Clear Water Microzone 300 User manual

850-E Capitolio Way, San Luis Obispo, CA 93401 • 805-549-9724 phone • 805-549-0306 fax • service@cwtozone.com

www.cwtozone.com • Copyright © 2008 - ClearWater Tech, LLC.• Reproduction of any kind is prohibited • LIT94 • REV111208

ClearWater Tech, LLC

Ozone Systems for Water & Air Purication

Ozone Systems

Installation & Operation Manual

Microzone 300 & 500

Corona Discharge Ozone Generators

• Read and follow all instructions

•Save these Instructions

• Before attempting any electrical connections, be sure all power is off at the main circuit

breaker.

• Install all electrical equipment at least ve feet from any open body of water using

non-metallic plumbing.

• Install check valves and a Hartford Loop to prevent water from contacting the electrical

equipment.

• Be sure to bond (ground) the system using the copper bonding lug on the bottom of

the ozone generator. The system should be bonded with solid copper wire conforming

with all local, state and national electrical codes.

Two aspects of ClearWater Tech ozone generators represent potential

dangers, ozone gas and high voltage electricity.

OZONE GAS - WARNING: Low concentrations of ozone can cause

irritation to the eyes, throat and respiratory system.

HIGH VOLTAGE - WARNING: ClearWater Tech ozone generators operate at high

voltages. If contact is made with operating high voltage components electric shock will occur.

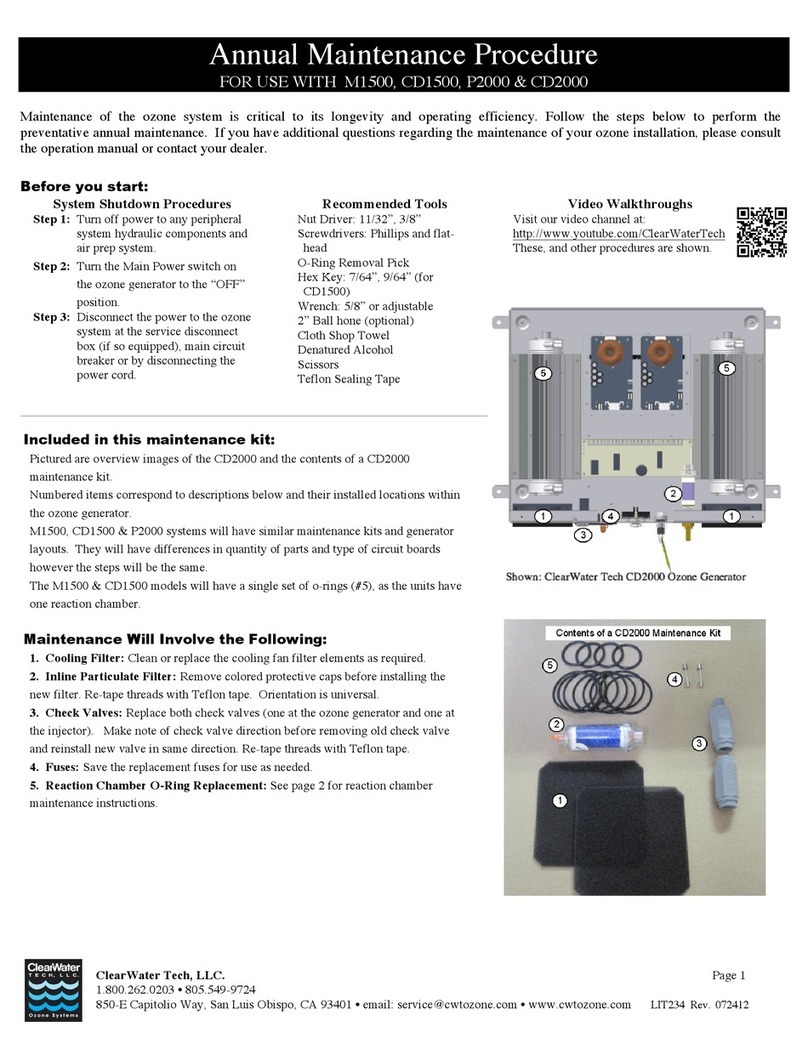

OZONE GENERATOR - Microzone 300

OZONE GENERATOR - Microzone 500

1

ACCESSORIES

SAFETY WARNINGS

FRONT VIEW BOTTOM VIEW TOP VIEW

FRONT VIEW BOTTOM VIEW SIDE VIEW

Power

Light

Variable

Off/On Switch

Check Valve Diffuser Stone Parts Bag: (2) screws, 8” Clear Hose

(2) hose clamps

OZONE

GAS

CAUTION!

ClearWater Tech, LLC Limited One-Year Warranty

SUMMARY OF THE WARRANTY

ClearWater Tech, LLC (“CWT”) makes every effort to assure that its products meet high quality and durability standards and warrants the

products it manufactures against defects in materials and workmanship for a period of one (1) year, commencing on the date of original

shipment from CWT, with the following exceptions: 1) The warranty period shall begin on the installation date if the installation is performed

within 90 days of the original shipment from CWT: 2) The warranty period shall begin on the date of the bill of sale to the end user if the

installation date is more 90 days after the original shipment date. To validate the warranty, a warranty card must be returned to CWT and

must include the following information:

• End user name

• Complete address, including telephone number

• Date installed

• Complete model and serial number information

• Name of company from which the unit was purchased

Repairs and replacement parts provided under this warranty shall carry only the unexpired portion of this warranty or 90 days, whichever

is longer.

ITEMS EXCLUDED FROM THE WARRANTY

This warranty does not extend to any product and/or part from which the factory assigned serial number has been removed or which has

been damaged or rendered defective as a result of:

• An accident, misuse, alteration or abuse

• An act of God such as ood, earthquake, hurricane, lightning or other disaster resulting only from the forces of nature

• Normal wear and tear

• Operation outside the usage parameters stated in the product user’s manual

• Use of parts not sold by CWT

• Service or unit modication not authorized by CWT • Check valve/solenoid valve failure

• Failure to meet service requirements as outlined in the I & O manual • Damage which may occur during shipping

OBTAINING SERVICE UNDER THE WARRANTY

Any product and/or part not performing satisfactorily may be returned to CWT for evaluation. A Return Goods Authorization (RGA) number

must rst be obtained by either calling or writing your local authorized dealer, distributor or CWT direct, prior to shipping the product. The

problem experienced with the product and/or part must be clearly described. The RGA number must appear prominently on the exterior of

the shipped box(es). The product and/or part must be packaged either in its original packing material or in comparable and suitable packing

material, if the original is not available. You are responsible for paying shipping charges to CWT and for any damages to the product and/

or part that may occur during shipment. It is recommended that you insure the shipment for the amount you originally paid for the product

and/or part.

If, after the product and/or part is returned prepaid and evaluated by CWT, it proves to be defective while under warranty, CWT will, at its

election, either repair or replace the defective product and/or part and will return ship at lowest cost transportation prepaid to you except

for shipments going outside the 50 states of the United States of America. If upon inspection, it is determined that there is no defect

or that the damage to the product and/or part resulted from causes not within the scope of this limited warranty, then you must bear the

cost of repair or replacement of damaged product and/or part and all return freight charges. Any unauthorized attempt by the end user to

repair CWT manufactured products without prior permission shall void any and all warranties. For service, contact your authorized dealer

or distributor or CWT direct at (805) 549-9724, extension 23.

EXCLUSIVE WARRANTY

There is no other expressed warranty on CWT products and/or parts. Neither this warranty, or any other warranty, expressed or implied,

including any implied warranties or merchantability of tness, shall extend beyond the warranty period. Some states do not allow limitations

on how long an implied warranty lasts, so that the above limitation or exclusion may not apply to you.

DISCLAIMER OF INCIDENTAL AND CONSEQUENTIAL DAMAGES

No responsibility is assumed for any incidental or consequential damages; this includes any damage to another product or products resulting

from such a defect. Some states do not allow the exclusion or limitation of incidental or consequential damages, so that above limitation or

exclusion may not apply to you.

LEGAL REMEDIES OF PURCHASER

This warranty gives you specic legal rights and you may also have other rights which vary from state to state.

THIS STATEMENT OF WARRANTY SUPERSEDES ALL OTHERS PROVIDED TO YOU AT ANY PRIOR TIME.

Power Cord

Power Light Variable

Off/On Switch

Inlet/Outlet Ground

Lug

Power Cord

Ground Lug

Inlet/Outlet

Compare the ozone system equipment to packing list provided. Before beginning any

installation procedures, thoroughly inspect all components for damage. If damage is noticed,

promptly notify the freight carrier and request an on site inspection. Inspect all packing

materials for small parts before discarding.

• When placing ozone system components, make sure to consider safety, maintenance

requirements, local building and re codes.

• To determine the most favorable placement, the following should be considered:

• Located downstream of all other existing water system components.

• Located upstream of the residual sanitizer injection point (if so equipped).

• The pH adjustment chemical injection point should be located downstream of the

residual sanitizer injection point (if so equipped).

• Location of ozone generator should be no more than 8 feet from point of use.

• Adequate protection from weather, dust and excessive heat. Ambient temperature

range: 20ºF to 85º F continuous.

NOTE: Equipment installed in extreme environmental conditions will void manufacturers warranty.

• The ozone generator is equipped with a 0 to 100% variable OFF/ON switch. Depending

on the amount of ozone required you may adjust the ozone output control switch

counter clockwise for minimum output or off and clockwise for maximum output.

• The ozone generator is equipped with a main power indicating light next to the variable

switch. This light will be illuminated when the switch is not in the off position.

• The ozone generator will not produce ozone until airow is initiated.

Disconnect power from unit before any maintenance procedures.

• Check valve – replace diaphragm check valve, annually.

• Reaction chamber - replace the reaction chamber every 3 years.

Microzone 300

• Electrical – 120VAC 60Hz 0.2A, 220VAC 50Hz 0.1A

• Dimensions – 5.875" h x 5.375" w x ” x 2" d, 2 lbs.

• Ozone Output – 0.3 g/h @ 6 SCFH

Microzone 500

• Electrical – 120VAC 60Hz 0.4A, 220VAC 50Hz 0.2A

• Dimensions – 6.250” h x 9.375” w x 3.5” d. 3 lbs.

• Ozone Output – 0.5 g/h @ 5 SCFH

52

UNPACKING

NOTE: The top of the Hartford loop and the check valve must be mounted above the water line

MAINTENANCE

SPECIFICATIONS

START-UP

EQUIPMENT PLACEMENT

The microzone ozone generators may

be used to inject or diffuse ozone

into water. The injection method

requires a venturi injector to draw the

ozone from the ozone generator and

into the water line. ClearWater Tech

has developed the PRO Series Sys-

tem with magnetic drive pump, program-

mable timer and venturi to provide a

suitable suction port for the injection

method (see Figure 1). For typical spa

applications the spa manufacture has

provided an “ozone ready” suction port,

which eliminates the need for additional

equipment (see spa manual for

installation). The diffusion method requires

a pressurized

air source, which feeds air

through the ozone generator and out to

an atmospheric body of water. A diffuser

stone provided with the Microzone ozone

generator is used for increased mixing

of ozone in solution. For this applica-

tion ClearWater Tech has developed the

OAS7 compressor, with programmable

timer to provide the pressure required

(see Figure 2).

Note:

Regardless of application, water back ow

prevention devices such as a check valve

and Hartford Loop should be implemented

with the use of the Microzone ozone

generators (see gure 3).

THEORY OF OPERATION & PRODUCT DESCRIPTION

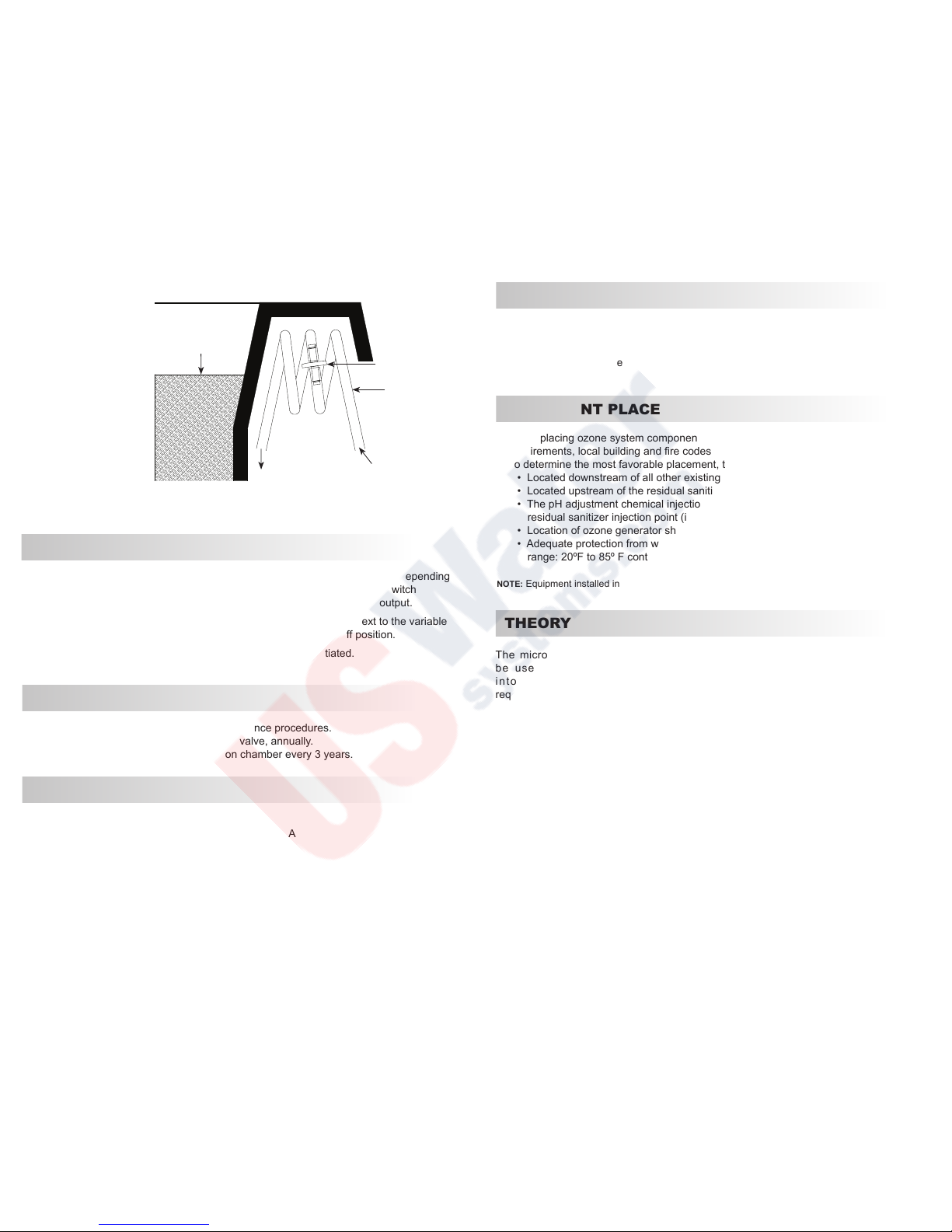

Figure 3

Shown: Hartford Loop

Check Valve

Coiled Tubing

Min. of three

12” loops

(Harford Loop)

To point of use From ozone generator

Waterline

Air Flow

Diffuser Stone

Check Valve

Air Flow

Switched

Power

Air Prep Outlet

Main Power

K

OZONE GENERATOR

Microzone 300

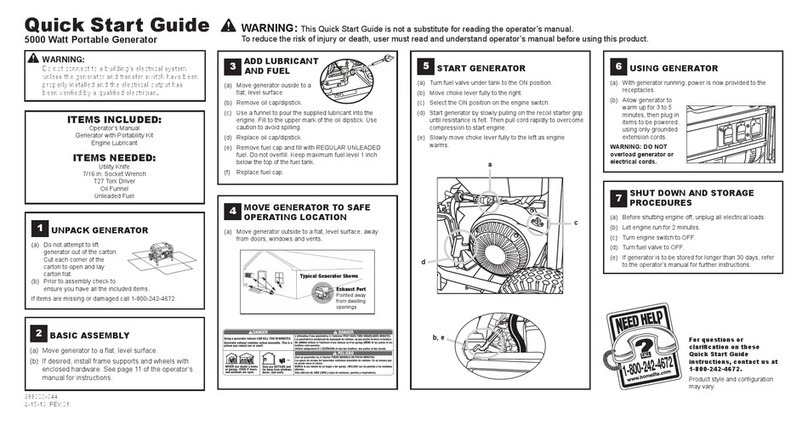

Step 1: Mount the Microzone ozone generator to a suitable at surface, using the two

self-tapping screws provided. NOTE: The distance from the Microzone to the

injection port should be no more than 8 feet.

Step 2: Attach one end of the supplied tubing to the ozone outlet port of the Microzone

generator and secure with a hose clamp provided.

Step 3: Coil the tubing to create a “Hartford Loop” above the water line. Insert the check

valve provided at the highest point of the Hartford Loop (see Figure 3).

Determine orientation of the check valve by blowing through it, ow should be

directed to the point of use.

Step 4: Attach the other end of the tubing to the injection port and secure with the hose

clamp provided.

Step 5: Plug the Microzone into a suitable outlet. If the PRO Series system is being used,

the Microzone may be plugged into its switched outlet provided. NOTE: All

equipment wiring and grounding must comply with all local electrical codes.

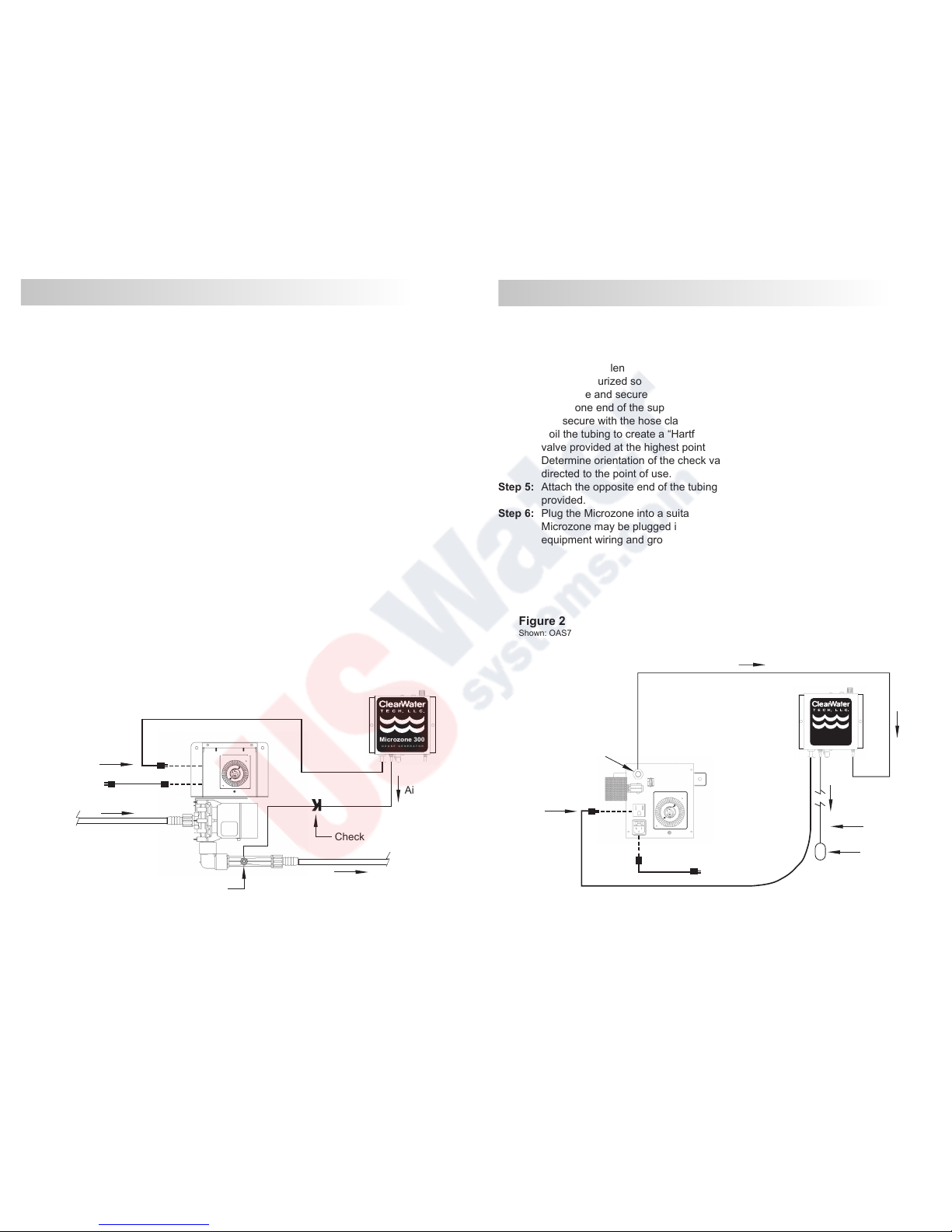

Figure 1

Shown: PRO10 with Microzone 300 ozone generator

Step 1: Mount the Microzone ozone generator to a suitable at surface, using the two

self-tapping screws provided. NOTE: The distance from the Microzone to point

of diffusion should be no more than 8 feet.

Step 2: Cut a suitable length of the supplied tubing, attach one end to the air prep outlet

of the pressurized source used. Attach the other end to the air inlet port of the

Microzone and secure with a hose clamp provided.

Step 3: Attach one end of the supplied tubing to the ozone outlet port of the Microzone

and secure with the hose clamp provided.

Step 4: Coil the tubing to create a “Hartford Loop” above the water line. Insert the check

valve provided at the highest point of the Hartford Loop (see Figure 3).

Determine orientation of the check valve by blowing through it, ow should be

directed to the point of use.

Step 5: Attach the opposite end of the tubing to the barbed tting of the diffuser stone

provided.

Step 6: Plug the Microzone into a suitable outlet. If the OAS7 is being used the

Microzone may be plugged into its switched outlet provided. NOTE: All

equipment wiring and grounding must comply with all local electrical codes.

Figure 2

Shown: OAS7 with Microzone 300 ozone generator

34

INJECTION METHOD INSTALLATION DIFFUSION METHOD INSTALLATION

Note: OAS7 maximum head pressure: 6 feet

K

Check Valve

Air Flow

Water Flow

Injector Port

Water Flow

Switched

Power

Main Power

OZONE GENERATOR

Microzone 300

This manual suits for next models

1

Table of contents

Other Clear Water Portable Generator manuals

Popular Portable Generator manuals by other brands

Winco

Winco WL12000HE-04/A Installation & operator's manual

Keysight Technologies

Keysight Technologies X Series Installation note

DAYLIFF

DAYLIFF DG1200E Installation & operating manual

Tektronix

Tektronix AFG3000 Series Service manual

Champion Global Power Equipment

Champion Global Power Equipment 100520 quick start guide

Durapac

Durapac DPA-38D instruction manual