3

Contents

1General information ........................................................................ 5

1.1 Legal notice.......................................................................................5

1.1.1 Copyright...........................................................................................5

1.1.2 Manufacturer and service address.....................................................5

1.1.3 Updates.............................................................................................5

1.2 Introduction .......................................................................................6

1.2.1 Target group of these operating instructions......................................6

1.2.2 Liability and damages........................................................................7

1.2.3 Validity7

1.2.4 Product identification.........................................................................8

1.2.5 Typographical conventions................................................................9

1.2.6 Safety information in the text...........................................................10

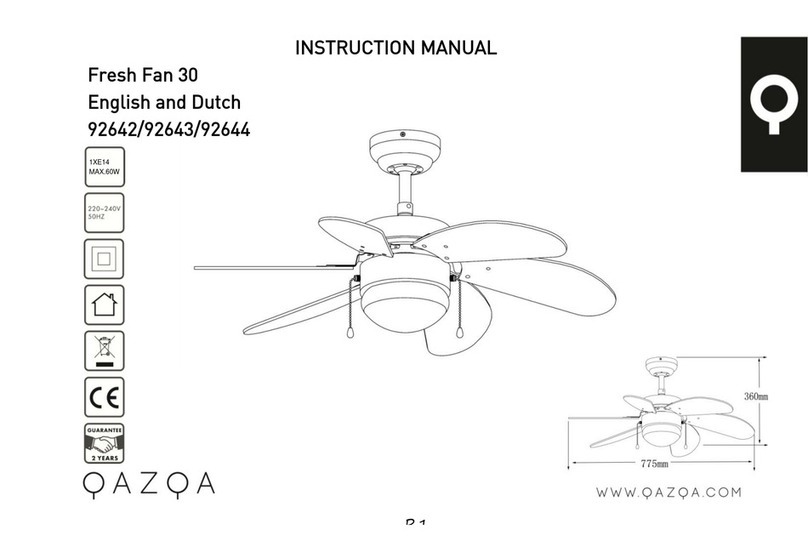

1.3 Product description..........................................................................11

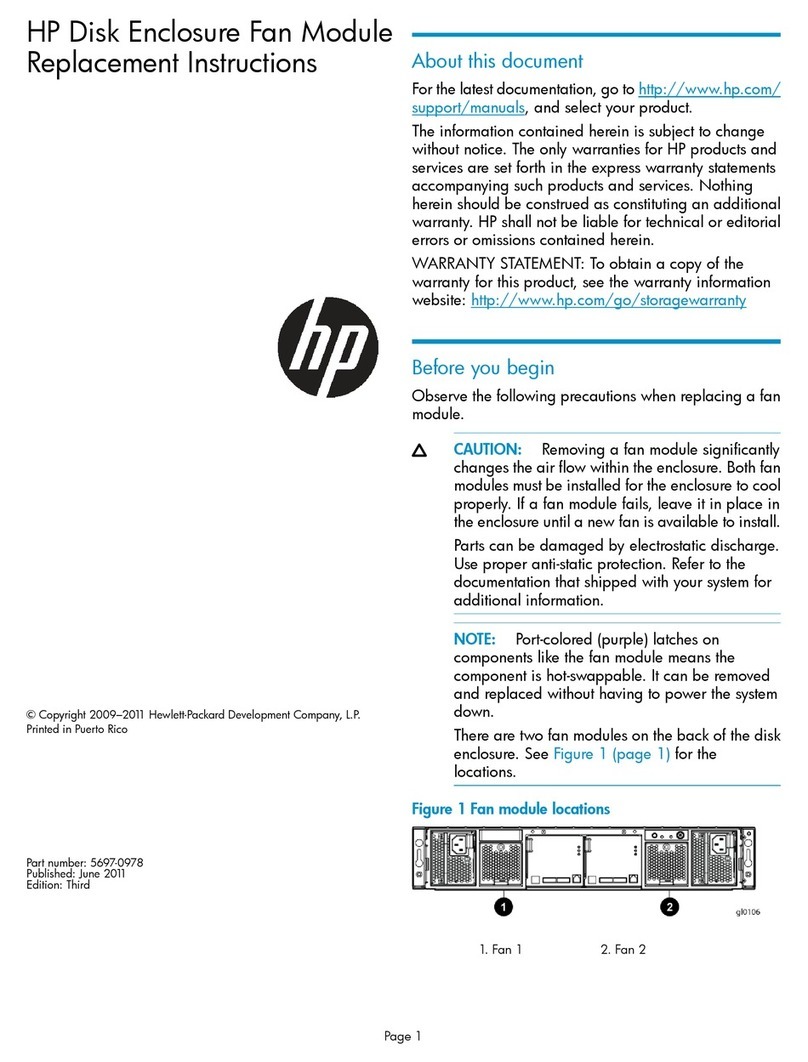

1.3.1 Pneumatic fan components.............................................................11

1.3.2 Hydraulic fan components...............................................................12

1.3.3 Cleanfix®electrical components ......................................................13

2Safety ............................................................................................. 14

2.1 Intended use....................................................................................14

2.2 Other regulations.............................................................................14

2.3 Safety information ...........................................................................15

3Required tools............................................................................... 18

4Removing the manufacturer’s fan................................................ 19

5Installing the Cleanfix®reversible fan.......................................... 20

5.1 Mounting the Cleanfix®flange..........................................................20

5.2 Attaching the pressure hose to the fan ............................................22

5.2.1 Pneumatic.......................................................................................22

5.2.2 Hydraulic.........................................................................................23

5.3 Mounting the Cleanfix®reversible fan..............................................25

5.4 Checking the smooth movement of the Cleanfix®reversible fan......31

5.4.1 Pneumatic.......................................................................................31

5.4.2 Hydraulic.........................................................................................33

5.5 Mounting the hydraulic hose fitting (only for H162 fans) ..................34

6Mounting the Cleanfix®electrical components ........................... 37

6.1 For pneumatic activation .................................................................39

6.1.1 Cleanfix®valve / for railway vehicles with a compressed air

system 39

6.1.2 Cleanfix®valve unit with Mini-Timer or Multi-Timer / for vehicles

with a compressed air system .........................................................43

6.1.3 Cleanfix®standard compressor unit / for vehicles without a

compressed air system....................................................................47

6.1.4 Cleanfix®control unit with Mini-Timer or Multi-Timer........................51

6.2 For hydraulic activation....................................................................55