Operating Instructions SATAgraph 1

Prior to putting the unit/paint spray gun into operation, read the operating instructions comple-

tely and thoroughly. The stipulations contained therein are to be respected in any case. After

that, the operating instructions are to be stored in a safe place, accessible for every user of the

equipment. The unit/paint spray gun may only be put into operation by persons familiar with its

use. Inappropriate use of the unit/paint spray gun, modification of any kind or combination with

inappropriate other parts may cause material damage, serious hazard to the user‘s, other person‘s

or animal‘s health or even death. SATA shall not take any responsibility for such damages (e.g.

failure to respect the stipulations laid out in the operating instructions). The applicable safety,

workplace and worker health protection regulations of the respective country or area/district in

which the system/the paint spray gun is used are to be respected in any case (e.g. the German

Rules for the Prevention of Accidents BGR 500 (BGV D25) and BGV D24 issued by the Central

Office of the Professional Trade Associations, etc.).

Preface

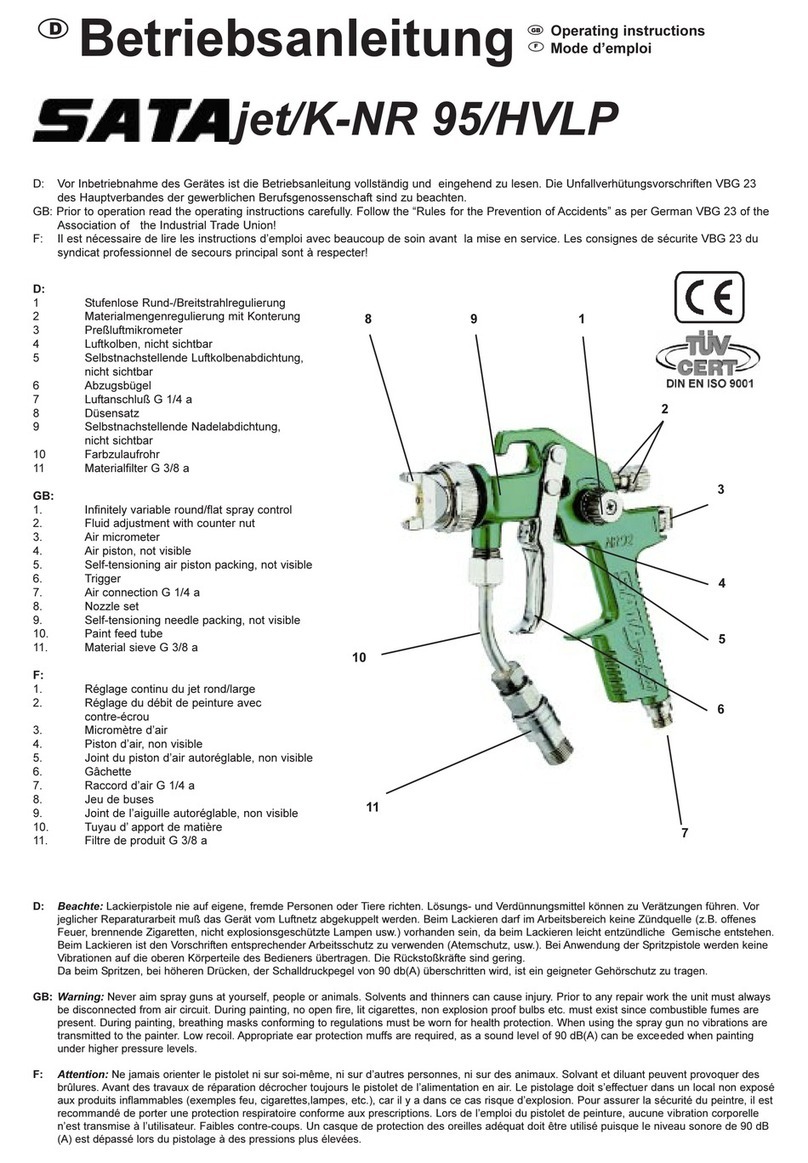

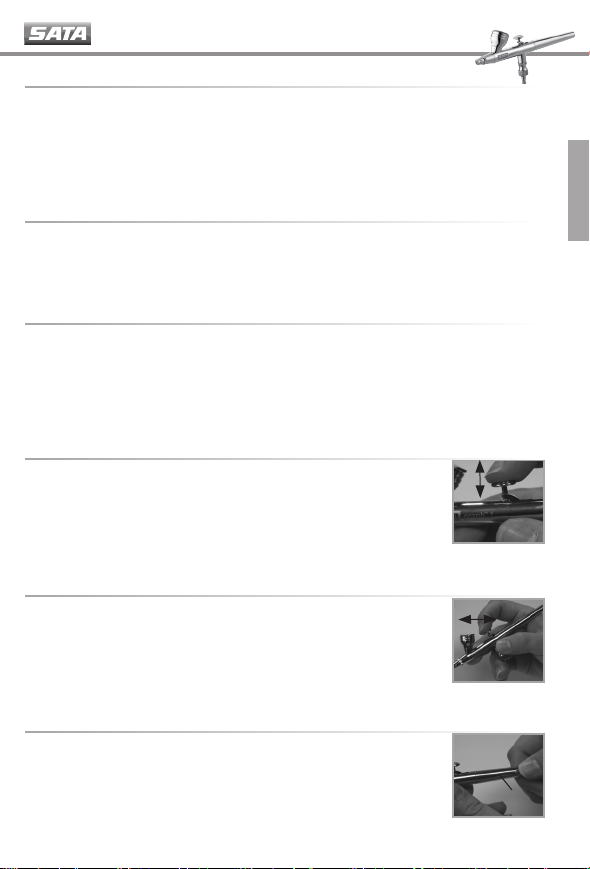

Never point paint spray guns at yourself, at other persons or animals. Solvents and thinners can

cause burns. Only the respective quantities of solvents and paints required for work progress may

be present in the direct surroundings of the unit (after work, solvents and paints are to be returned

to their assigned storage rooms). Prior to any repair work the unit must be disconnected from the

air supply. Prior to putting the unit into operation, especially after each cleaning and each

repair work, check all screws and nuts for tight fit, as well as the sealing performance of

the spray guns and hoses. Defective components must be replaced or repaired accordingly. To

obtain best possible coating results, and for maximum safety, only use original spare parts. No

sources of ignition (e.g. open flames, burning cigarettes, lamps without ex-protection etc.) may be

present during painting, as easily flammable mixture are generated during the painting process.

Occupational safety regulations must be applied when painting (respiratory protection, etc.). No

vibration is transmitted to the upper parts of the operator‘s body during use of the paint spray

gun. Recoil forces are negligible. The use of this product in explosion hazard areas Zone 0

is prohibited.

SATA, the SATA Logo and/or other SATA products referenced herein are either registered trade-

marks or trademarks of SATA GmbH & Co. KG in the U.S. and/or other countries. The names of

companies and products mentioned herein may be the trademarks of their respective owners.

To be noted

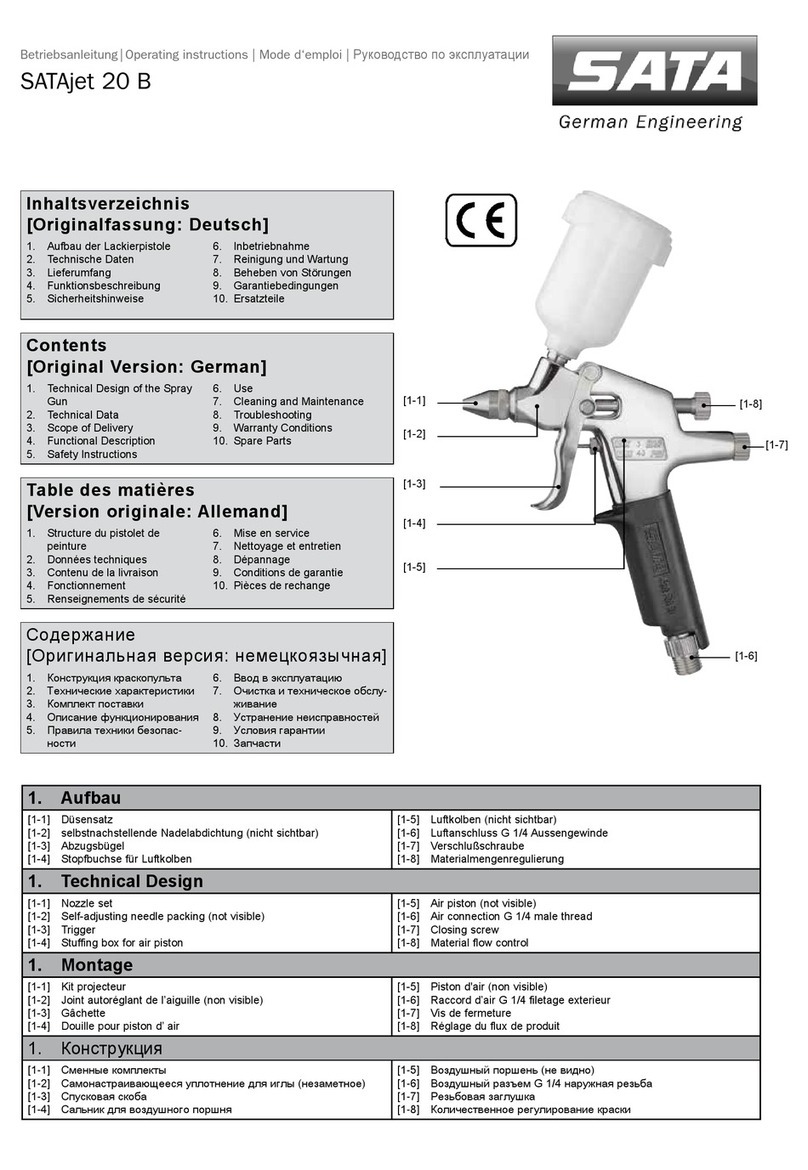

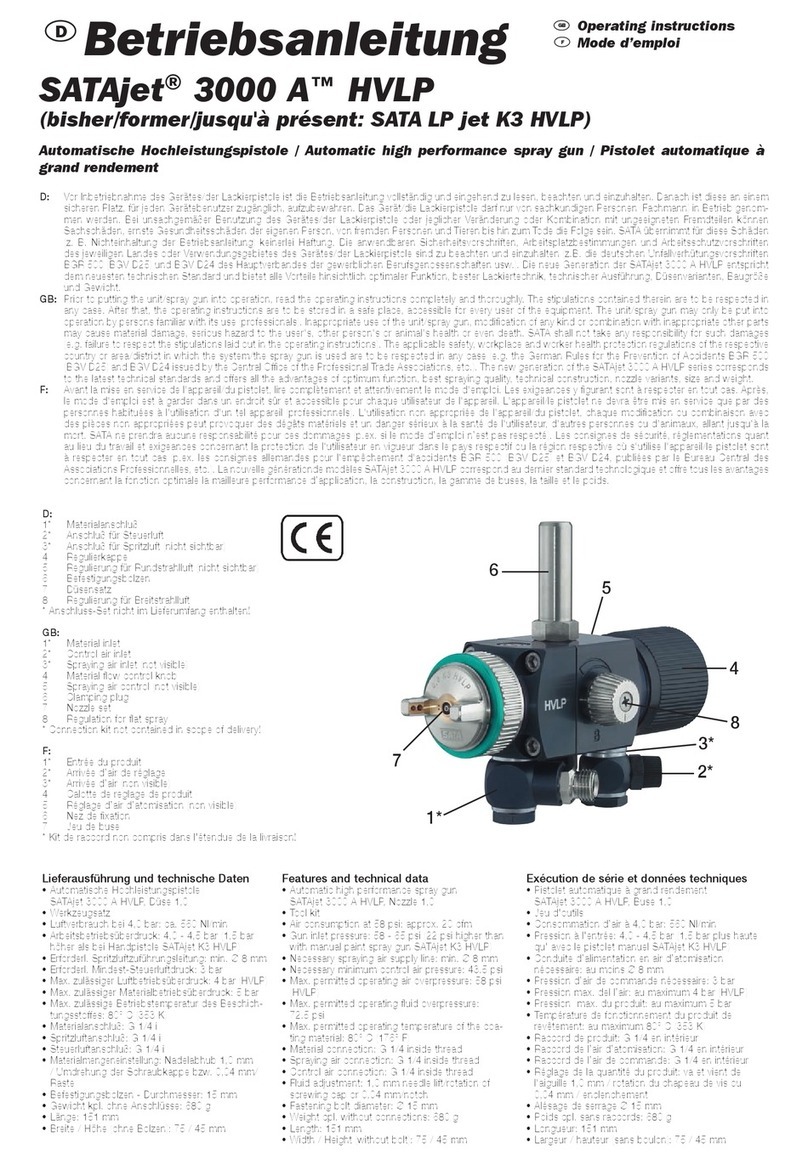

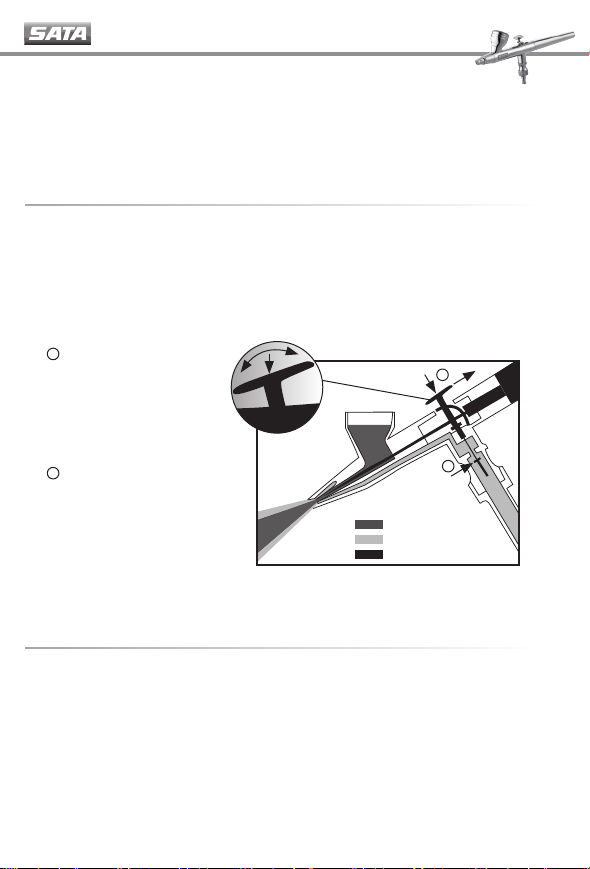

1.1. Gravity flow cup version

• Gun with nozzle 0.25

• 2.5 ml gravity flow cup with lid

• Replacement “O“ ring for paint nozzle

• Weight: approx. 94 g

• Operating pressure between 1.0 and 3.0

bars (14 to 43 psi)

1. Features and technical data

• Recommanded un inlet pressure

2.5 bars (35 psi)

• Max. gun inlet pressure 4 bars

(58 psi)

english

II.1

134742_SATAgraph1_mitCZ.indd 11 17.02.2017 10:19:06