CWH2312 Rating at 100% Duty Cycle:

CWHTL312 Rating at 100% Duty Cycle:

CWH3512 Rating at 100% Duty Cycle:

Cooling Method:

Torch Cable Length:

Feed Cable Length (soft wire):

Feed Cable Length (hard wire):

CWM2312 Rating at 100% Duty Cycle:

CWM3512 Rating at 100% Duty Cycle:

CWMT412 Rating at 100% Duty Cycle:

CWMT512 Rating at 100% Duty Cycle:

Cooling Method:

Torch Cable Length:

Feed Cable Length (soft wire):

Feed Cable Length (hard wire):

7

CHECKLIST:

OPTIONAL

ITEMS:

INSTALLATION:

WF5 Wire Feed Unit

CWMES:

CWH:

ITEMS REQUIRED FOR COLD WIRE TIG WELDING NOT PROVIDED:

Drive Roll Set - for wire size and type specified (installed)

Torch Outfit with Feed Cable, Wire Guide and Wire Guide

Bracket - model specified at time of order

Remote switch with 11 ft. (3.4m) lead - required for machine torch operation, but

must be ordered as a separate item.

The CK Cold Wire TIG Wire Feed Unit requires 115 volts Alternating Current to

operate. The 115V MUST be supplied by an ISOLATED, GROUNDED outlet. Do not

connect to the 115V AC outlet on the power source. 220V also available.

1. Attach the water cooled power cable of the TIG torch to the electrode terminal on the

power source. A power cable adapter is required to make the proper connection (the

water cooled power cable is the water out line).

2. Attach the ground cable from the power source ground terminal to the work or fixture.

The ground cable should be adequate size and no longer than the torch leads.

3. Attach the torch water in and gas supply hoses to their respective connections points.

4. Plug the feed unit control cord into an isolated, grounded 115V AC outlet. Do not con-

nect feed unit control cord into the 115V AC on the welding power source. For feed

units requiring 220V AC, install an appropriate plug. Then plug the feed unit control cord

into an isolated, grounded 220V AC outlet.

5. Do not set the Cold Wire Feeder directly on the power supply without an insulating

barrier.

Hand held feed assembly and remote switch with 8 ft. (2.4m) feed cable for soft

wire, 10 ft. (3m) feed cable for hard wire.

1. Welding power source - suitable for TIG welding.

2. Water recirculator - for cooling welding torch.

3. Regulator / Flowmeter - for control of shielding gas flows.

4. Shielding gas and cylinders.

5. Full cover welding helmet with proper shaded lens.

6. Leather welding gloves.

7. 12” (30.5cm) spool of welding wire.

8. Ground Cable - sized to suit current range - and ground clamp.

8

INSTALLATION: FITTING AND THREADING THE FILLER WIRE:

CAUTION: Do not feed wire through the drive rolls under pressure.

Keep hands away from the wire guide end while feeding

the wire through the feed cable.

When using soft aluminum wire, it may be necessary to

unscrew the compression nut fastening the feed tube to

the wire guide, and manually feed the wire through the

wire guide.

CAUTION:

NOTE:

6. Remove the right side Wire Feed Unit cover and install a spool of welding wire. Drive

rolls have two grooves. Check the feed roll to be sure it is on the correct side for the

filler wire being used. See page 21 for drive roll sizes. Unlatch and raise the pressure

roll arm. Thread the wire through the inlet guide to the drive rolls. Feed the wire across

the drive roll groove and into the feed cable inlet guide. Close and relatch the pressure

roll arm.

7. After the wire has been started into the feed cable, straighten feed cable and feed wire

under power by actuating the torch switch. Keep the Feed Cable as straight as possible

and continue pushing the switch until the wire has completely fed through.

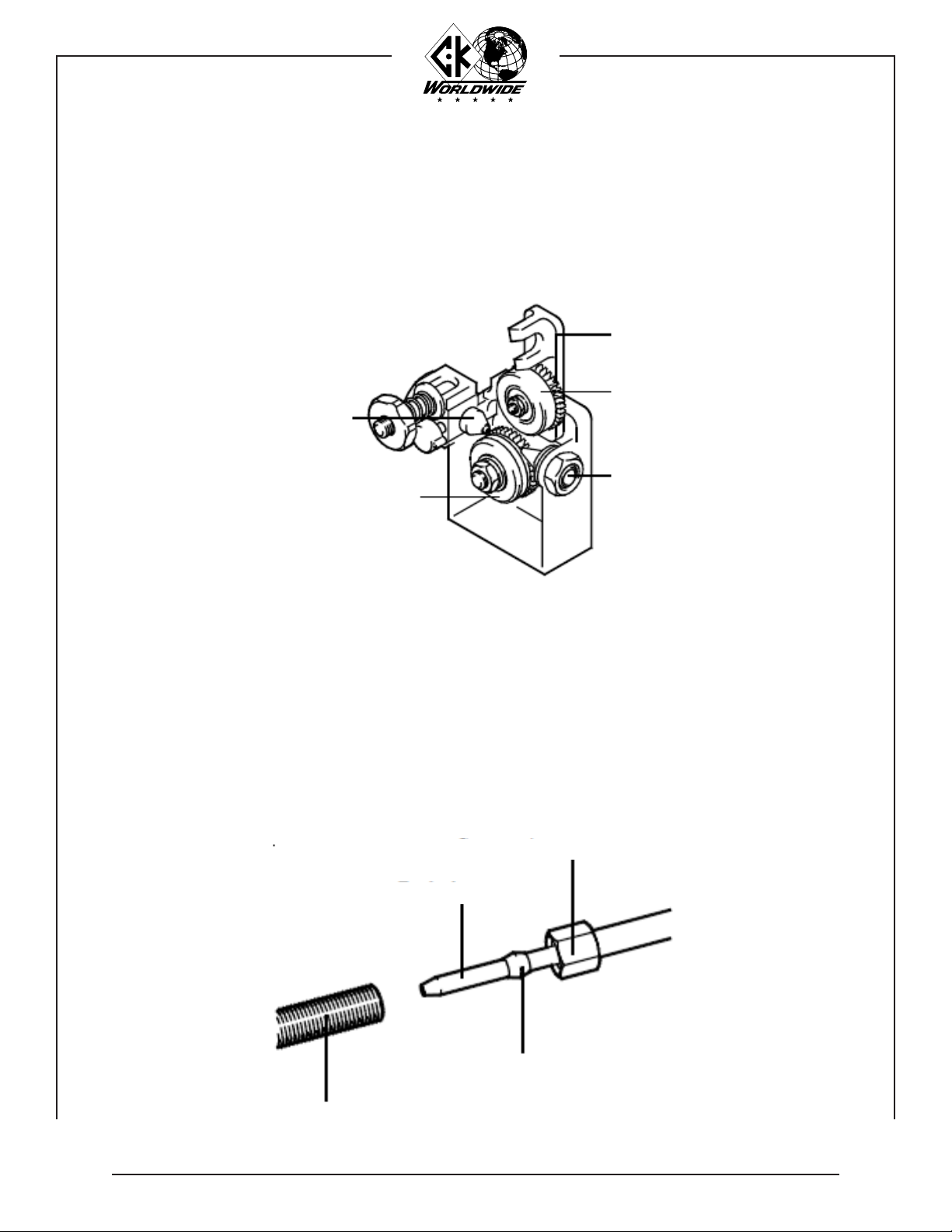

Feed Cable Inlet Guide

Drive Roll

Inlet Guide

Pressure Roll

Pressure Roll Arm

Compression Nut

Feed Tube

Wire Guide

Compression Fitting

9

INSTALLATION: WIRE FEED ROLL ADJUSTMENT:

SPOOL BRAKE ADJUSTMENT:

To adjust the feed rolls, tighten the pressure roll adjusting nut

approximately one-half turn past the point where the rolls

just begin to “grab” the welding wire.

Too much braking force will needlessly overload the drive

motor.

Always replace and lock the cover door after loading wire.

Feed rolls that are adjusted too tightly will result in deformed

wire and needless overload of the drive motor.

IMPORTANT:

WARNING:

NOTE:

WARNING:

8. The wire feed rolls and spool brake are properly adjusted at the factory, prior to delivery. As

componenets “seat in”, it may be necessary to adjust the settings.

9. Adjust the spool brake by turning the brake adjusting nut IN to increase braking force and OUT

to decrease the braking force. Adjust the brake just tight enough to prevent the welding wire

from over-running when feeding has stopped.

Pressure Roll

Adjusting Nut

Pressure Roll

Drive Roll

Retaining Clip - CW804

Spool Brake Adjusting Nut

10

OPERATION:

WELDING:

MAINTENANCE:

HAND HELD:

MACHINE:

Prior to commencing welding, the following preparations should be made to ensure

optimum performance of the system.

With the shield gas flowing, initiate an arc between the tungsten electrode and

the workpiece. When the desired weld pool has formed, depress the switch on the

torch to start the wire feeding. Adjust the Wire Speed and, if in Pulse mode adjust

the Drive time and Dwell time to produce the desired bead.

The recommended torch angle for hand held welding is 15° from perpendicular.

The filler wire is fed into the leading edge of the molten pool.

The recommended torch angle for machine mounting welding is perpendicular. The

filler wire is fed into the leading edge of the molten pool.

1. Make sure that the pieces of metal to be welded are free of grease, dirt, paint,

and scale. Use a wire brush to remove dirt and scale. Use a stainless steel wire

brush on stainless or aluminum. Paint must be completely removed to bare metal.

Failure to clean the metal properly will result in porous and contaminated welds.

2. Check that the system has been properly installed per the installation instructions.

3. Check the control cable and weld cables for proper connection. Make sure the

ground clamp is firmly attached to a cleaned area on the piece to be welded.

4. Prepare the torch for welding. Check the gas supply and adjust the flowmeter for

the recommended flow rate. Check the water circulator for proper operation.

5. Set the controls on the power source and the Cold Wire TIG Feed Unit.

1. Blow foreign matter from the feed cable with compressed air before loading a new

spool of welding wire.

2. Replace the wire guide tube if it has been arced, bent, or is badly worn.

3. Wire drive motor brushes should be inspected at regular intervals and replaced if

worked to a 1/4” (6.4mm) length.

Whenever a brush is removed for inspection, be sure it is put back in the

same position. It must not be turned around in the brush holder. Excessive

arcing and loss of power will result if it is put back incorrectly.

NOTE:

Direction of Travel

15°

3-3/4"

Direction of Travel

11

TROUBLESHOOTING

CHART:

This troubleshooting chart is a guide in identifying and correcting possible troubles

which may occur when operating this equipment.

Not affiliated with this equipment, refer to power source owners manual.

PROBLEM CAUSE SOLUTION

Pilot light is out 1. Unit is not plugged in.

2. Switch is in off position.

3. Switch is faulty.

4. Light is burned out.

5. Circuit breaker is blown.

1. Plug in unit.

2. Turn switch to on position.

3. Replace switch.

4. Replace light.

5. Reset or replace circuit breaker.

Drive indicator light does not

light when remote switch is

engaged

1. Light is burned out.

2. Remote switch is faulty.

3. Switch wire is damaged.

4. Amphenol plug is damaged.

5. Motor control board is faulty.

6. Power to unit is off.

1. Replace light.

2. Replace remote switch.

3. Repair or replace switch wire.

4. Repair or replace Amphenol plug.

5. Replace motor control board.

6. Turn power on.

Loss of wire feed 1. Circuit breaker tripped.

2. Motor control board is faulty.

3. Potentiometer is set at zero.

4. Wire supply is exhausted.

5. Wire feed cable tangled.

6. Wire is bird nested.

7. Feeder is unplugged.

8. Feed cable is plugged.

9. Drive roll is misaligned.

10. Drag is excessive.

11. Wire guide tube has worn out.

1. Reset circuit breaker.

2. Replace motor control board.

3. Set wire feed speed.

4. Resupply wire.

5. Straighten feed cable.

6. Loosen pressure roll / re-thread wire.

7. Plug in feeder to a 115V AC wall outlet.

8. Replace feed cable.

9. Align inlet and outlet guides with drive

roll.

10. Adjust spool brake.

11. Replace wire guide tube.

Erratic wire feeding 1. Feed unit plug is connected to power

supply.

2. Wire tangled on spool.

3. Wrong or worn feed cable.

4. Wrong or worn wire guide.

5. Wrong drive roll groove.

6. Incorrect drive roll pressure.

7. 12V DC relay failed.

1. Unplug then plug into 115V AC wall

outlet.

2. Remove tangled section and rethread.

3. Replace feed cable.

4. Replace wire guide.

5. Refer to chart on Page 21.

6. Adjust pressure roll.

7. Replace relay.

Faulty Delay - Retract 1. Potentiometer failed.

2. Toggle switch failed.

3. 12V DC relay failed.

1. Replace potentiometer.

2. Replace toggle switch.

3. Replace relay.

Motor will not turn off 1. Faulty trigger switch.

2. Switch control cable damaged.

3. Amphenol plug shorted.

4. 12V DC relay failed.

5. Logic board failed.

1. Repair or replace switch.

2. Repair or replace cable.

3. Repair or replace plug.

4. Replace relay.

5. Replace logic board.

Wire will not feed 1. Coiled feed cable - friction on wire.

2. Wire is bent or curved.

1. Keep feed cable as straight as possible.

2. Keep wire straight as it enters feed

rolls.

Loss of weld current 1. Weld cables disconnected.

2. Power source contactor open.

3. Poor contactor connection.

1. Repair or replace cables.

2. Check contactor connections.

3. Make proper connections.

Erratic weld current 1. Poor ground connection.

2. Poor welding cable connection.

1. Make proper connections.

2. Make proper connections.

12

CABLES AND

GUIDES:

WIRE TYPE WIRE SIZE: FEED CABLE:

Hard Wire:

-10 ft. (3m) for

Stainless Steel

-Black Strain Relief

.023” (.55mm) CW-FC

.030” (.8mm) CW-FC

.035” (.9mm) CW-FC

.045” (1.1mm) CW-FC

1/16” (1.6mm) CW-FC116

Soft Wire:

-8 ft. (2.4m) for

Aluminum

-Red Strain Relief

.023” (.55mm) Not recommended

.030” (.8mm) Not recommended

.035” (.9mm) CW-FCN

.045” (1.1mm) CW-FCN116

1/16” (1.6mm) CW-FCN116

TORCHES: WIRE SIZE: REPLACEMENT TIP: REPLACEMENT

TUBE:

WIRE GUIDE

ASSEMBLIES:

Body Mount:

(CWH180)

(CWH230)

(CWM230)

(CWMT500)

.023” (.55mm) CWT023 CWGB

(Curved)

CWGBS

(Straight)(S)

CWG023B(S)

.030” (.8mm) CWT030 CWG030B(S)

.035” (.9mm) CWT035 CWG035B(S)

.045” (1.1mm) CWT045 CWG045B(S)

1/16” (1.6mm) N/A CWG116B(S)

Head Mount:

(CWH), (CWM), (CWH150),

(CWH210), CWHTL312),

(CWH350), (CWM350),

(CWMT400)

.023” (.55mm) CWT023 CWGH

(Curved)

CWGHS

(Straight)(S)

CWG023H(S)

.030” (.8mm) CWT030 CWG030H(S)

.035” (.9mm) CWT035 CWG035H(S)

.045” (1.1mm) CWT045 CWG045H(S)

1/16” (1.6mm) N/A CWG116H(S)

NOTE: A bracket extension is needed for complete installation with a part number of 3-WGBX-60.

FEEDING DIFFICULT

WIRE/BRACKET

EXTENSION:

Due to the nature of certain wires it may be difficult to feed a wire through the length of the feed

cable and through the curved wire guide. Friction and drag may put too much resistance on the wire

when it is forced through the curved wire guide. Typically this is encountered when using very small

diameter soft wires and large diameter hard wires. To alleviate this problem a wire guide extension

bracket is recommended. This will relieve the resistance on the wire. In addition to the use of the

wire guide extension bracket, it is important to keep the feed cable as straight as possible.

PART # 3-WGBX-60

13

WF5 ELECTRICAL DIAGRAM:

120V AC

60 HZ

PILOT

LIGHT

12V DC

RELAY

12V DC

RELAY

LOGIC CIRCUIT

CARD

MOTOR

2 OHM

50 WATT

DELAY

SW-2

DELAY

P-1

RETRACT

SW-3

RETRACT

P-2

1

1

11

12

10

3

2

12

K1 K2

1314

893

6

+12V

11 13 10

9

4

4

C1 C2 C3

5

5

6

7

7 FIELD

8

TRIGGER

MOTOR DRIVE CIRCUIT

CARD

SPEED

ADJUSTMENT

BLACK

BROWN

WHITE

RED

14

A

B

C

D

E

F

G

H

I

J

K

L

M

N

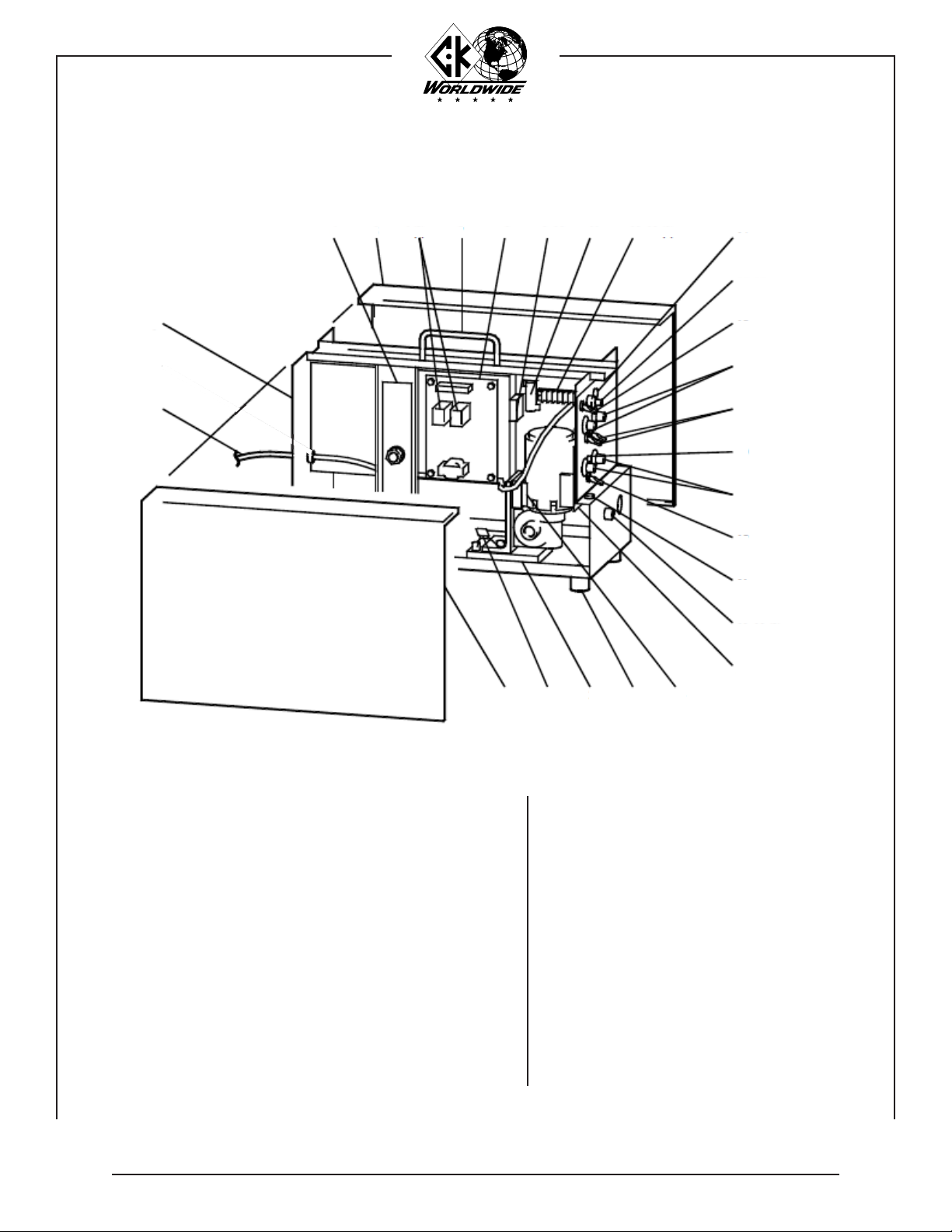

FUNCTIONS OF

CONTROLS:

The following controls are located on the front of the WF5 wire feed unit.

FUNCTIONS OF

CONTROLS:

A. ON / OFF Switch

Main power switch - energizes control circuit

and pilot light.

B. Delay Start Time Control

Variable resistor - sets the time delay from

remote switch actuation to wire feed start.

C. Delay Start ON / OFF Switch

Activates the delay start timer.

D. Drive Time Control

Variable resistor - sets the on time of the wire

feeding into the weld puddle in pulse mode.

E. Pulse / Continuous Selector Switch

Controls mode of operation - Continuous or

Pulse wire feed mode.

F. Circuit Breaker

5 amp breaker provides overload protection for

control circuit.

G Remote Amphenol

WF5 activation.

H. Wire Speed Control

Ten turn potentiometer - controls speed of wire

drive motor.

I. Pilot Light

Illuminates when feed unit is on.

J. Retract Time Control

Variable resistor - controls time of wire in

retract mode.

K. Retract ON / OFF Switch

Activates wire retract circuit.

L. Dwell Time Control

Variable resistor - sets the off time of the wire

when not feeding wire into weld puddle in

pulse mode.

M. Drive Indicator Light

Illuminates when motor is feeding wire.

N. Feed Cable Connection

Connection point for wire feed cable.

15

PARTS:

PARTS LIST:

WF5 COLD WIRE FEED UNIT LEFT SIDE VIEW: (see page 18 for right side view)

ITEM:

1

2

3

4

5

6

7

8

9

10

11

12

ITEM:

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

PART NUMBER:

312003-01

400-0001-81

400-0037-81

400-0004-81

400-0168-87 (2)

DK-1107

400-0170-87

400-2026-95

400-2027-95

01-2207-79

400-0176-79

400-0018-81 (5)

PART NUMBER:

01-5089-79

400-0130-82

400-0129-82

400-0012-81 (4)

400-0009-81 (4)

400-0177-87 (2)

400-0111-81

400-0015-81

11-0051-79

400-0169-87

400-0167-87

001-1107-79 (4)

400-0166-87

400-0181-92

400-0003-81

DESCRIPTION:

Power Cord

Cabinet

Strap, Spool Hub

Right Door

12V DC Relay

Handle

Motor Drive Circuit Card

Fuse Holder

Fuse 5 amp, 250 Volt

2 Ohm Resistor

Terminal Board

Capacitor

3 on Amphenol Connector

2 on Terminal Board

DESCRIPTION:

Pilot Light

10 Turn Dial

10 Turn Potentiometer

2 Position Switch

Knob

100 K Potentiometer

Pilot Light

Circuit Breaker, 5 amp

Amphenol Receptacle

Logic Circuit Card

Motor Spacer

Footpad

Motor Pad

Capacitor

Left Door

1

2

3 4 5 (2) 7 8, 9 10 13

14, 15

16

16 (2)

16

19

20

22

2324252627

17 (2), 18 (2)

17 (2)

21, 12 (3)

11, 12 (2)6

16

PARTS: WF5 COLD WIRE FEED UNIT RIGHT SIDE VIEW:

PARTS LIST:

Consisting of the following:

Consisting of the following:

ITEM:

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

ITEM:

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

PART NUMBER:

CW900

CW400

CW111

CW109

CW110

CW112 (2)

CW113

CW101

CW104

CW103

CW105

CW108

CW100

CW106

CW107

CW303

CW304

CW305

CW306

Drive Roll - Select from:

30-45DR

45-564DR

PART NUMBER:

CW201

CW203

CW204

CW200

CW500

CW503 (3)

CW504 (3)

CW300

CW302

CW301

CW800

CW810

CW805

CW802

CW806

CW811

CW803

CW811

CW801

CW807

CW805

CW808

CW809

CW804

DESCRIPTION:

Motor and Drive Assembly

Motor and Gear Box

Pressure Roll Tension Bolt

Tension Nut

Pressure Spring

Tension Bolt Washer

Tension Bolt Roll Pin

Pressure Roll

Pressure Roll Screw

Pressure Roll Bushing

Pressure Roll Retainer Nut

Pressure Roll Spacer

Pressure Roll Arm

Shoulder Bolt

Spring Washer

Outlet Guide Mount

Outlet Guide Washer

Outlet Guide Nut

Thumb Screw

.030” - .045” (.8mm - 1.1mm) Wire

.045” - 1/16” (1.1mm - 1.6mm) Wire

DESCRIPTION:

Drive Shaft Key

Drive Roll Lockwasher

Drive Roll Nut

Drive Roll Gear

Drive Housing Bracket

Drive Housing Bolt

Drive Housing Lockwasher

Inlet Guide

Inlet Guide Washer

Inlet Guide Nut

Hub Assembly

Bolt

Flat Washer

Tension Spring

Notched Washer

Bushing

Shaft

Bushing

Spool Holder

Nylon Flat Washer

Flat Washer

Lock Washer

Bolt

Wire Spool Retaining Clip

16, 17, 18

25, 26, and 27 28, 29, and 30

32, 33, 34, 35, 36, 37, 38, 40,

41, 42, and 43

3, 4, 5, 6, and 7

20, 21, 22, 23, and 24

8, 9, 10, 11, 12,

13, 14, and 15

1

2

19

31

39

44

17

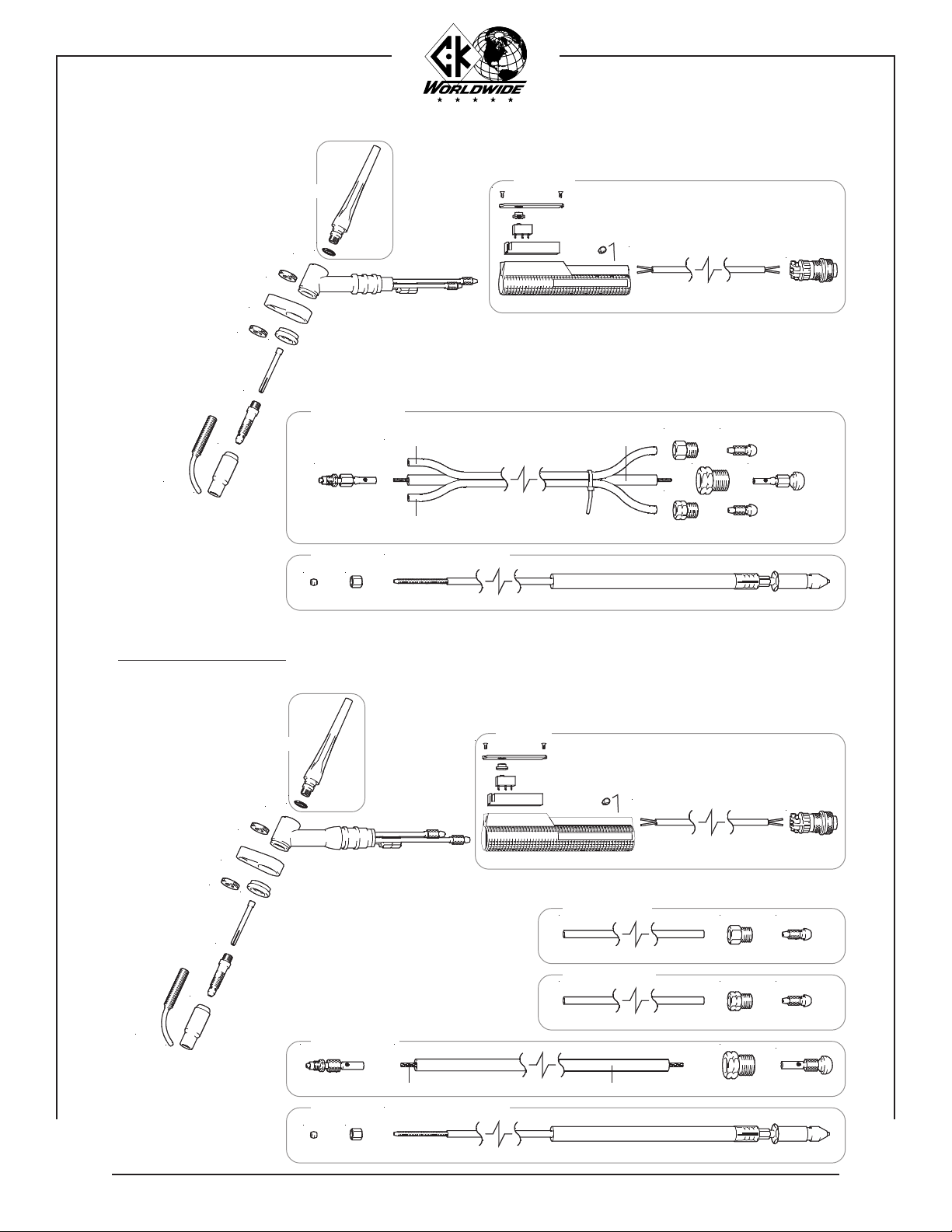

PARTSLIST:

PARTSLIST:

* Note: See Page 22 for additional

options on head consumables.

CWH2312 HAND TORCH:

* Note: See Page 22 for additional

options on head consumables.

CWH1812 HAND TORCH:

CWKN

6S5

3035

SWB

SW4

3036

SS1

6S5

CWH23H (including 6S5's and SS1)

SC-BULK 01-0127

CWH23HA

2GHS

CK230

200R

200M

2A7*

2CB332*

2C332GS*

CWKNSee Page 12

CWFCWN1

CWFC or CWFCN

2312TF - 12.5 ft (3.8m)

2AN 3HF

2WN 3HF

2PN 23PF223PF1

2312PC -12.5 ft (3.8m)212AH - 12.5 ft (3.8m)

212WH - 12.5 ft (3.8m)

01-0032

CK180

80THS

8CB332*

8C5*

8C332*

WGB-B

CWKNSee Page 12 CWKN

6S5

3035

SWB

SW4

3036

SS1

6S5

CWH18H (including 6S5's and SS1)

SC-BULK 01-0127

CWH18HA

CWFCWN1

CWFC or CWFCN

212TF - 12.5 ft (3.8m)

2AN 3HF

2WN 3HF

2PN2PF22PF1

2312PC - 12.5 ft (3.8m)212AH - 12.5 ft (3.8m)

212WH -12.5 ft (3.8m)

01-0032

(set screw incl.)

WGB-B

(set screw incl.)

18

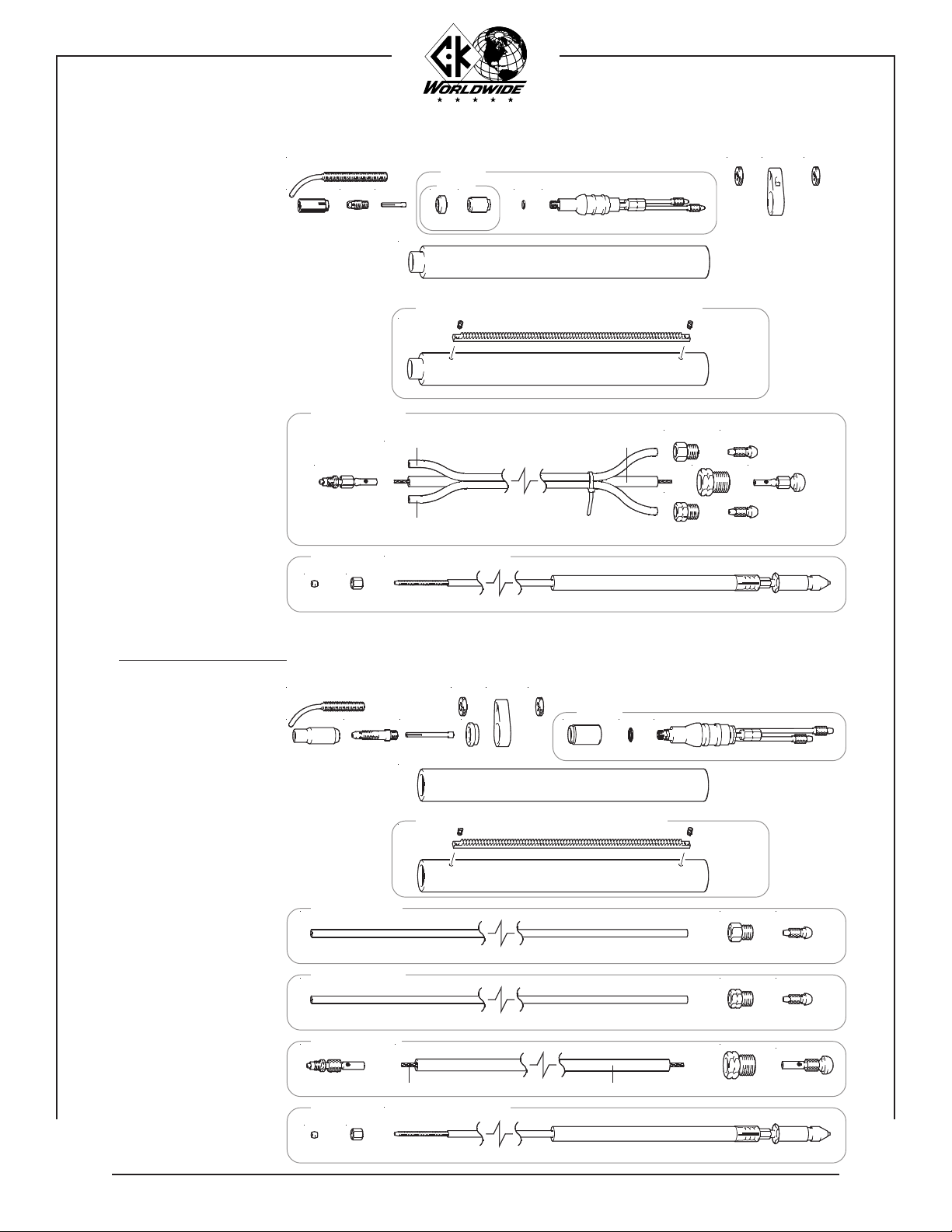

PARTSLIST:

* Note: See Page 23 for additional

options on head consumables.

CWH3512 HAND TORCH:

CWFC or CWFCN / CWFC116 or CWFCN116

CWFCWN1

2312TF 12.5 ft. (3.8m)

2AN 3HF

2WN 3HF

2PN 23PF223PF1

2312PC 12.5 ft. (3.8m)212AH 12.5 ft. (3.8m)

212WH 12.5 ft. (3.8m)

01-0032

CWFC or CWFCN / CWFC116 or CWFCN116

CWFCWN1

CWHTL312 HAND TORCH:

CWKN

CWKN

CWHS

3C332GS*

See Page 12

3A7*

3CB332*

TL300

WGB-3

300R

300L 6S5

3035

SWB

SW4

3036

SS1

6S5

CWHTL3HA

230HE

(including 6S5's and SS1)

SC-BULK 01-0127

512PC 12.5 ft. (3.8m)

2PN 51PF251PF1

2WN 3HF3H-BULK

312WH 12.5 ft. (3.8m)

2AN 3HF3H-BULK

312AH 12.5 ft (3.8m)

PARTSLIST:

CWKN

CWKN

CWHS

3C332GS*

300R

300L

CK350

WGB-3

3CB332*

3A7*

See Page 12

* Note: See Page 23 for additional

options on head consumables.

6S56S5

CWH35HA

300HE

(including 6S5's and SS1)

01-0127SC-BULK

SS1

3036

SW4

SWB

3035

5PCH-BULK5PCW-BULK

19

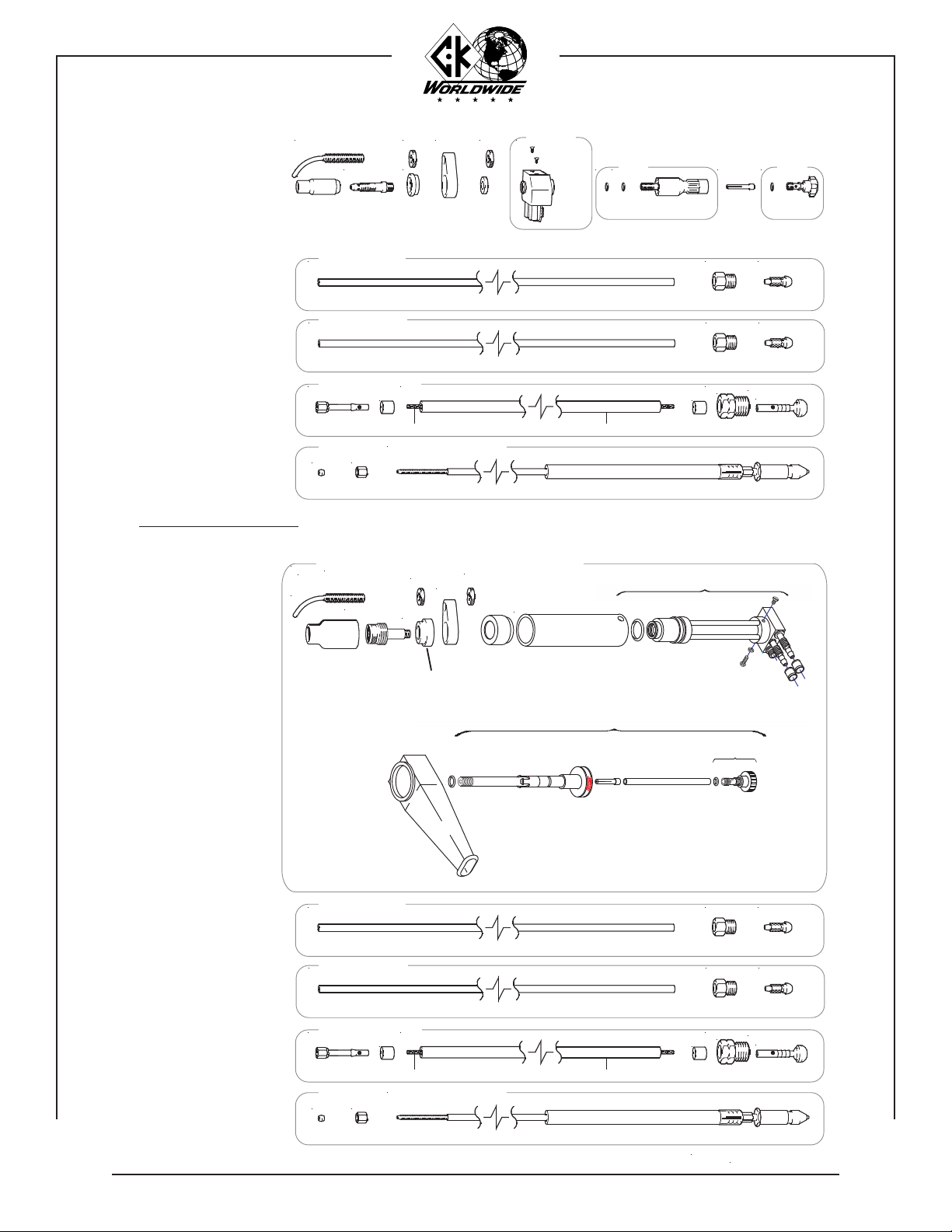

CWM2312 MACHINE TORCH:

CWM3512 MACHINE TORCH:

CWKNCWKN

230M-HCW

PARTSLIST:

PARTSLIST:

2312TF 12.5 ft. (3.8m)

2AN 3HF

2WN 3HF

2PN 23PF223PF1

2312PC 12.5 ft. (3.8m)212AH 12.5 ft. (3.8m)

212WH 12.5 ft. (3.8m)

01-0032

See Page 12

3CB332*3A7*

See Page 12

2A7* 230M-B200R

2GHS

230M-C

2C332GS*

CKM230

350M-C300R350M-B

CKM350

* Note: See Page 24 for additional

options on head consumables.

* Note: See Page 25 for additional

options on head consumables.

CWKNCWKN

CWHS3C332GS*WGB-3

CWFC or CWFCN / CWFC116 or CWFCN116

CWFCWN1

312WH 12.5 ft. (3.8m)

2WN 3HF3H-BULK

312AH 12.5 ft. (3.8m)

2AN 3HF3H-BULK

CWFC or CWFCN / CWFC116 or CWFCN116

CWFCWN1

2CB332*

512PC 12.5 ft. (3.8m)

2PN 51PF251PF1 5PCH-BULK5PCW-BULK

HR-24 or HR-32

HR-SHR-S

230M-HCWR24 or 230M-HCWR32 (optional item - ordered separately)

350M-H

HR-24 or HR-32

350M-HR24 or 350M-HR32 (optional item - ordered separately)

HR-S HR-S

WGB-B

(set screw incl.)

20

CWMT412 MACHINE TORCH:

PARTSLIST:

PARTSLIST:

* Note: See Page 27 for additional

options on head consumables.

CWFC or CWFCN / CWFC116 or CWFCN116

CWFCWN1

312AH 12.5 ft. (3.8m)

2AN 3HF3H-BULK

* Note: See Page 26 for additional

options on head consumables.

CWMT512 MACHINE TORCH:

See Page 12 CWKN

WGB-3

CWHS

3GL332LD*

MT500C-7 (7” - 17.8cm body) or MT500C-18 (18” - 45.7cm body)

CWHS 4C332*

See Page 12

3CB332*3A6* 200R

(2 required)

200R

AS35ACM

WGB-3

CWKNCWKN CWMT400

118-024

(2 required)

CWKN

M512PC-1 12.5 ft. (3.8m)

MTPCFA 5PCH-BULK5PCW-BULK

312WH 12.5 ft. (3.8m)

2WN 3HF3H-BULK

3AG12LD

CWTS

2PN

51F 1184

51F

CWFC or CWFCN / CWFC116 or CWFCN116

CWFCWN1

212AH 12.5 ft. (3.8m)

2AN 3HF2H-BULK

M512PC-1 12.5 ft. (3.8m)

MTPCFA 5PCH-BULK5PCW-BULK

212WH 12.5 ft. (3.8m)

2WN 3HF2H-BULK

2PN

51F 1184

51F

MTSB

INCLUDES WASHER

H1-3

MT500BC - 18 (18” (45.7cm))

or

MT500BC - 7 (7” (17.8cm))

R-7

MTS (3 req.)

MTH-18 (18” (45.7cm))

or

MTH-7 (7” (17.8cm))

1006 (2 req.)

AS35

4CE500 - 7 (7” (17.8cm))

4CXXX*

ACM500 - 7 (7” (17.8cm))

300R

BOOT-MT

4CE500 - 18 (18” (45.7cm))

or

*NOTE: 4 SERIES COLLET REQUIRED

INCLUDES O-RING

ACM500 - 18 (18” (45.7cm))

or

CWHSLD

Table of contents

Other CK WORLDWIDE Welding System manuals