Quick Reference Guide QRG-02

4S-03

RESET

RESET

Error Message Reason Solution

Too Long Fiber

•

The fiber end-face is placed on the electrode

centerline, or beyond it

•

The cleave length (bare fiber part) is too long

•

Dust or dirt is on the objective lens

Press , and set the fiber end-face between the

electrode centerline and the V-groove edge.

Confirm the placement of the stripped fiber end on the fiber

cleaver. Check the cleave length.

Execute [Dust Check]. Clean the lens when dust or dirt exists.

Too Dusty Fiber

•

Dust or dirt is on the fiber surface

•

Dust or dirt is on the objective lens.

•

[Cleaning Fuse] time is too short or “OFF”.

•

Splicing fibers with unresolvable core positions using

the SM or DS modes

•

[Align] is set to “Core” when splicing fibers with unresolvable

core positions when using other splice modes

•

[Focus] is incorrectly set when using other

splice modes.

Completely prepare the fiber again (strip, clean and cleave).

Execute the [Dust Check]. Clean the lens if dust or dirt exists.

Set the [Cleaning Fuse] time to “150ms.” When splicing carbon

coated fibers, set to “200ms.”

Use the MM mode to splice fibers with unresolvable core

positions (i.e. MM fiber).

Set [Align] to “Clad” to splice these fibers (i.e. MM fiber).

Set [Focus] to “Edge” to splice fibers with unresolvable core

positions (i.e. MM fiber). To splice distinct core fibers, “Auto”

or the correct focus value should be entered.

ZL/ZR Motor

Overrun

•

The fiber is set too far back and does not reach

the splice point

•

The cleave length (bare fiber part) is too short.

•

Splicing loose buffer tube fiber without protrusion engaged

Press , re-position the fiber again with the end-face

closer to the electrodes.

Confirm the placement of the stripped fiber end on the fiber

cleaver. Check the cleave length.

Flip the protrusion switch so it engages the loose buffer tube fiber.

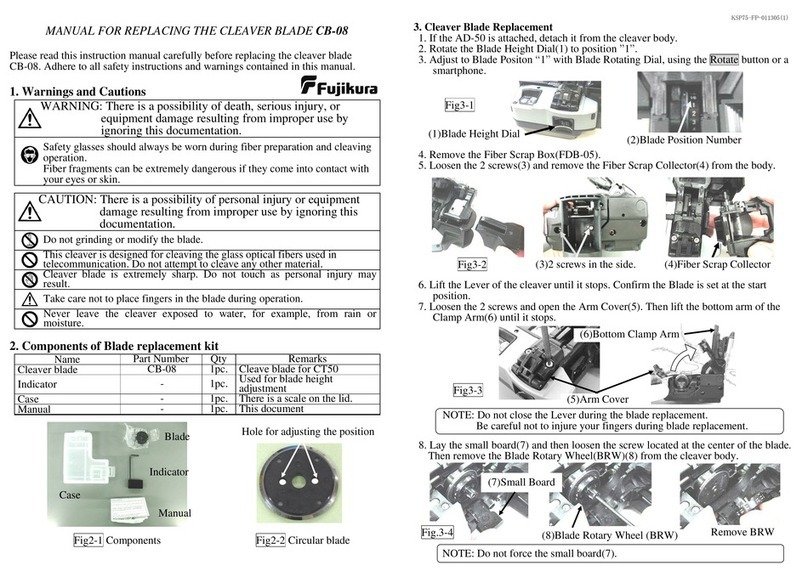

Large Cleave

Angle

•

Bad fiber end-face

•

[Cleave Limit] was changed to a low cleave angle.

Check the condition of the fiber cleaver. If the blade is worn,

rotate the blade to a new position.

Load the default cleave angle value from the splice mode database.

Cleave

Shape NG

•

Bad fiber end-face Clean and check the condition of the fiber cleaver.

If the blade is worn, rotate the blade to a new position.

High Estimated

Loss

•

Dust or dirt is on the fiber surface

•

Bad fiber end-face

•

Improper splice mode selected

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Unstable fusing discharge

Completely prepare the fiber again (strip, clean and cleave).

*This table only shows a few possible errors. Refer to the instruction manual for a more comprehensive list.

Check the condition of the fiber cleaver. If the blade is worn,

rotate the blade to a new position.

Select proper splice mode

Electrodes might be worn. Perform [Electrode Stabilization] or

replace electrodes.

Fujikura Ltd.

1-5-1, Kiba, Koto-ku, Tokyo 135-8512, Japan

General inquiries : +81-3-5606-1164

Service & support : +81-3-5606-1534

Fujikura Asia Ltd. 438A Alexandra Road,Block A Alexandra Technopark #08-03, Singapore 119967

General inquiries, service & support : +65-6-278-8955 https://www.fujikura.com.sg

Fujikura Europe Ltd.

C51 Barwell Business Park, Leatherhead Road, Chessington, Surrey, KT9 2NY, UK

General inquiries : +44-20-8240-2000

Service & support : +44-20-8240-2020 https://www.fujikura.co.uk

AFL

260, Parkway East, Duncan, SC29334, USA

General inquiries : +1-800-235-3423

Service & support : +1-800-866-3602 https://www.aglobal.com

Fujikura (CHINA) Co., Ltd 7thFloor, Shanghai Hang Seng Bank Tower, 1000 Lujiazui Ring Road, Pudong New Area, Shanghai 200120, CHINA

General inquiries, service & support : +86-21-6841-3636 http://www.fujikura.com.cn

Authorized Splicer Distributor

Contact Addresses

Solutions for Common Splicer Errors

https://www.fujikura.com

Quick Reference Guide QRG-02

S-03 1

LED

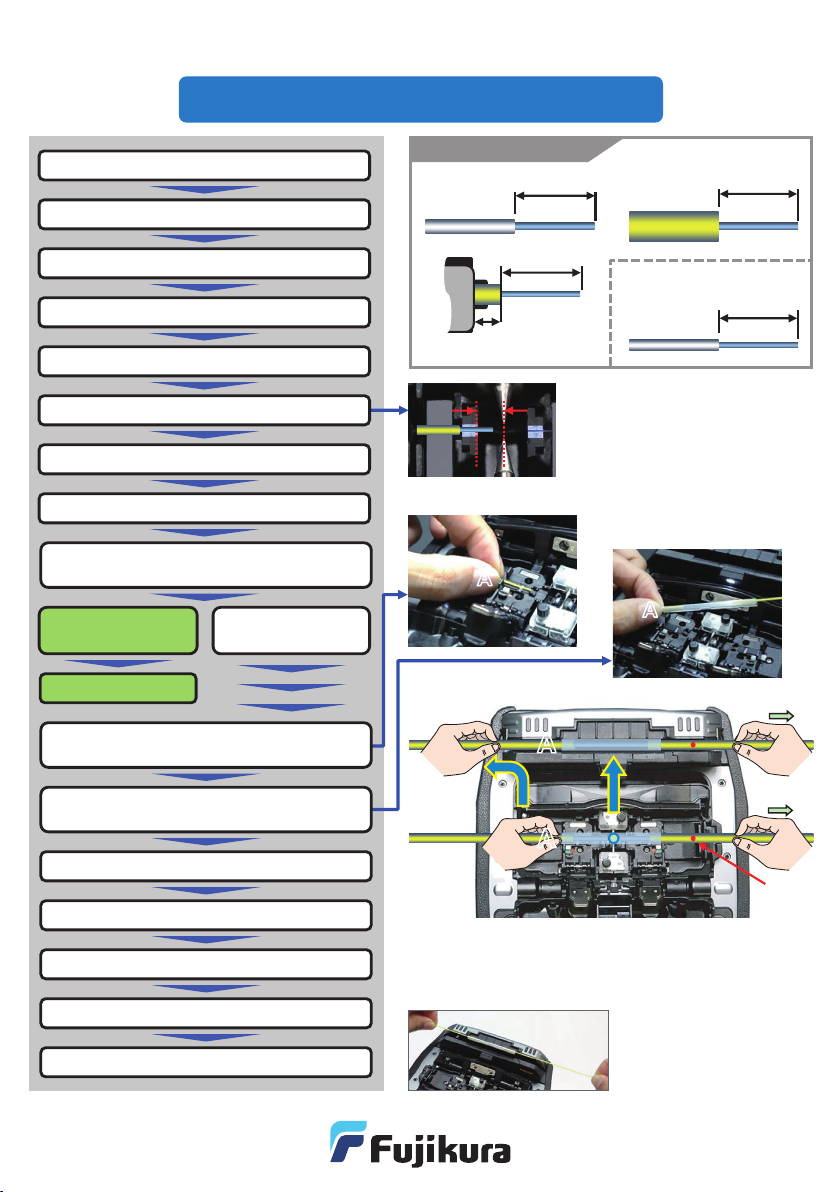

Tools for Splicing Operation

Fusion Splicer

Core Alignment

Consumables for

cleaning

•Cotton

•Cotton swab

•Alcohol

Single Fiber

Stripper

Optical Fiber

Cleaver Protection sleeve

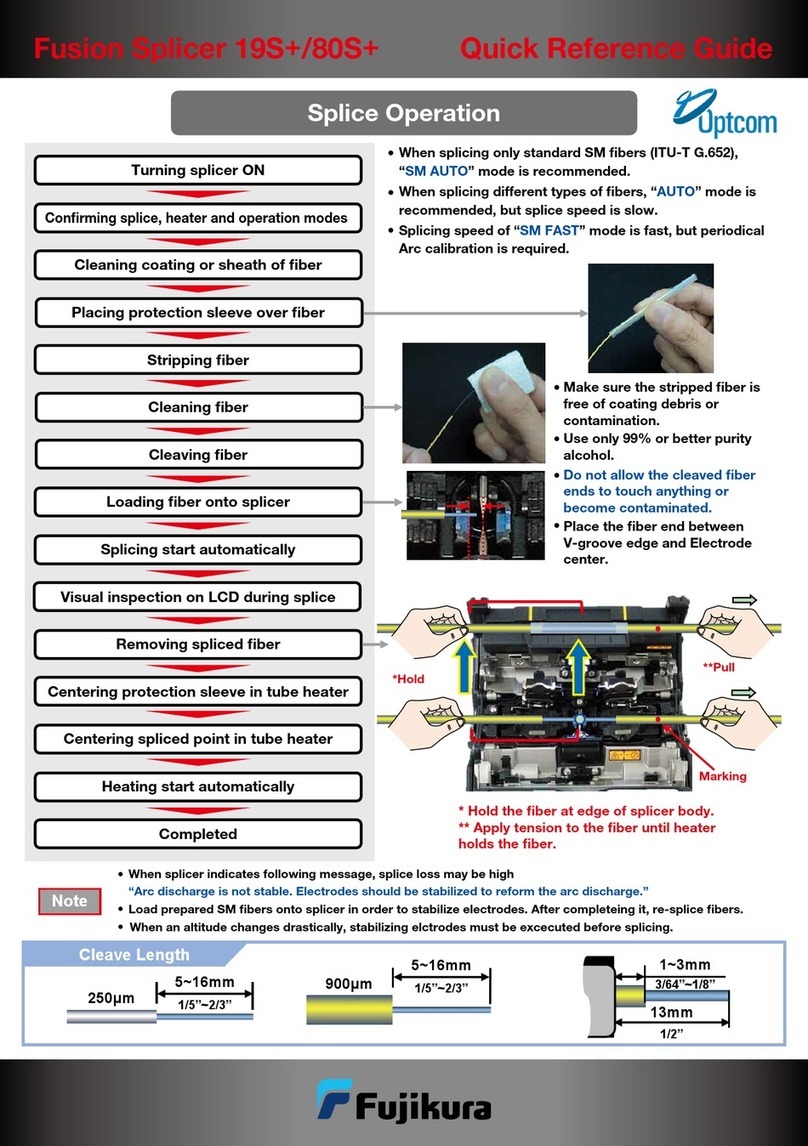

The following items are standard tools for optical fiber splicing.

Setup & Preparation Before Splicing

Turning ON

Press key until green LED

turns on.

Turning OFF

Press

turns on.

Install battery pack or DC adaptor

Plug AC adaptor into the DC adaptor.

*No need when using battery pack.

Turn splicer ON.

Confirm Heater Mode

Check Wireless Communication status

Clean before splicing

Setup & Preparation completed

Confirm Splice Mode

•Select “G652/SM AUTO” to splice standard SM

•Select “AUTO” mode to splice unknown fiber types.

However, splice time might be longer.

•“G652/SM FAST” will shorten the splice time. However,

periodic Fusing Power Calibrations are neccesary.

•Select the adequate heater mode according to the sleeve.

The [READY] screen shows the current heater mode.

•When using a protection sleeve which is not made by Fujikura,

please set parameters based on the specific sleeve.

•Splicr can connect to the CT50 cleaver and RS02/03 ribbon

stripper.

•When wireless comunication is established, the splicer

monitors the conditon of these tools. If the splicer sees that the

tool has an issue, it alerts the operator with an on-screen alarm.

•After initial pairing, the devices are always paired.

Communication between splicer, cleaver and stripper resumes

automatically even after power cycling.

•Refer to the setting guide “SG-02” or instruction manual for

wireless communication function details.

Basic operations can be performed from the

touch screen after the power is turned on.

*

Splice Mode

Heater Mode

Wireless communication with accessories

key until red LED

fibers (ITU-T G.652).