DRIVE LINES SECTION 23

Drive Lines Chapter 1

Section Description Page

23 000 Specifications 1.................................................................

Torque Settings and Tools 2......................................................

Cross-Sectional Views 3..........................................................

Transmission shafts and guard (Disassembly - Assembly) 4...........................

Drive gear housing (Removal - Installation) 5........................................

Drive gear housing removed (Disassembly - Assembly) 6.............................

FRONT AXLE MECHANICAL TRANSMISSION SECTION 25

Front Axle Mechanical Transmission Chapter 1

Section Description Page

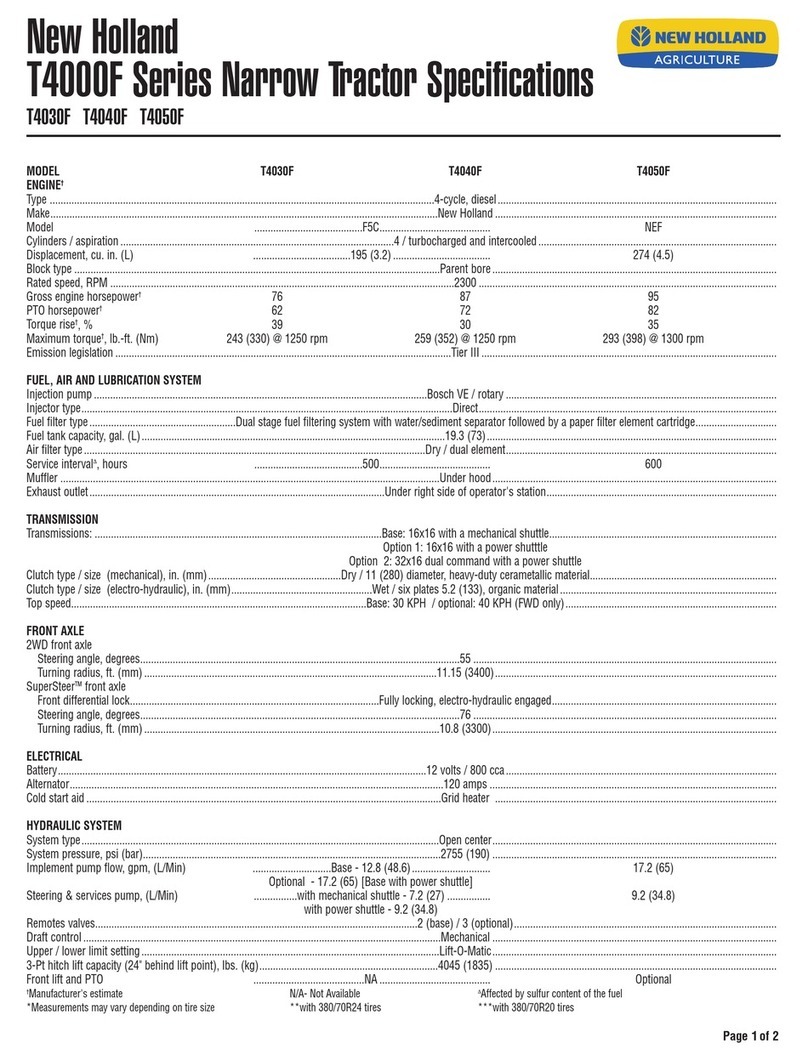

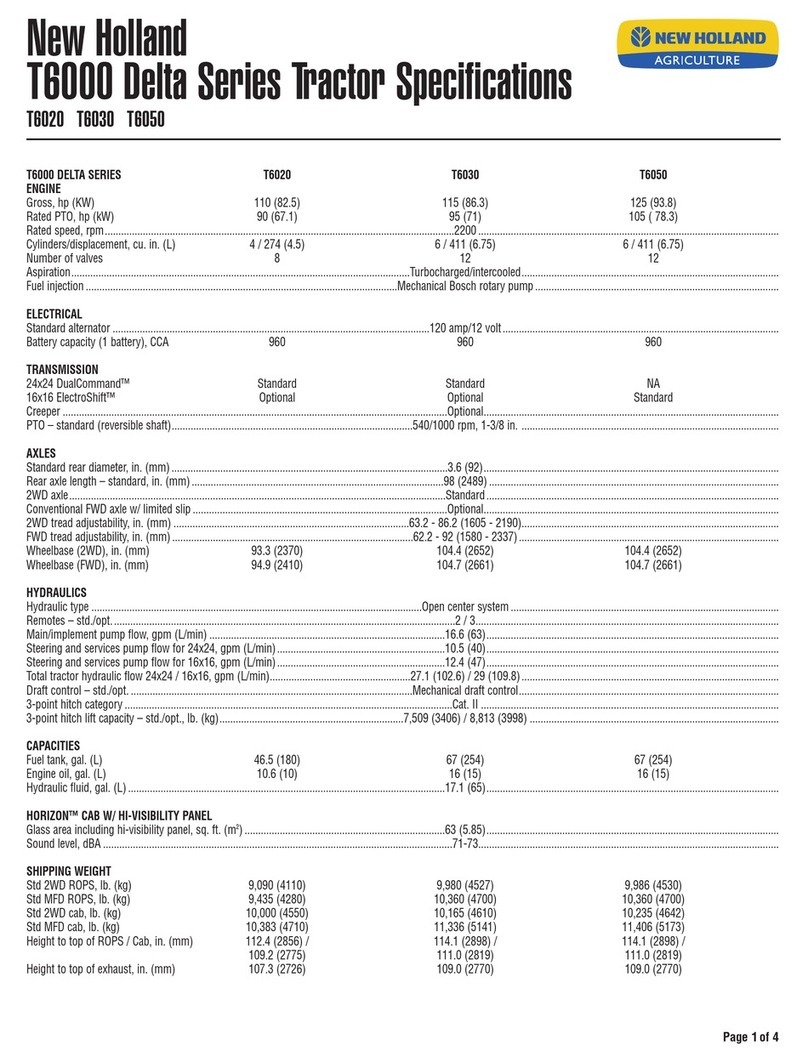

25 000 Specifications 2.................................................................

TIGHTENING TORQUES 3.......................................................

Tools 6.........................................................................

Cross Sectional Views 7..........................................................

Description and Operation 9.......................................................

25 100 30 Complete front axle. Remove - Install 10...........................................

25 100 38 Front axle. Remove - Install 15...................................................

25 108 46-47 Steering knuckle bearing pins. Replace 22.........................................

Stub axle adjustment 23.........................................................

Wheel hub bearing adjustment 25.................................................

Bevel drive adjustment 26........................................................

25 102 24 Front Axle Differential. Overhaul 32...............................................

25 100 27 Front axle differential with LIM-SLIP. Overhaul 33...................................

44 511 80 Leading drive wheels toe-in check 35..............................................

REAR AXLE AND TRANSMISSION SECTION 27

Rear Axle And Transmission Chapter 1

Section Description Page

21 000 Specifications 2.................................................................

Tightening Torques 3............................................................

Liquid Sealants 6...............................................................

Special Tools 7.................................................................

Cross Sectional Views 7.........................................................

Troubleshooting 10...............................................................

Description and Operation 10......................................................

Low Gear Drive Line Schema 13...................................................

Reverse Gear Drive Shaft 13......................................................

High Gear Drive Shaft 14.........................................................

Transmission Assembly, Removal - Installation 16....................................

Internal Components, Disassembly - Assembly 33...................................

Find manuals at https://best-manuals.com