CleanDigital PSU12 User manual

PSU12

Integrated Switching Power Supply

All Rights Reserved

Version: PSU12_2016V1.0

User Manual

Integrated Switching Power Supply

Preface

Read this user manual carefully before using this product. Pictures shown in this

manual is for reference only, different model and specifications are subject to real

product.

This manual is only for operation instruction only, not for any maintenance usage. The

functions described in this version are updated till August 2016. In the constant effort to

improve our product, we reserve the right to make functions or parameters changes

without notice or obligation. Please refer to the dealers for the latest details.

All product function is valid till 2016-8-15.

Trademarks

Product model and logo are trademarks. Any other trademarks mentioned in this

manual are acknowledged as the properties of the trademark owner. No part of this

publication may be copied or reproduced without the prior written consent.

FCC Statement

This equipment generates, uses and can radiate radio frequency energy and, if not

installed and used in accordance with the instructions, may cause harmful interference

to radio communications. It has been tested and found to comply with the limits for a

Class B digital device, pursuant to part 15 of the FCC Rules. These limits are designed

to provide reasonable protection against harmful interference in a commercial

installation.

Operation of this equipment in a residential area is likely to cause interference, in which

case the user at their own expense will be required to take whatever measures may be

necessary to correct the interference.

Any changes or modifications not expressly approved by the manufacture would void

the user’s authority to operate the equipment.

Integrated Switching Power Supply

SAFETY PRECAUTIONS

To insure the best f r o m t h e p roduct, please read all i n s t ructions carefully b e f o r e u s i n g

the device. Save this manual for further reference.

l Unpack the equipment carefully and save the original box and packing material for

possible future shipment

l Follow basic safety precautions to reduce the risk of fire, electrical shock and injury

to persons.

l Do not dismantle the housing or modify the module. It may result in electrical shock

or burn.

l Using supplies or parts not meeting the products’ specifications may cause

damage, deterioration or malfunction.

l Refer all servicing to qualified service personnel.

l To prevent fire o r s h o c k h a z a r d , do not expose the unit t o r a in, moisture or in s t a l l

this product near water.

l Do not put any heavy items on the extension cable in case of extrusion.

l Do not remove the housing of the device as opening or removing housing may

expose you to dangerous voltage or other hazards.

l Install the device in a place with fine ventilation to avoid damage caused by

overheat.

l Keep the module away from liquids.

l Spillage into the housing may result in fire, electrical shock, or equipment damage.

If an object or liquid falls or spills on to the housing, unplug the module immediately.

l Do not twist or pull by force ends of the optical cable. It can cause malfunction.

l Do not use liquid or aerosol cleaners to clean this unit. Always unplug the power to

the device before cleaning.

l Unplug the power cord when left unused for a long period of time.

l Information on disposal for scrapped devices: do not burn or mix with general

household waste, please treat them as normal electrical wastes.

Integrated Switching Power Supply

Contents

1. Introduction .................................................................................................................. 1!

1.1 Brief Introduction ................................................................................................ 1!

1.2 Features ............................................................................................................. 1!

1.3 Package List ....................................................................................................... 1!

2. Panel Description ........................................................................................................ 2!

2.1 Front Panel ......................................................................................................... 2!

2.2 Rear Panel ......................................................................................................... 2!

3. System Connection ..................................................................................................... 4!

3.1 Usage Precautions ............................................................................................. 4!

3.2 System Diagram ................................................................................................. 4!

3.3 Connection Procedure ....................................................................................... 4!

4. System Operations ...................................................................................................... 5!

4.1 Front Panel Buttons ........................................................................................... 5!

4.2 RS232 Control .................................................................................................... 5!

4.2.1 Installation/uninstallation of RS232 Control Software .............................. 5!

4.2.2 Basic Settings .......................................................................................... 5!

4.2.3 RS232 Communication Commands ......................................................... 6!

4.3 Web-based GUI Control ..................................................................................... 9!

4.3.1 Control Menu ......................................................................................... 10!

4.3.2 Voltage Setting Menu ............................................................................. 11!

4.3.3 Network Menu ........................................................................................ 11!

4.3.4 Password Menu ..................................................................................... 12!

4.3.5 Web-based GUI Update ......................................................................... 13!

5. Specification .............................................................................................................. 14!

6. Panel Drawing ........................................................................................................... 15!

7. Troubleshooting & Maintenance .................................................................................. 1!

8. After-sales Service ...................................................................................................... 3!

Integrated Switching Power Supply

1

1. Introduction

1.1 Brief Introduction

The product is an integrated switching power supply designed for converting AC into

DC power. It provide 2 input channels and 12 output channels, input voltage

100~240VAC, output 5/12/24VDC, the max power consumption of single channel is

15W.

Base on the sequential control technology, when power on, the 12 output channels will

turned on orderly every 100ms.In addition, each output channel also can be switch

on/off via front panel button, RS232 commands or Web-based GUI, and the output

voltage on each output channel can be selected as 5/12/24V DC via the TACT Switch

on rear panel, RS232 command, or web-based GUI.

1.2 Features

l Double input channel designed for ensuring the stable AC source.

l Total 12 output channels, and each channel has three kinds of output voltage

(5/12/24VDC) can be selected.

l Output channels can be switch on/off by via the front panel buttons, RS232

commands or Web-based GUI.

l Output voltage (5/12/24VDC) can be selected via the TACT Switch on rear

panel, RS232 commands, or web-based GUI.

l Adopt sequential control technology.

l Supports online software upgrading.

1.3 Package List

l 1 x Integrated Switching Power Supply

l 1 x Power Cable

l 12 x 2-Pin phoenix connectors

l 1 x 3-Pin phoenix connector

l 1 x RS232 cable (DB9 to 3-Pin phoenix connector)

l 2 x DC cables

Note

:

Please confirm if the product and the accessories are all included, if not, please

contact with the dealers.

Integrated Switching Power Supply

2

2. Panel Description

2.1 Front Panel

No.

Name

Description

①

FIRMWARE

USB port for updating system firmware.

②

AC1 & AC2

Input AC source indicators.

l Off when there is no power to the device

l Red when the device is in standby mode

l Green when the device is powered on and normal

output.

③

01~12

Output channel switching buttons and Activity LEDs, 12 in

total.

Press the button to trun on/off the corresponding channel,and

the corresponding LED will turn green and keep on.

Note: Pictures shown in this manual are for reference only, different model and

specifications are subject to real product.

2.2 Rear Panel

FIRMWARE

01 02 03 04 05 06

07 08 09 10 11 12

AC 2

AC 1

PSU12

12 3

C

24V

+

DC

12V

5V

+

SELECT

AC100V 240V-

Tx Rx

RS232 TCP IP/

24V

+

AC100V 240V-

AC1 AC2

DC

12V

5V

+ ++ ++ ++ ++ ++ ++ ++ ++ ++ ++ ++

SELECT

24V

DC

12V

5V

SELECT

24V

DC

12V

5V

SELECT

24V

DC

12V

5V

SELECT

24V

DC

12V

5V

SELECT

24V

DC

12V

5V

SELECT

24V

DC

12V

5V

SELECT

24V

DC

12V

5V

SELECT

24V

DC

12V

5V

SELECT

24V

DC

12V

5V

SELECT

24V

DC

12V

5V

SELECT

24V

DC

12V

5V

SELECT

1

A

B

234

Integrated Switching Power Supply

3

No.

Name

Description

①

01~12

12 output channals.

A. DC: 2-Pin phoenix connector, connect with the device

needed to be powered.

B. SELECT: Press the TACT Switch to select the output

voltage as 5/12/24VDC.

C. 5/12/24V indicators: The green indicator of the current

selected output voltage will blink slowly and and keep

on.

②

RS232

Serial port, 3-Pin phoenix connector, connect with a control

device (such as PC) to control the product via RS232

commands.

③

TCP/IP

Ethernet port, connect with PC to control the product via

Web-based GUI.

④

AC1& AC2

2 AC input channels. Input voltage is AC100~240V.

Note: Pictures shown in this manual are for reference only, different model and

specifications are subject to real product.

Integrated Switching Power Supply

4

3. System Connection

3.1 Usage Precautions

l

System should be installed in a clean environment and has appropriate

temperature and humidity control.

l

All of the power switches, plugs, sockets and power cords should be insulated

and safe.

l

All devices should be connected before power on.

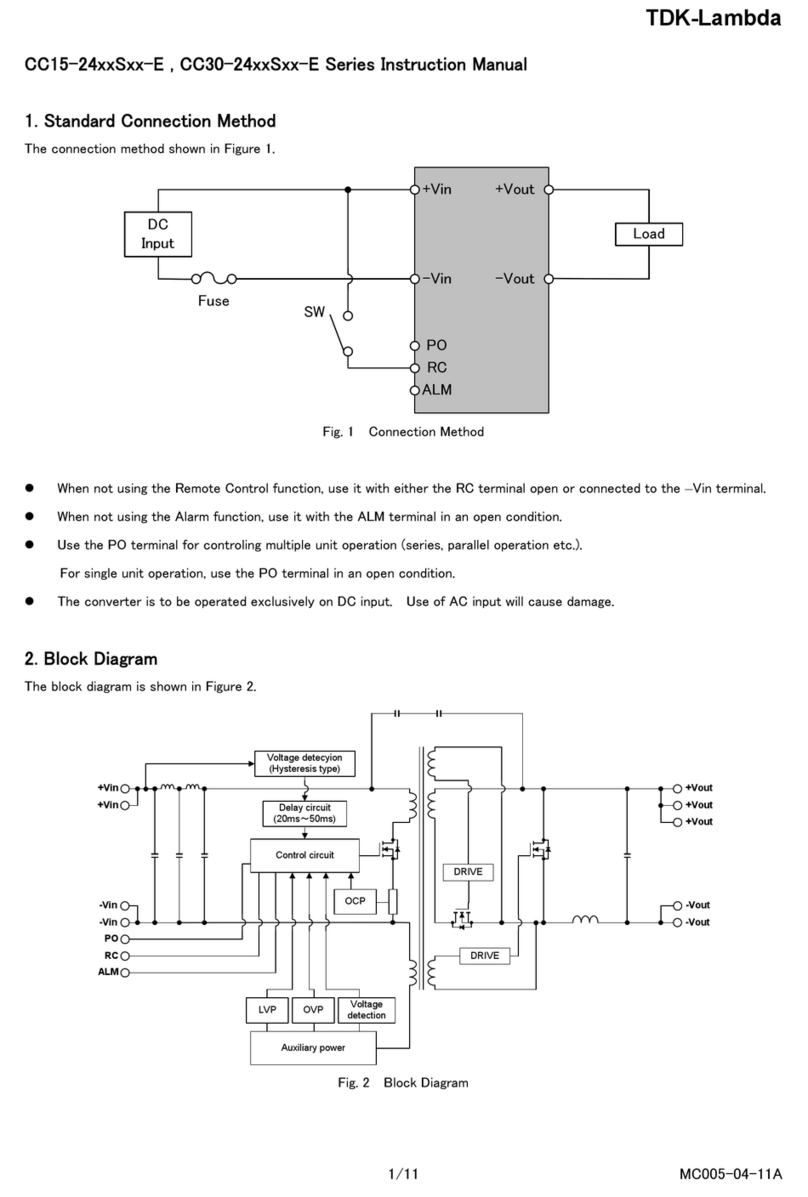

3.2 System Diagram

3.3 Connection Procedure

Step1. Connect the devices needed to be powered to the DC ports on rear panel.

Step2. Connect the PC to the RS232 port on rear panel.

Step3. Connect the PC to the TCP/IP port on the rear panel.

Step4. Connect the power cables to the one or both of AC1 and AC2 input port.

AC100V 240V-

Tx Rx

RS232 TCP IP/

24V

+

AC100V 240V-

AC1 AC2

DC

12V

5V

+ ++ ++ ++ ++ ++ ++ ++ ++ ++ ++ ++

SELECT

24V

DC

12V

5V

SELECT

24V

DC

12V

5V

SELECT

24V

DC

12V

5V

SELECT

24V

DC

12V

5V

SELECT

24V

DC

12V

5V

SELECT

24V

DC

12V

5V

SELECT

24V

DC

12V

5V

SELECT

24V

DC

12V

5V

SELECT

24V

DC

12V

5V

SELECT

24V

DC

12V

5V

SELECT

24V

DC

12V

5V

SELECT

Powered Device 1 Powered Device 2 Powered Device 3

100~240VAC

RS232 Control

TCP IP Control/

Power Supply

Integrated Switching Power Supply

5

4. System Operations

4.1 Front Panel Buttons

l Switch on/off output channels:

Press 01~12 buttons on front panel to switch on/off the corresponding output channel.

l Select the output voltage:

Press SELECT button on corresponding output channel to select the output voltage as

5V, 12V or 24V.

After switching the output voltage, the output channel will be turned off based on

overvoltage protection control, and it needs to be turned on via the corresponding

output channel switching button on front panel.

4.2 RS232 Control

Connect a PC to the RS232 port on the rear panel, and then install the RS232 control

software on the PC, the product can be controlled by sending RS232 commands via

the RS232 control software.

4.2.1 Installation/uninstallation of RS232 Control Software

l Installation Copy the control software file to the computer connected with the

product.

l Uninstallation Delete all the control software files in corresponding file path.

4.2.2 Basic Settings

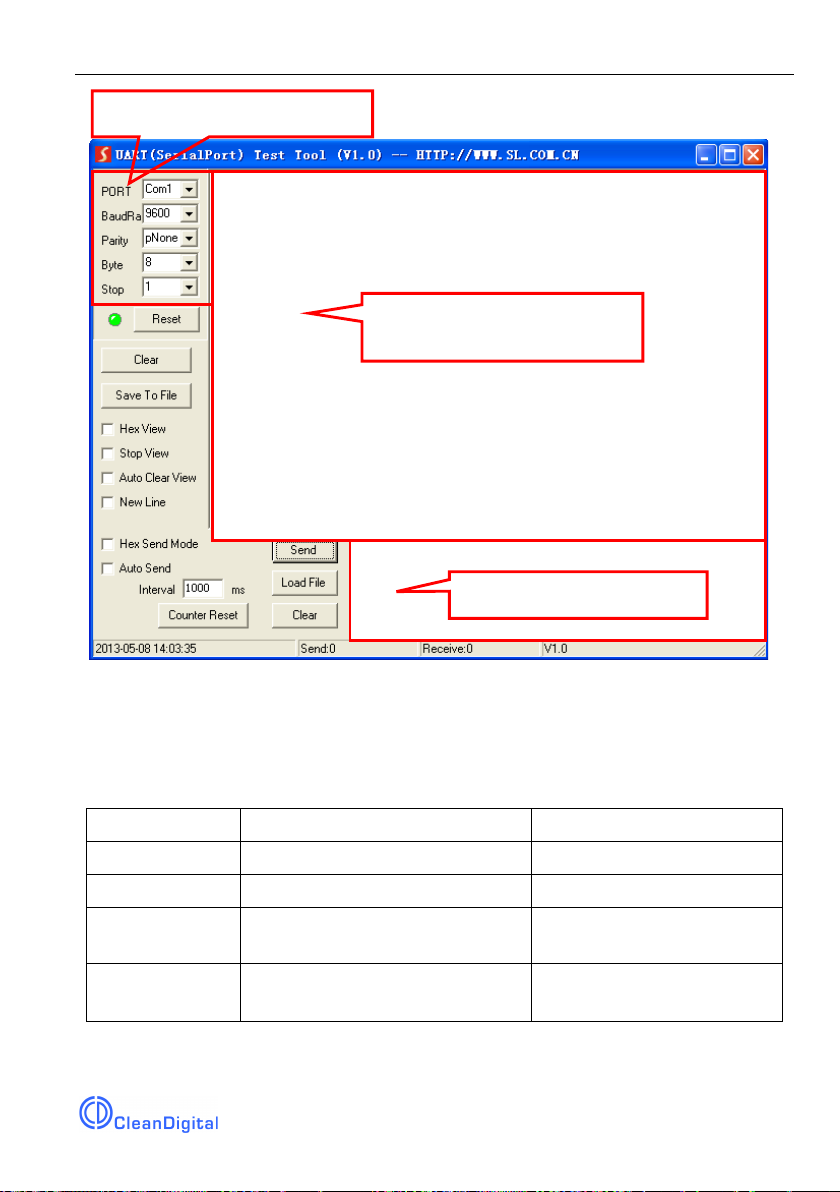

Double-click the software icon to run this software.

Here we take the software CommWatch.exe as example. The icon is showed as

below:

The interface of the control software is showed as below:

Integrated Switching Power Supply

6

Please set the parameters of COM number, baud rate, data bit, stop bit and the parity

bit correctly, and then you are able to send command in Command Sending Area.

4.2.3 RS232 Communication Commands

Communication protocol: RS232 Communication Protocol

Baud rate: 9600 Data bit: 8 Stop bit: 1 Parity bit: none

Command

Function

Feedback Example

All@.

Switch on all output channels.

All Open.

All$.

Switch off all output channels.

All Closed.

[x]@.

Switch on the output channel [x],

x =1~12.

[x] Open.

[x]$.

Switch off the output channel [x],

x =1~12.

[x] Closed.

Parameter Configuration area

Monitoring area, indicates if

the command sent works.

Command Sending area

Integrated Switching Power Supply

7

Command

Function

Feedback Example

Output/[x]V/[y].

When y = NULL, Set the output

voltage as x for all output

channels.

x =5/12/24.

All Output [x]V.

When y =1~12, Set the output

voltage as X for the output

channel y.

x =5/12/24.

[y] Output [x]V.

Status[x].

When x = NULL, query the on-off

status of all output channels.

01 Open.

02 Closed.

03 Closed.

…

When x = 1~12, query the on-off

status of the output channel x.

[x] Open.

[x] Closed.

Save[x].

Save the current on-off status to

Group x. x =1~5.

Save To F[x].

Recall[x].

Invoke the on-off status of Group

x. x =1~5.

If Group x has no data, the

feedback information:

F[x] no data.

If Group x has data, the

feedback information:

Recall From F[x].

Out 01 02 03 04 05 06 07

08 09 10 11 12

State S S S S S S S S S S S

S

Vm 12 12 12 12 12 12 12 12

12 12 12 12

Over N N N N N N N N N N

N N

Clear[x].

When x =NULL, clear the data of

all Group.

Clear All.

Integrated Switching Power Supply

8

Command

Function

Feedback Example

When x =1~5, clear the data of the

Group x.

Clear F[x].

QueryGroup[x].

When x = NULL, query all groups.

Out 01 02 03 04 05 06 07

08 09 10 11 12

Vm1 12 12 12 12 12 12 12

12 12 12 12 12

Vm2 XX XX XX XX XX XX

XX XX XX XX XX XX

……

When x = 1~5, query the group x.

Out 01 02 03 04 05 06 07

08 09 10 11 12

Vm[x] 12 12 12 12 12 12 12

12 12 12 12 12

%0911.

Restore Factory Defaults.

Factory Default

/*Name;

Query the manufacturer.

XXX

/*Type;

Query the product model

PSU12

/^Version;

Query the software version.

V x. x. x

Baud[x].

Set the baud rate as x. x = 1200,

2400,4800,9600,19200,38400,

57600,115200.

When x =NULL, the default baud

rate is 9600.

Baud [x] not change.

Baud [y] change to [x].

%0964.

Query the IP address.

IP XXXX

Note: After sending the “Output/[x]V/[y].” to change the output voltage, the

corresponding output channel will be switch off, the command “[x]@.” should be sent

to switch on this output channel again.

Integrated Switching Power Supply

9

4.3 Web-based GUI Control

In addition to control the product via front panel button and RS232 communication

software. This product can be controlled via web-based GUI. It allows users to interact

with the product through graphical icons and visual indicators.

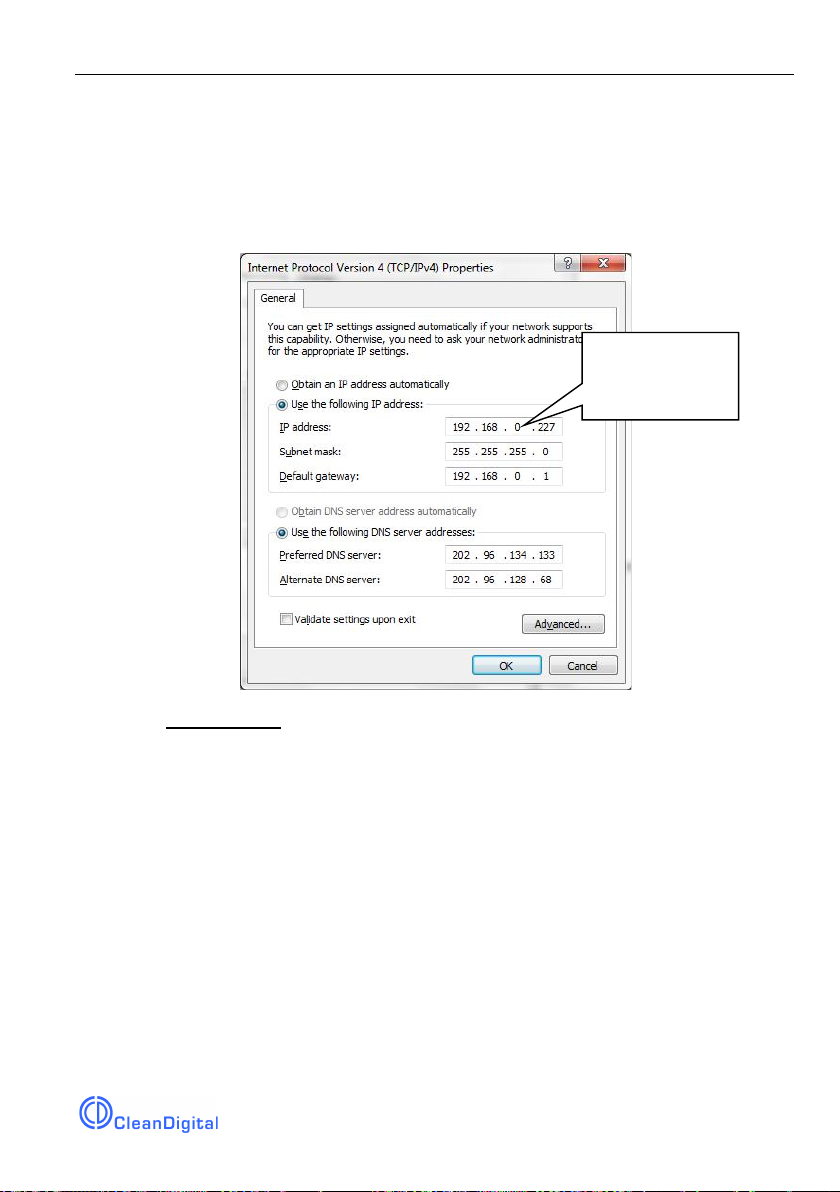

1. Connect a PC to the TCP/IP port on the rear panel, and set its network segment to

the same as the default IP of the product (192.168.0.178, port No.: 4001).

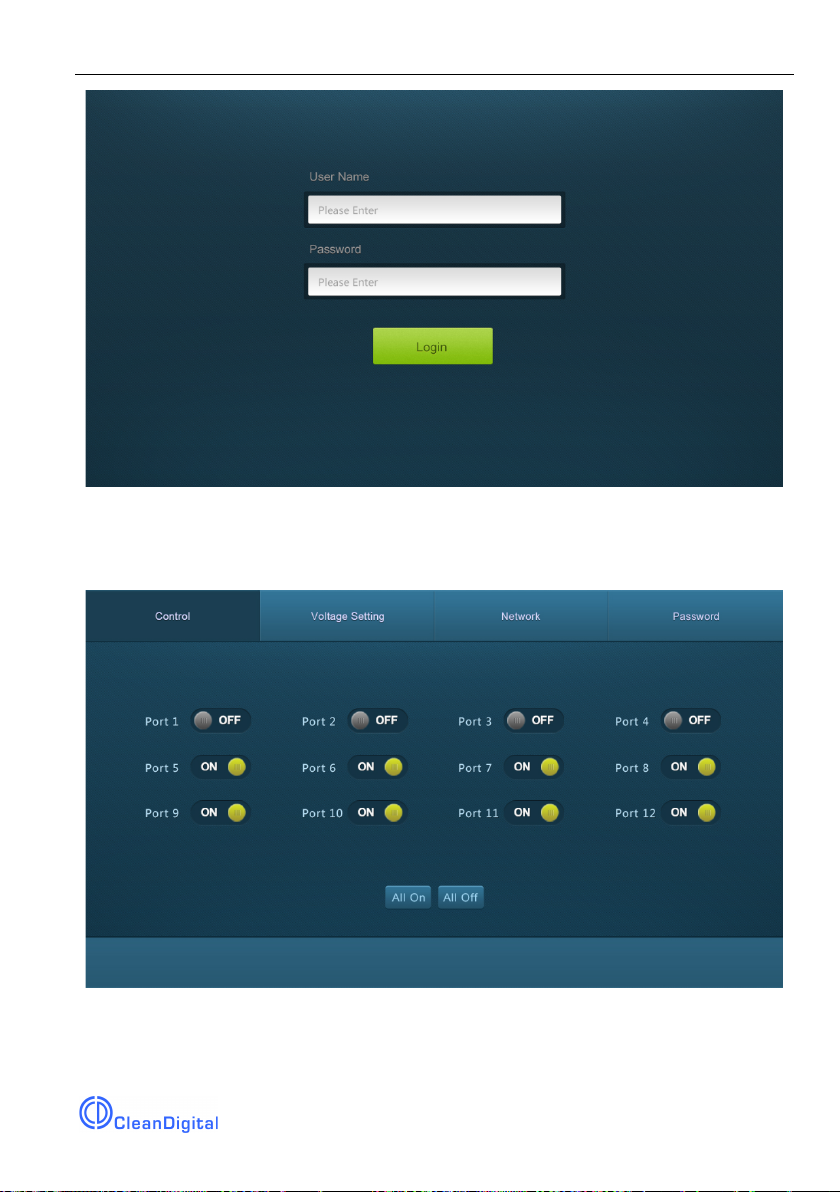

2. Type 192.168.0.178 in your browser, it will enter the log-in interface shown as

below:

Same network

segment as the

product.

Integrated Switching Power Supply

10

4.3.1 Control Menu

Type user name: user and password: user (default setting) on the log-in interface, and

then click Login to enter Control menu shown as below:

l Select the ON/OFF to switch on/off the output channel.

l Click the All On to switch on all output channels.

l Click the All Off to switch off all output channels.

Integrated Switching Power Supply

11

4.3.2 Voltage Setting Menu

Click Voltage Setting on the top of page to enter voltage setting menu shown as

below:

In this interface, you can select 5V, 12V, or 24V for each output channel.

4.3.3 Network Menu

Click Network on the top of page to enter network setting menu shown as below:

Integrated Switching Power Supply

12

In this interface, dynamic or static IP mode can be selected. Under static IP mode, IP

address and subnet mask, gateway can be set and make sure the IP addresses are

different to avoid IP conflict.

4.3.4 Password Menu

Click Password on the top of page to enter password menu shown as below:

Integrated Switching Power Supply

13

In this interface, the password can be modified as you need.

4.3.5 Web-based GUI Update

Web-based GUI for the Scaler Switcher supports online update in

http://192.168.0.178:100. Type the username and password (the same as the GUI log-

in settings, modified password will be available only after rebooting) to log in the

configuration interface. After that, click Administration at the source menu to get to

Upload Program as shown below:

Select the desired update file and press Apply, it will start upgrading then.

Integrated Switching Power Supply

14

5. Specification

Input & Output

Input Port

AC1 & AC2

Input Voltage

100~240VAC 50~60Hz

Output Port

Tota l 1 2 D C port (2-Pin phoenix connectors)

Output Voltage

5V, 12V or 24V can be selectable.

Output Voltage Range

5V: 4.75~5.25V

12V: 11.4~12.6V

24V: 22.8~25.2V

Maximum output power

consumption of signal channel

15W

Total output power consumption

180W

Control Part

Buttons Control

Front Panel: 01~12, total 12 buttons.

Rear Panel: Total 12 TACT Switches, named

SELECT.

RS232 Control

RS232 port (3-Pin phoenix connector).

Baud rate support 1200, 2400, 4800, 9600

(default), 19200, 38400, 57600,115200.

Web-based GUI Control

TCP/IP port (RJ45).

Default IP: 192.168.0.178

Port No.: 4001

General

Temperature

0 ~ +50℃

Humidity

10% ~ 90%

Dimension (W*H*D)

437mm x 44mm x 357mm

Net Weight

4.2Kg

Integrated Switching Power Supply

15

6. Panel Drawing

FIRMWARE

01 02 03 04 05 06

07 08 09 10 11 12

AC 2

AC 1

PSU12

AC100V 240V-

Tx Rx

RS232 TCP IP/

24V

+

AC100V 240V-

AC1 AC2

DC

12V

5V

+ ++ ++ ++ ++ ++ ++ ++ ++ ++ ++ ++

SELECT

24V

DC

12V

5V

SELECT

24V

DC

12V

5V

SELECT

24V

DC

12V

5V

SELECT

24V

DC

12V

5V

SELECT

24V

DC

12V

5V

SELECT

24V

DC

12V

5V

SELECT

24V

DC

12V

5V

SELECT

24V

DC

12V

5V

SELECT

24V

DC

12V

5V

SELECT

24V

DC

12V

5V

SELECT

24V

DC

12V

5V

SELECT

437 mm

44 mm

7. Troubleshooting & Maintenance

Problems

Causes

Solutions

No output voltage

Power supply protect function

will start when over loaded.

Please reduce loads.

After selecting output voltage,

the output channel will switch off

automatically.

Switch on the output

channel via front panel

button.

Fail or loose connection

Make sure the connection

is good.

AC1 or AC2 indicator

doesn’t work or no

respond to any

operation

Fail connection of power cord.

Make sure the power cord

connection is good.

Cannot control the

device by control

device (e.g. a PC)

through RS232 port

Wrong RS232 communication

parameters

Type in correct RS232

communication

parameters.

Fail or loose connection

Make sure the connection

is good.

Broken RS232 port

Send it to authorized

dealer for checking.

Cannot control the

device by front panel

buttons while can

control it through

RS232 port

The front panel buttons are

broken

Send it to authorized

dealer for repairing.

Cannot control the

device via Web-

based GUI

The IP address of control PC

and TCP/IP port are not on the

same network segment

Modify control PC’s

network segment to the

same with the TCP/IP port.

The port No. are wrong.

The correct port No. is

4001.

Fail or loose connection

Make sure the connection

is good.

Broken TCP/IP port

Send it to authorized

dealer for checking.

Cannot control the

device by RS232 /

front panel

The device has already been

broken.

Send it to authorized

dealer for repairing.

Table of contents

Popular Power Supply manuals by other brands

Daintree

Daintree GE Tetra GEPS24-300U-GLX2 installation guide

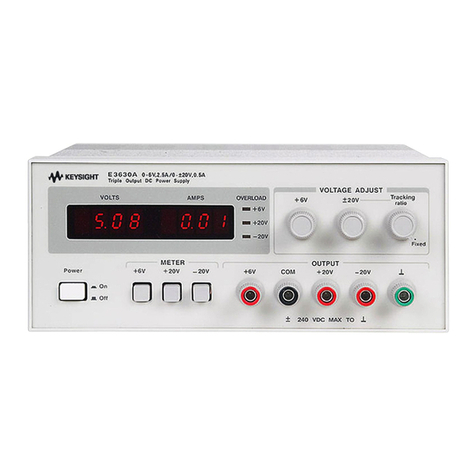

Keysight

Keysight E3630A Operating and service manual

Poppstar

Poppstar 1010214 Instructions for use

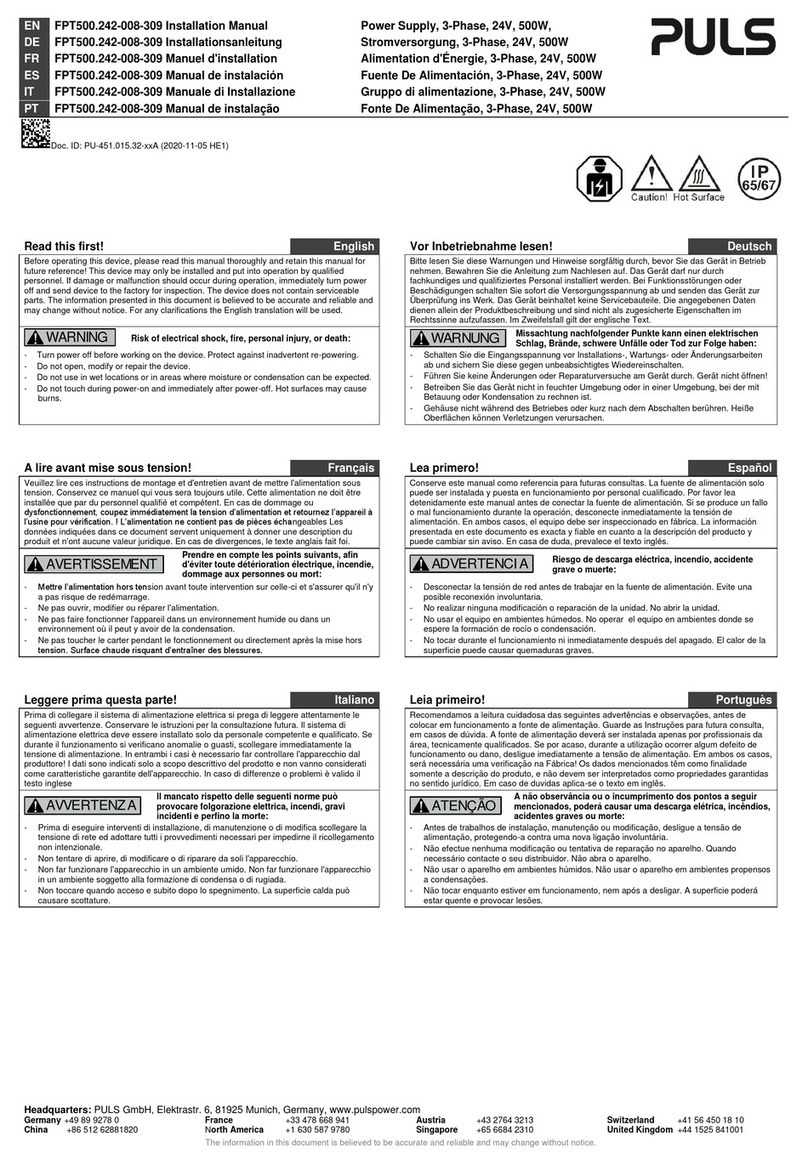

Puls

Puls FPT500.242-008-309 instruction manual

MAIMAN ELECTRONICS

MAIMAN ELECTRONICS MBL1500A user manual

Vimar

Vimar ELVOX 6837 INSTALLATION DIAGRAMS