Classeq CST Quick start guide

Table of contents

Other Classeq Dishwasher manuals

Classeq

Classeq DUO 750 Administrator Guide

Classeq

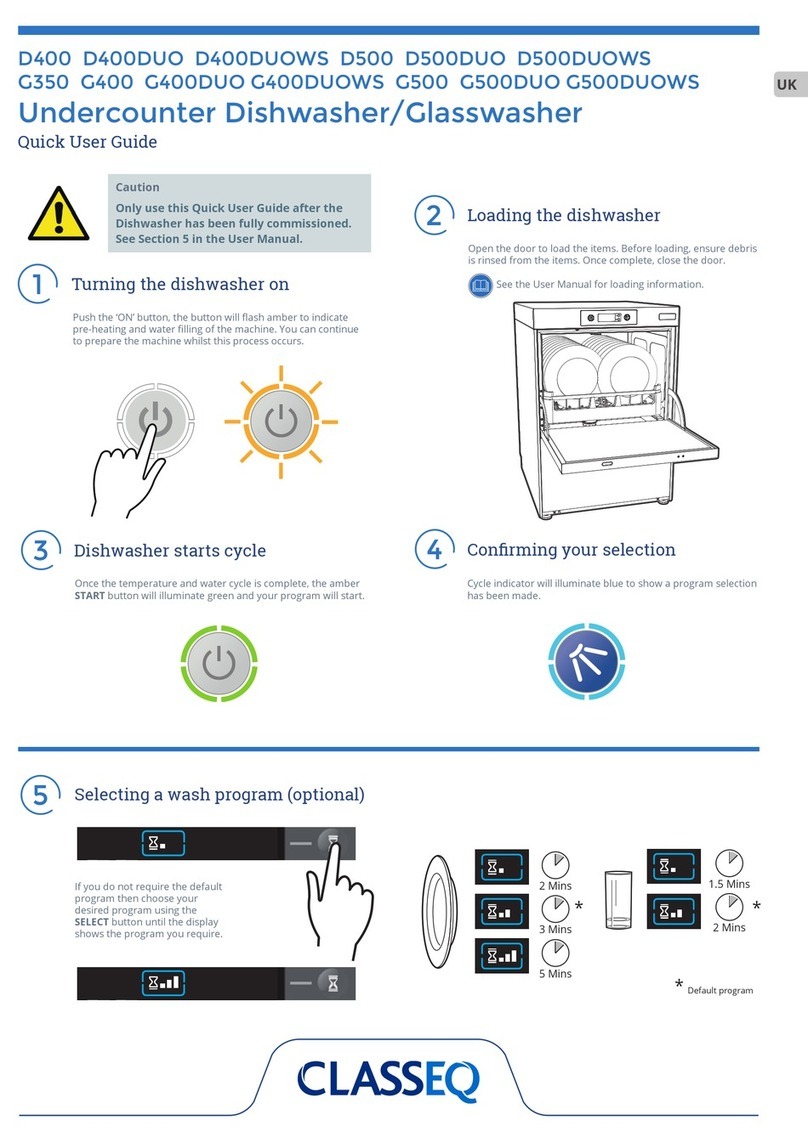

Classeq G 350 Quick start guide

Classeq

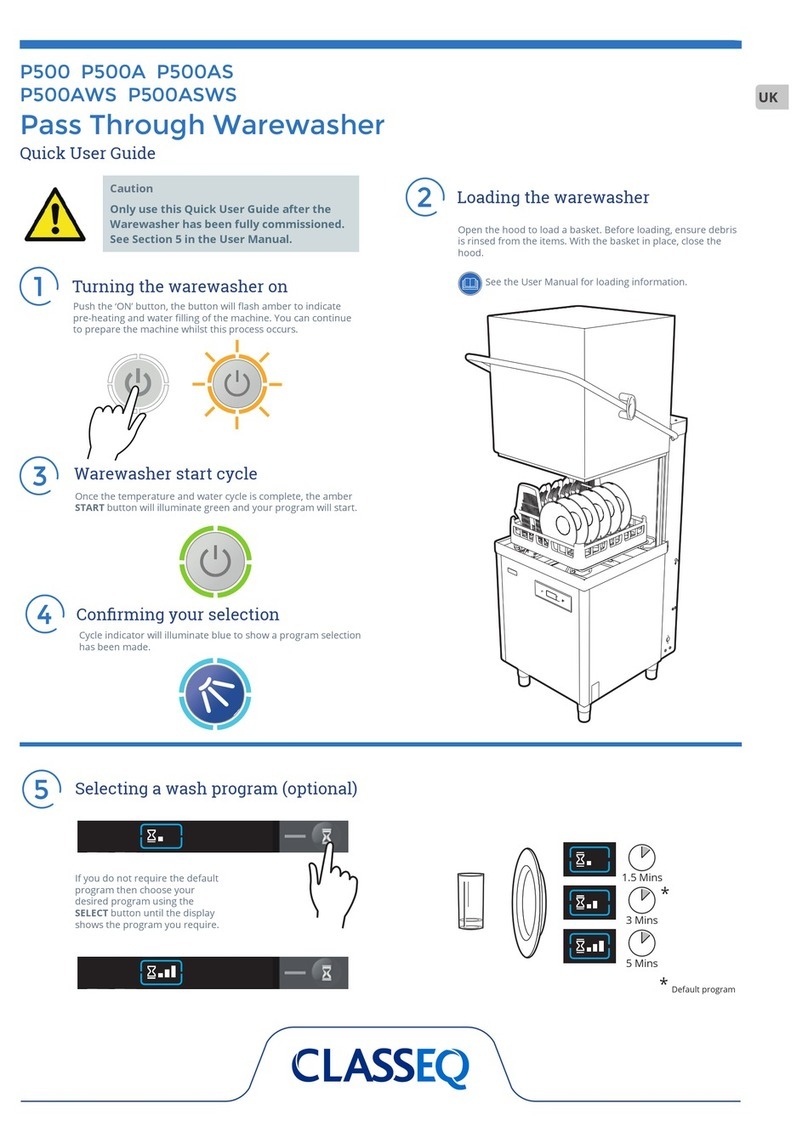

Classeq P500 User manual

Classeq

Classeq H750 Guide

Classeq

Classeq DUO 750 Installation instructions

Classeq

Classeq D 400 User manual

Classeq

Classeq P500A User manual

Classeq

Classeq ECO 2 Administrator Guide

Classeq

Classeq CST 100 Installation instructions

Classeq

Classeq D 400 Instruction manual

Classeq

Classeq HYDRO 850 User manual

Classeq

Classeq G 350 User manual

Classeq

Classeq C200G Administrator Guide

Classeq

Classeq P500AS User manual

Classeq

Classeq P500 Instruction manual

Classeq

Classeq ECO 3 Installation instructions

Classeq

Classeq D 400 Instruction manual

Classeq

Classeq D12000 Installation instructions

Popular Dishwasher manuals by other brands

Zanussi

Zanussi DS 22 Instruction booklet

Tricity Bendix

Tricity Bendix CDW 086 Operating and installation instructions

Candy

Candy CDF 718 T Installation - use - maintenance

Whirlpool

Whirlpool ADB1400AGW installation instructions

arcelik

arcelik 6343 user manual

Bosch

Bosch SGE63E15UC/01 operating instructions