CleanCraft ADSG 15 User manual

Battery-operated pressure

sprayer

ADSG 15

Operating Instructions

ADSG 15

2ADSG 15 | Version 1.03

Imprint

Product Identification

Battery-operated pressure sprayer Item number

ADSG 15 7350000

Manufacturer

Stürmer Maschinen GmbH

Dr.-Robert-Pfleger-Str. 26

D-96103 Hallstadt

Fax: 0049 (0) 951 96555 - 55

E-Mail: [email protected]

Internet: www.cleancraft.de

Indications regarding the Operating Instructions

Original Instruction

Edition: 01.03.2021

Version: 1.03

Language: English

Author: RL

Copyright

Copyright © 2021 Stürmer Maschinen GmbH, Hallstadt,

Germany.

The contents of these operating instructions are the sole

property of the company Stuermer Maschinen GmbH.

Passing on as well copying of this document, the use

and distribution of its content are prohibited if nit explicitly

permitted. Contra-ventions ere liable to compensation.

Subject to technical modifications and error.

Contents

1 Introduction ............................................. 3

1.1 Copyright ............................................................ 3

1.2 Customer service................................................ 3

1.3 Limitation of liability............................................. 3

2 Safety ....................................................... 3

2.1 Symbol explanation ............................................ 3

2.2 Obligations of the operating company ................ 4

2.3 Requirements to staff.......................................... 4

2.4 Personal protective equipment ........................... 5

2.5 General safety regulations.................................. 5

2.6 Safety data sheets .............................................. 9

2.7 Safety signs on the device.................................. 9

3 Intended Use ......................................... 10

3.1 Misuse .............................................................. 10

4 Technical Data....................................... 11

4.1 Table................................................................. 11

4.2 Type plate ......................................................... 11

5 Transport, Packaging, Storage ............ 11

5.1 Delivery and transport....................................... 11

5.2 Packaging......................................................... 11

5.3 Storage ............................................................. 11

6 Description ............................................ 12

6.1 Scope of delivery .............................................. 12

7 Accessories........................................... 12

8 Installation ............................................. 12

8.1 Assembly .......................................................... 12

8.2 Electrical connection......................................... 14

9 Operation ............................................... 14

9.1 Avoid operating the battery pressure sprayer

without water. This may damage the pump. ..... 14

10 Cair, Maintenance, Repair .................. 15

10.1 Care by cleaning............................................ 15

10.2 Maintenance and repair................................. 16

11 Disposal/Recycling of old devices .... 16

11.1 Take out of service ........................................ 16

11.2 Disposal of electrical devices......................... 16

11.3 Disposal via municipal collection points......... 16

12 Spare Parts .......................................... 17

12.1 Ordering spare parts...................................... 17

12.2 Spare Parts Drawing...................................... 18

13 Electrical wiring diagram.................... 20

14 EC Declaration of Conformity ............ 21

Introduction

ADSG 15 | Version 1.03 3

1 Introduction

You have made a good choice by purchasing the

CLEANCRAFT the pressure sprayer.

Read the operating manual thoroughly before com-

missioning the machine.

It gives you information about the proper commissioning,

intended use and safe and efficient operation and main-

tenance of your the pressure sprayer

The operating manual is part of the the pressure sprayer

package. Always keep this operating manual in the loca-

tion where your the pressure sprayer is being operated.

All local accident prevention regulations and general

safety instructions for the operating range of your the

pressure sprayer must also be complied with.

1.1 Copyright

The contents of these instructions are copyright. They

may be used in conjunction with the operation of the the

pressure sprayer. Any application beyond those de-

scribed is not permitted without the written approval of

Stuermer Maschinen GmbH. For the protection of our

products, we shall register trademark, patent and design

rights, as this is possible in individual cases. We strongly

oppose any infringement of our intellectual property.

1.2 Customer service

Please contact your dealer if you have questions con-

cerning your the pressure sprayer or if you need techni-

cal advice. They will help you with specialist information

and expert advice.

Germany:

Stürmer Maschinen GmbH

Dr.-Robert-Pfleger-Str. 26

D-96103 Hallstadt

Repair service:

Fax: 0049 (0) 951 96555-111

E-Mail: service@stuermer-maschinen.de

Internet: www.cleancraft.de

Spare part orders:

Fax: 0049 (0) 951 96555-119

E-Mail: ersatzteile@stuermer-maschinen.de

We are always interested in valuable experience and

knowledge gained from using the application-which then

could be shared and be valuable to develop our products

even further.

1.3 Limitation of liability

All information and notes in these operating instructions

were summarised while taking applicable standards and

rules, the state-of-the-art technology and our long-term

knowledge and experiences into consideration.

In the following cases the manufacturer is not liable for

damages:

- Non-observance of the operating instructions,

- Inappropriate use

- Use of untrained staff,

- Unauthorised modifications

- Technical changes,

- Use of not allowed spare parts.

The actual scope of delivery may deviate from the expla-

nations and presentations described here in case of spe-

cial models, when using additional ordering options or

due to latest technical modifications.

The obligations agreed in the delivery contract, the gen-

eral terms and conditions as well as the delivery condi-

tions of the manufacturer and the legal regulations at the

time of the conclusion of the contract are applicable.

2 Safety

This section provides an overview of all important safety

packages for the protection of operating personnel as

well as for safe and fault-free operation. Other task-

based safety notes are included in the paragraphs of the

individual phases of life.

2.1 Symbol explanation

Safety instructions

The safety notes in these operating instructions are high-

lighted by symbols. The safety notes are introduced by

signal words which express the concern of the risk.

DANGER!

This combination of symbol and signal words indi-

cates an imminently dangerous situation which may

lead to death or severe injury if not avoided.

WARNING!

This combination of symbol and signal word indicates

a potentially hazardous situation that, if not avoided,

will result in death or serious injury.

4ADSG 15 | Version 1.03

Safety

Tips and recommendations

2.2 Obligations of the operating com-

pany

The operating company is the person who operates the

the pressure sprayer for business or commercial rea-

sons by herself, or leaves it to a third party for use or ap-

plication, and who bears the legal product responsibility

for the protection of the user, the staff or for third parties.

Obligations of the operating company

If the the pressure sprayer is used for commercial pur-

poses, the operating company of the the pressure

sprayer must comply with the legal working safety regu-

lations.

Therefore, the safety notes in this operating manual, as

well as the safety, accident prevention and environment

protection regulations applying for the area of application

of the the pressure sprayer must be met. The following

applies in particular:

- The operating company must be informed about the

applying industrial safety regulations and further an-

alyse hazards resulting from the special working

conditions at the place of use of the the pressure

sprayer. She must implement these in form of oper-

ating manuals for the operation of the the pressure

sprayer.

- During the entire lifetime the the pressure sprayer,

the operating company must verify whether the op-

erating manuals prepared by her correspond to the

current status of the regulations, and must adapt

these if necessary.

- The operating company must unambiguously regu-

late and determine the responsibilities for installa-

tion, operation, troubleshooting, maintenance and

cleaning.

- The operating company must ensure that all per-

sons who work with the the pressure sprayer, have

read and understood this manual. Furthermore she

must instruct the staff in regular intervals and in-

form them about the hazards.

- The operator must provide the necessary protec-

tive equipment to the staff and order the use of the

necessary protective equipment in a binding way.

Furthermore the operating company is responsible to

keep the the pressure sprayer always in a technically

flawless state. Thus, the following applies:

- The operator must ensure that the maintenance in-

tervals described in this manual are kept.

- The operator must have all safety devices checked

regularly for their good working order and their in-

tegrity.

2.3 Requirements to staff

Qualifications

The different tasks described in this manual represent

different requirements to the qualification of the persons

entrusted with these tasks.

Only persons reliable working procedures can be ex-

pected from, are allowed to perform all works. Persons

the responsiveness of which is affected by e. g. drugs,

alcohol or medication, are not allowed to work with the

machine.

The qualifications of the personnel for the different tasks

are mentioned below:

CAUTION!

This combination of symbol and signal words indi-

cates a potentially dangerous situation which may

lead to slight or minor injury if not avoided.

ATTENTION!

This combination of symbol and signal words indi-

cates a possibly dangerous situation which may lead

to property and environmental damages if they are

not avoided.

NOTE!

This combination of symbol and signal words indi-

cates a potentially dangerous situation which may

lead to material or environmental damage if not

avoided.

Tips and recommendations

This symbol highlights useful tips and recommenda-

tions as well as information for an efficient and trou-

ble-free operation.

WARNING!

Danger in case of insufficient quali-

fication of the staff!

Insufficiently qualified persons cannot estimate the

risks while using the the pressure sprayer and

expose themselves and others to the danger of

severe or lethal injuries.

- Have all works only performed by qualified persons.

- Keep insufficiently qualified persons out of the work-

ing area.

Safety

ADSG 15 | Version 1.03 5

Operator

The operator is instructed by the operating company

about the assigned tasks and possible risks in case of

improper behaviour. Any tasks which need to be per-

formed beyond the operation in the standard mode must

only be performed by the operator if it is indicated in

these instructions and if the operating company expres-

sively commissioned the operator.

Electrically qualified person

Electrically qualified person is due to their professional

training, knowledge and experience as well as knowl-

edge of the relevant standards and regulations, in a posi-

tion to carry out work on the electrical systems and to in-

dependently recognize and avoid possible dangers.

Qualified personal

Due to their professional training, knowledge and experi-

ence as well as their knowledge of relevant regulations

the specialist staff is able to perform the assigned tasks

and to recognise and avoid any possible dangers them-

selves.

Manufacturer

Certain works may only be performed by specialist per-

sonnel of the manufacturer. Other personnel is not au-

thorized to perform these works. Please contact our cus-

tomer service for the execution of all arising work.

2.4 Personal protective equipment

The personal protective equipment serves to protect per-

sons against impairments of safety and health while

working. The staff member has to wear personal protec-

tive equipment while performing different tasks on and

with the battery-operated pressure sprayer which are in-

dicated in the individual paragraphs of these instructions.

The personal protective equipment is explained in the

following paragraph:

2.5 General safety regulations

The following must be observed:

Wear mask, helmet, protective clothing, waterproof

gloves and water resistant boots during operation.

Fig. 1: Wear protective clothing

Ear protection

Ear protection protects the ears from hearing dam-

age caused by noise.

Face protection

The face mask protects the face from flying around

parts.

Breathing protection

Use the breathing protection!

Protective gloves

The protective gloves serve to protect the hands

against sharp components as well as against fric-

tion, abrasions or deep injuries.

Safety boots

Safety boots protect the feet from being crushed, fall-

ing parts and slipping over on slippery ground.

Protective clothes

Protective clothes are made of a tightly fitted fabric

without the protruding parts of low tear strength.

6ADSG 15 | Version 1.03

Safety

Keep the plant protection product out of the reach of child-

ren. Dispose of plant protection products in strict com-

pliance with the pesticide manufacturer's safety instructi-

ons.

Fig. 2: Keep pesticides away from children

Take care not to inhale the toxic spray fog! Should this

happen, go to a well ventilated place and lie down. If skin

and mucous membranes are affected, wash the skin ar-

eas immediately with clean water. If swallowed, drink

water or warm salt water to induce vomiting and consult

a doctor as soon as possible.

Fig. 3: Consult a doctor if inhaled spray fog

Keep the spray solution with plant protection agent in a

special bottle at a secure place or dispose of the product

in strict compliance with the regulations. In no case

should the plant protection products simply be disposed

of in the environment.

Fig. 4: Never dispose of plant protection products in nature

Avoid working with pesticides if you are pregnant or suf-

fer from a disease, fatigue, injury or allergy.

Fig. 5: Allergic reaction

Safety

ADSG 15 | Version 1.03 7

To kill pests, only use plant protection products that are

intended for the appliance.

Fig. 6: Highly toxic plant protection products prohibited

Do not leave the Pressure Sprayer unattended to avoid

danger to the public.

Fig. 7: Do not leave the device unattended

The battery pressure sprayer may only be used in the

range of temperature from 0° C to 45° C.

Fig. 8: Maintain operating temperature

Test the pressure sprayer with water before use to avoid

any leakage and to ensure that the sprayer is intact.

Fig. 9: Test run of the device with water only

DANGER!

The use of high toxic and aggressive pesticides

is strictly forbidden for the application on vegetables,

melons, fruit trees, tea, medicinal and cultivated

plants.

8ADSG 15 | Version 1.03

Safety

Never spray pesticides against the wind, on people, ani-

mals or food.

Do not point the nozzle at the energized device to avoid

the danger of a electric short circuit.

Fig. 10: Do not target at people, animals or any device.

Mix and dilute the liquid according to the instructions and

recommendations of the pesticide manufacturer. Do not

change the dilution ratio at will. This will prevent damage

to people or plants. It is also possible that the desired ap-

plication effect may not be achieved.

.

Fig. 11: Observe mixing ratio

Change clothes after use and wash all parts of the body

thoroughly with soap and water. Take a shower if

necessary.

Fig. 12: Shower after application

ATTENTION!

- Do not use the device for cleaning of your body or

your clothing.

- Children or unqualified persons must not use the

pressure sprayer.

- Do not use the device if it is damaged. If a defect in

the battery or power supply unit is noticed, it must

be replaced by the manufacturer or maintenance

personal.

- The components used for this product, battery and

power supply unit, may cause fire or burns if hand-

led improperly. Never disassemble, short circuit,

heat to more than 60°C or throw into fire. Also keep

out of the reach of children.

Safety

ADSG 15 | Version 1.03 9

Warnings: Battery and charger

Do not place the battery and charger in water or moisten

them.

Do not charge, use or store the battery and charger near

hot areas or heat sources!

Only use original accessories which are intended for the

pressure sprayer.

Do not short-circuit the positive and negative electrodes

of the components with cables or other objects!

Do not damage the battery and the charger.

Never try to disassemble the battery. Do not use the bat-

tery or charger if they are damaged. A damaged battery

or charger must be returned to a disposal centre.

The application must be stopped immediately if there is a

smell, color or shape change. The battery must be char-

ged and discharged every three months when not in use.

The charger and battery may only be used indoors and

when charging, they should be placed in a well ventilated

place.

Do not allow children or unauthorized persons to handle

the battery or charger.

To disconnect the charger from the power supply, al-

ways pull on the plug, never on the cable.

Make sure the cable is placed correctly to avoid tripping

over or damaging the power adapter

Do not install the charger on a wall or permanently

mount it on a surface. The charger must be placed on a

flat and stable surface (e.g. desk, workbench).

The charger is only intended for connection to the 220

volt mains supply.

Notes on operation

2.6 Safety data sheets

Safety data sheets on hazardous materials can be obtai-

ned from your specialist dealer or by calling

+49 (0)951/96555-0. Specialist dealers can find safety

data sheets in the down-load area of the partner portal.

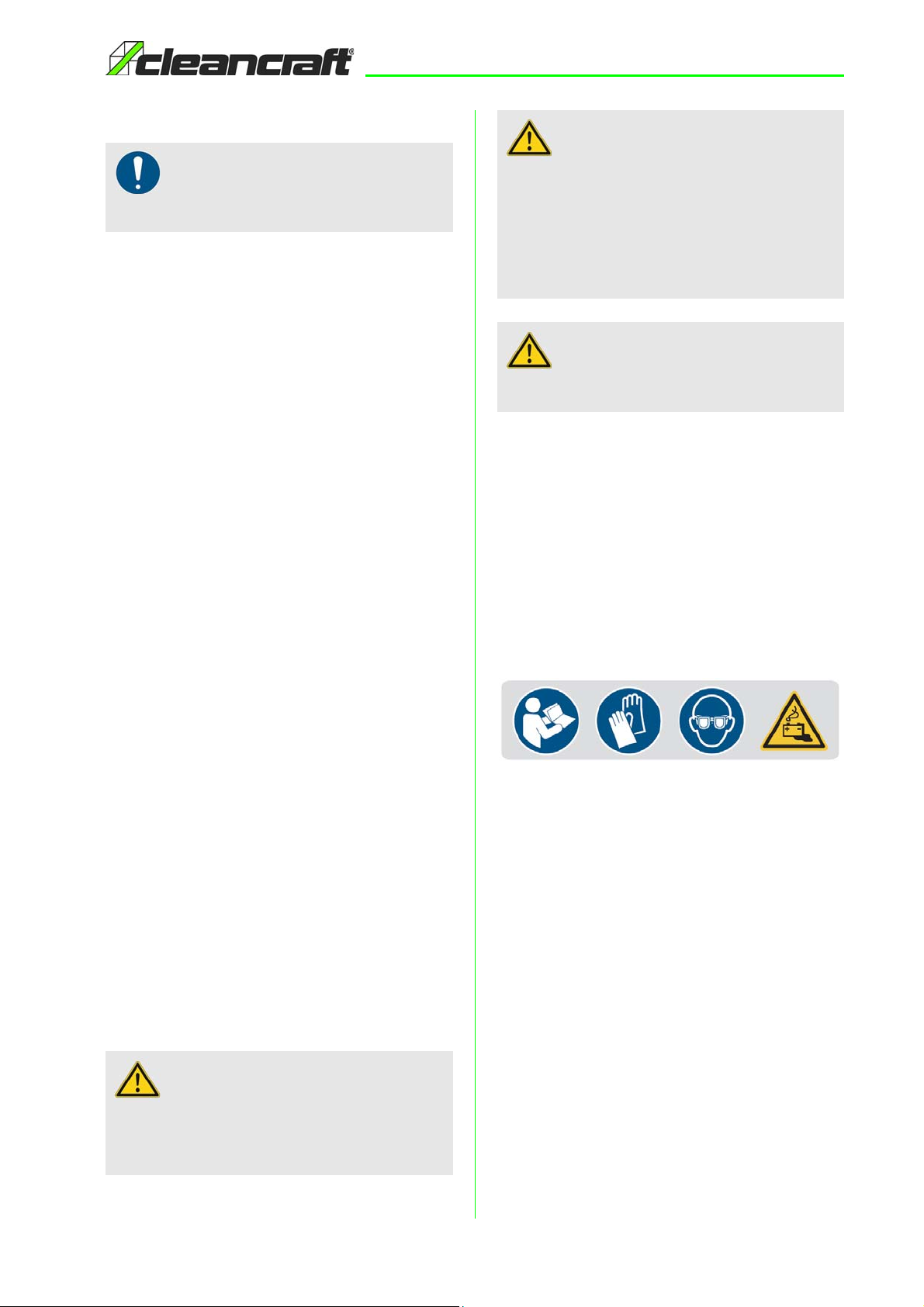

2.7 Safety signs on the device

Safety markings and instructions are attached to the de-

vice (Fig. 1), which must be observed and followed.

Fig. 13: Mandatory signs and warning signs

Damaged or missing safety symbols on the machine can

cause incorrect handling with personal injury and mate-

rial damage. The safety symbols attached to the ma-

chine must not be removed. Damaged safety symbols

must be replaced immediately.

From the moment the signs are not immediately visible

and comprehensible at first sight, the machine must be

taken out of operation until the new signs are attached.

NOTE!

The battery reaches its maximum capacity only after

several charging cycles.

ATTENTION!

Never operate the device with flammable, toxic

liquids or liquids that could affect its proper operation.

It is forbidden to operate the device in a flammable or

explosive environment.

ATTENTION!

- Due to the strong spray pressure, improper hand-

ling can be dangerous.

- DO NOT point the sprayer at people or animals.

- DO NOT point the sprayer at yourself or others for

cleaning clothing or shoes.

- DO NOT point the sprayer at the sprayer itself,

electrical components or other electrical equipment.

WARNING!

All electrically powered parts must be PROTECTED

against the water jet.

10 ADSG 15 | Version 1.03

Intended Use

3 Intended Use

The pressure sprayer is intended only for spraying the

following liquids:

- Water

- Plant protection products

- Weedkiller

- Natural oils dissolved in water (e.g. neem oil, rape

oil)

- Fertilizers dissolved in water

The area of application includes the house, garden and

greenhouses. The liquid fertilizers, herbicides and plant

protection agents used must be approved by the local li-

censing authority in the country of use. For these authori-

zed substances, as well as natural oils dissolved in wa-

ter, no negative effects on the materials used are known

at the time of manufacture of the device.

Liquids that are dissolved in water and are to be used for

spraying must have a similar consistency to water. More

viscous liquids can not be sprayed or can only be

sprayed with limited performance. Fertilizers, plant-pro-

tection agents and herbicides may only be sprayed in the

concentrations specified by the spraying agent manufac-

turer.

The pressure sprayer is not designed for use in the food

industry. It is also not designed for spraying liquids ab-

ove the permissible operating temperature and also for

acid, corrosive and flammable liquids with a flammable

point below 55°C. In addition, no impregnating or desin-

fection agents, paints or varnishes, glazes, lipids, mine-

ral oils and synthesised oils may be sprayed.

The device is not intended for commercial use. The pres-

sure sprayer is approved for private use only.

The pressure sprayer may not be operated in explosive

environments.

Proper use also includes compliance with all information

in this manual.

Stürmer Maschinen GmbH accepts no liability for design

and technical modifications to the battery-operated pres-

sure sprayer. Claims of any kind for damage due to im-

proper use are excluded.

3.1 Misuse

The pressure sprayer must never be used

- for flaming

- for the storage of liquids

ATTENTION!

Sprayed/Atomized flammable liquids are highly flam-

mable even at a flash point above 55°C.

ATTENTION!

Any modification of the device is prohibited. The

modification may cause fire and injuries, even to fatal

ones, for the user, in addition to voiding the war-

ranty. The manufacturer does not accept any liability

for damage to objects or persons as a result of failure

to follow these instructions or misuse of the device.

WARNING!

Risk of misues

Improper use of the pressure sprayer can cause dan-

gerous situations.

- Only operate the Battery-operated pressure sprayer

in the power range listed in the technical data.

- Never bypass or disable the safety devices.

- Only operate the Battery-operated pressure sprayer

in technically perfect condition.

- DO NOT operate the device outdoors in rain.

Technical Data

ADSG 15 | Version 1.03 11

4 Technical Data

4.1 Table

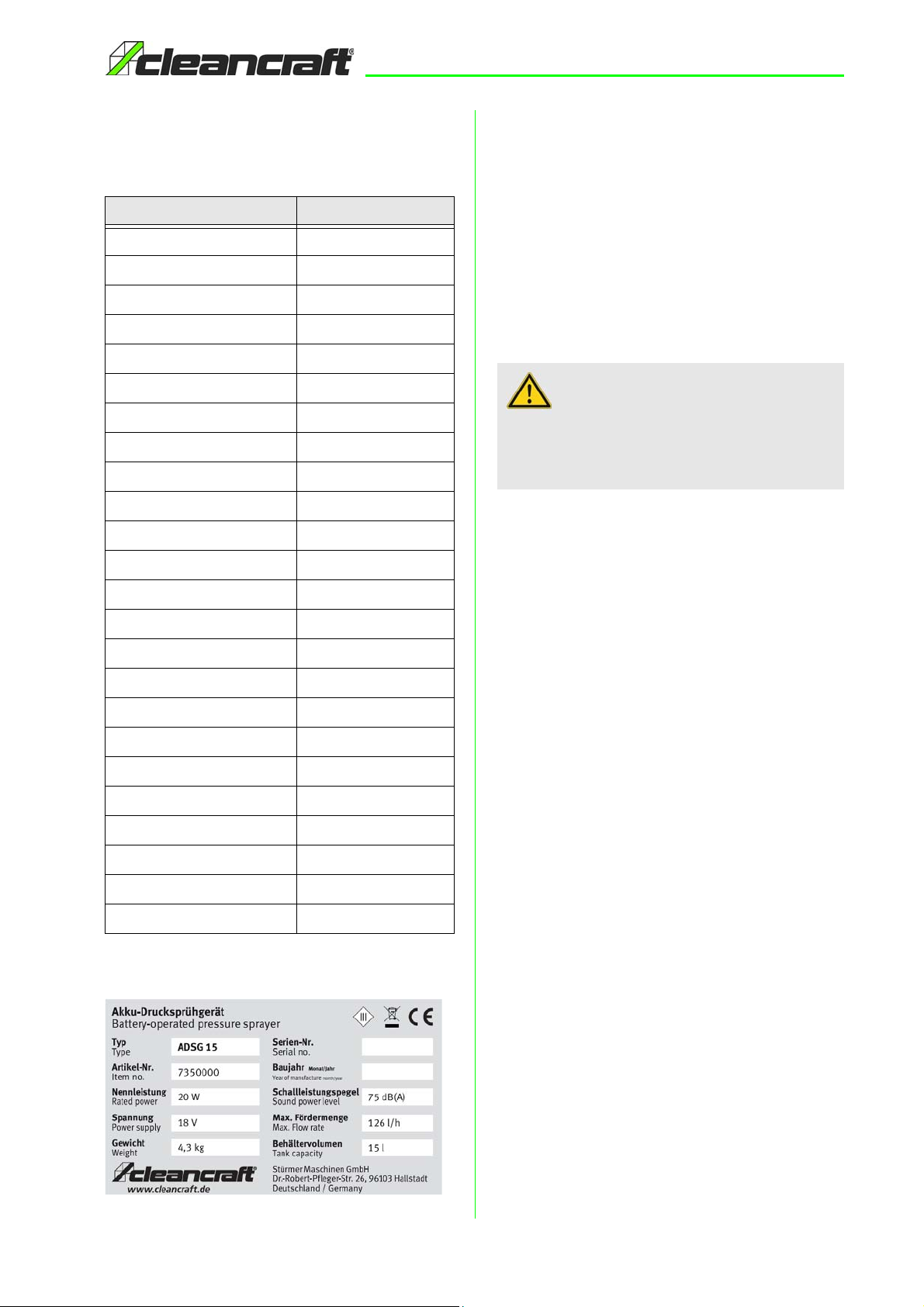

4.2 Type plate

Fig. 14: Type plate

5 Transport, Packaging, Sto-

rage

5.1 Delivery and transport

Delivery

Check the battery-operated pressure sprayer for visible

transport damage after delivery. If you discover any da-

mage to the battery-operated pressure sprayer, please

report this immediately to the transport company or the

retailer.

Transport

Improper transport of single devices, packed or unpac-

ked non-secured devices that are stacked on top of each

other or next to each other is liable to accidents and can

cause damage or malfunctions for which we do not pro-

vide liability or guarantee.

Transport the scope of delivery secured against shifting

or tilting to the place of installation with a sufficiently di-

mensioned industrial truck.

Transport may only be carried out by authorized and

qualified persons.

5.2 Packaging

All packaging materials and packaging aids used for the

Battery-operated pressure sprayer are recyclable and

must always be returned for material recycling.

Shredded packaging components should be disposed of

in the waste paper container.

The foils are made of polyethylene (PE) and the padded

parts of polystyrene (PS). These materials can be han-

ded in at a recycling collection depot or to your local wa-

ste disposal company.

5.3 Storage

Store the battery-operated pressure sprayer in a dry,

clean and frost-free environment.

Data ADSG 15

Length (product) ca. 344 mm

Width/Depth (product) ca. 241 mm

Height (product) ca. 486 mm

Weight (net) ca. 4,3 kg

Supply voltage 18 V

Current type DC

Working pressure 1,2 - 4,5 bar

Working pressure (max) 4,5 bar

Pump pressure 3,2 - 4,6 bar

Pump pressure (max) 6,5 bar

Delivery rate (max) 126 l/min

Working capacity 48 - 90 l/min

Inlet temperature 40 °C

Sound pressure level 63,4 dB(A)

Sound power level 75 dB(A)

Engine speed 2100 rpm

Protection class Charger II / Device III

Engine insulation class A

Total current consumption 0,8 A

Tank 15 Liter

High-pressure hose length 1,7 m

Battery capacity 2 Ah

Operating time 2 - 3 h

Charging time ca. 5 h

ATTENTION!

Danger of injury due to objects falling over or off the

forklift, pallet truck or transport vehicle.

Only use transportation equipment and load slings

that can carry the total weight.

12 ADSG 15 | Version 1.03

Description

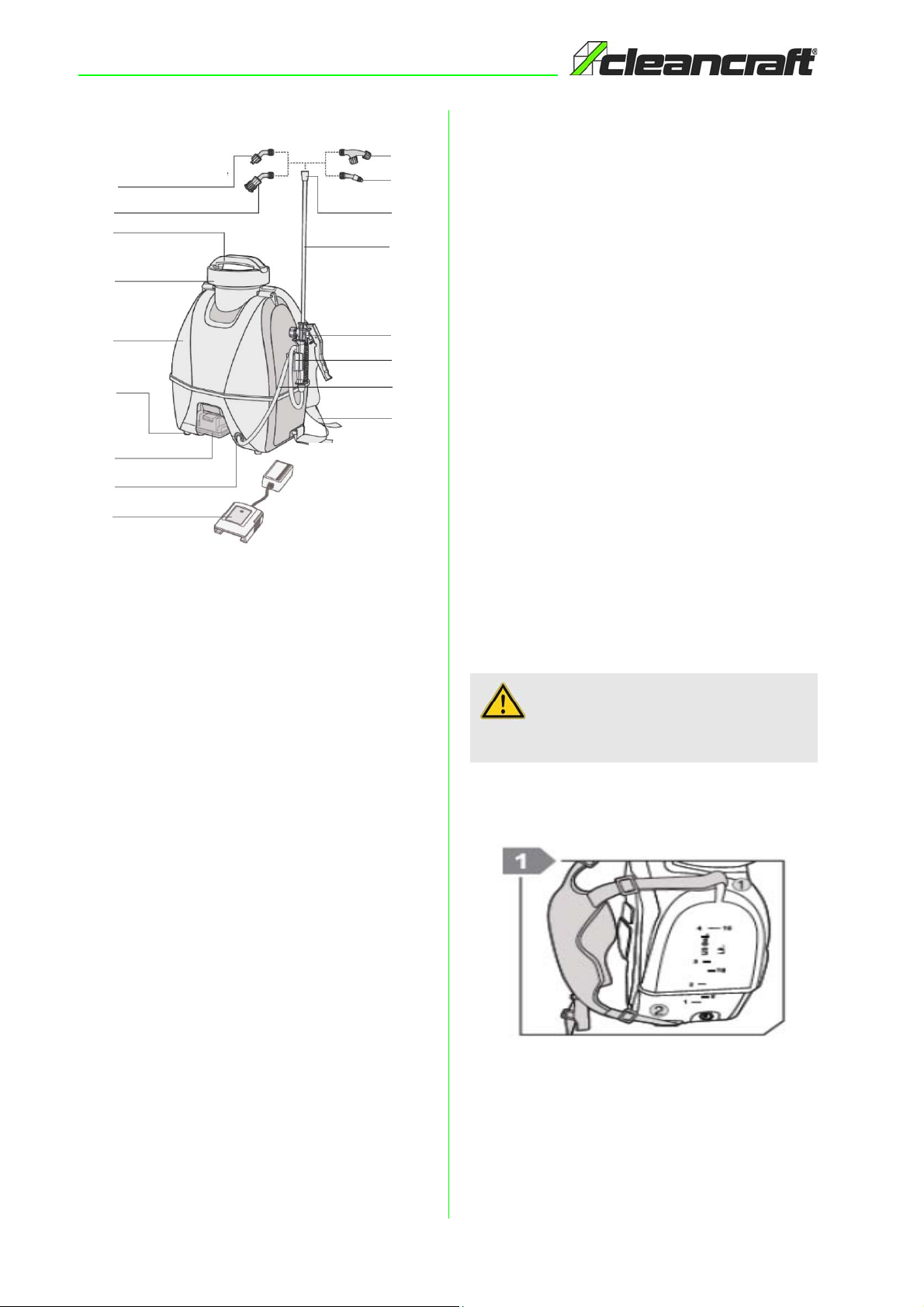

6Description

Fig. 15: Desciption

1 Blower nozzle

2 Shower nozzle

3 Carrying grip

4 Cover

5 Barrel body

6 Pedestals

7 Battery pack

8 Outlet

9 Battery charger

10 Double nozzle

11 Tapering nozzle

12 Outlet component

13 Spray tube

14 Spray gun switch

15 Spray gun holder

16 Discharge line

17 Belt installation

6.1 Scope of delivery

- Spray Gun

- Lance

- Flexible tube

- Round nozzle

- Double nozzle

- Adjustable nozzle

- Flat nozzle

- Samsung battery pack 2 Ah/18V DC

(The safety data sheet can be obtained from your

specialist dealer or by calling +49 (0)951/96555-0)

- Charger 0,4 A

- Harness

- Battery pressure sprayer

- Instruction manual

7 Accessories

- Battery 18V / 4,0 Ah

Item number: 7013547

- Charger 2,0 A

Item number: 7013548

- Spray gun

Item number: 7360000

- Lance

Item number: 736001

- High pressure hose 2,5m

Item number: 7360002

- Round nozzle

Item number: 7360003

- Double nozzle

Item number: 7360004

- Adjustable nozzle

Item number: 7360005

- Flat nozzle

Item number: 7360006

- Harness

Item number: 7360007

8 Installation

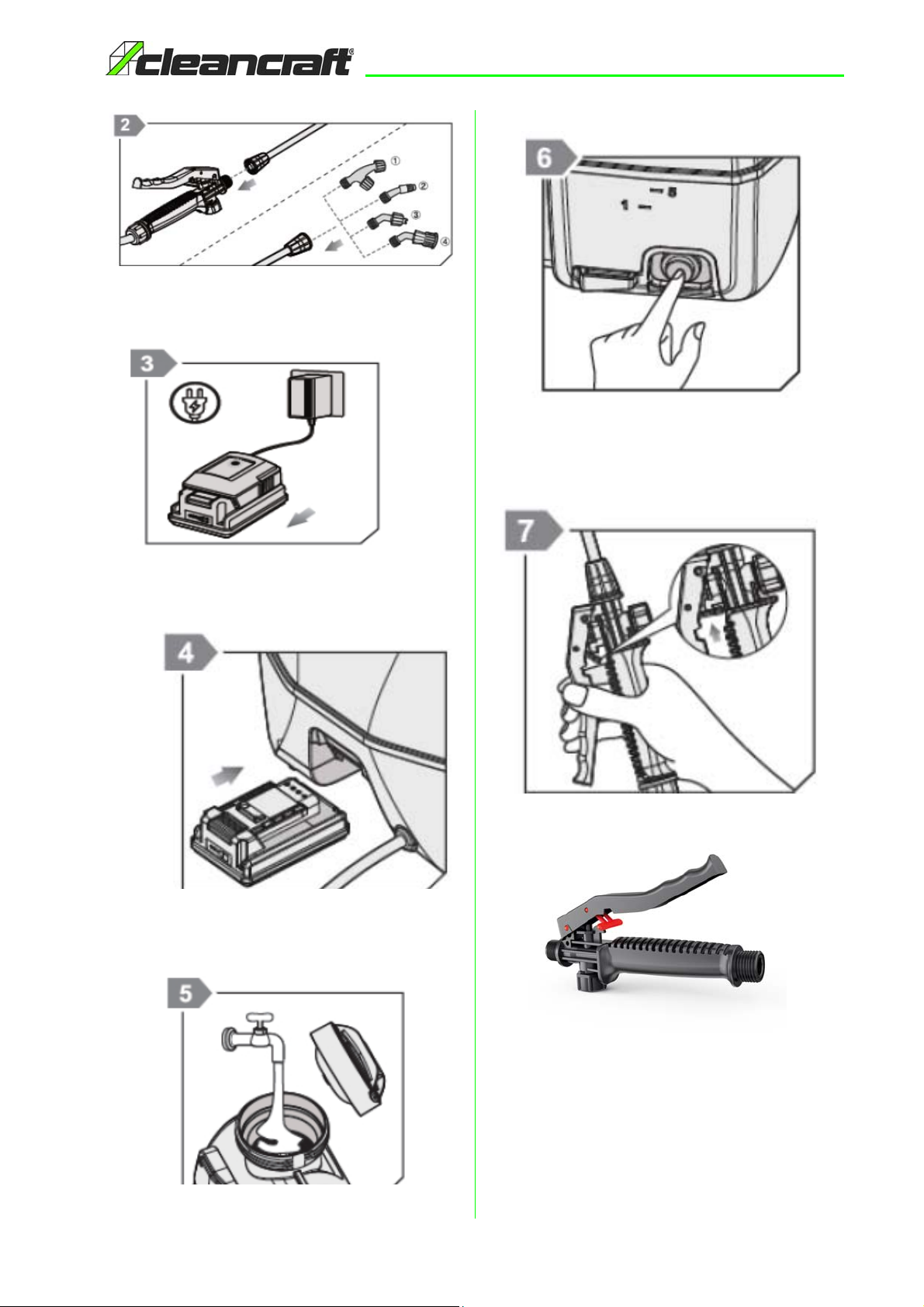

8.1 Assembly

Step 1: Remove the parts of the Battery Pressure

Sprayer from the packaging and attach the belt

to the Battery Pressure Sprayer (Fig.16).

Fig. 16: Mounting the belt

Step 2: Install one of the four nozzles of the gun rod

(Fig.17).

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

ATTENTION!

The device must be disconnected from the power

supply for all installation- and assembly work.

Installation

ADSG 15 | Version 1.03 13

8

Fig. 17: Mounting the spray gun

Step 3: Remove the battery and charge it (Fig.18)

.8

Fig. 18: Charge the battery

Step 4: Insert the full charged battery into the battery

socket on the device (Fig.19).

8

Fig. 19: Insert the battery

Step 5: Test the battery pressure sprayer at first with wa-

ter before adding chemicals (Fig. 20).

8

Fig. 20: Functional test with water

Step 6: Press the Power button on the device (Fig. 21).

8

Fig. 21: Switch ON the device

Step 7: Press the trigger on the pistol grip to start the de-

vice. Press the red locking mechanism in posi-

tion to keep it switched on (Fig. 22).

8

Fig. 22: Locking mechanism for continuous operation with the spray gun

Fig. 23: Spray gun with locking mechanism

14 ADSG 15 | Version 1.03

Operation

8.2 Electrical connection

9Operation

9.1 Avoid operating the battery pres-

sure sprayer without water. This

may damage the pump.

- Test the battery pressure sprayer with water before

first use to ensure there is no leakage or the atomi-

zation is not working properly.

- Do not use the Battery Pressure Sprayer below

0°C.

- Do not start the device while it is frozen. Frost da-

mages are not covered by the warranty!

- Always observe the safety instructions of pestici-

des.

- Make sure that the device stands safely and stable.

- Operate the appliance upright (Fig. 24).

Fig. 24: Operating position of the device

- Do not cover the device and do not use it in poorly

ventilated rooms.

To help that the product operates at a constant tempera-

ture and prolong the working time and life of the battery,

do not use the product when the surface of the battery is

hot.

Before Operation

The battery is charged before delivery. However, it is

possible that it will be automatically discharged during

transport and storage.

Step 1: Charge the battery in the charger.

During operation

Step 2: Remove the fully charged battery from the char-

ger and put it into the pressure sprayer.

Step 3: Fill the battery pressure sprayer with the liquid.

Step 4: Hold the pistol grip firmly in both hands and be

considered that spraying will cause a kickback.

Step 5: Press the trigger on the spray gun to start spray-

ing. Activate the red lock to perform a continuous

spraying operation (Fig. 22/23).

Step 6: Execute the spraying process.

Step 7: Stop the spraying process by unlocking the loc-

king mechanism and releasing the trigger.

DANGER!

Danger due electric shock!

The pressure sprayer is operated by a rechargeable

battery.

Caution when operating the charger on 220 V mains

voltage.

WARNING!

The Pressure Sprayer can be used with chemicals

which can cause serious injuries through inhalation

or contact with the user.

Failure to read and follow the operating instruction

manuals before using the product may result in

serious injury.

DANGER!

Follow the safety instructions to avoid serious perso-

nal injuries or material damage.

ATTENTION!

Only use CLEANCRAFT batteries and chargers for

this device. Damages caused by the use of other bat-

teries or chargers are not covered by the warranty.

DANGER!

Do not use the Battery Pressure Sprayer in any loca-

tion where there is a risk of explosion or fire.

DANGER!

Do not operate the battery pressure sprayer at high

temperatures for long periods of time.

Do not spray pesticides against the wind, on people,

animals or food.

Do not direct the nozzle towards the electrical parts

of the device to avoid the risk of short circuits.

Cair, Maintenance, Repair

ADSG 15 | Version 1.03 15

After Operation

Step 1: Turn off the device with the switch off button

(Fig.25).

Fig. 25: switch-OFF button

Step 2: Empty the pressure sprayer completely

Step 3: Clean and dry the battery pressure sprayer after

use and before storage.

If you store the device, remove the battery first.

10 Cair, Maintenance, Repair

Turn off the spray switch and remove the battery before

servicing, cleaning and repairing the unit.

Contact CLEANCRAFT for maintenance and use of ori-

ginal accessories.

Turn the unit off with the OFF switch when:

- Start or stopfails.

- The unit vibrates.

- Pressure fluctuations occur.

- Engine noises occur.

- Fuses blow.

Switch off the power supply immediately and contact

your dealer.

The O-ring and washer are wearing parts. The frequency

of replacement depends on the time of use, the sprays

used and regular cleaning of the pressure sprayer.

If the unit is clogged, loosen the nut on the pipe, check

the pipes and clean them.

10.1 Care by cleaning

The pressure sprayer must always be kept in a clean

condition.

Do not wash the battery pressure sprayer in water.

Do not use aggressive acids, strong bases or flammable

liquids for cleaning.

Disconnect the charger from the power outlet before

cleaning.

ATTENTION!

Many spray liquids will dry out and harden if kept in

the battery pressure sprayer. This can cause a clog-

ging of the nozzle, shut-off valve and tube.

DANGER!

Risk of electric shock!

Remove the battery before servicing, cleaning or

repairing the device.

Protective gloves

Wear suitable protective gloves for cleaning!

16 ADSG 15 | Version 1.03

Disposal/Recycling of old devices

10.2 Maintenance and repair

If the pressure sprayer does not work properly, contact a

specialist dealer or our customer service. The contact

details can be found in chapter 1.2 ‘Customer Service‘.

Maintenance the battery

Please pay attention to the capacity of the battery. If the

battery capacity is low, recharge in time. If the battery is

disconnected from the mains for a long period of time,

the battery will go into a resting mode.

Charge and Store the battery

To obtain longer battery life, avoid charging immediately

after a full discharged battery. Let the battery cool down

for a few minutes.

Safety instructions for the battery

The battery is a sealed device with no safety risk under

normal conditions. Avoid contact with the battery liquid if

the battery leaks. In case of contact with battery fluid,

take the following precautions:

- Skin contact with the battery fluid may cause irrita-

tion. Wash with soap and water.

- Inhalation of vapors may cause respiratory irrita-

tion. Breathe fresh air and seek for medical consul-

tation.

- In case of eye contact, the battery fluid may cause

irritation. Immediately flush eyes thoroughly with

water for at least 15 minutes and seek medical

consultation.

Recycling the battery

Proceed as follows with the battery to be recycled:

- Do not use the battery again.

- Remove the battery from the device.

- Disconnect it from the charger.

- Do not throw the battery in the household waste

- Dispose of the battery according to local laws and

regulations.

11 Disposal/Recycling of old de-

vices

In your own interest and in the interest of the environ-

ment, please ensure that all components of the device

are disposed of only through the designated and appro-

ved methods.

11.1 Take out of service

Worn-out devices must be immediately taken out of ser-

vice in a professional way in order to avoid later misuse

and to avoid environmental or personal hazards.

- Remove all environmentally harmful operating materi-

als from the old device.

- If necessary, dismount the device into manageable

and recyclable parts and components.

- Dispose of the device components and operating ma-

terials in the designated disposal method.

11.2 Disposal of electrical devices

Please note that electrical equipment contains a variety

of recyclable materials and environmentally harmful

components.

Please help to ensure that these components are sepa-

rated and properly recycled. If in doubt, please contact

your local waste disposal company.

You may need to seek the assistance of a specialized

waste disposal service for processing.

11.3 Disposal via municipal collection

points

Disposal of used and electronic equipment (Applicable in

the countries of the European Union and other European

countries with a separate collection point for this device).

The symbol on the product or its package indica-

tes that this product should not be treated as normal

household waste and should be disposed of at a collec-

tion point for the recycling of electronic devices. By hel-

ping to dispose of this product correctly, you will help to

protect the environment and the health of people around

you. Environment and health are at risk if incorrect dispo-

sal is made. Material recycling helps to reduce the

consumption of resources. For more information about

recycling this product, contact your local authority, muni-

cipal waste disposal service or the store where you

purchased the product.

ATTENTION!

Maintenance and repair work must always be car-

ried out by qualified personal: To maintain the war-

ranty, use only original parts approved by the

manufacturer.

Spare Parts

ADSG 15 | Version 1.03 17

12 Spare Parts

12.1 Ordering spare parts

Spare parts are available from authorised retailers or di-

rectly from the manufacturer.

Contact details:

Fax: 0049 (0) 951 96555-119

E-mail: ersatzteile@stuermer-maschinen.de

Always quote the following key data with your spare

parts orders:

- Device type

- Article number

- Position number

- Year of manufacture

- Quantity

- Desired shipping type (post, freight, sea, air, express)

- Shipping address

Spare parts orders without the aforementioned data can-

not be taken into account. The supplier shall determine

the shipping type if no relevant data was provided.

Information about the device type, article number and

year of manufacture can be found on the type plate. The

type plate is mounted on the device.

Example:

The pump for the battery-operated pressure sprayer has to

be ordered. The pump has the number 24 in the spare parts

drawing (1).

When ordering spare parts, send a copy of the spare parts

drawing (1) with marked component (pump) and marked

item number (24) to the authorized dealer or to the spare

parts department and provide the following information:

- Type of device:

Battery-operated pressure sprayer

ADSG 15

- Item number: 7350000

- Drawing number: 1

- Position number: 24

The part number of your device:

Battery-operated pressure sprayer ADSG 15: 7350000

DANGER!

Risk of injury due to use of incorrect

spare parts!

The use of incorrect or faulty spare parts can lead to

dangers for the operator, damage and malfunctions.

- Only original spare parts from the manufacturer or

spare parts approved by the manufacturer may be

used.

- Always contact the manufacturer if you are in any

doubt.

NOTE!

The manufacturer's warranty expires if unauthorized

spare parts are used.

18 ADSG 15 | Version 1.03

Spare Parts

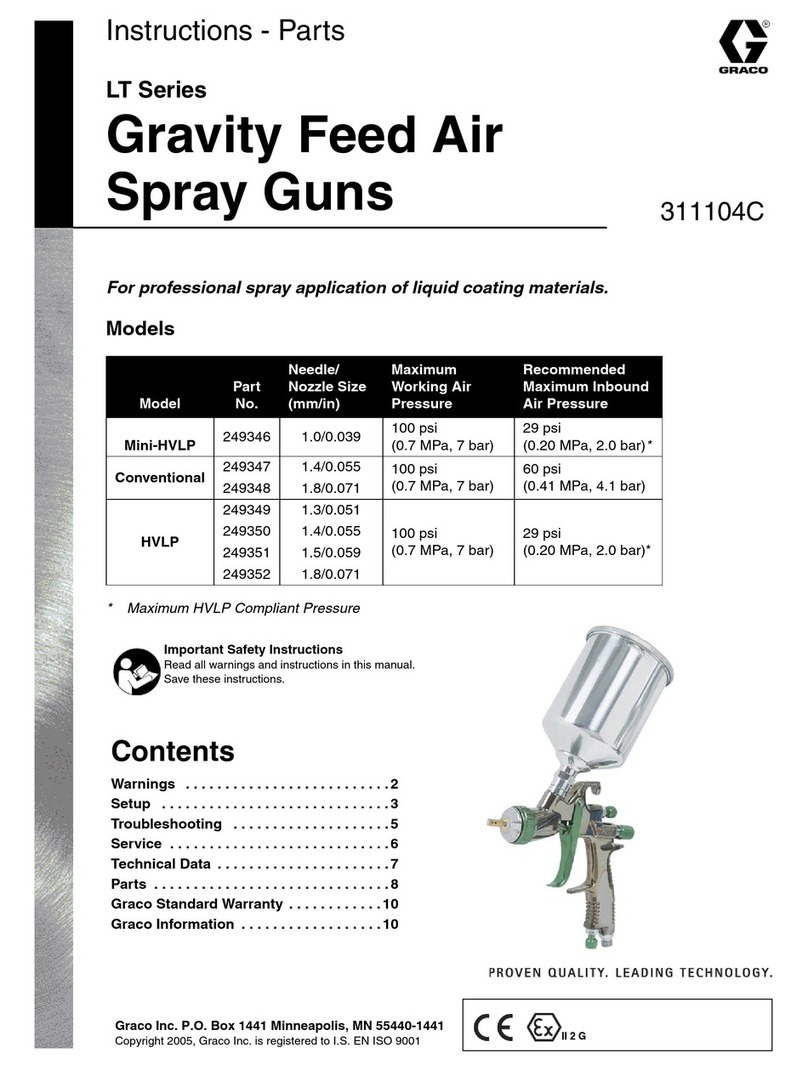

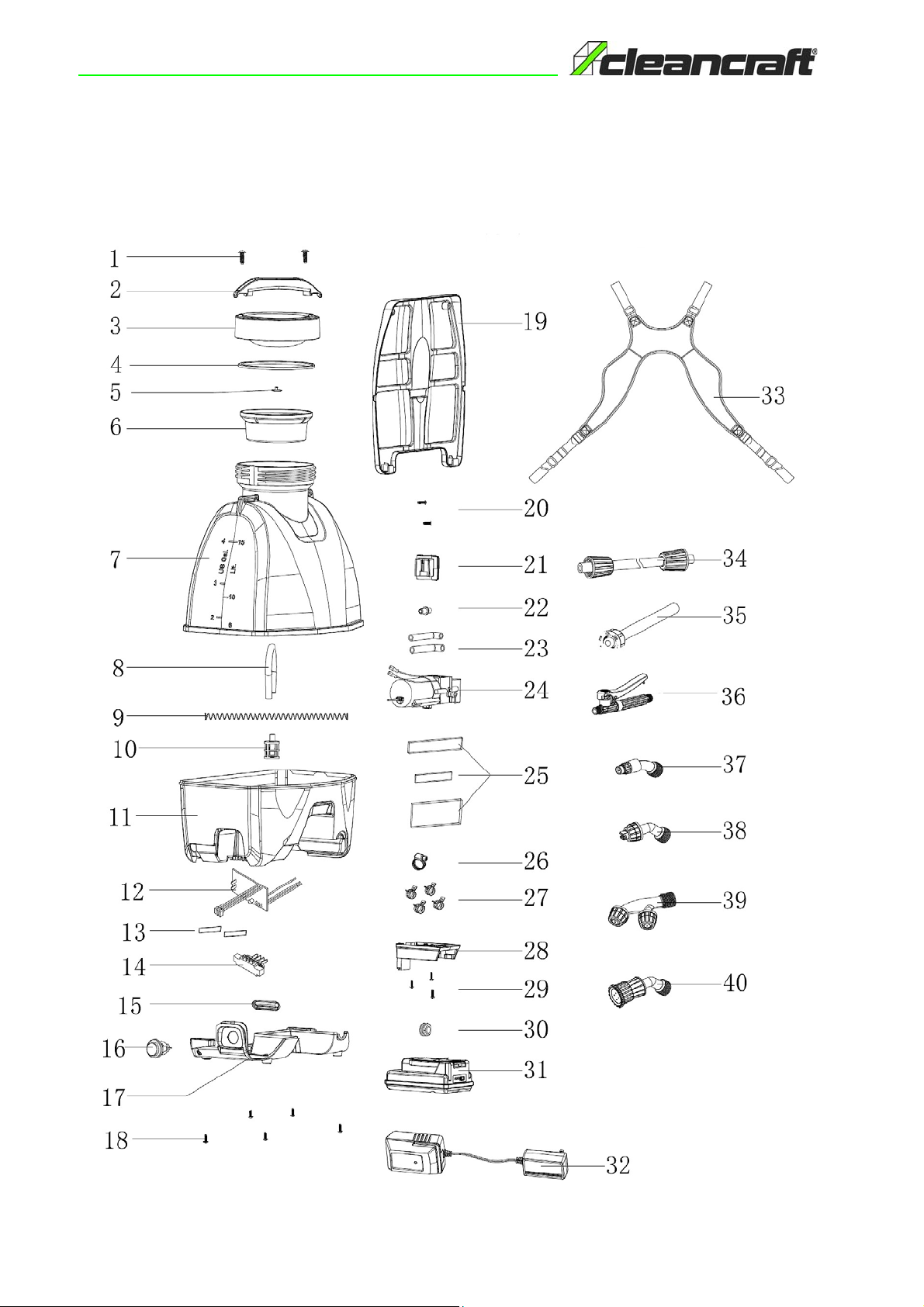

12.2 Spare Parts Drawing

The following drawing should help to identify the necessary spare parts in case of service.

Spare parts drawing 1

Fig. 26: Spare parts drawing 1

Spare Parts

ADSG 15 | Version 1.03 19

Parts list:

Position Designation Quantity

1 Screw 2

2Grip 1

3 Cover disc 1

4 Sealing ring 1

5 Waterproofing membrane 1

6Prefilter 1

7Tank 1

8 Connecting tube 1

9 Inlet line spring 1

10 Exhaust filter component 1

11 Lower part tank 1

12 Circuit board 1

13 Circuit board EVA label 2

14 Plug connection component 1

15 Seam sealing 1

16 Switch 1

17 Base housing 1

18 Screw 5

19 Back board 1

20 Screw 2

21 Hook for lance 1

22 Inlet line connector 1

23 Inlet pipe 2

24 Pump 1

25 Pump label 1

26 Hose clamp 1

27 Elastic clamp 4

28 Battery pack socket 1

29 Screw 3

30 Outlet pipe jacket 1

31 Battery pack

32 Charger 1

33 Belt/Strap 1

34 rod components 1

35 Outlet pipe assemble 1

20 ADSG 15 | Version 1.03

Electrical wiring diagram

13 Electrical wiring diagram

Fig. 27: Electrical wiring diagram

36 Spray gun 1

37 Conical nozzle 1

38 Flat blower nozzle 1

39 Double-holed nozzle 1

40 Adjustable shower nozzle 1

Position Designation Quantity

pump

switch

Battery pack

Table of contents