10 310–523

Operation

Pressure Relief Procedure

WARNING

INJECTION

HAZARD

The system pressure must be manually

relieved to prevent the system from

starting or spraying accidentally

. Fluid

under high pressure can be injected through the

skin and cause serious injury

. T

o reduce the risk of

an injury from injection, splashing fluid, or moving

parts, follow the

Pressure Relief Procedure

whenever you:

D

are instructed to relieve the pressure,

D

stop spraying/dispensing,

D

check or service any of the system equipment,

D

or install or clean the spray tip/nozzle.

1.

Lock the gun/valve trigger safety

.

2.

Shut of

f and lock-out the air to the pump.

3.

Close the bleed-type master air valve (required in

your system).

4.

Unlock the gun/valve trigger safety

.

5.

Hold a metal part of the gun/valve firmly to the side

of a grounded metal pail, and trigger the gun/valve

to relieve pressure.

6.

Lock the gun/valve trigger safety

.

7.

Open the drain valve (required in your system)

and/or the pump bleeder valve, having a container

ready to catch the drainage.

8.

Leave the drain valve open until you are ready to

spray/dispense again.

If you suspect that the spray tip/nozzle or hose is

completely clogged, or that pressure has not been fully

relieved after following the steps above,

very slowly

loosen the tip guard retaining nut or hose end coupling

and relieve pressure gradually

, then loosen completely

.

Now clear the tip/nozzle or hose.

Before Pumping Fluid

WARNING

MOVING

P

ARTS HAZARD

Keep hands and fingers away from the

priming piston, ram plate, pump fluid

inlet, and lip of the fluid container when

raising or lowering the ram and whenever the pump

is charged with air

. Moving parts can amputate a

hand or finger

. Follow the

Pressure Relief Proce

-

dure

at left before checking or repairing the ram or

any other part of the system and when shutting

down the system.

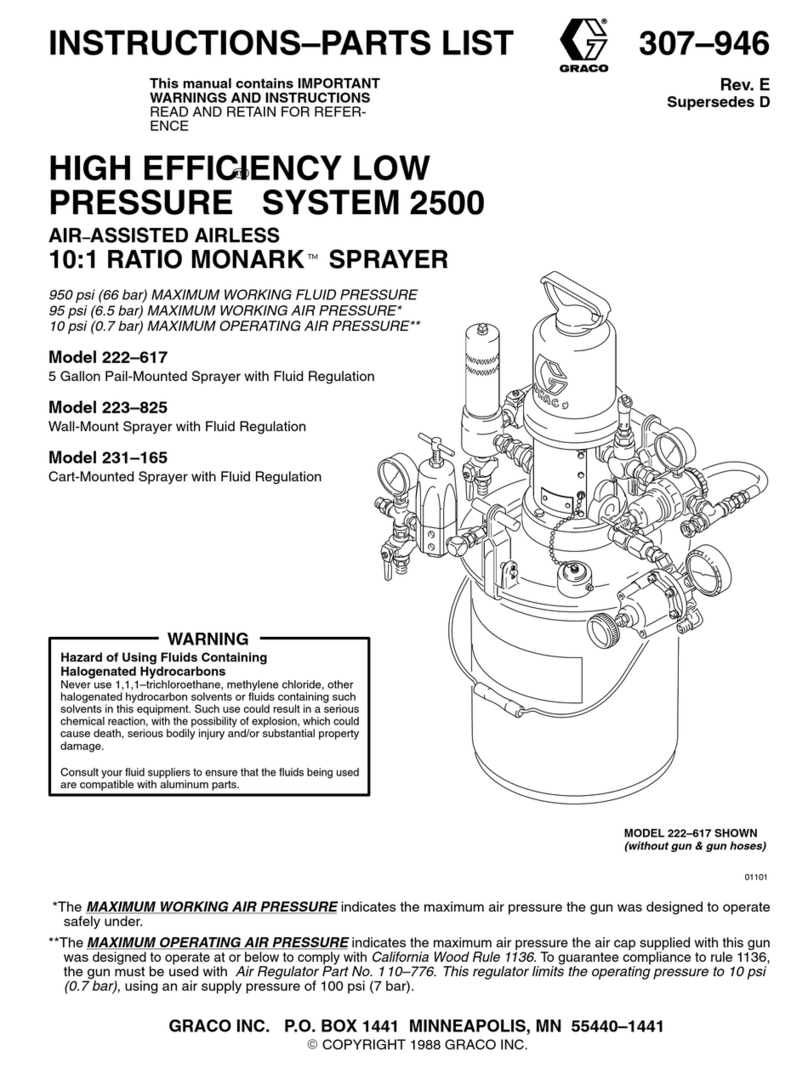

1.

Move the hand valve lever (30) to the center

position (OFF). Close the ram air regulator and

main air control valve.

2.

Move the hand valve lever to UP

. Open the main

air control valve and ram air regulator until the ram

starts to move upward. Let the ram rise to its full

height.

3.

Set a full drum of fluid on the ram base, slide it

back against the drum stop (if supplied), and

center it under the ram plate. See the T

ypical

Installation on page 9 and the Accessories sec

-

tion for drum clamps (80) that center

, hold, and

properly align the drum with the ram.

NOTE:

Do not use drums that have side bungs or

large dents with this ram. Rough bung openings or

large dents will damage the wipers or stop the ram

plate, resulting in a runaway pump.

4.

Move the hand valve lever to the DOWN position

and lower the ram until the ram plate is just ready

to enter the drum, then move the valve to OFF

.

Reposition the drum so the wipers will not hit the

drum lip, then open the vent valve (not shown) on

the ram plate.

5.

Move the hand valve lever to the DOWN position,

lower the ram plate until all air is forced out and

fluid comes out of the vent opening. Then move

the hand valve lever to OFF and close the vent

valve (not shown).

6.

Set the air pressure to the ram at 50 psi (4 bar).

Move the hand valve lever to the DOWN position.

Start the pump (open the bleed-type master air

valve and fluid dispensing valve). Let the pump run

until the system is primed and all air is forced out.

Close the bleed-type master air valve or fluid

dispensing valve to stop the pump.

NOTE:

Increase air pressure to the ram if the pump

does not prime properly with heavier fluids. If fluid is

forced out around the top wiper

, ram pressure is too

high and the air pressure should be decreased.