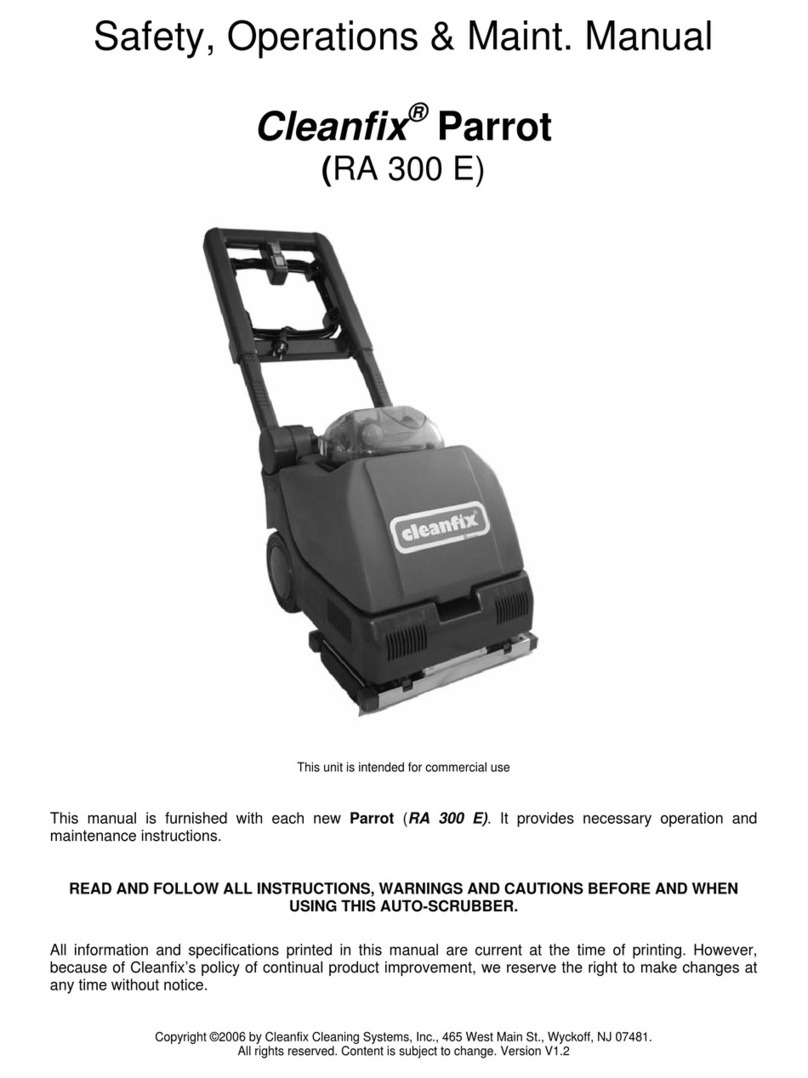

Cleanfix Parrot RA 300 E User manual

RA 300 E

Swiss Made Quality.

01 / 2012BA 300.001

English

These operating instructions have been made for the

operators of the RA 300 E.

☞Please get acquainted with the components, safety

instructions and operation details, maintenance and

recommandations mentioned in these instructions.

☞This allows you to optimise the performance, usage,

maintenance and saftey of the machine and allows

you to keep the machine at a perfect level throughout

it’s life.

☞The manufacturer takes no responsability for damages

caused to property or persons due to improper use of

the machine!

Safety instructions, Safety précautions English 7

Description of pictures English 8

Technical Specification English 8

Machine applications / Advantages English 9

Preparations for work / Operation English 9

Working with external accessories English 9

Emptying and cleaning the machine after use English 9+10

Maintenance English 10

Disturbances / Fault finding English 10

Storage, Environmental protection English 11

Daclaration of Conformity English 11

●The ideal compact machine may only be operated by

persons who have been fully trained and authorised

to use it.

●This equipment is not intended to be used by persons

(including children) with restricted physical, sensory or

mental abilities or who have no experience and/or

knowledge of its use, unless supervised by a person

who is responsible for their safety, or they have

received instructions from this person on how to use

the equipment.

Children should be monitored in order to ensure that

they do not play with the equipment.

●The ideal compact machine is not suitable for

cleaning surfaces, from which any type of dust or

substances which are flammable, poisonous, caustic,

irritating are remove that represent a health hazard.

●Never drive over steps!

●Never drive over power cables!

Danger of electric shock!

The usage of the the auto scrubbing machine is subjected

to national regulations.

After the operating instructions and the nationales rules for

safety in the work place, we also recommend that the

unwritten rules of safe working be respected. Using the

auto scrubber on public roads, paths and any other

outdoor surface is prohibited.

All auto scrubbers are destined for wet cleaning of

waterproof surfaces inside of buildings.

●The ideal compact machine for smaller areas of all

types of hard floor.

●All other usage is considered improper. The manu-

facturer takes no responsablility for damages due to

the improper use of the auto scrubber. The user takes

the entire risk for damages due to improper use.

●Respecting the operation, maintenance and repairs

instructions are also an important part of the proper

operation.

●The appropriate accident prevention rules, as well as

other known regulations for health and safety in

operation, must be respected.

●Any unaquthorised modification to the auto scrubber

will result in refusal of the manufacturer to take any

guarantee or responsability for damage that may

occur as a result of those changes.

●Check the suitability of floor surfaces before using the

machine.

●Check that the wheels will not damage the surface of

any plastic surfaces especially in gymnasiums.

●Should the auto scrubber be miss-used, the manu-

facturer will not be responsible for any form of

guarantee.

The operator of the machine is strictly informed that the

auto scrubber is only to be used according to the operating

instructions. Should the autoscrubber not be operated

properly, this happens at the own risc and own liability of

the operator. In such a case any form of guarantee is

refused by the manufactuer.

●Do not run the brushes when the machine is

stationary as it may cause damage to the surface

being cleaned.

●Care should be taken when driving the machine over

thresholds or sills as damage may occur to the

brushes, wheels and squeegee assembly. It is

advisable to lift the brushes and the squeegee.

●When transporting in elevators, their safety

regulations and precautions are to be respected as

well as the maximum load capacity of the elevator.

●The working place of the operator is behind the push

bar of the machine.

●The auto scrubber may only be maintained by autho-

rised specialists who have full training on the

maintenance of the auto scrubber.

●Please always consult correct use and safety

precautions as detailed on the manufacturers label. If

necessary wear appropriate clothing and safety

glasses.

●Only use low foaming an non-inflammable cleaning

agents which do not included hazardous

components.

●We emphasise the danger of using inflammable,

poisonous, hazardous and explosive cleaning agents.

●On delivery of this machine full training will normally

be provided by representative of the manufacturer.

●Where this is not the case, the owner is responsible

for training their staff.

Contents

Safety instructions

General

Proper Operation

Product Liability

Sources of Danger

Place or Work

Authorised Service Staff

Cleaning Agents

First Operation

Read these instructions

carefully before operating

the machine!

RA 300 E - English

Technical Data RA 300 E

Tension 230 V 1 N~/ 50 Hz 6 A

Total power 1200 W

Vacuum 180 mbar

Fresh water capacity 13 litres

Dirty water capacity 16 litres

Brush rotation (r / min.) 120

Working width 350 mm

Brush diameter 2 x 170 mm

Productivity rate theoretical 1380 m2/ h

Vacuum width 390 mm

Measurements l / w / h 550 / 390 / 460 mm

Weight 22 kg

Cable length 7,5 m

Safety class I

Sound pressure level 77 dB A

Rms acceleration value < 2.5m/s²

English 8

Machine description RA 300 E

24

22

23

3

1

2

6

1 Electrical cable with plug

2 Pushbar (adjustable in height and in

angle)

3 Lever for height adjustment

4

Knob for adjusting angle of the pushbar

5 Switch for vacuuming

6 Switch for brush drive

7 Lever for spraying solution

8 Tank cover

9 Clean and waste water tank

10 Clean water membrane tank and

Clean water tank opening

11 Waste water tank opening

12

Cover for waste water emptying

13 Tank cover seal

14 Grip for tank lifting

15 Clean water suction hose with filter

16 Suction Hose

17 Suction motor hose

18 Coupling for spraying hose

19 Lever for lifting of squeegee

20 Squeegee, Suction nozzle

21 Disc brushes

Optional Accessories

22 Driving disc

23 Pad

24 Zubehörkit, Teppich- und Hartboden-

Adapter

4

16

19

20

21

12

11

4

18

17

8

57

10

9

13

14 20

15

18

19

RA 300 E - English

1. Machine applications

1.1 Surface type

Daily or weekly cleaning on water-proof surfaces.

1.2 Cleaning agent

Floor cleaner, degreaser, maintenance cleaner, scented

cleaner depending degree of dirt on surface.

Maximum water and cleaning agent temperature

60°Celsius.

1.3 Brush / Pad

Nylon brushes or driving discs (optional accessory).

2. Advatages

●Easy to use scrubber dryer

●Large clean and waste water tank

●Manual control of cleaning solution quantity

●Comfortable push bar handle

●Pushbar adjustable in height and in angle

●Brushes can easily be changed to pads for intensive

cleaning

●Squeegee can be lifted for scrubbing cleaning agent

for pre-cleaning of very dirty surfaces

●Unit can easily be moved over stairs and is very light

for transportation (only 22 kg)

3. Preparations for work / Operation

Depending of cleaning work to be undertaken choose either

Brushes or Pads.

☞Adjust the pushbar to the

best position that allows

you comfortable operation.

☞Fill clean water tank with

water and the cleaning

agent required for the

specific task. (Dilution rates

are marked on the label of

the cleaning agent).

☞Make sure that the tank

cover (8) is positioned cor-

rectly! Place the clean water

suction hose (15) to the far

side of the tank and make

sure the hose is not bent.

Place the tank cover to the

rear rim for the tank cover

(A) and press the tank

cover seal (B) gently into

the front rim.

☞Unwind the electrical cable

and plug-in the socket.

Now switch-on the vacu-

uming switch (5), brush

drive (6) and lever for

spraying solution (7).

☞By pushing the machine forwards and backwards the

surface is cleaned and the dirty water is vacuumed

into the tank.

☞Should the floor be very dirty switch-off the

vacuuming motor (5). Lift the squeegee by the lever

(19) and add the cleaning agent by pulling the lever for

water solution. Scrubb the floor thoroughly. Finally

switch-on the vacuuming motor switch (5), let the

squeegee (19)to the floor and vacuum the dirty

solution.

Only clean waterproof surfaces!

4. Working with external accessories

☞Remove suction hose (16)

from the cover and attach the

suction hose of the external

accessory (X) to the cover.

Remove spraying hose (18) from

the coupling and attach the

nipple of the spraying hose of

the external accessory (Y) to the

coupling. Attach required

accessory to the other end of the spray and suction hose.

☞ To switch on the spray-

ing pump press the 3-way

tumbler switch (6) in position

“I”. Switch-on the tumbler

switch (ON/OFF) (5).

☞ Cleaning procedure:

Place the accessory on the

surface to be cleaned and pull

the lever of the valve (C). The

cleaning solution is sprayed

onto the surface. Pull accessory

slowly over the surface.

☞ The vacuuming power can

be regulated by turning the ring

on the suction hose (Z).

5.

Emptying and cleaning the machine after use

☞ Remove tank cover from the

tank and let it down behind the

machine.

☞ Lift tank by the grip and

carry to the closest drain. Re-

move cover for waste water dis-

charge (12) and empty the waste

water. Remove membrane tank by

pulling the tab of the mem-

brane tank upwards gently.

8

15

B

A

5

7

6

16

18 XY

Z

X

Y

5

6

C

12

English 8

RA 300 E - English

☞ Once the edge of the mem-

brane tank comes over the rim

of the tank opening push the

entire membrane into the tank

and remove the membrane

tank through the large opening

of the waste water tank . Em-

pty the membrane tank and

rinse with clean water.

☞Hang up the membrane

tank for drying.

☞Rinse the waste water tank with clean water.

When replacing the membrane tank make sure the tank fits

properly into the waste water tank.

☞

The tab of the membrane tank must be fitted on the left

side of the clean water tank opening (seen from behind

the machine).

☞

Remove the vacuuming hose

and the clean water hose from

the tank cover and rinse the tank

cover thoroughly. Make sure that

the filtre (A) of the clean water

suction hose (B) is cleaned too.

☞

Clean the machine and the

squeegee with a damp cloth.

☞Rinse brushes or pads with clean water. To clean the

brushes and pads tilt the unit to the back and remove

the brushes or pads by slightly pulling them

downwards. When replacing make sure they rest into

the groves.

6. Maintenance

If you maintain the machine carefully the unit will stay in

working order for a long period of time. Regularly inspect

the machine for wear and tear.

Regularly inspect the rubbel Blattes of the squeegee.

The machine should not be cleaned with a prssure

washer ore steam cleaner.

For repairs and service only original parts may be

used.

Before repairing the machine disconnect electrical

cable!

7. Disturbances / Fault finding

5.

Emptying and cleaning the machine after use

B

A

Disturbance Reason Removal

Machine does not work

Insufficient vacuuming power

Unclean vacuuming by squeegee

Not enough water flow or no water

coming to the brushes

☞Electrical supply interrupted

☞Fuse blown

☞Electrical supply interrupted

☞Suction nozzle plugged

☞Squeegee blocked

☞Tank cover not properly fitted or

seal defective

☞Connection of cover open

☞Filter in tank covered blocked

☞Cover of waste water discharge not

well placed.

☞Rubber blades on squeegee dirty or

worn-out

☞Water tubes blocked

●Plug-in connection.

●Check fuse.

●Check and replace fuses or the

motor protection swithes.

●Eliminate plugging.

●Removed dirt from squeegee.

●

Place tank cover correctly or

replace seal.

●Connect hose

●Clean filtre with water.

●Check cover and place it

properly.

●

Clean or remove rubber blades.

Remove entire squeegee by

pushing the two levers on the body

of the squeegee.

●Rinse clean water tank and tubes

leeding to the brushes.

●

Clean vacuuming filtre in the tank.

Disconnect electrical cable before working on the unit!

Only do repairs and service that are mentioned in these operating instructions.

Leave service and repairs, especially repairs on electrical components, the after sales service of an authorised service agent.

The following advise will help you detect disturbances and help you resolve them:

English 8

RA 300 E - English

Should the vacuum cleaner not work after checking above faults, please contact authorised service agent!

We,

Cleanfix Reinigungssysteme AG

Stettenstrasse - CH-9247 Henau

declare under our sole responsibility that the product,

Autoscrubber

RA 300 E

from serial code No. 9001 and following

(name,type, serial number)

to which this declaration relates is in

conformity with the following stand- ard(s) or other

normative document(s).

Low voltage, machinery:

EN 60335-1 (ed.3); am1; am 2; EN 60335-2-72 (ed.2);

am1

Emission:

EN 55014-1:00+A1:01+A2:02; CISPR 14-1:05 (ed.5)

Immunity:

EN 55014-2-97+A1:01; CISPR 14-2:97+A1:01

(Cons. ed. 1.1)

EMF:

EN 50366:03+A1:06; IEC 62233:05:05(ed.1)

Harmonics:

EN 61000-3-2:06; IEC 61000-3-2:05(ed.3);

Voltage fluctuations:

EN 61000-3-3:95+A1:01+A2:05; IEC 61000-3-3:94

+A1:01+A2:05 (Cons. ed. 1.2)

( title and/or number and date of issue of the standard(s) ).

following the provisions of Directive

2006 / 95 / EG - 2006 / 42 / EG - 2004 / 108 / EG

8. Storage

If the machine is not to be used it should be stored in a dry

room which is always above 0° C.

Always make sure that the sqeegee is lifted when stored to

avoid distorting the blades.

Environmental protection

The packaging material can be recycled.

Please do not throw the packaging

material into household waste; please

send it for recycling.

Old appliances contain valuable materi-

als that can be recy-cled; these should

be sent for recycling.. Batteries, oil, and

similar substances must not enter the

environment. Please dispose of your old

appliances using appropriate collection

systems.

Declaration of Conformity

RA 300 E - English

RA 300 E

Cover

As at: 07/07/15 Time:10:26

RA 300 E

Cover

As at: 07/07/15 Time:10:26

Pos. Description Reference

01 Tank cover complete - including: items 2-17 300.700

02 Bent tube 380.552

03 Tank cover 380.510

04 Ring for filter 380.556

05 Filter 400.766A

06 Partition complete - including: items 7-9 300.580

07 Clean water tank cover 300.584

08 Angle 300.585

09 Blind rivet dm 4x9.5 mm P...485 Y

10 PT screw KA 30x6 P...515 Y

11 Hexagon socket screw M 3x10 P...487 Y

12 Fitting SW22 G3/8´´ 380.555

13 Gasket 030.015

14 Seal for cover 380.554

15 Angled fitting G1/4´´ P...541 I

16 Hose 6/12 x 250 mm 300.703

17 Fresh water filter P...528

18 Complete hose compl. 300.743

19 Suction motor hose compl. - including: items 20+21 300.741

20 Hose 380.743

21 Air control slide 380.745

22 Tank complete - including: items 23-25 300.550

23 Fresh water tank 300.722

24 Tank 300.550

25 Cover 300.731

26 Suction hose 12/x530 300.072

RA 300 E

Handle housing

As at: 07/07/15 Time:10:26

RA 300 E

Handle housing

As at: 07/07/15 Time:10:26

Pos. Description Reference

01 Handle housing 300.610

02 Cover for handle 300.620

03 Controlling lever 380.267

04 Switch 950.453

05 Cable tightener 380.252

06 PT-screw KA 40x16 mm P...516C

07 Mains cable Europe P...276

07 Mains cable Switzerland P...275

07 Mains cable England P...276A

08 Cable grommet P...280

09 screw WN 1412 KA30 x 14 P...516 S

10 Marking plate P...394

11 Electrical terminal (4) P...383B

12 Tumbler switch P...240

13 Fixing lever 380.262

14 Fixing plate 380.259

15 Pin 380.265

16 Cable 300.315

17 Lower lever 300.615

18 Star handle 380.276

19 Tumbler switch P...240H

RA 300 E

Pump

As at: 07/07/15 Time:10:27

RA 300 E

Pump

As at: 07/07/15 Time:10:27

Pos. Description Reference

01 NDS-L - pump 220-240V 50Hz P...815

02 Ring P...815 H

03 Cover P...815 B

04 Counter ring P...809 N

05 Valve spring P...809 P

06 Valve cone P...810 S

07 Valve seating P...809 Q

08 O-ring 12x1,5 mm P...809 L

09 O-ring 14x1,5 mm P...809 K

10 Counter ring P...815 X

11 Piston P...809 B

12 Pressure spring for piston P...809 E

13 P...815 M

14 Spring support P...809 F

15 Raising NDS-L P...815 A

16 Spring support compl. Including: items 8,9+14 P...810 X

17 Valve seating compl. Including: items 4-9 P...810 Y

RA 300 E

Pump assembly

As at: 07/07/15 Time:10:27

RA 300 E

Pump assembly

As at: 07/07/15 Time:10:27

Pos. Description Reference

01 Brush motor 300.281

02 Motor fixing plate 300.357

03 PT-screw KA 40x16 mm P...516 G

04 Air canal cover 300.058

05 Air canal plate 300.061

06 Rubber clamp P...014 A

07 Capacitor 5uF P...385 I

08 Plate for electrical terminals 380.047

09 Electrical terminal (6) P...383 C

10 Screw KA 30x14 mm P...516 S

11 Suction hose 12/6x530 mm 300.072

12 Hose clamp 14.5 mm P...550 A

13 Rubber clamp P...207 A

14 NDS-L pump P...815

15 Pump holder P...207 B

16 Cover P...171 C

17 Hexagon nut M4 P...491 Q

18 Spring ring M4 P...498 A

19 Pan head screw M 4x12 mm P...476 L

20 PT-screw KA 30x6 mm P...515 Y

21 Capacitor 0.2uF P...387 A

22 Holder for capacitor P...109 C

23 Blind rivet 3x6 mm P...485 H

24 Cable tightener 380.251

25 Cover for electrical terminals 380.048

26 PT-screw KA 40x16 mm P...516 C

27 Spring ring M4 P...498 A

28 Spring ring M6 P...497 W

29 Washer 6/25x1.8 mm P...497 Y

30 Vane wheel 300.281 F

RA 300 E

Suction nozzle

As at: 07/07/15 Time:10:27

RA 300 E

Suction nozzle

As at: 07/07/15 Time:10:27

Pos. Description Reference

01 Angled connector P...533H

03 Sealing ring P...533I

04 Connection hose 640mm 300.165

05 Water canal isolation 300.081

06 Water canal 300.022

07 Rivet 3.2x16.2mm P...485B

08 Guide sleeve 300.435

09 Suction nozzle holder compl. 300.405

10 Washer M6 P...497W

11 Screw M6x40 P...486 Y

12 Suction nozzle complete 300.420

13 Compression spring 700.171

14 Washer DIN 125 A M 10 10,5/20/2 P...496 T

17 Lever 300.416

18 Hexagon nut M6 P...490D

19 Protection of lever 300.411

20 Rear guiding holder for lever 300.413

21 Front guiding holder for lever 301.415

22 PT-screw KA40x16 P...516C

23 Screw M4x8 P...481P

24 Washer M 6 P...496L

25 Serrated lock washer M8 P...498G

26 Hexagon screw M8x10 P...471B

27 Splash protection 300.312

28 Cap black P...170K

RA 300 E

Vaccum motor

As at: 07/07/15 Time:10:27

RA 300 E

Vaccum motor

As at: 07/07/15 Time:10:27

Pos. Description Reference

01 Chassis cover 300.052

02 Suction motor P...870C

03 Pair of Charbon brushes P...870KB

04 Motor sealing ring P...971C

05 Sealing ring 380.019

06 Hose connection cap 380.021

07 Screw 2.9x9.5 mm P...483H

08 Motor cover 380.017

09 PT-screw KA 50x16 mm P...515Z

10 PT-screw KA 40x18 mm P...516C

11 Air canal cover 380.022

12 Air canal compl. 300.410

13 Coupling 380.045

14 Security ring P...098

15 Washer M12 P...496A

16 Reducer P...521E

17 Angled connector P...541R

18 Pressure hose 6/12x420 mm 300.178

20 Connecting nippel 300.088

21 Hose clamp 14.5 mm P...550A

22 Connection hose 250 mm 300.172

24 Hexagon nut 3/8«« P...535B

25 Angled connector P...533C

26 Connection hose 640 mm 300.165

27 Straight nipple with reducer 300.085

28 Hose clamp 13.3 mm P...550I

RA 300 E

Wheel

As at: 07/07/15 Time:10:27

RA 300 E

Wheel

As at: 07/07/15 Time:10:27

Pos. Description Reference

01 Bottom plate 300.111

02 Wheel 380.135

03 Distance piece 380.137

04 Washer M8 P...496Q

05 Screw DIN 912 M 8x60 mm P...487 Fa

06 Wheel cover 300.242

07 Isolation 300.065

08 Hexagon screw M 8x10 mm P...471B

09 Serrated lock washer M8 P...498G

10 Round buffer 300.118

11 Idler pulley compl. - including:items 12-20 300.375

12 Washer M6 P...496L

13 Retaining ring dm 28 mm P...499G

14 Ball bearing P...316J

15 Pulley compl. 300.375

16 Bearing pin d 18/12x14.7 mm 300.377

17 Fixation for pulley 300.161

18 Hexagon screw M 6x20 mm P...472T

19 Serrated lock washer M6 P...499D

20 Hexagon screw M 6x12 mm P...472R

21 Guide pulley - including: items 22-24 300.385

22 Bearing pin 300.388

23 Screw M 6x30 mm P...481G

24 Stop nut M6 P...493K

25 Hexagon socket screw M 4x14 mm P...486F

26 holder for pulley 300.387

27 Rivet 3.2x12 mm P...485B

28 300.243

Other manuals for Parrot RA 300 E

1

Table of contents

Other Cleanfix Floor Machine manuals

Cleanfix

Cleanfix RA 431B User manual

Cleanfix

Cleanfix TW Compact User manual

Cleanfix

Cleanfix R53-1100 User manual

Cleanfix

Cleanfix PowerDisc LS User manual

Cleanfix

Cleanfix PowerDisc Guide

Cleanfix

Cleanfix R 44-120 User manual

Cleanfix

Cleanfix R 53-1100 UHS User manual

Cleanfix

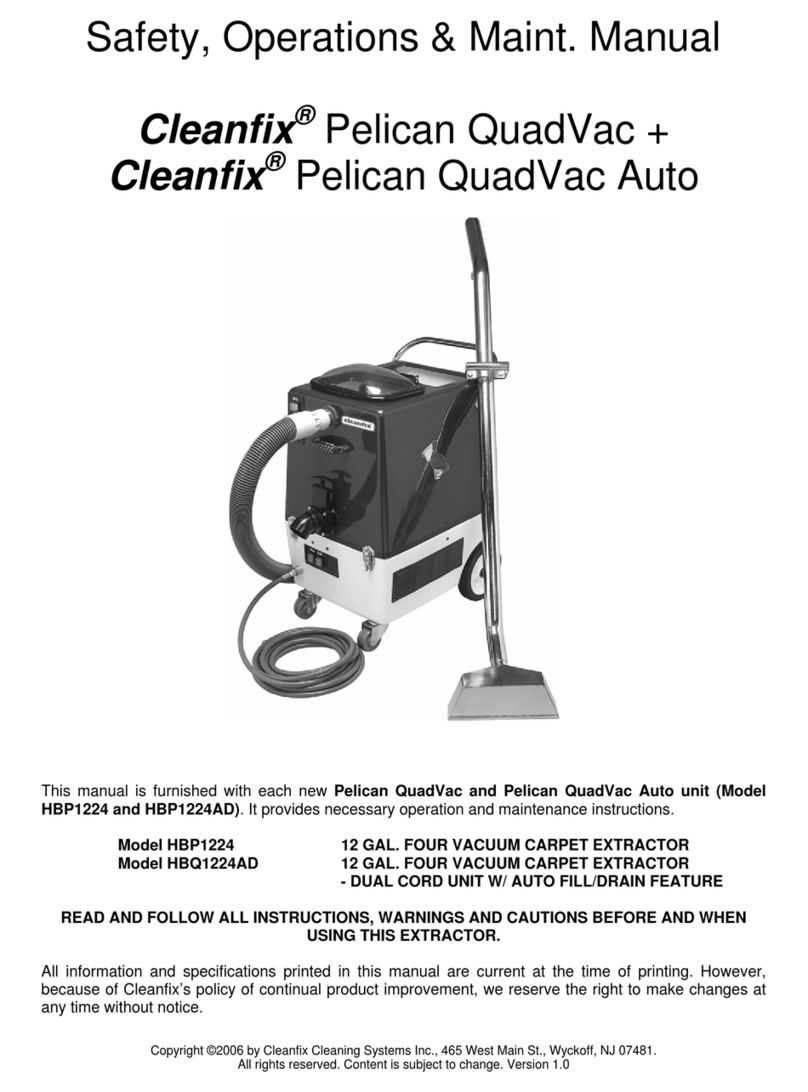

Cleanfix Pelican QuadVac + Guide

Cleanfix

Cleanfix TW411 User manual

Cleanfix

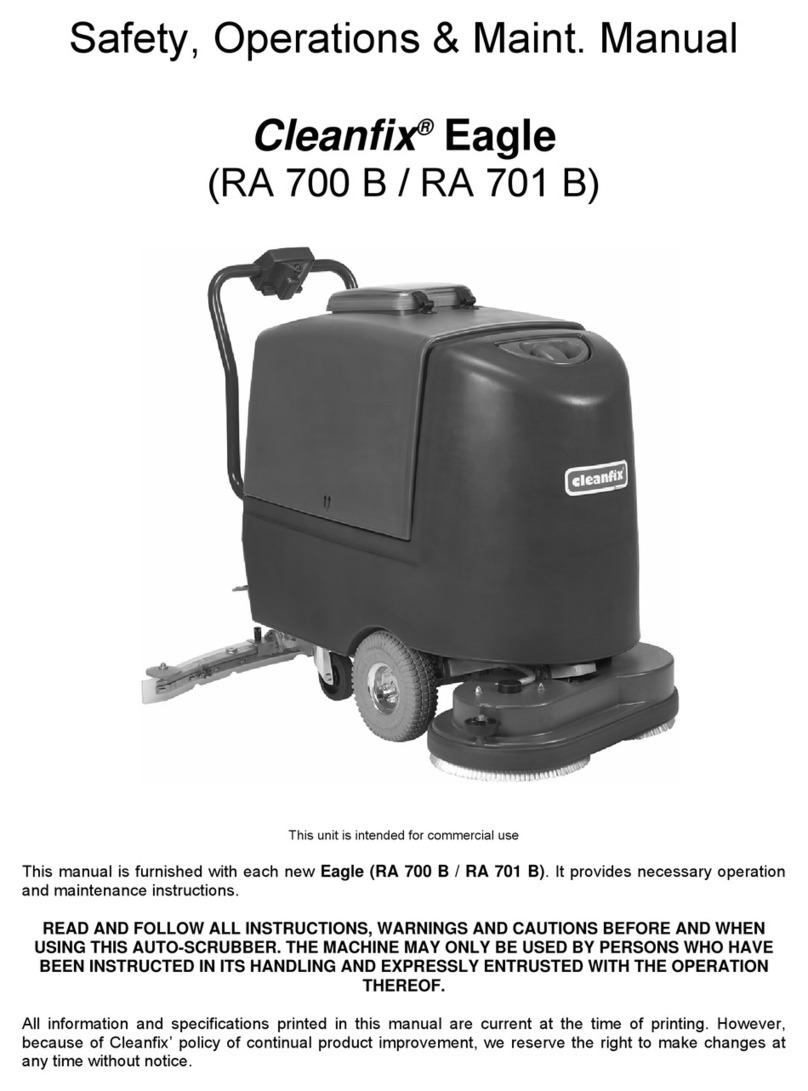

Cleanfix Eagle RA 700 B Guide