Claas JAGUAR Series Installation guide

JAGUAR 830 - 880 (500)

Information and Basic Field Settings

Introduction

Safety

Drive Concept

Right Hand Switch Panel

Multifunction Lever

CEBIS

Road Travel Display

Harvest Display

Keys and Symbols

HOTKEY

Feed Rollers

Metal Detector and Stop Rock

Opening Feed Rollers

Chopping Cylinder

Sharpening

Cylinder Concave

Shear Bar

Corn Cracker

Removing the Corn Cracker

Accelerator

Discharge

Other Machine Features

Front Attachment

PICK UP

DIRECT DISC

ORBIS

Pitching and Dampening

Silage Quality - Adjustments

Useful Part Numbers

03

04

05-06

07

08

09

10

11

11

13-14

16

17-19

20

23

24

25

26-27

28

29

30

31-33

35-38

39-40

41-45

47

49-50

53

Contents

03 04

Introduction

This quick reference guide has

been produced to aid operator’s with

familiarisation and settings of CLAAS JAGUAR

forage harvesters.

CLAAS forage harvesters are designed for output

and efciency but this can only be achieved

with correct operation and maintenance of the

machine.

This guide is not designed to replace

the Operator’s Manual but purely as

a reference document.

More in depth information is available

in the Operators Manual.

Downtime costs output

To get the most from the machine, the wheels must be turning.

In order to keep downtime to a minimum, it’s vital that routine

maintenance is not neglected.

As well as servicing the machine according to the operator’s

manual, a good check of the machine is essential. It is false

economy to put off the replacement of worn parts until they

break.

Abbreviations

Throughout this guide the following abbreviations are used:

‘LHS’ and ‘RHS’ refer to the Left Hand Side and Right Hand

Side of the machine respectively, taken from the rear of the

machine facing in the direction of travel.

• Make sure you are familiar with the controls and operation

of the machine and have read the Operator’s Manual.

• The forage harvester has many moving parts, guards are

designed to keep you safe, please ensure that all guards are

kept in place and in good condition when operating

the machine.

• When doing any maintenance work or making

adjustments outside of the machine make sure that the

engine is switched off and the battery isolator key is

removed.

• Some of the maintenance has to be carried out at height,

please asses the risks that this poses and ensure that the

task is carried out safely.

• When operating the machine be aware of the presence

of people particularly in farmyards, always get someone to

help you when reversing in conned areas.

• Be aware of the size of your machine, particularly the

height, you may be at risk from contact with overhead

power lines and overhead obstructions particularly but not

exclusively when the spout is in the working position and if

extra aerials have been tted to your machine.

ALWAYS READ THE OPERATORS MANUAL BEFORE

OPERATING YOUR FORAGE HARVESTER.

The information is therefore not complete for the purpose of

working on the machine. This document does not replace the

relevant operators manual and repair documentation! Subject to

changes due to continued technical developments.

Safety is of the utmost

importance whilst you are

operating and maintaining

your forage harvester.

Make sure that all of the

risks are assessed to

reduce the likelihood of

an accident.

For more in depth safety

information please consult

your operators manual.

Always read the Operator’s

Manual before using any new

machine.

Safety

05

Drive Concept

Drive is taken directly from

the diesel engine (1)

via a power band belt (2)

to the cutting cylinder (3),

and the accelerator (4).

The accelerator shaft drives

the corn cracker (5) by means of

another belt drive.

The cutting cylinder shaft

transmits the power to the right side

via the third power band belt (6),

driving the front attachment drive (7)

and the feed rollers.

The feed rollers are reversed

using the hydraulic motor (8).

1

2

3

4

5

6

7

8

Right Hand Console

1. Info Key

Provides extra information

2. Hot Key

Additional machine functions

3.CEBIS Rotary Switch

Main Menu functions

4. Back Key

Back step / cancels a change

5. Radio Functions Keys

Operates radio and bluetooth

5

1

2

3

4

Right Hand Switch Panel

1. Main Drive Switch

Engages the chopping cylinder

2. Partial Widths Adjustment

3. Steering Centralisation Adjustment

4. Header Height Adjustment

5. Cruise Piolet Speed Adjustment

6. AUTO FILL ll height adjustment

7. Discharge chute raise/lower

8. Front attachment

9. Additive system switch

10. 4 Trac on/off switch

11. Gear selection switches

1

23

56

7

8

9

10

4

11

Multi-Function Lever

1. Lower Front Attachment

2. Raise Front Attachment

3. AUTOCONTOUR On/Off

4. Cutting Height Pre-Selection

5. AUTOPILOT On/Off

6. Spout Control In/Out and Chute L/R

7. Front Attachment / Feed Roller Reverse

8. HOTKEY Operation

08

9. Front Attachment / Feed Roller

Disengagement

10. Auto Chute Positioning

11.. Auto Chute/Auto Fill parking position/

engagement

3

5

6

7

8

9

10

4

1

211

10

CEBIS Harvest Display

1. Main Menu

2. Fuel Level

3. Urea Level

4. Coolant Temperature Level

5. Gear / 4WD Status

6. Forward Speed

7. User Dened Displays

CEBIS Road Travel Display

09

1. Main Menu

2. AUTOCONTOUR Height Control

3. Pre-Set Cutting Height

4. Message Fields

5. Gear Selection

6. Engine Speed

7. Ground Speed

8. Engine Load

9. Performance Monitor

10. Camera Selection

11. Machine Setting and Adjustments

12. User Dened Displays

* Pre-set as a standard, may be modied.

5

2

3

4

6

1

1

12

3

2

10

11

78

9

6

54

7

HOTKEY

11

The HOTKEY is used to adjust the most

frequently changed settings on the

machine.

To adjust any of the hot key functions

activate the hot key button (1) on the arm

rest or CMOTION drive stick and select the

required function for change.

The HOTKEY menu (2) will be displayed

for 5 seconds when activated and when

the desired menu is slecteced it will be

displayed in box (3). Functions in box

(3) can then be quickly adjusted via the

CMOTION lever.

1

1

3

2

14

13

Feed Rollers

The purpose of the feed rollers is to compress the crop before it enters the chopping cylinder.

The feed roller speed is adjusted using the manual gearbox to achieve the required chop length.

Bottom Plate

When harvesting whole crop or maize,

the grain collection plate (1) needs to be

tted underneath the feed rollers to stop

any grains from falling out under the machine.

This needs to be removed for grass harvesting.

Plastic Strips

It is advisable to remove the Teon strips

off the upper feed roller during maize harvest.

This will allow optimal feeding of the crop to

the cutting cylinder.

Cylinder

V-Classic 28

Number of knives 28

4.0, 5.5, 7.5, 10.0, 13.0, 15.5

24

4.5, 6.5, 9.0, 12.0, 15.0, 18.0

20

6.0, 8.0, 11.0, 15.0, 18.0, 22.0

Number of knives

Number of knives

Length of cut range (mm)

Length of cut range (mm)

Length of cut range (mm)

V-Classic 24

V-Classic 20

Application Complete set of knives

16

Metal Detector and Stop Rock

A metal detector is installed in the bottom

roller of the feeder unit.

When a sudden instance of magnetic

metal is fed into the feeder unit, the feeder

unit stops before the metal can enter the

chopping cylinder.

The sensitivity can be adjusted in the cab

using CEBIS.

Sensitivity Adjustment: 1 > 5

It is not possible to switch off the metal

detector. The sensitivity can be adjusted from the

cab using CEBIS.

Sensitivity Adjustment: 0 > 10

It is recommended to deactivate

Stop Rock when harvesting maize,

using sensitivity setting 0.

Stop Rock, is used to detect stones

entering the feed rollers by monitoring the

movement of the upper precompression

rollers.

A sudden movement of the feed rollers

indicates a foreign object, the machine will

then stop the feed rollers similar to a

metal detection.

When the metal detector

DIRECTSTOP function is activated

in CEBIS, the machine’s forward

motion will stop automatically if the

metal detector or stone detector

detects a foreign object.

This function can be activated and

deactivated through CEBIS as is

required.

17 18

Opening Feed Rollers

1. Lower the legs on the front attachment and lower

the feeder housing as far as possible.

2. Undo the 13mm bolt and retaining collar to remove the

panel over the drive belt on the RHS of the feeder.

3. Remove the guard over the drive belt on the RHS of the

feeder housing and remove front attachment belt.

4. Undo the 24mm locking bolt underneath the feeder

housing until the hooks become free.

5. Remove the electrical, lubrication and air connections

on the machine RHS and the hydraulic motor

connections on the LHS.

6. Slacken the bolt and swing out the locking unit on

both sides. The Jaguar can now be reversed, leaving

the feeder housing attached to the front attachment.

Make sure the cutting cylinder is not lifted from the cab,

while the feeder housing is removed.

In order to remove the feed rollers, the front

attachment must remain on the front of the feed

rollers and the following steps need to be followed:

123

456

Opening Feed Rollers

19

The feeder housing can also be V’d open as shown to

give a brief inspection of the blades. In order to V open

the feeder housing, the following steps must be followed:

1. The front attachment must remain on the feeder housing.

2. The feeder housing must rst be lowered to the lowest

possible position.

3. The locks, electrical connections and hydraulic connections

can then be removed.

4. It is important not to unlatch hooks underneath

feeder housing.

5. The engine can now be started and lift the front attachment

with caution to any hoses or cables.

6. It should now be possible to gain access as can be

seen above.

Chopping Cylinder

20

The chopping unit has the task of cutting the material

compressed by the feeder housing to the pre-set chopping

length and of accelerating this material out of the

cutting plane.

There are 3 cylinder variants available:

•V20 (20 Knives)

•V24 (24 Knives)

•V28 (28 Knives)

Changing the Knives

When the shear bar can not be adjusted any further, CEBIS

will indicate wear on knife edge. As the knives are xed

using elongated holes, the position of the knife can be

readjusted to the shear bar.

Please refer to the operators manual (section 9.12.13) for

full instructions on replacing the knives.

When working on the cutting cylinder, ensure the machine

is stopped and the cylinder locking tool is in place.

Sharpening Cylinder Concave

23 24

The sharpening process is carried out

from within the cab. This is completed

with the main drive engaged at idle

engine RPM. The procedure and the

number of cycles can be adjusted

from CEBIS.

There are two types of concaves available for under

the cylinder. The smooth version tted as standard

for normal conditions or the heavy duty premium line

version for use in conditions where wear from sandy soil

etc is a problem.

Concave Adjustment

Once the blades wear on the machine,

the bottom ‘concave’ may need to be adjusted to

achieve optimum crop ow, this can be done by

removing the shims tted as required.

Refer to section 9.12.3 in the operators manual for

instructions on how to carry out adjustment.

The sharpening stone readjusts

automatically during the sharpening

process, however after approx. 450

cycles this needs to be manually reset.

Please refer to section 9.12.15 of the

operators manual to carry out this

adjustment.

Number of cycles

The number of cycles can be

adjusted through CEBIS, as few as

possible to obtain a good cutting

edge but as many as needed to

maintain the edge. It is best to

sharpen frequent with less cycles as

opposed to daily with many cycles.

Sharpening Interval

The sharpening interval should be

adjusted dependant on the degree

of wear on the knives. This must be

checked visually, as the degree of

wear will vary dependant on:

• Throughput Volume

• Crop Type

• Sand proportion (stubble height, raking depth)

• Chop Length

Shear Bar Corn Cracker

25 26

Shear Bar Adjustment

The shear bar can be adjusted automatically from

the comfort of the cab using CEBIS. The shear bar should

be readjusted after each sharpening and where possible

between sharpening intervals.

The crop coming from the chopper unit is crushed between

the Corn Cracker rollers and conveyed to the accelerator.

The purpose of the cracker is to open each kernel of maize in

order to free its starch to allow its starch to be free for digestion.

When the Corn Cracker is not in use, it should be completely

removed from the machine because at stand still the high

performance bearings might be damaged by the vibrations

in the machine.

Multi Crop Cracker Variants (MCC)

Please refer to the operators manual Section 9.12.9, for

full instructions.

Recommendations:

The condition and the adjustment of the shear bar are essential

to obtain optimum chopping quality, maximum efciency and long

service lives of knives and shear bar.

1. Readjust the shear bar after every sharpening process.

2. If needed, the shear bar should be readjusted without knife

sharpening, ie. if clearance too great.

3. Adjust the shear bar as close as possible to the knives, for

optimum chop quality. The knives must not touch the shear bar,

otherwise wear increases. A feeler gauge can be used to monitor

the gap.

4. To assess the wear condition of the shear bar, the rear side

must be inspected. (The rear of the shear bar must be able to sit

straight on the knife).

> The cutting edges of PREMIUM LINE shear bars have a longer

service life and therefore improve chopping quality and

service life.

Shear Bar Adjustment

When the shear bar is worn or cannot be readjusted any further,

it must be turned around or replaced.

Type Machine

MCC - M - 80/100 teeth

JAGUAR

830-870 6 - groove

JAGUAR

870-880 7 - groove

MCC “L” 125/125 teeth

MCC - M - 125/125 teeth (whole crop)

MCC MAX 120/130

MCC - M - 100/100 teeth

MCC “L” 150/150 teeth

MCC “L” 100/125 teeth

Shredlage 110/145

Power Band Belt

Corn Cracker

27 28

100%

150%

150%

V-28 V-24 V-20

Halbmesser

Half knives

V-24 / V-28

3,5-15 mm 4-17 mm 5-21 mm 8-28 mm / 7-30 mm

3

,

5

4

5

6

7

8

9

1

0

1

1

1

2

1

3

1

4

1

5

1

6

1

7

1

8

1

9

2

0

2

1

2

2

2

3

2

4

2

5

2

6

2

7

2

8

2

9

3

0

MULTI CROP CRACKER

m

m

m

m

JAGUAR 800

K

U

R

Z

S

C

H

N

I

T

T

S

H

O

R

T

C

U

T

L

A

N

G

S

C

H

N

I

T

T

S

H

R

E

D

L

A

G

E

®

L

O

N

G

C

U

T

Aufbereitungsintensität

Processing intensity

MCC MAX

MCC SHREDLAGE®

MCC CLASSIC

M

C

C

M

A

X

M

C

C

S

H

R

E

D

L

A

G

E

®

M

C

C

C

L

A

S

S

I

C

1

0

0

/

1

2

5

M

C

C

C

L

A

S

S

I

C

1

2

5

/

1

2

5

1

2

3

1. MCC L Roller

2. MCC Shredlage Roller

3. MCC L Max Roller

Removing the Corn Cracker

In crops where the corn cracker is not needed, it is recommended that the corn cracker is completely removed from the

machine. During this time, the ller housing needs to be tted to replace the dismounted corn cracker, this allows the

crop ow directly from the cylinder to the accelerator.

For this conversion, the drive belt of the Corn Cracker is removed (R15), the lock is released as shown in picture 3 (loosen

bolts [1] and rotate locks [2]) and the Corn Cracker can then be retracted, using the ratchet wheel [3]. After this, the ller

housing is put into place and fastened by tightening the locking tabs.

For full information regarding the removal of the Corn Cracker please refer to Section 7.20.11 of the Operators manual.

1 2 3 4

29 30

Accelerator Discharge

The discharge accelerator receives the crop from the Corn Cracker or directly from

the chopper unit and conveys it through the square discharge tube and the upper

discharge chute out of the machine at high velocity. The crop is expelled

via the discharge

chute into the trailer,

the chute can be

moved to maximise

trailer lling using the

buttons on the joystick

as shown earlier in

the booklet.

Different length chutes

Different length chute extensions need to be added or removed according to the width of

header which is attached to the front of the machine. Chute extensions come in 750mm

lengths and the L chute has 2 sections added.

Mechanical Adjustment

On the standard machine the gap between the housing and the accelerator can

be adjusted manually both LHS and RHS.

Why change the clearance in the accelerator?

If the maximum blow is not needed, the accelerator position can be set to a wider

opening this reduces wear and fuel consumption. Setting the accelerator closer to

the plate will increase the blowing capability.

Accelerator Paddles

There are toothed accelerator paddles tted as standard. Smooth paddles can be

tted if needed to increase the blowing capacity of the machine, e.g in very dry crops.

If changing the paddles, it is important to note the difference in height of the paddles,

so it is important to adjust the accelerator clearance afterwards.

Please Refer to the operators manual Section 9.13.20 for full procedure.

33 32

Other Machine Features

The JAGUAR can also be tted with the

OPTI FILL automated discharge chute control system.

This feature delivers the following functions:

• Extended swivel action, segmented in intervals

of approximately 70cm

• Automatic ap adjustment to ensure trailers lled

at the centre point as chute swivels

• Extended chute angle to 225° (standard 210°)

• Automatic return of chute to road travel position

• Automatic swivelling from one side to the other

AUTO FILL (Optional)

AUTO FILL is an option which

allows fully automatic control of

the discharge spout. This consists

of an additional camera on the

spout which monitors the trailer

position and ll level.

There is also an additional

monitor tted in the cab to allow

the operator to view the trailer

and spout position.

The AUTO FILL system can be

activated by pressing switch

pictured on the joystick.

Customer Benets

• Optimised operation when lling trailers.

• Ease of Operation to park/rotate chute.

• Convenient to use.

Other Machine Features

Additive Application

The JAGUAR is tted with an additive tank as standard. This can

carry up to 375 litres of liquid.The system can be activated from

the cab.

The ensiling agent system is activated under the following

conditions:

1. The JAGUAR must be travelling forwards.

2. The chopping unit and the attachment must both be engaged.

3. The attachment must be in the working position.

Dosing Options

• Constant dosing mode – 20 > 400 L/hour

• Throughput dependant dosing – 500 >2000 ml/tonne

(up to 200tonne/hour throughput)

ACTISILER (Optional)

The independent ACTISILER system is available for adding lactic

acid bacteria. A 37L storage container supplies the dosing pump.

As 23L fresh water tank is also tted for ushing which can be

activated from the cab.

Dosing Options

• Constant dosing mode – 200ml > 20,000 ml/hour

• Throughput dependant dosing – 10ml > 50 ml/ tonne

Flushing of the lines is possible from the cab.

CONTOUR

ACTIVE CONTOUR

Mechanischer Ausgleich der PICK UPRegelimpulsAuflagendrucksteuerung

35

PICK UP

36

PICK UP

ACTIVE CONTOUR is activated when

auto contour function is enabled and

the cutting height control is above

0%. When the cutting height control

is below 0%, ground pressure mode

is activated and ACTIVE CONTOUR is

deactivated. Note that damage can be

cause by excess ground so ACTIVE

CONTOUR is the preferred method

of operation.

A 32 and 17 tooth sprocket are tted on the feed auger

drive from the factory - this is recommended for medium to

long chop lengths.

Two further sprockets are included in the shipping package

for adjusting the auger speed. These are 33 and 15

toothed sprockets for short chop lengths.

Auger speeds can further be adjusted by means of the 3

speed gearbox.

On the pick-up 300, the entire drive is from the mechanical

drive from the JAGUAR via quick coupler (1). From there,

the pick-up drive (2) and the feed auger (3) are driven.

Using the 3-speed gearbox (3) there is a shift lever which

enables the feed auger speed to be switched between

three gears.

A centre sensing wheel (4) further improves ground

adaptation especially on soft and very uneven ground.

1

2

3

4

37

PICK UP

38

PICKUP

Maintenance checks by operational hours.

Check tightness of all gearboxes

Check all oils

Check drive shaft, chains and clutches

Check all connections

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Check all connections

Check tightness of gearboxes

Ensure all connections are tight

and secured correctly

Prior to harvest

Daily

Check all gearbox oils

Lubricate all grease points

Check chain tension on intake auger

Check pick up chain tension

Change all gearbox oils

Check clutches

Check all chain tensions

Check all connections

Check all connections are tight

and correctly seated

50 hours

500 hours

General Adjustments

• Ensure the height of the sensing wheels is correct

• Adjust the speed of the feed auger via the 2 stage

gearbox or different sprockets

• Check chain tensions regularly

• Ensure overrun clutches operate correctly

• Check bearings for play regularly

• Check tines and tine bars at the beginning

of the working day

• Check type pressures on sensing wheels regularly

This manual suits for next models

4

Table of contents

Other Claas Tractor manuals

Popular Tractor manuals by other brands

Case IH

Case IH FARMALL 75C Service manual

Fort

Fort VISION USE AND MAINTENANCE MANUAL AND ASSEMBLY INSTRUCTIONS

MTD

MTD Cub Cadet H20 Original operating instructions

MASSEY FERGUSON

MASSEY FERGUSON MF 9000 Service manual

Cub Cadet

Cub Cadet TANK L 48 Operator's manual

Agromehanika

Agromehanika AGT 106 operating instructions

Hitech

Hitech VALTRA A74 quick start guide

Jodale Perry Corporation

Jodale Perry Corporation Jacobsen HR9016 Mounting instructions

New Holland

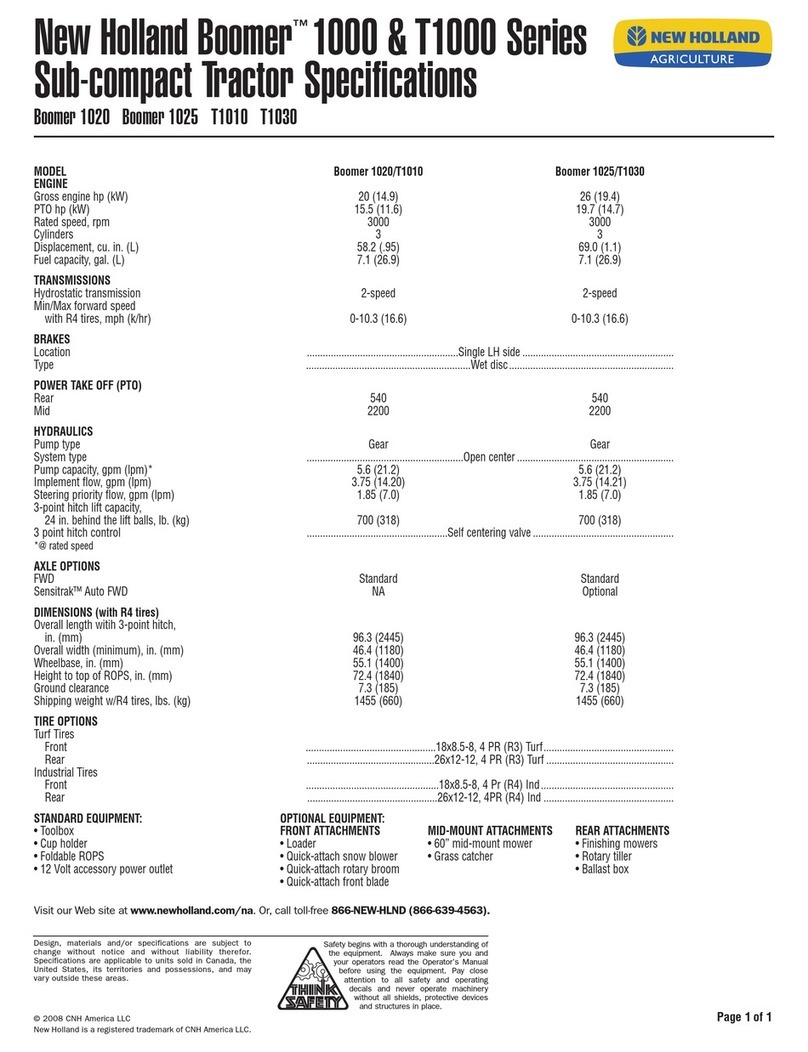

New Holland Boomer 1020/T1010 Specifications

Bolens

Bolens Husky 1476 Operator's manual

Husqvarna

Husqvarna TS 138 Operator's manual

AGCO

AGCO VALTRA BF65 Operator's manual